.2 FOURTH QUARTER 2025 EARNINGS CALL LEON TOPALIAN Chair and CEO STEVE LAXTON President, COO and CFO January 27, 2026

FORWARD-LOOKING STATEMENTS Certain statements made in this presentation may constitute forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. These statements involve risks and uncertainties. The words “anticipate,” “believe,” “expect,” “intend,” “may,” “project,” “will,” “should,” “could” and similar expressions are intended to identify forward-looking statements. These forward-looking statements reflect the Company’s best judgment based on current information, and although we base these statements on circumstances that we believe to be reasonable when made, there can be no assurance that future events will not affect the accuracy of such forward-looking information. The Company does not undertake any obligation to update these statements. The forward-looking statements are not guarantees of future performance, and actual results may vary materially from the projected results and expectations discussed in this presentation. Factors that might cause the Company’s actual results to differ materially from those anticipated in forward- looking statements include, but are not limited to: (1) competitive pressure on sales and pricing, including pressure from imports and substitute materials; (2) U.S. and foreign trade policies affecting steel imports or exports; (3) the sensitivity of the results of our operations to general market conditions, and in particular, prevailing market steel prices and changes in the supply and cost of raw materials, including pig iron, iron ore and scrap steel; (4) the availability and cost of electricity and natural gas, which could negatively affect our cost of steel production or result in a delay or cancellation of existing or future drilling within our natural gas drilling programs; (5) critical equipment failures and business interruptions; (6) market demand for steel products, which, in the case of many of our products, is driven by the level of nonresidential construction activity in the United States; (7) impairment in the recorded value of inventory, equity investments, fixed assets, goodwill or other long- lived assets; (8) uncertainties and volatility surrounding the global economy, including excess world capacity for steel production, inflation and interest rate changes; (9) fluctuations in currency conversion rates; (10) significant changes in laws or government regulations affecting environmental compliance, including legislation and regulations that result in greater regulation of greenhouse gas emissions that could increase our energy costs, capital expenditures and operating costs or cause one or more of our permits to be revoked or make it more difficult to obtain permit modifications; (11) the cyclical nature of the steel industry; (12) capital investments and their impact on our performance; (13) our safety performance; (14) our ability to integrate businesses we acquire; (15) the impact of any pandemic or public health situation; and (16) the risks discussed in “Item 1A. Risk Factors” of the Company’s most recent Annual Report on Form 10-K and elsewhere therein and in the other reports we file with the U.S. Securities and Exchange Commission. 2

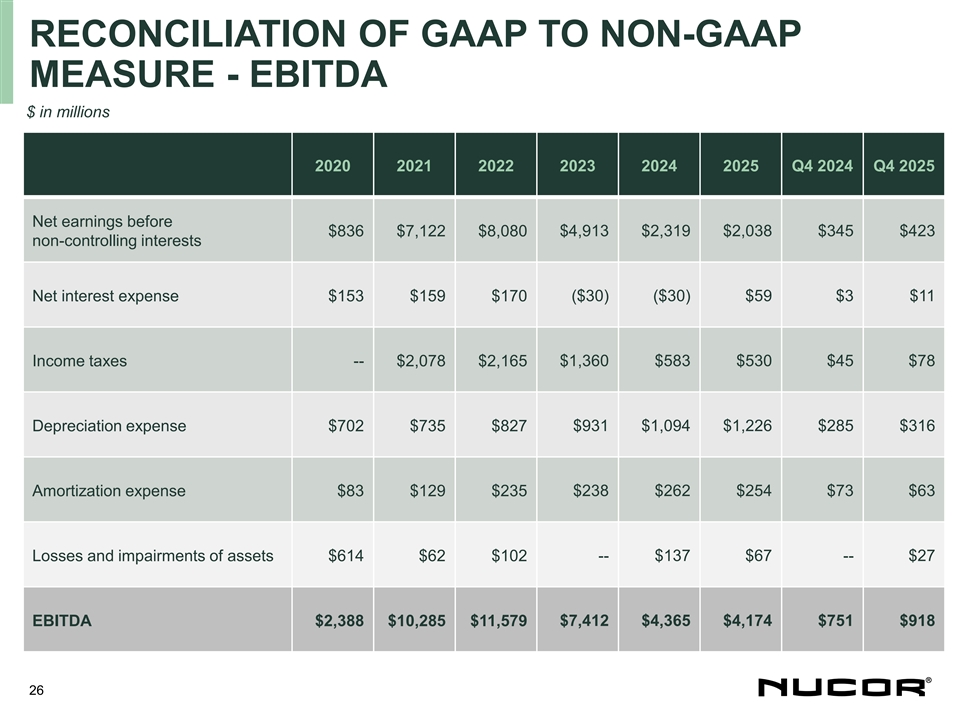

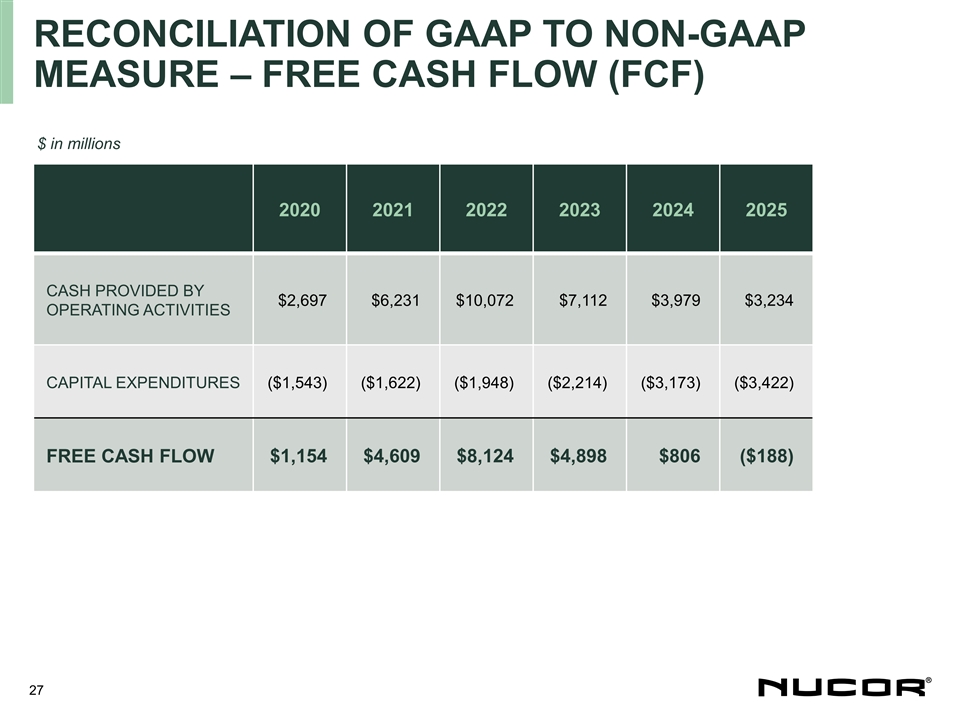

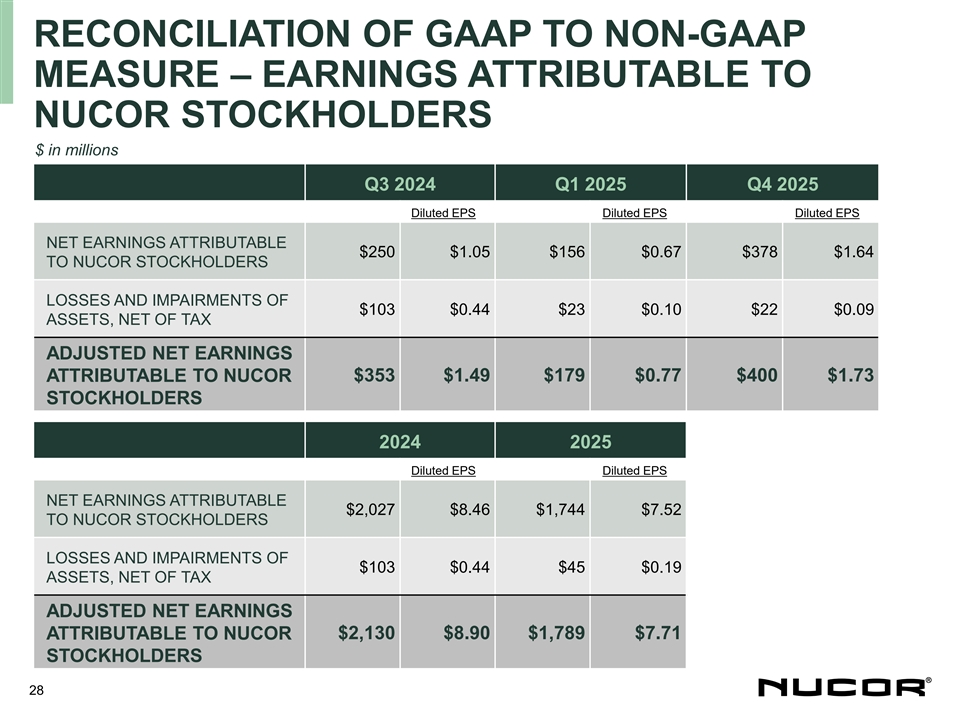

NON-GAAP FINANCIAL MEASURES The Company uses certain non-GAAP (Generally Accepted Accounting Principles) financial measures in this presentation, including adjusted earnings, EBITDA and Free Cash Flow (FCF). Generally, a non-GAAP financial measure is a numerical measure of a company’s performance or financial position that either excludes or includes amounts that are not normally excluded or included in the most directly comparable financial measure calculated and presented in accordance with GAAP. We define EBITDA as net earnings before noncontrolling interests adding back the following items: interest expense, net; provision for income taxes; depreciation; amortization; and losses and impairments of assets. We define Free Cash Flow (FCF) as Cash Provided by Operating Activities less Capital Expenditures. Please note that other companies might define their non-GAAP financial measures differently than we do. Management presents non-GAAP financial measures because it considers them to be an important supplemental measure of performance. Management believes that these non-GAAP financial measures provide additional insight for analysts and investors evaluating the Company’s financial and operational performance by providing a consistent basis of comparison across periods. Non-GAAP financial measures have limitations as an analytical tool. Investors are encouraged to review the reconciliation of non-GAAP financial measures to their most directly comparable GAAP financial measures provided in this presentation, including in the accompanying tables located in the Appendix. 3

