DESCRIPTION OF OUR BUSINESS

In this Business Section, unless the context indicates otherwise, references to “Biovest,” “the Company,” “our Company,” “we,” “us,” and similar references refer to Biovest International, Inc. and its subsidiaries, Biovest Europe, Ltd. and ViraCell Advanced Products, LLC.

Overview

Biovest is a biotechnology company focused on developing and commercializing BiovaxID™, as a personalized therapeutic cancer vaccine for the treatment of B-cell blood cancers; the continued development, commercialization, manufacture and sale of AutovaxID® and other instruments and disposables; and the commercial sale and production of cell culture products and services. We were incorporated in Minnesota in 1981, under the name Endotronics, Inc. In 1993, our name was changed to Cellex Biosciences, Inc. In 2001, we changed our corporate name to Biovest International, Inc. and changed our state of incorporation from Minnesota to Delaware.

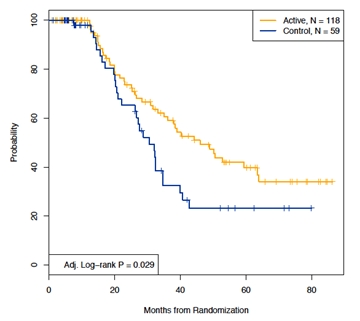

As a result of our collaboration with the National Cancer Institute (“NCI”), we are developing BiovaxID as a personalized therapeutic cancer vaccine for the treatment of non-Hodgkin’s lymphoma (“NHL”), a B-cell cancer, specifically, follicular lymphoma (“FL”) and mantle cell lymphoma (“MCL”), and potentially other B-cell cancers. Both FL and MCL are generally considered to be incurable with currently approved therapies. These generally fatal diseases arise from the lymphoid tissue and are characterized by an uncontrolled proliferation and spread throughout the body of mature B-cells, which are a type of white blood cell. Three clinical trials conducted under our investigational new drug application (“IND”) have studied BiovaxID in NHL. These studies include a Phase 2 clinical trial and a Phase 3 clinical trial in patients with FL, as well as Phase 2 clinical trial in patients with in MCL. The Phase 3 randomized, controlled trial demonstrated a statistically significant disease free survival benefit in patients who received BiovaxID compared to patients who received control vaccine (46.0 vs. 30.6 months respectively, P= 0.029 adjusted; HR= 0.58, %95 CI: 0.360-0.960). We believe that these clinical trials demonstrate the safety and efficacy of BiovaxID.

Based on our scientific advice meetings with multiple European Union (“EU”)-Member national medicines agencies, on June 13, 2012 we filed our formal notice of intent to file a marketing authorization application (“MAA”) with the European Medicines Agency (“EMA”) which began the EU marketing approval application process. Subsequently, on December 3, 2013, we submitted an MAA with the EMA for BiovaxID. Additionally, based on a scientific advice meeting conducted with Health Canada, we announced plans to file a new drug submission application (“NDS”) seeking regulatory approval in Canada. We also conducted a formal guidance meeting with the U.S. Food and Drug Administration (“FDA”) in order to discuss the path for our filing of a biologics licensing application (“BLA”) for BiovaxID’s U.S. regulatory/marketing approval. As a result of this guidance meeting, we plan to conduct a second Phase 3 clinical trial to complete the clinical data gained through our first Phase 3 clinical trial and our BiovaxID development program to support our filing of our BLA for BiovaxID. We are preparing to initiate this second Phase 3 clinical trial, subject to required funding.

To support our planned commercialization of BiovaxID and to support the products of personalized medicine and particularly, patient specific oncology products, we developed and commercialized a fully automated, reusable instrument that employs a fully disposable, closed-system cell-growth chamber incorporating a hollow fiber cell-growth cartridge called AutovaxID. Since it is fully enclosed, computer controlled and automated, AutovaxID requires limited supervision and manpower to operate, compared to manual instruments. AutovaxID is suitable for growing antibody-secreting cell lines, including hybridomas and Chinese hamster ovary (“CHO”) cells, which are among the leading kinds of cell lines used for commercial therapeutic protein manufacture. AutovaxID has a small footprint and supports scalable production. We plan to utilize the AutovaxID technology to streamline the commercial manufacture of BiovaxID. We believe that AutovaxID is the first cell culture system that enables production of personalized cell-based treatments economically. AutovaxID uses a disposable production unit which provides for robust and dependable manufacturing while complying with the industry current good manufacturing practices (“cGMP”) standards. We are collaborating with the U.S. Department of Defense (“DoD”) and others to further develop AutovaxID and related hollow fiber systems and to explore potential production of additional vaccines, including vaccines for viral indications such as influenza and other contagious diseases. We also manufacture instruments and disposables used in the hollow fiber production of cell culture products. We manufacture mammalian cell culture products such as whole cells, recombinant and secreted proteins, and monoclonal antibodies for third parties, primarily researchers. We have produced over 7,000 cell based products for an estimated 2,500 researchers around the world. We consider our vast experience in manufacturing small batches of different cell based products, together with our expertise in designing and manufacturing instruments for personalized medicines as important competencies supporting our development of patient specific immunotherapies.

PRODUCTS

BIOVAXID™ - Personalized Therapeutic Cancer Vaccine

The Human Immune System

The immune system functions as the body’s natural defense mechanism for identifying and killing or eliminating disease-causing pathogens, such as bacteria, viruses, or other foreign microorganisms. However, with regard to cancer, including lymphomas, the immune system’s natural defense mechanism is believed to be largely thwarted by natural immune system mechanisms which seek to protect “self-cells” from attack. In humans, the primary disease fighting function of the immune system is carried out by white blood cells (leukocytes), which mediate two types of immune responses: innate immunity and adaptive immunity. Innate immunity refers to the broad first-line immune defense that recognizes and eliminates certain pathogens prior to the initiation of a more specific adaptive immune response. While the cells of the innate immune system provide a first line of defense, they cannot always eliminate or recognize infectious organisms. In some cases, new infections may not always be recognized or detected by the innate immune system. In these cases, the adaptive immune response has evolved to provide a highly-specific and versatile means of defense which also provides long-lasting protection (immune memory) against subsequent re-infection by the same pathogen. This adaptive immune response facilitates the use of preventative vaccines that protect against viral and bacterial infections such as measles, polio, diphtheria, and tetanus. We believe that BiovaxID creates an adaptive immune response to cancerous B-cells.

Adaptive immunity is mediated by a subset of white blood cells called lymphocytes, which are divided into two types: B-cells and T-cells. In the bloodstream, B-cells and T-cells recognize antigens, which are molecules that are capable of triggering a response in the immune system. Antigens are molecules from bacterial, viral, or fungal origin, foreign (non-self) proteins, and in some cases, tumor-derived proteins that can stimulate an immune response. The human body makes millions of different types of B-cells that circulate in the blood and lymphatic systems and perform immune surveillance. Each B-cell has a unique receptor protein (immunoglobulin) on its surface that binds to one particular antigen. Once a B-cell recognizes its specific antigen and receives additional signals from a T-helper cell, it can proliferate and become activated in order to secrete antibodies (immunoglobulins; Ig) which can neutralize the antigen and target it for destruction. T-cells may also recognize antigens on foreign cells, whereby they can promote the activation of other white blood cells or initiate destruction of the targeted cells directly. A person’s B-cells and T-cells can collectively recognize a wide variety of antigens, but each individual B-cell or T-cell will recognize only one specific antigen. Consequently, in each person’s bloodstream, only a relatively few lymphocytes will recognize the same antigen. Since B-cell cancers such as NHL are tumors arising from a single malignant transformed B-cell, the tumor cells in NHL maintain on their surface the original malignant B-cell’s immunoglobulin (collectively referred to as, the “tumor idiotype”) that is distinct from those found on normal B-cells. The tumor idiotype maintained on the surface of each B-cell lymphoma serves as the tumor-specific antigen for the BiovaxID cancer vaccine.

In many cases, including in NHL, cancer cells produce molecules known as tumor-associated antigens, which may or may not be present in normal cells but may be over-produced in cancer cells. T-cells and B-cells have receptors on their surfaces that enable them to recognize the tumor associated antigens. While cancer cells may naturally trigger a B- or T-cell-based immune response during the initial appearance of the disease, this response may be only weakly specific or attenuated in such a way that it does not fully eradicate all tumor cells. Subsequently, tumor cells gradually evolve and escape from this weak immune response and are able to grow into larger tumors. In addition, because cancer cells arise from normal tissue cells, they are often able to exploit or increase existing immune tolerance mechanisms to suppress the body’s immune response which would normally destroy them. In other cases, chemotherapy or other treatment regimens used to treat the cancer may themselves weaken the immune response and render it unable to reject and kill tumor cells. Even with an activated immune system; however, the number and size of tumors can often overwhelm the immune system.

In the case of cancer and other diseases, immunotherapies are designed to activate a person’s immune system in an attempt to combat the disease. There are two forms of immunotherapy used to treat diseases: passive and active. Passive immunotherapy is exemplified by the intravenous infusion into a patient of antibodies specific to the particular antigen. While passive immunotherapies have shown clinical benefits in some cancers, they require repeated infusions and can cause the destruction of normal cells in addition to cancer cells. An example of passive immunotherapy to treat lymphoma is monoclonal antibodies such as rituximab. An active immunotherapy, on the other hand, seeks to generate a durable adaptive immune response by introducing an antigen into a patient, often in combination with other components that can enhance an immune response to the antigen. BiovaxID is an example of active specific immunotherapy. Although active immunotherapies have been successful in preventing many infectious diseases, their ability to combat cancers of various types has been limited by a variety of factors, including the inability of tumor antigens to elicit an effective immune response, difficulty in identifying suitable target tumor antigens, inability to manufacture tumor antigens in sufficiently pure form, and inability to manufacture sufficient quantities of tumor antigens.

Nevertheless, in 2010 one active immunotherapy, Provenge® (sipuleucel-T) developed by Dendreon Corporation, received marketing approval from the FDA for the treatment of asymptomatic or minimally symptomatic metastatic castrate resistant (hormone refractory) prostate cancer. This represents the first case of an active immunotherapy to successfully gain marketing approval in the U.S. In March 2011, a second active immunotherapy, Yervoy® (ipilimumab), developed by Bristol-Myers Squibb received marketing approval from the FDA, for the treatment of late-stage metastatic melanoma. In addition to BiovaxID, there are a number of other active immunotherapeutics for cancer in various stages of clinical trials that have demonstrated promising results.

A number of features of the NHLs make these tumors particularly suitable for treatment with a therapeutic cancer vaccine. The malignant B-cell lymphocytes of NHL express a unique, identifiable tumor-specific antigen which is not expressed by other (healthy) cells in the body. In contrast, the majority of human cancers typically lack strong ubiquitous expression of tumor-specific antigens to distinguish them from normal cells, or they express a potentially widely-varying mix of antigens which can be difficult to identify and formulate into a successful therapeutic vaccine.