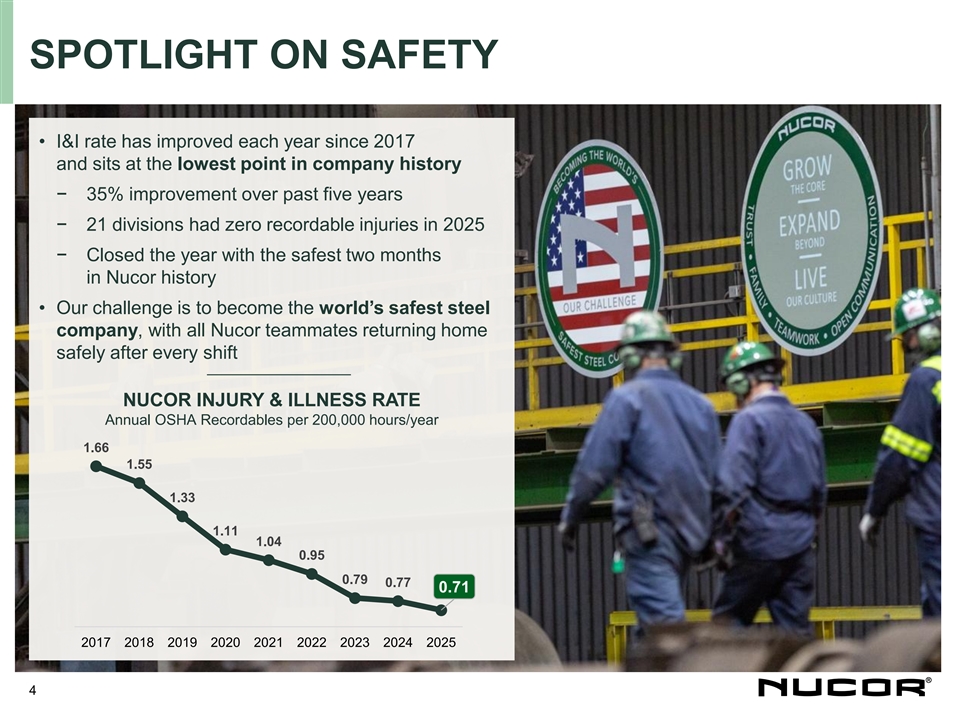

SPOTLIGHT ON SAFETY • I&I rate has improved each year since 2017 and sits at the lowest point in company history − 35% improvement over past five years − 21 divisions had zero recordable injuries in 2025 − Closed the year with the safest two months in Nucor history • Our challenge is to become the world’s safest steel company, with all Nucor teammates returning home safely after every shift NUCOR INJURY & ILLNESS RATE Annual OSHA Recordables per 200,000 hours/year 1.66 1.55 1.33 1.11 1.04 0.95 0.79 0.77 0.71 2017 2018 2019 2020 2021 2022 2023 2024 2025 4

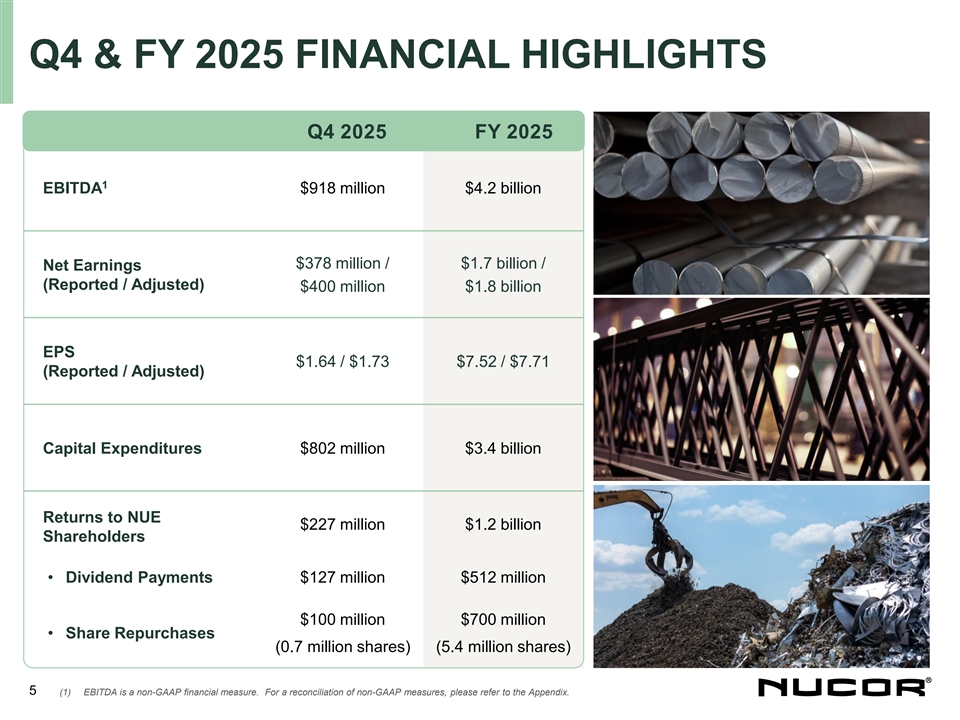

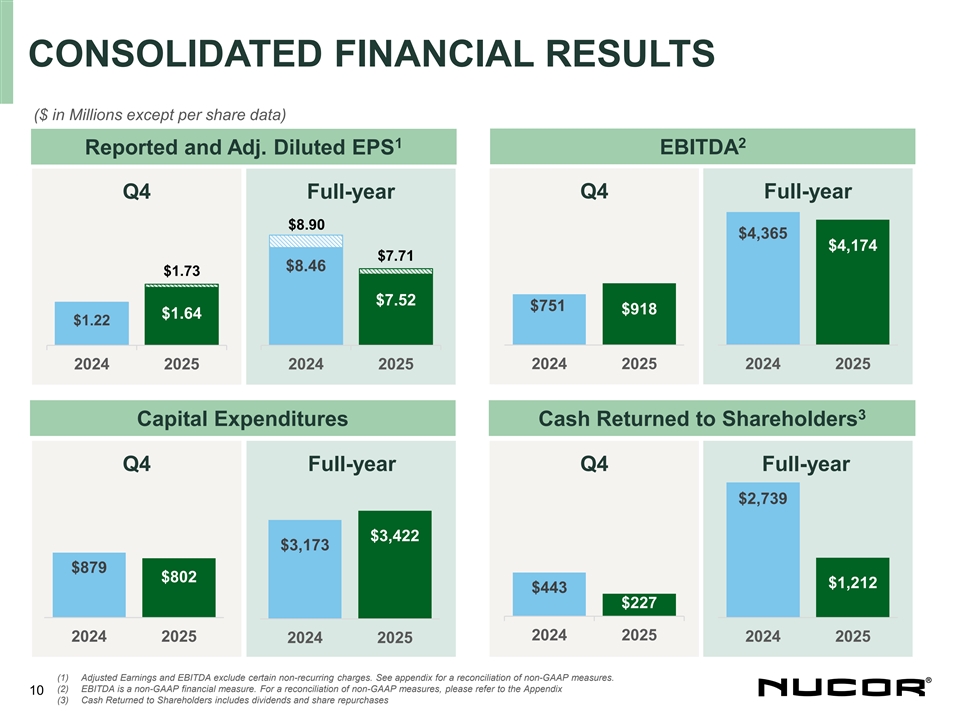

Q4 & FY 2025 FINANCIAL HIGHLIGHTS Q4 2025 FY 2025 1 EBITDA $918 million $4.2 billion $378 million / $1.7 billion / Net Earnings (Reported / Adjusted) $400 million $1.8 billion EPS $1.64 / $1.73 $7.52 / $7.71 (Reported / Adjusted) Capital Expenditures $802 million $3.4 billion Returns to NUE $227 million $1.2 billion Shareholders • Dividend Payments $127 million $512 million $100 million $700 million • Share Repurchases (0.7 million shares) (5.4 million shares) 5 (1) EBITDA is a non-GAAP financial measure. For a reconciliation of non-GAAP measures, please refer to the Appendix.

ADVANCING ALONG OUR GROWTH JOURNEY Growth Projects Completed Strategic Initiatives Executed • Bar: Kingman, AZ bar mill melt shop • Repurposed two facilities into Nucor Data • Bar: Lexington, NC rebar micro-mill Systems operations 2025 • Sheet: Crawfordsville, IN coating complex • Restructured Cold Finish Group; Exited POK • Towers & Structures: AL facility • Expanded into Data Center Infrastructure and High-Performance Overhead Doors 2024 • Tube: Gallatin, KY Tube Mill • Retired Chicago tube facility • Sheet: Gallatin, KY mill expansion • Acquired 51% of CSI and modernization • Expanded into Overhead Doors 2022-2023 • Plate: Brandenburg, KY mill and Towers & Structures • Retired Longview, TX plate mill • Bar: Rebar micro-mills in • Expanded into Insulated Metal Frostproof, FL and Sedalia, MO Panels and Warehouse Racking PRE-2022 • Bar: Expansion/modernization • Restructured Nucor Buildings at Kankakee, IL and Marion, OH and Rebar Fab Groups • Sheet: Galv/paint lines and cold • Exited Duferdofin JV mill at Hickman, AR 6

2026 GROWTH PRIORITIES West Virginia Sheet Mill Towers & Structures Greenfields Decatur, Alabama Towers & Structures West Virginia Sheet Mill 2026 Sheet Coating Projects Ramp-Ups of Recent Projects New Berkeley County galv line Lexington, NC rebar micro mill 7