Non-Hodgkin’s Lymphoma

Non-Hodgkin’s lymphoma (“NHL”) is a heterogeneous group of malignancies of the lymphatic system with differing clinical behaviors and responses to treatment. BiovaxID™ has been studied in two distinct forms of NHL, namely, FL and MCL. NHL was the seventh most common type of cancer in the U.S. in 2011 (Lymphoma and Leukemia Society- Facts 2012), with an estimated prevalence of 484,336 cases in 2011 in the U.S. (Surveillance, Epidemiology, and End Results- SEER Stat Fact Sheets: Non-Hodgkin’s Lymphoma). NHL accounts for 3% of all cancer deaths in the U.S. (American Cancer Society- Facts and Figures 2012). NHL is one of the few malignancies in which there continues to be a rise in incidence. Since the early 1970’s, incidence rates for NHL have nearly doubled. Moreover, in spite of recent advances in the standard of care, the overall five-year survival rate remains at approximately 69% (Surveillance, Epidemiology, and End Results [SEER] Stat Fact Sheets: Non-Hodgkin Lymphoma, 2014). In 2012, it is estimated that 70,130 new cases of NHL will be diagnosed and 18,940 Americans will die from the disease (American Cancer Society- Facts and Figures 2012), with a comparable number estimated in Europe.

NHL is usually classified for clinical purposes as being either “indolent” or “aggressive,” depending on how quickly the cancer cells are likely to grow and spread. The indolent, or slow-growing, form of NHL has a very slow growth rate and may need little or no treatment for months or possibly years. The aggressive, or fast-growing, form of NHL tends to grow and spread quickly and cause severe symptoms, and patients with aggressive NHL have shorter overall survival (“OS”).

Follicular Lymphoma

Indolent (slow growing) and aggressive (fast growing) NHL each constitute approximately half of all newly diagnosed B-cell NHL, and roughly half of the indolent B-cell NHL is follicular lymphoma (“FL”). Accordingly, approximately 22% of new cases of NHL fall into the category of disease known as indolent FL, which translates in about 106,550 cases in 2011 in the U.S. (SEER Stat Fact Sheets: Non-Hodgkin’s Lymphoma). We have conducted a Phase 2 clinical trial followed by a Phase 3 clinical trial in FL under our IND. FL is a form of NHL that is derived from a type of cell known as a follicle center cell. Despite its slow progression, FL is almost invariably fatal. According to data from 2003-2009 from 18 SEER areas, the 5-year relative survival rate in FL patients is 85.4%. According to a recent publication based on data from patients treated at Stanford University during 1997-2003 (Tan et al., Blood 2013), after the introduction of rituximab OS in patients with grade 1-2 FL (i.e., indolent lymphoma) reached 72% at 10-years. This improvement in OS was attributed to better supportive care and effective therapies for relapsed disease. The current standard of care for treatment of advanced, bulky FL (bulky Stage II, Stage III-IV) as specified by the National Comprehensive Cancer Network (“NCCN”) includes initial treatment of newly-diagnosed patients with rituximab-containing chemotherapy. Rituximab is a monoclonal antibody (an immune protein capable of selectively recognizing and binding to a molecule) which targets a protein primarily found on the surface of both healthy and cancerous B-cells, known as CD20. Accordingly, rituximab seeks to bind and destroy all B-cells, including healthy B-cells, as a means of controlling the progression of FL in treated patients. Rituximab and other biologics currently approved for lymphoma are characterized as “passive immunotherapies”. Following administration, rituximab exerts its effects primarily through an unselective and near total destruction of a patient’s B-cells, including malignant as well as healthy B-cells. Rituximab and other passive immunotherapies are often administered in sequential, repeated doses to achieve their effect, and following cessation of administration are over time eliminated from the patient’s circulation by normal bodily functions. Rituximab is characterized as a targeted therapy since it targets CD20, which is present on both healthy and tumor cells. Rituximab is manufactured in bulk and is not considered to be a personalized therapy. By comparison, BiovaxID™ is characterized as an “active immunotherapy”. Active immunotherapies attempt to stimulate the patient’s immune system to respond to a disease. “Specific active immunotherapies” such as BiovaxID, specifically seek to induce cellular and/or humoral immune responses focused on specific antigens present on a diseased cell (such as a tumor cell). As a specific, active immunotherapy, BiovaxID targets only the cancerous B-cells while sparing healthy B-cells. Accordingly, BiovaxID is highly targeted. BiovaxID is manufactured specifically and entirely for each patient and is considered to be a highly “personalized therapy”. If approved, BiovaxID will represent the only specific active immunotherapeutic approved for the treatment of FL and therefore will represent a new class of drugs that provides a new therapeutic option for patients with lymphoma. In February 2011, the NCCN issued treatment guidelines recognizing “consolidation therapy” as a defined treatment category for FL in first remission. Consolidation therapy options differ from induction therapies in that they primarily seek to prolong first remission duration by consolidating the effects of induction therapy, which primarily seeks to reduce active, bulky tumor masses. The following anti-CD20 monoclonal antibody drug products are currently approved consolidation treatment options for the first-line consolidation or extended dosing in FL: Rituxan® and Zevalin®. All of these treatment options are passive immunotherapies that result in profound B-cell depletion. Following the results of the Eastern Cooperative Oncology Group E4402 protocol, also called RESORT (Rituximab Extended Schedule or Re-treatment Trial), reported at the 2011 annual meeting of the American Society of Hematology (“ASH”), the NCCN revised its clinical practice guidelines on FL. Since 2012 NCCN guidelines have considered Rituxan maintenance therapy and Zevalin consolidation therapy as ‘optional’ therapeutic approaches post-induction therapy, rather than ‘recommended’ therapeutic approaches.