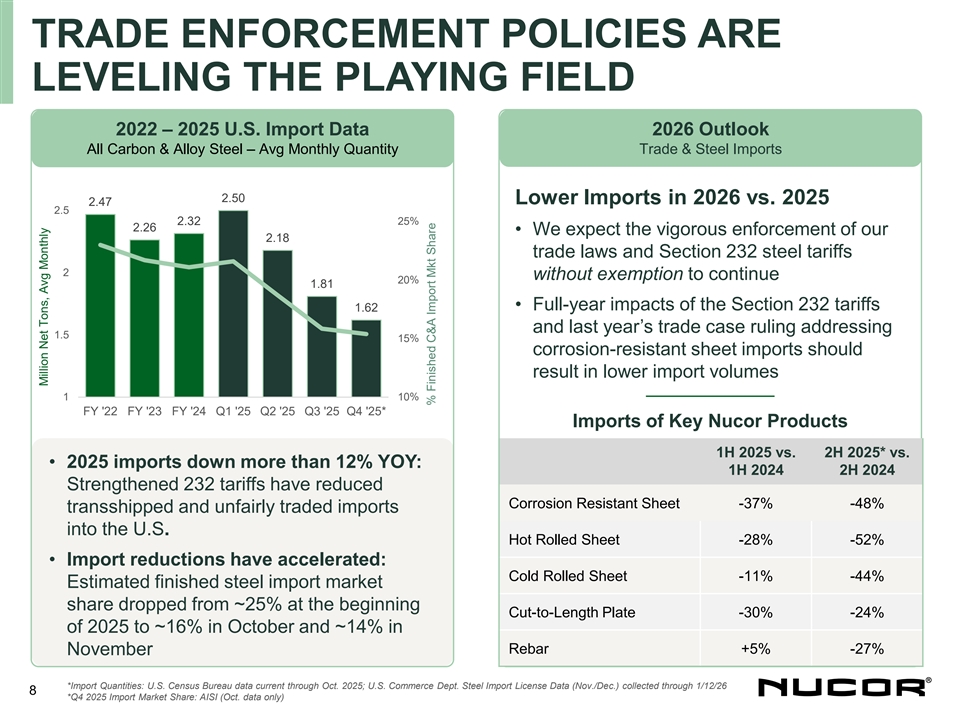

TRADE ENFORCEMENT POLICIES ARE LEVELING THE PLAYING FIELD 2022 – 2025 U.S. Import Data 2026 Outlook All Carbon & Alloy Steel – Avg Monthly Quantity Trade & Steel Imports 2.50 Lower Imports in 2026 vs. 2025 2.47 2.5 2.32 25% 2.26 • We expect the vigorous enforcement of our 2.18 trade laws and Section 232 steel tariffs 2 without exemption to continue 20% 1.81 • Full-year impacts of the Section 232 tariffs 1.62 and last year’s trade case ruling addressing 1.5 15% corrosion-resistant sheet imports should result in lower import volumes 1 10% FY '22 FY '23 FY '24 Q1 '25 Q2 '25 Q3 '25 Q4 '25* Imports of Key Nucor Products 1H 2025 vs. 2H 2025* vs. • 2025 imports down more than 12% YOY: 1H 2024 2H 2024 Strengthened 232 tariffs have reduced Corrosion Resistant Sheet -37% -48% transshipped and unfairly traded imports into the U.S. Hot Rolled Sheet -28% -52% • Import reductions have accelerated: Cold Rolled Sheet -11% -44% Estimated finished steel import market share dropped from ~25% at the beginning Cut-to-Length Plate -30% -24% of 2025 to ~16% in October and ~14% in Rebar +5% -27% November *Import Quantities: U.S. Census Bureau data current through Oct. 2025; U.S. Commerce Dept. Steel Import License Data (Nov./Dec.) collected through 1/12/26 8 *Q4 2025 Import Market Share: AISI (Oct. data only) Million Net Tons, Avg Monthly % Finished C&A Import Mkt Share

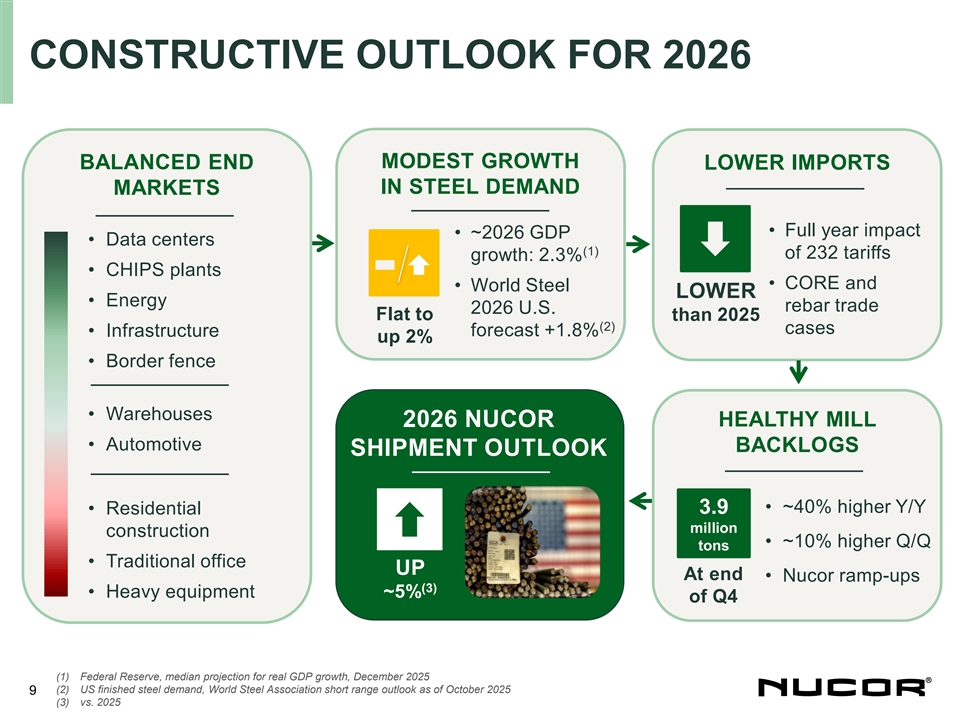

CONSTRUCTIVE OUTLOOK FOR 2026 MODEST GROWTH BALANCED END LOWER IMPORTS –––––––––––––––– MARKETS IN STEEL DEMAND –––––––––––––––– –––––––––––––––– • Full year impact • ~2026 GDP • Data centers (1) of 232 tariffs growth: 2.3% • CHIPS plants • CORE and • World Steel LOWER • Energy rebar trade 2026 U.S. Flat to than 2025 (2) cases forecast +1.8% • Infrastructure up 2% • Border fence –––––––––––––––– • Warehouses 2026 NUCOR HEALTHY MILL • Automotive BACKLOGS SHIPMENT OUTLOOK –––––––––––––––– –––––––––––––––– –––––––––––––––– • ~40% higher Y/Y • Residential 3.9 million construction • ~10% higher Q/Q tons • Traditional office UP At end • Nucor ramp-ups (3) ~5% • Heavy equipment of Q4 (1) Federal Reserve, median projection for real GDP growth, December 2025 (2) US finished steel demand, World Steel Association short range outlook as of October 2025 9 (3) vs. 2025

CONSOLIDATED FINANCIAL RESULTS ($ in Millions except per share data) 1 2 Reported and Adj. Diluted EPS EBITDA Q4 Full-year Q4 Full-year $8.90 $4,365 $4,174 $7.71 $8.46 $1.73 $7.52 $751 $918 $1.64 $1.22 2024 2025 2024 2025 2024 2025 2024 2025 3 Capital Expenditures Cash Returned to Shareholders Q4 Full-year Q4 Full-year $2,739 $3,422 $3,173 $879 $802 $1,212 $443 $227 2024 2025 2024 2025 2024 2025 2024 2025 (1) Adjusted Earnings and EBITDA exclude certain non-recurring charges. See appendix for a reconciliation of non-GAAP measures. (2) EBITDA is a non-GAAP financial measure. For a reconciliation of non-GAAP measures, please refer to the Appendix 10 (3) Cash Returned to Shareholders includes dividends and share repurchases

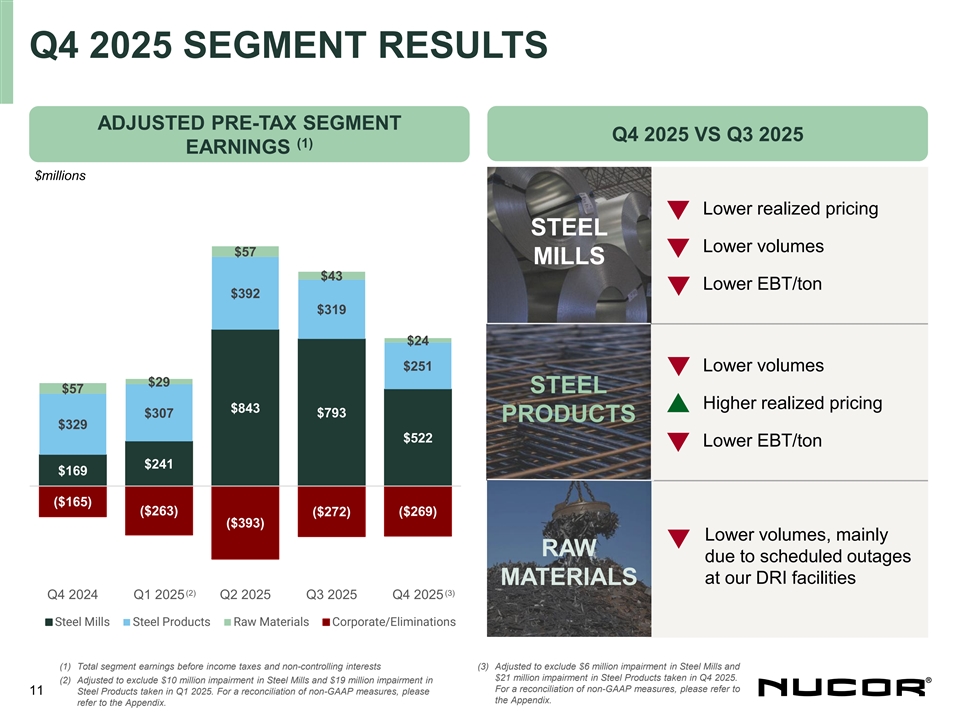

Q4 2025 SEGMENT RESULTS ADJUSTED PRE-TAX SEGMENT Q4 2025 VS Q3 2025 (1) EARNINGS $millions • Lower realized pricing STEEL • Lower volumes $57 MILLS $43 • Lower EBT/ton $392 $319 $24 $251 • Lower volumes $29 $57 STEEL • Higher realized pricing $843 $793 $307 PRODUCTS $329 $522 • Lower EBT/ton $241 $169 ($165) ($263) ($272) ($269) ($393) • Lower volumes, mainly RAW due to scheduled outages at our DRI facilities MATERIALS (2) (3) Q4 2024 Q1 2025 Q2 2025 Q3 2025 Q4 2025 Steel Mills Steel Products Raw Materials Corporate/Eliminations (1) Total segment earnings before income taxes and non-controlling interests (3) Adjusted to exclude $6 million impairment in Steel Mills and $21 million impairment in Steel Products taken in Q4 2025. (2) Adjusted to exclude $10 million impairment in Steel Mills and $19 million impairment in For a reconciliation of non-GAAP measures, please refer to 11 Steel Products taken in Q1 2025. For a reconciliation of non-GAAP measures, please the Appendix. refer to the Appendix.

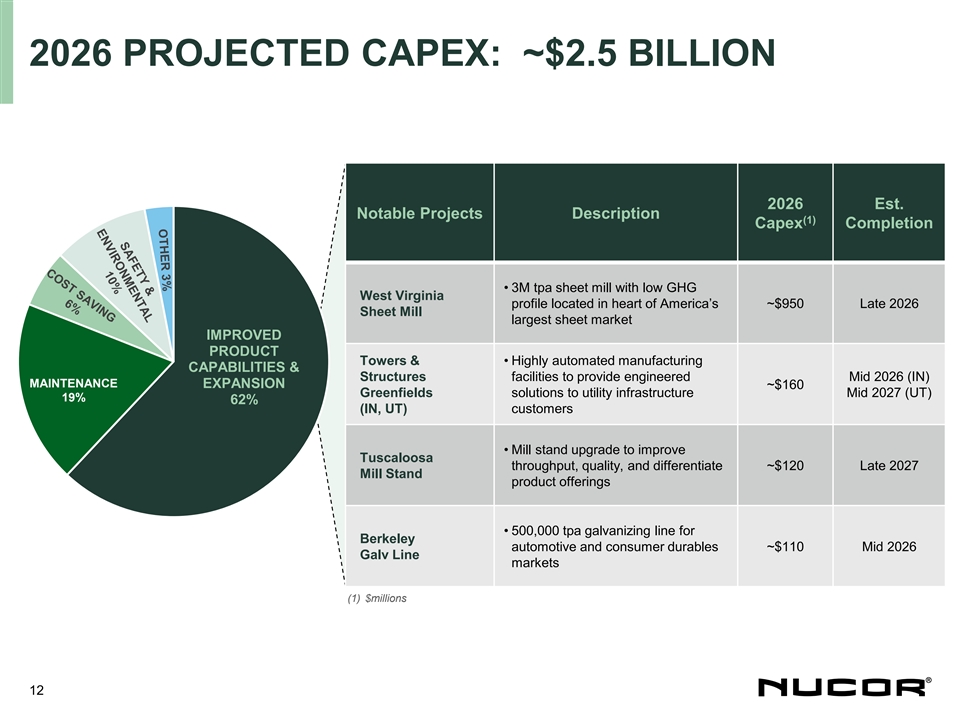

2026 PROJECTED CAPEX: ~$2.5 BILLION 2026 Est. Notable Projects Description (1) Capex Completion • 3M tpa sheet mill with low GHG West Virginia profile located in heart of America’s ~$950 Late 2026 Sheet Mill largest sheet market IMPROVED PRODUCT Towers & • Highly automated manufacturing CAPABILITIES & Structures facilities to provide engineered Mid 2026 (IN) MAINTENANCE EXPANSION ~$160 Greenfields solutions to utility infrastructure Mid 2027 (UT) 19% 62% (IN, UT) customers • Mill stand upgrade to improve Tuscaloosa throughput, quality, and differentiate ~$120 Late 2027 Mill Stand product offerings • 500,000 tpa galvanizing line for Berkeley automotive and consumer durables ~$110 Mid 2026 Galv Line markets (1) $millions 12

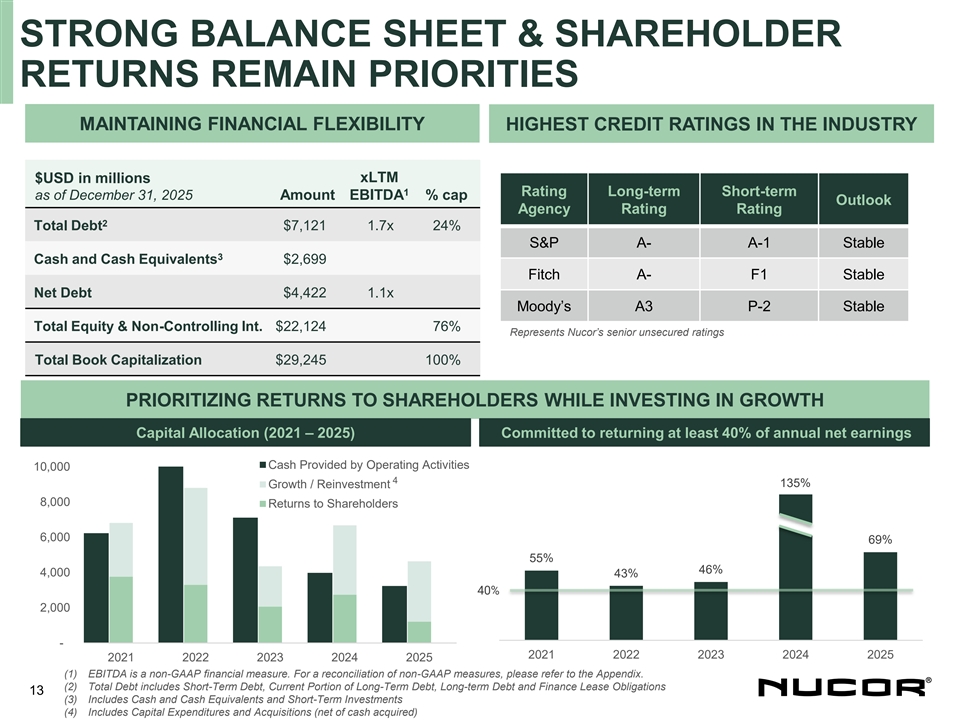

STRONG BALANCE SHEET & SHAREHOLDER RETURNS REMAIN PRIORITIES MAINTAINING FINANCIAL FLEXIBILITY HIGHEST CREDIT RATINGS IN THE INDUSTRY $USD in millions xLTM 1 Rating Long-term Short-term as of December 31, 2025 Amount EBITDA % cap Outlook Agency Rating Rating 2 Total Debt $7,121 1.7x 24% S&P A- A-1 Stable 3 Cash and Cash Equivalents $2,699 Fitch A- F1 Stable Net Debt $4,422 1.1x Moody’s A3 P-2 Stable Total Equity & Non-Controlling Int. $22,124 76% Represents Nucor’s senior unsecured ratings Total Book Capitalization $29,245 100% PRIORITIZING RETURNS TO SHAREHOLDERS WHILE INVESTING IN GROWTH Capital Allocation (2021 – 2025) Committed to returning at least 40% of annual net earnings Cash Provided by Operating Activities 10,000 4 135% Growth / Reinvestment 8,000 Returns to Shareholders 6,000 69% 55% 46% 4,000 43% 40% 2,000 - 2021 2022 2023 2024 2025 2021 2022 2023 2024 2025 (1) EBITDA is a non-GAAP financial measure. For a reconciliation of non-GAAP measures, please refer to the Appendix. (2) Total Debt includes Short-Term Debt, Current Portion of Long-Term Debt, Long-term Debt and Finance Lease Obligations 13 (3) Includes Cash and Cash Equivalents and Short-Term Investments (4) Includes Capital Expenditures and Acquisitions (net of cash acquired)

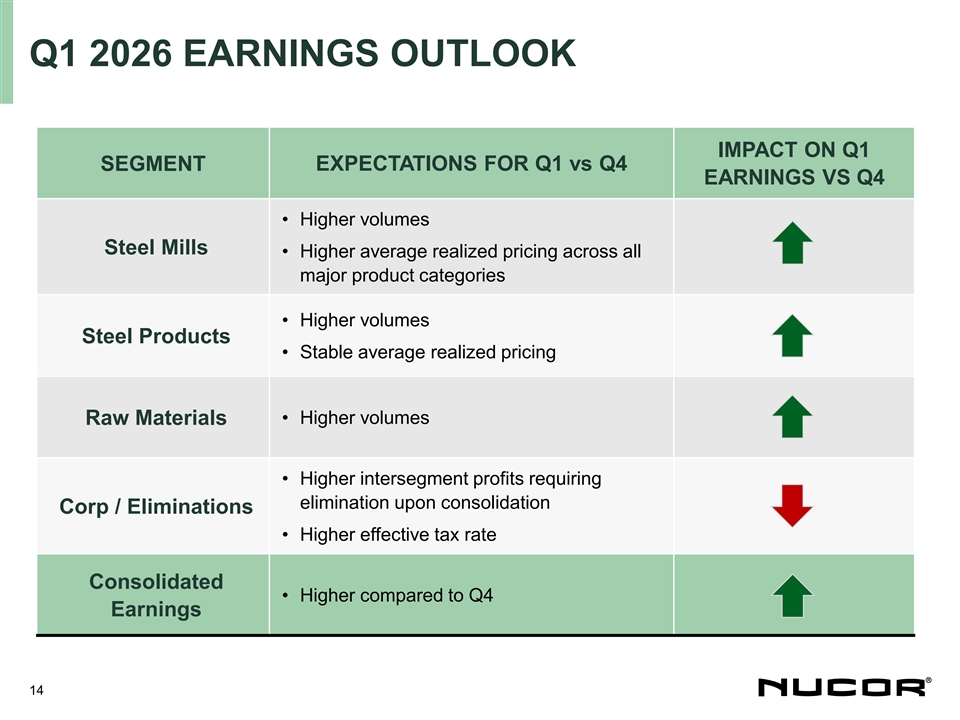

Q1 2026 EARNINGS OUTLOOK IMPACT ON Q1 SEGMENT EXPECTATIONS FOR Q1 vs Q4 EARNINGS VS Q4 • Higher volumes Steel Mills • Higher average realized pricing across all major product categories • Higher volumes Steel Products • Stable average realized pricing • Higher volumes Raw Materials • Higher intersegment profits requiring elimination upon consolidation Corp / Eliminations • Higher effective tax rate Consolidated • Higher compared to Q4 Earnings 14