Current U.S. Approved Consolidation Therapies for NHL and Urgent Need for Alternative Treatment Options

Rituxan® (rituximab): Rituximab maintenance consists of administration of the anti-CD20 antibody rituximab administered at a dose of 375 mg/m2 every 8 weeks for 24 months (12 injections) administered by IV infusion every 8 weeks starting 8 weeks ± 7 days after the last induction treatment (whether immuno-chemotherapy or rituximab, whichever is later). Administration of rituximab (and other anti-CD20 agent) maintenance extends the profound immunosuppression achieved by induction therapy, as it targets the pan-B-cell CD20 protein. This continued dosing of the induction agent induces profound B-cell depletion for the two-year duration of the regimen.

Zevalin® (ibritumomab tiuxetan): Zevalin is an immunoconjugate resulting from covalently-bonded anti-CD20 antibody ibritumomab and the linker-chelator tiuxetan [N-[2-bi(carboxymethyl)amino]-3-(p-isothiocyanatophenyl)-propyl]-[N-[2-bis(carboxymethylamino]-2-(methyl)-ethyl]glycine. This linker-chelator provides a high affinity, conformationally restricted chelation site for Indium-111 or Yttrium-90. Administration follows induction rituximab and requires preliminary dosimetry and imaging administration of In-111 (Day 1) followed by administration of Y-90 Zevalin on Day 7, 8, or 9. The maximum allowable dose of Y-90 Zevalin is 32.0 mCi (1184) MBq and physicians and patients receiving the agent must exercise radiation exposure precautions upon administering or handling the agent.

Urgent Need for New Consolidation Treatment Option for NHL: The currently approved consolidation agents are no longer recommended therapeutic options post-induction therapy by the NCCN clinical practice guidelines. Following the results of the Eastern Cooperative Oncology Group E4402 protocol, also called RESORT (Rituximab Extended Schedule or Re-treatment Trial), reported at the 2011 annual meeting of ASH, the 2012 NCCN revised guidelines include rituximab maintenance and radioimmunotherapy as ‘optional’ therapeutic options post-induction. BiovaxID™ is expected to offer a non-immunosuppressive alternative to rituximab maintenance as a consolidation therapy for FL and MCL. By its mechanism of action, BiovaxID is not riddled with the risk of development of rituximab-resistance. Thus, BiovaxID represents a potential novel option for consolidation therapy that is safe and effective, compatible with current induction regimens, and unlikely to interfere with future therapies while potentially increasing the utility of other therapies.

Mantle Cell Lymphoma

Mantle cell lymphoma (“MCL”) is a rare, aggressive subtype of NHL characterized by short remissions and rapid progression similar to aggressive lymphomas and successive relapses, reflecting incurability similar to indolent lymphomas. The median OS for MCL has been cited as 5-7 years (Perez-Galan et al., 2011). MCL represents approximately 6% of all NHL cases and worldwide there are approximately 7,800 new cases each year of which, approximately, one half are in the U.S. (see “Current treatment approaches for mantle-cell lymphoma” J Clin Oncol. Sep 10 2005 and “New approach to classifying non-Hodgkin’s lymphomas: clinical features of the major histologic subtypes.” J Clin Oncol. Aug 1998). The majority of MCL patients have disseminated disease and bone marrow involvement at diagnosis. Patients’ clinical outcomes from currently available therapies are poor. Although many therapeutic regimens are capable of rendering high initial response rates, these responses are of short duration (i.e., about 20 months) and the relative survival rates of MCL patients are among the lowest compared to other types of NHL. After a patient’s first relapse, the expected disease course and prognosis is very poor, with an expected median OS of about 1-2 years. No currently available therapeutic regimens are curative.

While there are several therapeutic regimens available to treat MCL patients, there currently exists no consensus standard of care for treatment of first-line relapsed MCL. As such, MCL remains incurable and it is generally considered that additional treatment options are required given this significant unmet medical need. Currently, upon first diagnosis MCL patients are often evaluated for eligibility for autologous stem cell transplantation (“autoSCT”). Stem cell transplantation, an aggressive treatment protocol consisting of high-dose chemotherapy, immunotherapy and full-body radiation, aims to treat the patient’s tumor and purge the bone marrow of lymphoma cells. MCL patients who are eligible for autoSCT receive either R-CHOP (rituximab, cyclophophamide, doxorubicin, vincristine, prednisone) followed by autoSCT or R-HyperCVAD (rituximab, cyclophosphamide, vincristine, doxorubicin, and dexamethasone alternating with rituximab plus high dose methotrexate and cytarabine) followed by observation. Although these therapeutic approaches do yield high response rates, they are associated with high rates of adverse events and treatment discontinuation, high risk of myelodysplastic syndrome, and high mortality rates. Consequently, the considerable toxicity associated with these regimens largely limits these options primarily to a select subset of the MCL patients who are younger and better fit to tolerate these high-intensity treatments. However, even this subset ultimately gains only modest benefits from existing treatment options. Moreover, the use of these more aggressive regimens appears not to result in superior OS as compared to standard therapies. Given that the median age for newly diagnosed MCL patients is 60 years, less aggressive therapeutic approaches are needed.

Development Status of BiovaxID™

Preliminary studies demonstrated that treatment of patients with NHL with an active immunotherapy could allow a patient’s immune system generate clinically significant immune responses. These studies have been published in The New England Journal of Medicine (October 1992), Blood (May 1997), and Nature Medicine (October 1999). In the treatment of cancer, residual tumor cells remaining in the patient after completion of surgery or anti-tumor therapy are often the cause of tumor relapse. These residual tumor cells cannot always be detected by standard imaging techniques but their destruction may be feasible by active immunotherapy. The use of such vaccines differs from traditional cancer treatment in that the ultimate mechanism of action against the tumor is indirect: the anti-tumor immunity induced by vaccination, rather than the vaccine itself, is ultimately responsible for treatment benefit. In 1994, the NCI filed for initiation of an IND for the purpose of conducting clinical trial(s) investigating the use of BiovaxID in NHL. Under this IND and also in 1994, the NCI began the Phase 2 clinical trial in FL; in 1999, the Phase 3 clinical trial in FL; and in 2000 a Phase 2 clinical trial in MCL. The NCI selected us to produce BiovaxID for the initial Phase 2 clinical trial in FL. In 2001, we entered into a formal cooperative research and development agreement (“CRADA”) with the NCI which formalized our collaboration with the NCI. In April 2004, the IND filed by the NCI was formally transferred to us, which made our Company the exclusive sponsor of the IND with full rights to complete the NCI-initiated Phase 3 clinical trial in FL and the NCI-initiated Phase 2 clinical trial in MCL, to communicate and negotiate with the FDA relating to marketing approval for BiovaxID and to conduct other clinical studies in NHL under the IND.