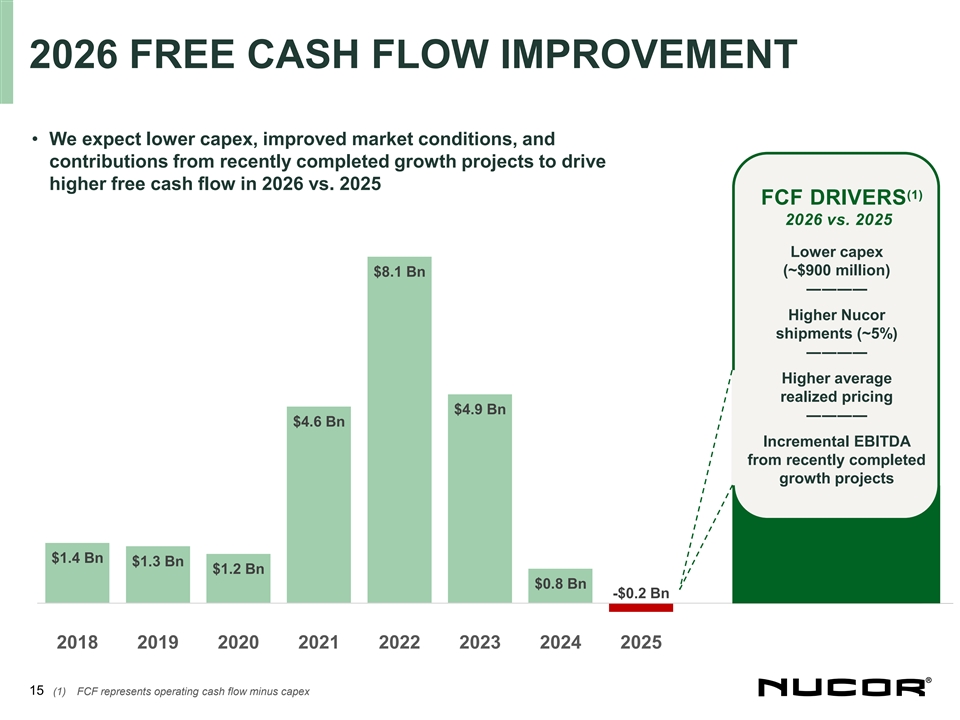

2026 FREE CASH FLOW IMPROVEMENT • We expect lower capex, improved market conditions, and contributions from recently completed growth projects to drive higher free cash flow in 2026 vs. 2025 (1) FCF DRIVERS 2026 vs. 2025 Lower capex (~$900 million) $8.1 Bn ―――― Higher Nucor shipments (~5%) ―――― Higher average realized pricing $4.9 Bn ―――― $4.6 Bn Incremental EBITDA from recently completed growth projects $1.4 Bn $1.3 Bn $1.2 Bn $0.8 Bn -$0.2 Bn 2018 2019 2020 2021 2022 2023 2024 2025 15 (1) FCF represents operating cash flow minus capex

APPENDIX 16

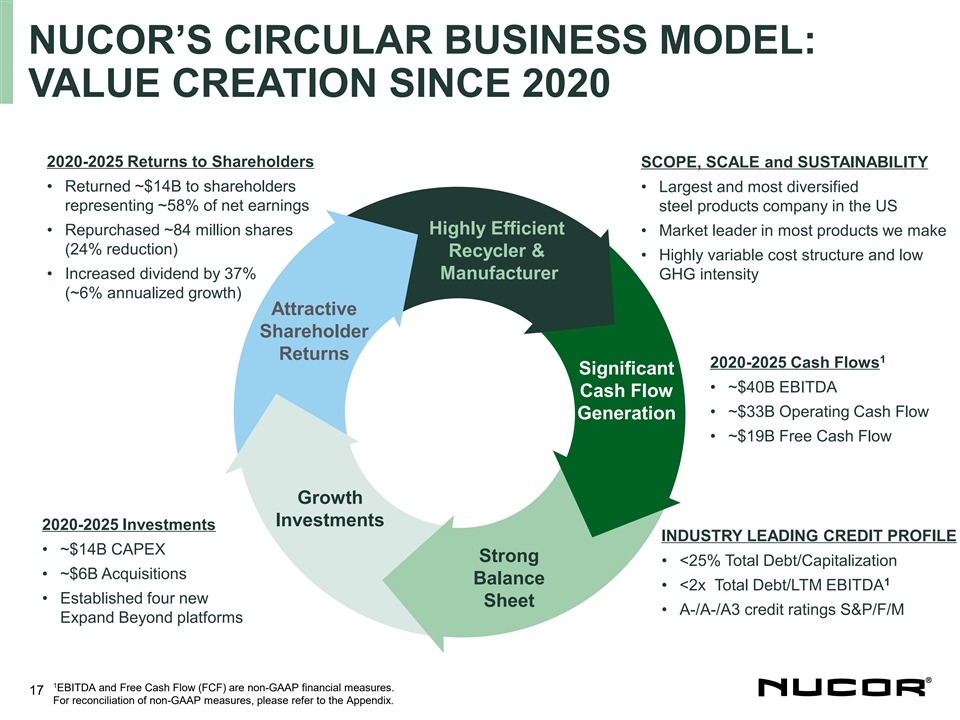

NUCOR’S CIRCULAR BUSINESS MODEL: VALUE CREATION SINCE 2020 2020-2025 Returns to Shareholders SCOPE, SCALE and SUSTAINABILITY • Returned ~$14B to shareholders • Largest and most diversified representing ~58% of net earnings steel products company in the US Highly Efficient • Repurchased ~84 million shares • Market leader in most products we make (24% reduction) Recycler & • Highly variable cost structure and low • Increased dividend by 37% Manufacturer GHG intensity (~6% annualized growth) Attractive Shareholder Returns 1 2020-2025 Cash Flows Significant • ~$40B EBITDA Cash Flow • ~$33B Operating Cash Flow Generation • ~$19B Free Cash Flow Growth Investments 2020-2025 Investments INDUSTRY LEADING CREDIT PROFILE • ~$14B CAPEX Strong • <25% Total Debt/Capitalization • ~$6B Acquisitions Balance 1 • <2x Total Debt/LTM EBITDA • Established four new Sheet • A-/A-/A3 credit ratings S&P/F/M Expand Beyond platforms 1 EBITDA and Free Cash Flow (FCF) are non-GAAP financial measures. 17 For reconciliation of non-GAAP measures, please refer to the Appendix.

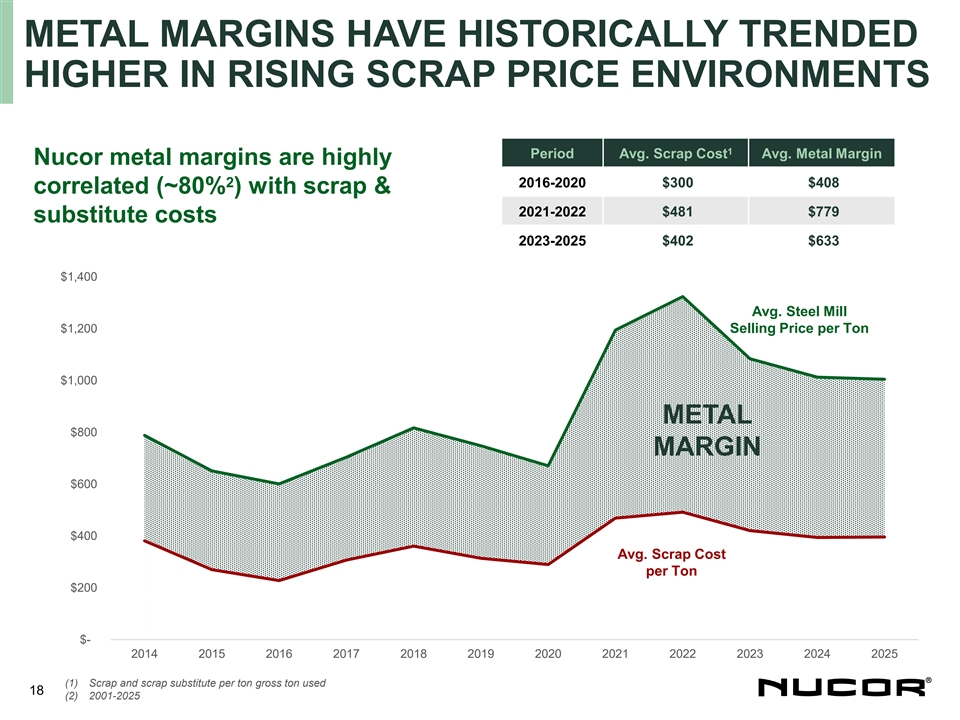

METAL MARGINS HAVE HISTORICALLY TRENDED HIGHER IN RISING SCRAP PRICE ENVIRONMENTS 1 Period Avg. Scrap Cost Avg. Metal Margin Nucor metal margins are highly 2 2016-2020 $300 $408 correlated (~80% ) with scrap & 2021-2022 $481 $779 substitute costs 2023-2025 $402 $633 $1,400 Avg. Steel Mill $1,200 Selling Price per Ton $1,000 METAL $800 MARGIN $600 $400 Avg. Scrap Cost per Ton $200 $- 2014 2015 2016 2017 2018 2019 2020 2021 2022 2023 2024 2025 (1) Scrap and scrap substitute per ton gross ton used 18 (2) 2001-2025