BiovaxID™ Clinical Trials

Phase 2 Clinical Trial of BiovaxID™ for Treatment of FL

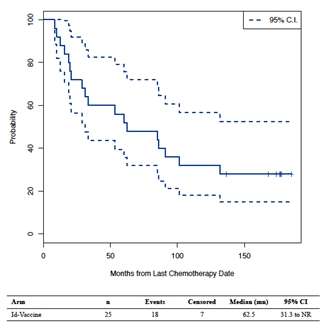

In 1994, the Phase 2 clinical trial (NCT00878488) was commenced by the NCI to evaluate the ability of BiovaxID to eradicate residual lymphoma cells in 20 patients with FL who were in chemotherapy-induced first clinical complete remission (“CR”). All 11 patients with a detectable lymphoma gene sequence (translocation) in their primary tumors had cells from the malignant clone detectable in their blood by DNA polymerase chain reaction (“PCR”) analysis both at diagnosis and after chemotherapy, despite being in CR. In this clinical trial, molecular remission was defined as patients lacking any detectable residual cancer cells bearing the translocation as determined by a very sensitive PCR technique. After vaccination, 8 of these 11 patients converted to lacking cells in their blood from the malignant lymphoma clone detectable by PCR. Anti-tumor T-cell responses were found in the vast majority of the patients (19 of 20 patients), whereas anti-tumor antibodies were detected, but apparently were not required for molecular remission. Vaccination was thus associated with clearance of residual tumor cells from the blood and long-term disease-free survival. The demonstration of molecular remissions besides uniform, specific T-cell responses against lymphoma tumor targets, as well as the addition of granulocyte-monocyte colony-stimulating factor (“GM-CSF”) to the vaccine formulation provided the rationale for the initiation of a larger Phase 3 clinical trial at the NCI in 2000. These results were published in Nature Medicine (Bendandi et al., 1999). At the latest data follow-up after a median of 167.9 months (range: 10.0- 214.3 months) median DFS was 62.5 months (Figure 2), median OS was not reached, and 80% of the patients were still alive.

Figure 1: Disease free survival in the Phase 2 clinical trial in FL patients

Phase 2 Clinical Trial of BiovaxID™ for Treatment of MCL

In 2000, the NCI initiated a Phase 2 open-label clinical trial (NCT00020215) of BiovaxID for the treatment of MCL. This Phase 2 clinical trial was based upon the NCI’s Phase 2 clinical trial in FL. The primary objective of this Phase 2 clinical trial was to study BiovaxID in treatment-naïve patients with MCL and to determine the safety and efficacy of BiovaxID following a rituximab-based immunotherapy. Twenty-six patients with untreated, mostly (92%) stage IV MCL, were enrolled. All patients received 6 cycles of EPOCH-R (which is a chemo-immunotherapy consisting of etoposide, prednisone, vincristine, cyclophosphamide, doxorubicin, rituximab); 92% of the patients achieved CR and 8% achieved partial response (“PR”). All but 3 patients (i.e., due to disease progression or inability to manufacture the heterohybridoma vaccine) received BiovaxID together with keyhole limpet hemocyanin (“KLH”), an immunogenic carrier protein, on day 1, along with GM-CSF (100 µg/m2/day) on days 1-4 at 1, 2, 3, 4, and 6 months starting at least 3 months post-chemotherapy.

The results of our MCL Phase 2 clinical trial were reported in Nature Medicine (Neelapu et a., 2005). As reported in Nature Medicine, at 46 months of follow-up the OS was 89%, the median event-free survival (“EFS”) was 22 months, and 5 patients remained in continuous first CR. Antibody responses to immunization were detected in 30% of the patients, following a delayed pattern (i.e., detected mostly after the 4-5th vaccination) which paralleled the peripheral blood B-cell recovery. Most importantly, specific CD4+ and CD8+ T-cell responses were detected in 87% of patients post-vaccine, and in 7 of 9 patients tested these responses were detected after the 3rd vaccination when peripheral B-cells were by and large undetectable. The detected cytokine release response included GM-CSF, INF-g, and TNF-a (type I). In this study, BiovaxID induced both humoral and cellular immune responses following almost complete depletion of B-cells following rituximab-containing chemotherapy. The adverse events observed in this clinical trial were minimal and were limited mostly to injection site reactions. The results of the latest follow-up of these patients performed in 2011 were presented at the 2011 annual meeting of ASH (Grant et al., ASH 2011 Abstract #2707). At a median follow-up of 99 months (range, 15.2 - 131.0 months), median PFS was 24.1 months, median OS was 99.04 months, and median TTNT was 37.8 months. This median PFS of 24.1 months is longer than the median PFS for combination chemotherapy (16 - 17 months) (Dreyling et al, 2005; Mangel et al, 2004) or CHOP-R chemotherapy (21 months) (Lenz et al, 2005). Similarly, the median OS of 99.04 months greatly exceeds the 5- 6 years obtained with current therapies (Dreyling & Hiddemann, 2009), and raises the possibility that BiovaxID vaccination modified the natural history of MCL.