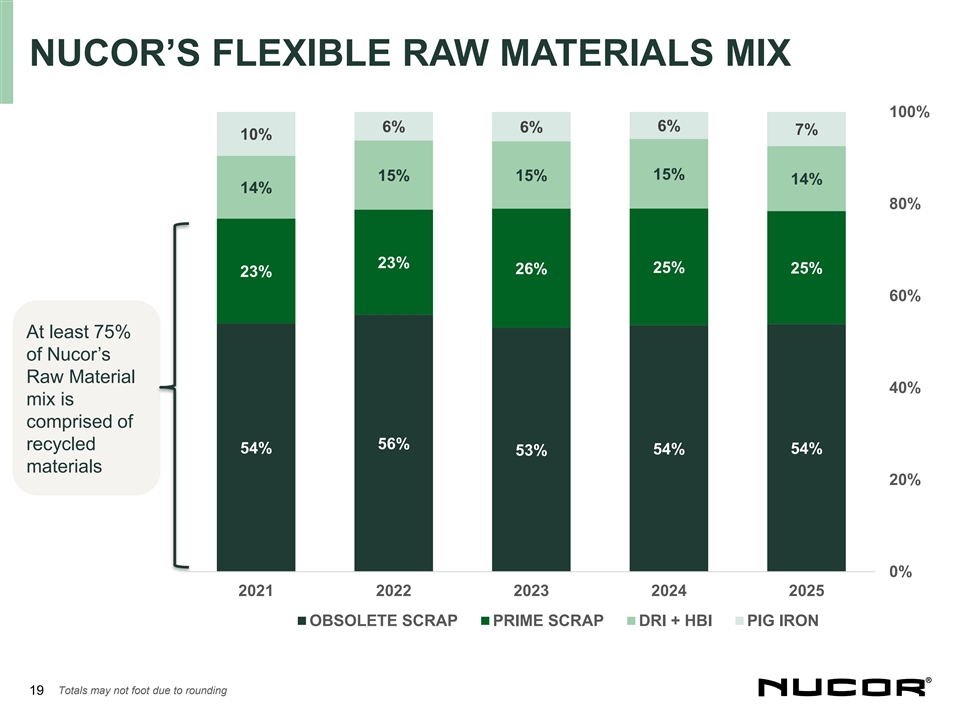

NUCOR’S FLEXIBLE RAW MATERIALS MIX 100% 6% 6% 6% 7% 10% 15% 15% 15% 14% 14% 80% 23% 25% 25% 26% 23% 60% At least 75% of Nucor’s Raw Material 40% mix is comprised of 56% recycled 54% 54% 54% 53% materials 20% 0% 2021 2022 2023 2024 2025 OBSOLETE SCRAP PRIME SCRAP DRI + HBI PIG IRON 19 Totals may not foot due to rounding

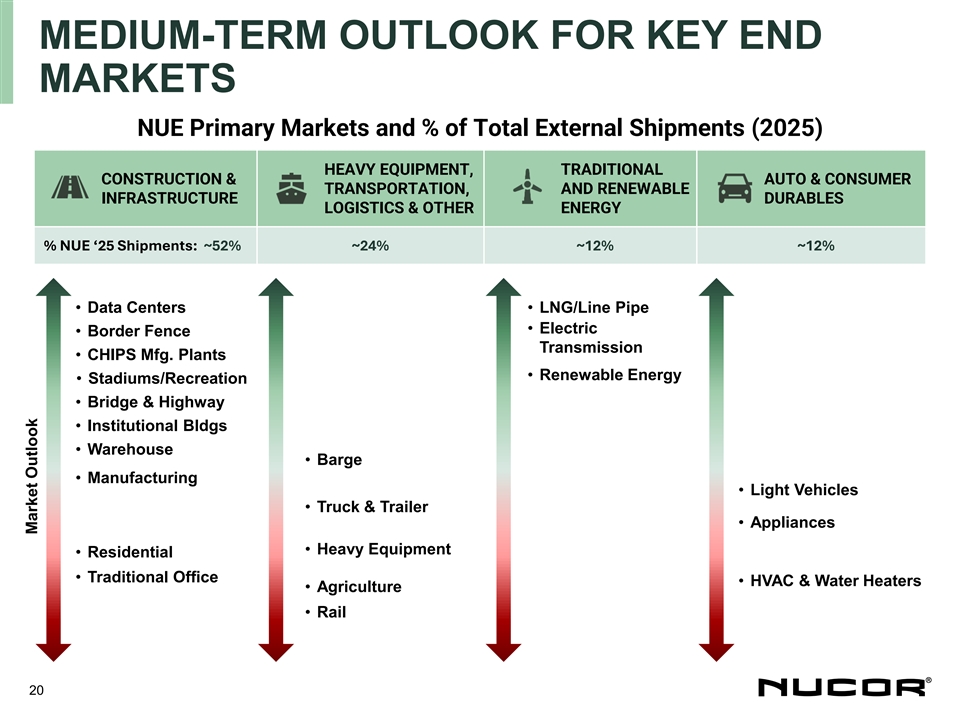

MEDIUM-TERM OUTLOOK FOR KEY END MARKETS NUE Primary Markets and % of Total External Shipments (2025) HEAVY EQUIPMENT, TRADITIONAL CONSTRUCTION & AUTO & CONSUMER TRANSPORTATION, AND RENEWABLE INFRASTRUCTURE DURABLES LOGISTICS & OTHER ENERGY % NUE ‘25 Shipments: ~52% ~24% ~12% ~12% • Data Centers • LNG/Line Pipe • Electric • Border Fence Transmission • CHIPS Mfg. Plants • Renewable Energy • Stadiums/Recreation • Bridge & Highway • Institutional Bldgs • Warehouse • Barge • Manufacturing • Light Vehicles • Truck & Trailer • Appliances • Heavy Equipment • Residential • Traditional Office • HVAC & Water Heaters • Agriculture • Rail 20 Market Outlook

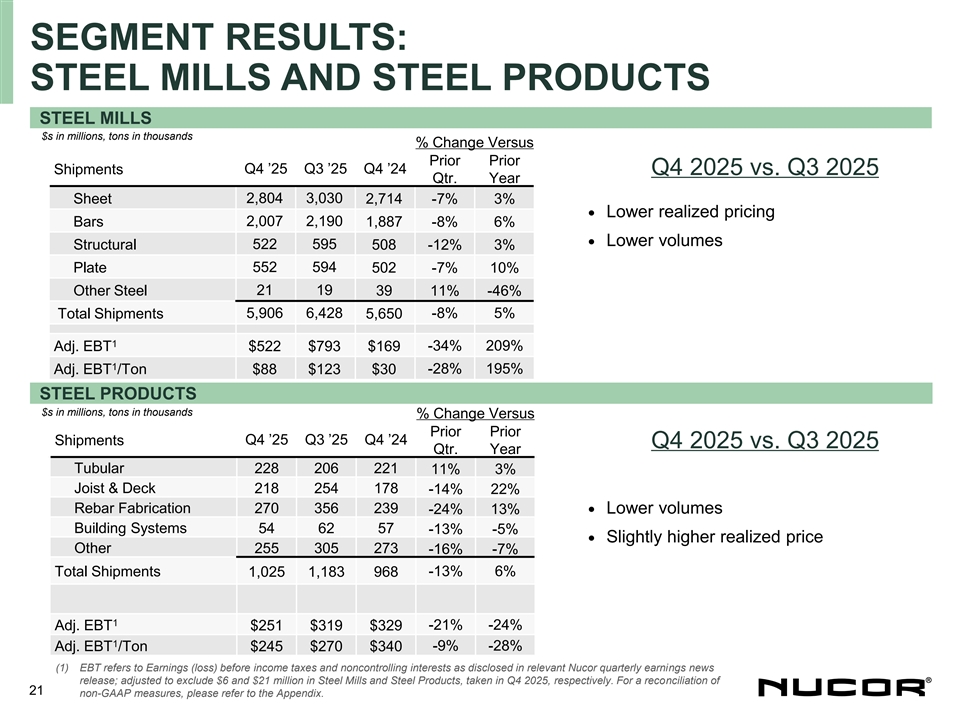

SEGMENT RESULTS: STEEL MILLS AND STEEL PRODUCTS STEEL MILLS $s in millions, tons in thousands % Change Versus Prior Prior Q4 ’25 Q3 ’25 Q4 ’24 Shipments Q4 2025 vs. Q3 2025 Qtr. Year Sheet 2,804 3,030 2,714 -7% 3% • Lower realized pricing Bars 2,007 2,190 1,887 -8% 6% • Lower volumes Structural 522 595 508 -12% 3% 552 594 Plate 502 -7% 10% 21 19 Other Steel 39 11% -46% Total Shipments 5,906 6,428 5,650 -8% 5% 1 -34% 209% Adj. EBT $522 $793 $169 1 -28% 195% Adj. EBT /Ton $88 $123 $30 STEEL PRODUCTS $s in millions, tons in thousands % Change Versus Prior Prior Shipments Q4 ’25 Q3 ’25 Q4 ’24 Q4 2025 vs. Q3 2025 Qtr. Year Tubular 228 206 221 11% 3% Joist & Deck 218 254 178 -14% 22% Rebar Fabrication 270 356 239• Lower volumes -24% 13% Building Systems 54 62 57 -13% -5% • Slightly higher realized price Other 255 305 273 -16% -7% Total Shipments -13% 6% 1,025 1,183 968 1 Adj. EBT $251 $319 $329 -21% -24% 1 -9% -28% Adj. EBT /Ton $245 $270 $340 (1) EBT refers to Earnings (loss) before income taxes and noncontrolling interests as disclosed in relevant Nucor quarterly earnings news release; adjusted to exclude $6 and $21 million in Steel Mills and Steel Products, taken in Q4 2025, respectively. For a reconciliation of 21 non-GAAP measures, please refer to the Appendix.