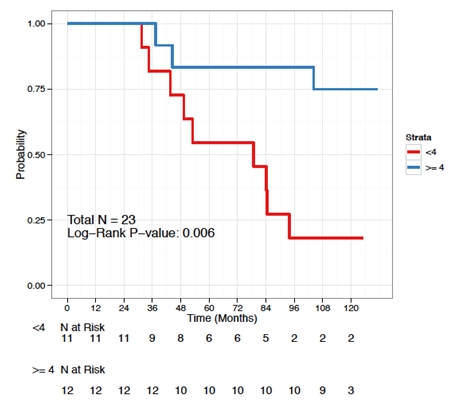

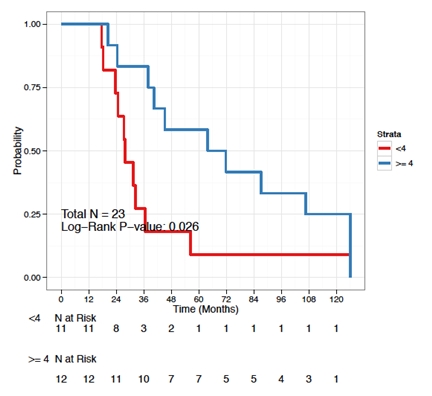

The association between OS and TTNT and tumor-specific GM-CSF cytokine induction observed at this long-term follow-up and presented at the 2011 annual meeting of the ASH and at the 2012 annual meeting of the American Society of Clinical Oncology (“ASCO”) suggests that the mechanism of action of BiovaxID is T-cell mediated and not B-cell (humoral) mediated. Patients with pre-vaccine-adjusted increases in tumor-specific normalized GM-CSF cytokine induction above the median value of 4 had a significantly longer median OS (not reached vs. 78.72 months, P= 0.006; Figure 2) and longer median TTNT (68.89 vs. 27.83 months, P = 0.026; Figure 4) compared to patients with pre-vaccine-adjusted increases in tumor-specific normalized GM-CSF cytokine induction < 4. There was no association between OS and specific anti-Id B-cell (humoral) responses or any other type of specific cellular responses. Additionally, the high impact of GM-CSF cytokine response mediated by antitumor T-cells on OS and TTNT suggest that anti-tumor immune responses significantly delayed tumor growth. In conclusion, these results demonstrate that administering BiovaxID post-rituximab is justifiable, as the effectively induced cellular responses underlie the fundamental mechanism of action of cancer vaccines. Given that rituximab-chemotherapy induction regimens represent the current therapeutic approach in B-cell lymphoma patients, BiovaxID is a compatible, effective, and safe consolidation therapy option.

Figure 2. Overall Survival by GM-CSF Cytokine Response (< and > than median)

Figure 3. Time to next treatment by GM-CSF Cytokine Response (< and > than median)

Phase 3 Clinical Trial of BiovaxID™ for Treatment of FL

Overview and Objectives. In January 2000, the Phase 3 clinical trial in FL (NCT00091676) was initiated by the NCI. The Phase 3 clinical trial was a multi-center, double-blind, randomized, controlled clinical trial that was designed to confirm the results reported in the NCI’s Phase 2 clinical trial.

As studied in the Phase 3 clinical trial, BiovaxID consisted of the patient-specific idiotype protein (Id) derived from the patient’s cancer cells conjugated or combined with KLH and administered with GM-CSF which is a biological response enhancer. The comparator studied in the Phase 3 clinical trial was a control vaccine consisting of KLH and administered with GM-CSF. Accordingly, the only difference between BiovaxID and the control vaccine was the inclusion of the idiotype protein from the patient’s own tumor in BiovaxID. BiovaxID or the control vaccine was administered following chemotherapy (also referred to as induction therapy) with a drug combination, of prednisone, doxorubicin, cyclophosphamide, etoposide (referred to as “PACE”). Induction therapy represents the “first-line” treatment for FL patients and attempts to induce complete tumor remission as defined by radiological evidence (“CT scans”). In FL, patients treated with the current standard of care often achieve complete remission but these remissions almost always are of limited duration and most treated patients must eventually be re-treated for their disease. In the majority of cases, however, even with re-treatment, the disease often relapses and develops resistance to therapy, leading to a need for bone marrow transplant and eventually resulting in the death of the patient. In the Phase 3 clinical trial, patients who achieved complete response following induction therapy were assigned to a limited waiting period prior to vaccination to allow for immune reconstitution following the induction chemotherapy. Patients who relapsed during this immune reconstitution period did not receive either BiovaxID or control treatment. Patients who maintained their complete remission following this immune recovery period received either BiovaxID or control administered as 5 subcutaneous injections monthly over a six month period (one month was skipped).

The primary objective of the Phase 3 clinical trial was to definitively confirm the safety and efficacy of BiovaxID (autologous immunoglobulin follicular lymphoma idiotype vaccine) assessed by significant prolongation of clinical DFS following BiovaxID immunization with GM-CSF in FL patients achieving a CR/CRu with standard dose chemotherapy, when compared to DFS following administration of KLH-KLH and GM-CSF.

The secondary objectives of the Phase 3 clinical trial included:

(1) to determine the ability of BiovaxID to produce a molecular CR in subjects in clinical CR, but with PCR evidence of residual disease after standard chemotherapy;

(2) to determine the impact of BiovaxID on molecular remission in FL patients;

(3) to evaluate the ability of BiovaxID to generate an immune response against autologous tumor;

(4) to determine and compare the OS of subjects randomized to receive either treatment assignment; and

(5) to evaluate the safety of BiovaxID administered with GM-CSF.

Biopsy, Chemotherapy, and Immune Recovery. Prior to chemotherapy, a small tumor biopsy was performed to obtain tissue for tumor classification and characterization, and to provide starting material necessary to manufacture BiovaxID. Following this biopsy patients were initially treated with PACE chemotherapy in order to induce a CR or a complete response unconfirmed (“CRu”) as measured by CT scans. The clinical trial protocol stipulated that for all patients, an immune recovery period of approximately 6 months following completion of chemotherapy was required to be completed without relapse (“Immune Recovery Period”) before vaccination. The Immune Recovery Period was required in order to maximize the potential for immune response to vaccine and to avoid confounding factors from any potential lingering immunosuppressive effects of chemotherapy.

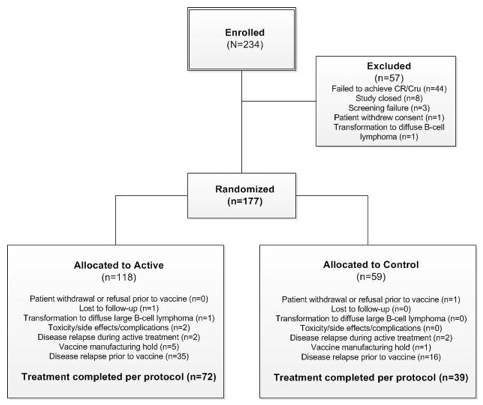

Randomization to Immune Recovery Followed by BiovaxID or Control. When the NCI designed the Phase 3 clinical trial in FL protocol, a decision was made to randomize patients, immediately after completion of chemotherapy and not to wait for the completion of the Immune Recovery Period in an effort to avoid expending NCI resources to manufacture patient-specific vaccines for patients who were not anticipated to receive the vaccine (e.g., control patients). In the Phase 3 clinical trial, of the 234 patients initially enrolled into the clinical trial, 177 patients completed chemotherapy, achieved CR/ CRu, and were randomized. As per the design of the Phase 3 clinical trial, patients who relapsed during the Immune Recovery Period were excluded from treatment with BiovaxID or control notwithstanding the fact that they had been randomized. In the Phase 3 clinical trial, of the 177 initially randomized patients, 117 remained eligible to be treated with either BiovaxID (76 patients) or control (41 patients) at the end of the Immune Recovery Period. Sixty patients of the 177 randomized patients were not treated with either BiovaxID or control mostly due to relapse during the immune recovery period (see Figure 4).

Figure 4. Enrollment, randomization, and treatment, Two hundred thirty-four patients were enrolled, and 177 patients were randomized to receive at least one dose of the blinded vaccine; 76 patients received Id-vaccine and 41 received control vaccine.

Trial Enrollment and the Use of Rituximab-Containing Induction Chemotherapy. During the course of the Phase 3 clinical trial, the standard of care for induction chemotherapy in FL changed to include rituximab, which reduced the ability to recruit and enroll patients into the study. In order to facilitate enrollment in the clinical trial, we amended the study protocol in 2007 to permit the use of a rituximab-containing chemotherapy regimen (“CHOP-R”), as induction therapy. However, the FDA requested that we abstain from vaccinating any patients who received CHOP-R and we did not vaccinate any of the patients who received CHOP-R chemotherapy under the Phase 3 clinical trial protocol.

Due to the protracted enrollment, the Phase 3 clinical trial’s Independent Data Monitoring Committee (“DMC”; a committee responsible for reviewing the available unblinded clinical trial data in the study and responsible for recommendations to the sponsor and the FDA) recommended an interim analysis of the clinical trial’s endpoints and overall safety profile which resulted in the termination and halting of the trial in 2008. As of April 15, 2008, when the Phase 3 clinical trial was officially closed, a total of 234 subjects had been enrolled and 177 subjects had been randomized. The total number of subject was less than the original planned sample size which called for 629 subjects to be enrolled and 540 to be randomized. While the termination of the Phase 3 clinical trial before completion of the planned accrual resulted in a smaller sample size than was originally intended, we believe that the randomized nature of our Phase 3 clinical trial yields a valid conclusion because the baseline characteristics of the patients in the 2 groups were balanced, the allocation to treatment arms was concealed, and the study was double-blinded.

Results of Phase 3 Clinical Trial. Of the 177 randomized patients in the ITT (intent to treat) population, 60 were censored due to ineligibility post-randomization due to the following: pre-vaccine relapse (n = 51, 28.8%), vaccine manufacturing hold (n = 6, 3.4%), and 1 each (0.6%) for lost to follow-up, withdrawal prior to vaccination, and transformation to diffuse large B-cell lymphoma. Importantly, relapse events that disqualified 51 patients for post-randomization treatment occurred in a blinded manner and were independent of external factors and were a consequence of each patient’s disease. Post-randomization relapse was equivalent between the two treatment groups: 29.7% versus 27.1%, active (BiovaxID+GM-CSF) to control (KLH-KLH+GM-CSF), respectively. Due to vaccine manufacturing failure, 5 patients who were randomized to receive active treatment (i.e., BiovaxID+GM-CSF) actually received control treatment (i.e., KLH-KLH+GM-CSF) but were analyzed as randomized, as per the prospective protocol provisions. In the ITT population there were no statistically significant differences in demographics and baseline characteristics between the treatment arms.

At a median follow-up of 56.6 months (range: 4.2 – 92.0 months), median DFS in the ITT population was 46.0 months for patients in the active treatment group (BiovaxID+GM-CSF) versus 30.6 months for patients in the control treatment group (KLH-KLH+GM-CSF) (log rank P = 0.029, controlled for FLIPI risk group and number of chemotherapy cycles) (Figure 5). BiovaxID vaccination therefore resulted in a 42% decrease in risk of relapse compared to control vaccination (HR= 0.58; %95CI: 0.370- 0.960).Median OS was not reached in either arm.