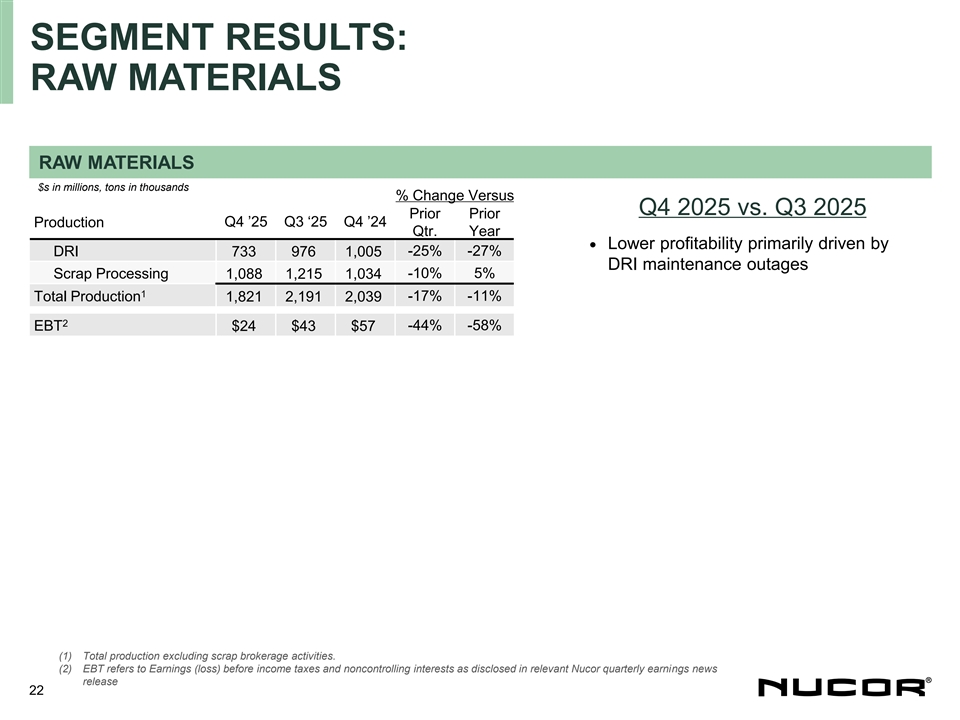

SEGMENT RESULTS: RAW MATERIALS RAW MATERIALS $s in millions, tons in thousands % Change Versus Q4 2025 vs. Q3 2025 Prior Prior Q4 ’25 Q3 ‘25 Q4 ’24 Production Qtr. Year • Lower profitability primarily driven by DRI -25% -27% 733 976 1,005 DRI maintenance outages Scrap Processing 1,088 1,215 1,034 -10% 5% 1 Total Production 1,821 2,191 2,039 -17% -11% 2 EBT $24 $43 $57 -44% -58% (1) Total production excluding scrap brokerage activities. (2) EBT refers to Earnings (loss) before income taxes and noncontrolling interests as disclosed in relevant Nucor quarterly earnings news release 22

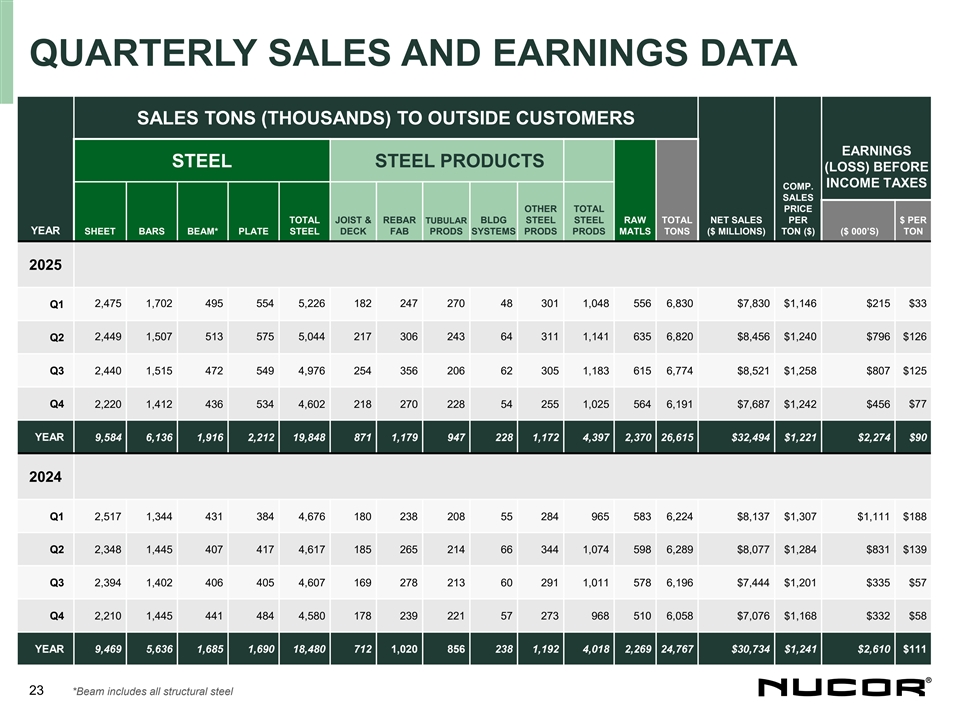

QUARTERLY SALES AND EARNINGS DATA SALES TONS (THOUSANDS) TO OUTSIDE CUSTOMERS EARNINGS STEEL STEEL PRODUCTS (LOSS) BEFORE INCOME TAXES COMP. SALES OTHER TOTAL PRICE TOTAL JOIST & REBAR TUBULAR BLDG STEEL STEEL RAW TOTAL NET SALES PER $ PER YEAR SHEET BARS BEAM* PLATE STEEL DECK FAB PRODS SYSTEMS PRODS PRODS MATLS TONS ($ MILLIONS) TON ($) ($ 000’S) TON 2025 2,475 1,702 495 554 5,226 182 247 270 48 301 1,048 556 6,830 $7,830 $1,146 $215 $33 Q1 2,449 1,507 513 575 5,044 217 306 243 64 311 1,141 635 6,820 $8,456 $1,240 $796 $126 Q2 Q3 2,440 1,515 472 549 4,976 254 356 206 62 305 1,183 615 6,774 $8,521 $1,258 $807 $125 Q4 2,220 1,412 436 534 4,602 218 270 228 54 255 1,025 564 6,191 $7,687 $1,242 $456 $77 YEAR 9,584 6,136 1,916 2,212 19,848 871 1,179 947 228 1,172 4,397 2,370 26,615 $32,494 $1,221 $2,274 $90 2024 Q1 2,517 1,344 431 384 4,676 180 238 208 55 284 965 583 6,224 $8,137 $1,307 $1,111 $188 Q2 2,348 1,445 407 417 4,617 185 265 214 66 344 1,074 598 6,289 $8,077 $1,284 $831 $139 Q3 2,394 1,402 406 405 4,607 169 278 213 60 291 1,011 578 6,196 $7,444 $1,201 $335 $57 Q4 2,210 1,445 441 484 4,580 178 239 221 57 273 968 510 6,058 $7,076 $1,168 $332 $58 YEAR 9,469 5,636 1,685 1,690 18,480 712 1,020 856 238 1,192 4,018 2,269 24,767 $30,734 $1,241 $2,610 $111 23 *Beam includes all structural steel

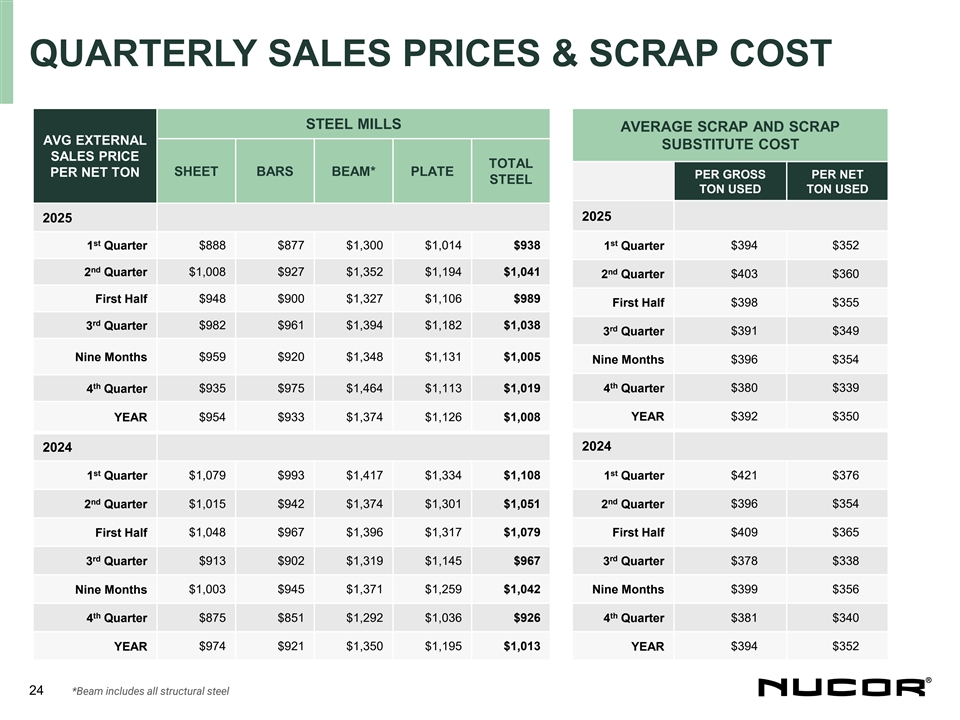

QUARTERLY SALES PRICES & SCRAP COST STEEL MILLS AVERAGE SCRAP AND SCRAP AVG EXTERNAL SUBSTITUTE COST SALES PRICE TOTAL SHEET BARS BEAM* PLATE PER NET TON PER GROSS PER NET STEEL TON USED TON USED 2025 2025 st st 1 Quarter $888 $877 $1,300 $1,014 $938 $394 $352 1 Quarter nd nd 2 Quarter $1,008 $927 $1,352 $1,194 $1,041 2 Quarter $403 $360 First Half $948 $900 $1,327 $1,106 $989 First Half $398 $355 rd 3 Quarter $982 $961 $1,394 $1,182 $1,038 rd $391 $349 3 Quarter Nine Months $959 $920 $1,348 $1,131 $1,005 Nine Months $396 $354 th th $935 $975 $1,464 $1,113 $1,019 4 Quarter $380 $339 4 Quarter $392 $350 YEAR $954 $933 $1,374 $1,126 $1,008 YEAR 2024 2024 st st 1 Quarter $1,079 $993 $1,417 $1,334 $1,108 1 Quarter $421 $376 nd nd 2 Quarter $1,015 $942 $1,374 $1,301 $1,051 2 Quarter $396 $354 $1,048 $967 $1,396 $1,317 $1,079 $409 $365 First Half First Half rd rd 3 Quarter $913 $902 $1,319 $1,145 $967 3 Quarter $378 $338 Nine Months $1,003 $945 $1,371 $1,259 $1,042 Nine Months $399 $356 th th 4 Quarter $875 $851 $1,292 $1,036 $926 4 Quarter $381 $340 YEAR $974 $921 $1,350 $1,195 $1,013 YEAR $394 $352 24 *Beam includes all structural steel

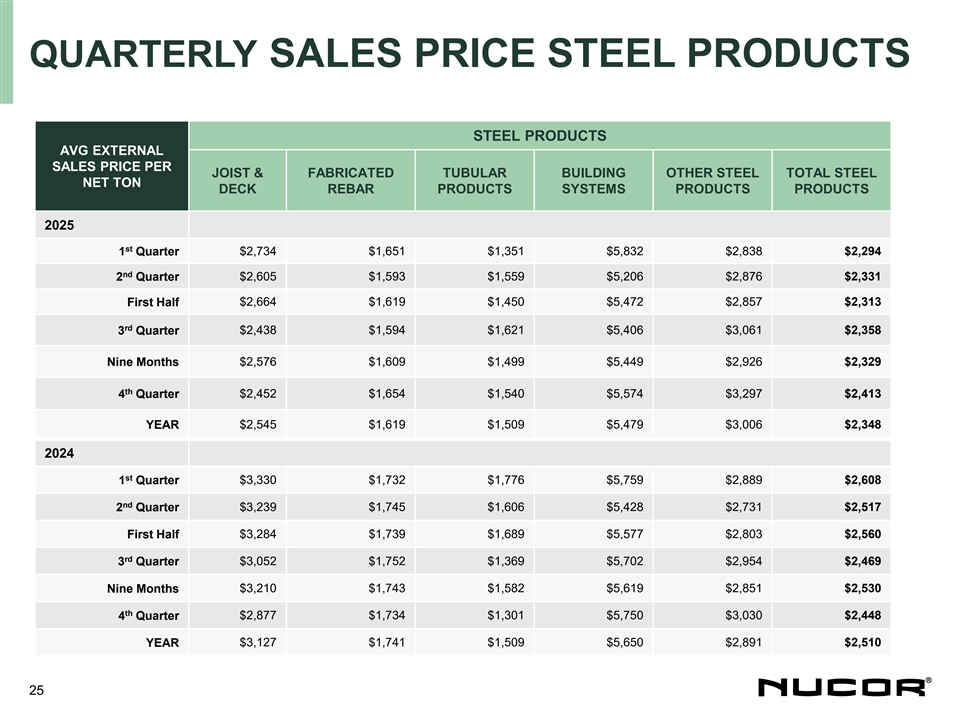

QUARTERLY SALES PRICE STEEL PRODUCTS STEEL PRODUCTS AVG EXTERNAL SALES PRICE PER JOIST & FABRICATED TUBULAR BUILDING OTHER STEEL TOTAL STEEL NET TON DECK REBAR PRODUCTS SYSTEMS PRODUCTS PRODUCTS 2025 st 1 Quarter $2,734 $1,651 $1,351 $5,832 $2,838 $2,294 nd 2 Quarter $2,605 $1,593 $1,559 $5,206 $2,876 $2,331 First Half $2,664 $1,619 $1,450 $5,472 $2,857 $2,313 rd 3 Quarter $2,438 $1,594 $1,621 $5,406 $3,061 $2,358 $2,576 $1,609 $1,499 $5,449 $2,926 $2,329 Nine Months th $2,452 $1,654 $1,540 $5,574 $3,297 $2,413 4 Quarter YEAR $2,545 $1,619 $1,509 $5,479 $3,006 $2,348 2024 st 1 Quarter $3,330 $1,732 $1,776 $5,759 $2,889 $2,608 nd 2 Quarter $3,239 $1,745 $1,606 $5,428 $2,731 $2,517 First Half $3,284 $1,739 $1,689 $5,577 $2,803 $2,560 rd 3 Quarter $3,052 $1,752 $1,369 $5,702 $2,954 $2,469 $3,210 $1,743 $1,582 $5,619 $2,851 $2,530 Nine Months th 4 Quarter $2,877 $1,734 $1,301 $5,750 $3,030 $2,448 YEAR $3,127 $1,741 $1,509 $5,650 $2,891 $2,510 25

RECONCILIATION OF GAAP TO NON-GAAP MEASURE - EBITDA $ in millions 2020 2021 2022 2023 2024 2025 Q4 2024 Q4 2025 Net earnings before $836 $7,122 $8,080 $4,913 $2,319 $2,038 $345 $423 non-controlling interests Net interest expense $153 $159 $170 ($30) ($30) $59 $3 $11 Income taxes -- $2,078 $2,165 $1,360 $583 $530 $45 $78 Depreciation expense $702 $735 $827 $931 $1,094 $1,226 $285 $316 Amortization expense $83 $129 $235 $238 $262 $254 $73 $63 Losses and impairments of assets $614 $62 $102 -- $137 $67 -- $27 EBITDA $2,388 $10,285 $11,579 $7,412 $4,365 $4,174 $751 $918 26

RECONCILIATION OF GAAP TO NON-GAAP MEASURE – FREE CASH FLOW (FCF) $ in millions 2020 2021 2022 2023 2024 2025 CASH PROVIDED BY $2,697 $6,231 $10,072 $7,112 $3,979 $3,234 OPERATING ACTIVITIES CAPITAL EXPENDITURES ($1,543) ($1,622) ($1,948) ($2,214) ($3,173) ($3,422) FREE CASH FLOW $1,154 $4,609 $8,124 $4,898 $806 ($188) 27

RECONCILIATION OF GAAP TO NON-GAAP MEASURE – EARNINGS ATTRIBUTABLE TO NUCOR STOCKHOLDERS $ in millions Q3 2024 Q1 2025 Q4 2025 Diluted EPS Diluted EPS Diluted EPS NET EARNINGS ATTRIBUTABLE $250 $1.05 $156 $0.67 $378 $1.64 TO NUCOR STOCKHOLDERS LOSSES AND IMPAIRMENTS OF $103 $0.44 $23 $0.10 $22 $0.09 ASSETS, NET OF TAX ADJUSTED NET EARNINGS $353 $1.49 $179 $0.77 $400 $1.73 ATTRIBUTABLE TO NUCOR STOCKHOLDERS 2024 2025 Diluted EPS Diluted EPS NET EARNINGS ATTRIBUTABLE $2,027 $8.46 $1,744 $7.52 TO NUCOR STOCKHOLDERS LOSSES AND IMPAIRMENTS OF $103 $0.44 $45 $0.19 ASSETS, NET OF TAX ADJUSTED NET EARNINGS ATTRIBUTABLE TO NUCOR $2,130 $8.90 $1,789 $7.71 STOCKHOLDERS 28

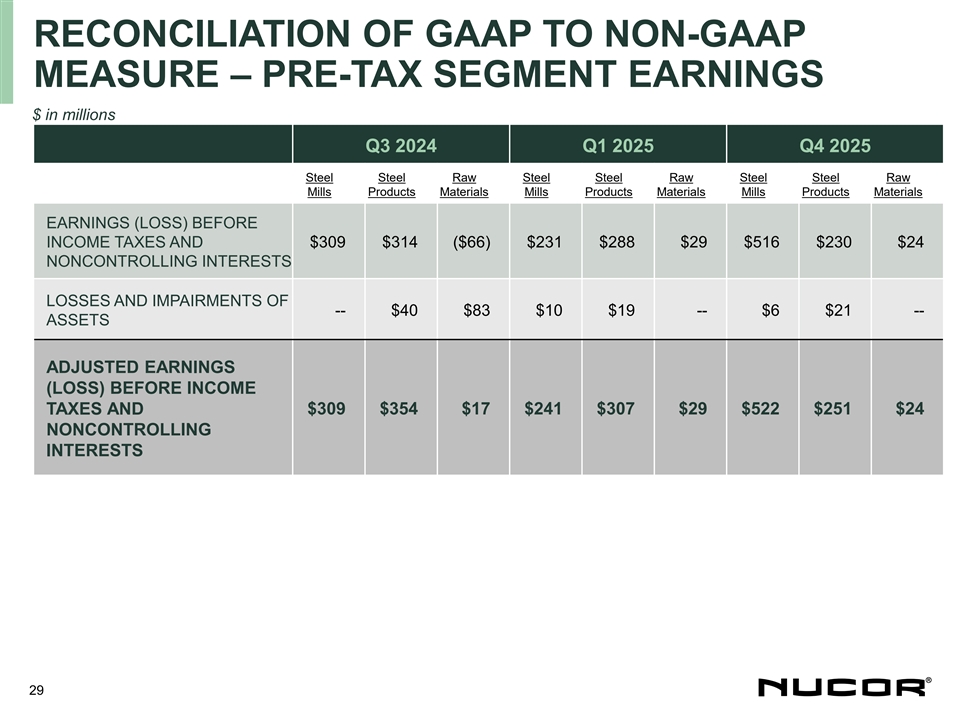

RECONCILIATION OF GAAP TO NON-GAAP MEASURE – PRE-TAX SEGMENT EARNINGS $ in millions Q3 2024 Q1 2025 Q4 2025 Steel Steel Raw Steel Steel Raw Steel Steel Raw Mills Products Materials Mills Products Materials Mills Products Materials EARNINGS (LOSS) BEFORE INCOME TAXES AND $309 $314 ($66) $231 $288 $29 $516 $230 $24 NONCONTROLLING INTERESTS LOSSES AND IMPAIRMENTS OF -- $40 $83 $10 $19 -- $6 $21 -- ASSETS ADJUSTED EARNINGS (LOSS) BEFORE INCOME TAXES AND $309 $354 $17 $241 $307 $29 $522 $251 $24 NONCONTROLLING INTERESTS 29