Figure 5. Disease-free survival (DFS) according to treatment arm for ITT Population (N = 177)

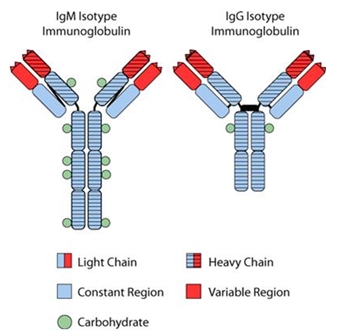

Analysis of Patients by Isotype. A typical antibody (“immunoglobulin”), including the lymphoma immunoglobulin expressed on the surface of each cancerous lymphoma cell, is composed of protein “heavy chains” and “light chains”. In humans, the heavy chains are classified as IgG, IgM, IgA, IgD and IgE, and the light chains are classified as either kappa or lambda. The Id protein expressed on the surface of FL cells is characteristic of the single B-cell from which the tumor arose. The immunoglobulin protein contains a region known as the “heavy chain” and a region known as the “light chain” (see Figure 6). Almost always in FL, the heavy chain region is characterized as either an IgM-isotype or an IgG-isotype. Figure 6 illustrates the dramatic differences in the structure of immunoglobulin protein characterized as an IgM-isotype as opposed that characterized as an IgG-isotype. Accordingly, an antibody may be referred to as IgG-isotype or IgM-isotype depending on its heavy-chain classification. In the normal immune response, antibody isotypes may have different roles and may help direct the appropriate immune response. The small region at the tip of the antibody is known as the “variable region”, or antibody binding site, and the balance of the isotype is known as the “constant region”. When we manufacture BiovaxID, we screen each patient’s tumor cells obtained by biopsy for the isotype. Approximately, 60% of patients with FL are diagnosed with tumors expressing an IgM isotype and approximately 40% of patients bear tumors expressing an IgG isotype. In rare cases (<1%), patients are diagnosed with another isotype (e.g. IgA). Infrequently, the patient’s tumor also contains cells with one or more isotype (a heterogenous or “mixed” isotype); in these patients we select either an IgG or IgM isotype for manufacture of BiovaxID. Each patient’s tumor isotype can be readily determined by standard analytical techniques (flow cytometry) at the time of the patient’s tumor biopsy. In both the Phase 2 and Phase 3 clinical trials in FL patients, the determination of tumor heavy-chain isotype determined the specific manufacturing and purification process used to make that patient’s vaccine. For patients who have tumors expressing an IgG (or an IgG-containing “mixed” isotype), we manufacture an IgG isotype vaccine and for patients determined to have tumors expressing an IgM (or an IgM-containing “mixed” isotype), we manufacture an IgM vaccine. Due to our manufacturing process (rescue fusion hybridoma), the isotype (IgG or IgM) of the tumor is entirely reproduced in each patient’s vaccine so that each patient’s BiovaxID vaccine matches the patient’s original tumor isotype (IgG or IgM).

Figure 6. The Id protein expressed on the surface of FL cells is an immunoglobulin protein characteristic of the single B-cell from which the tumor arose.

Preclinical data indicates that the ability to develop an immune response differs between IgM-isotype and IgG-isotype idiotypes (De Groot, 2008; Reitan, 1995; Reitan, 2002); however, we do not currently have immune response data from human clinical trials to confirm this preclinical data. The IgG-isotype idiotype was reported to be tolerogenic, meaning that the immune response against the specific tumor target is suppressed. On the other hand, the IgM-isotype idiotype was reported to be highly immunogenic, meaning that it induces an ample, persistent immune response against the specific tumor target. The unique feature of our Phase 3 clinical trial was the manufacturing and administration of tumor-matched isotype idiotype vaccines which, allowed us to investigate whether these preclinical data translate into differential clinical efficacy of the two isotype vaccines in our clinical trial.

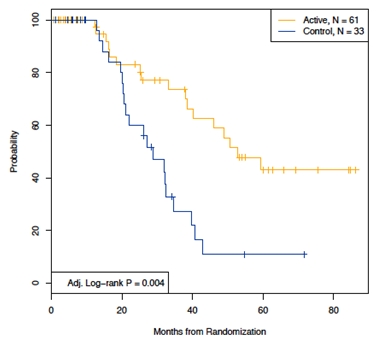

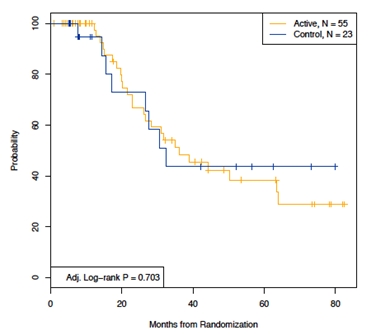

In an unplanned subgroup analyses, DFS was analyzed by tumor Ig heavy chain isotypes (IgM and IgG). Five patients from the ITT population were excluded from these analyses because their tumors isotype was mixed IgM/ or IgD. The IgM subgroup included 94 patients (N= 61 active, N= 33 control), and the IgG subgroup included 78 patients (N= 55 active, N= 23 control). In both isotype subgroups there were no statistically significant differences in baseline patient characteristics between experimental and control arms. Among patients receiving an IgM-Id vaccine, median time to relapse after randomization was 52.9 months versus 28.7 months in IgM tumor isotype control-treated patients (P= 0.004; HR= 0.33; 95% CI: 0.157- 0.727) (Figure 7). Among patients receiving IgG-Id vaccine, median time to relapse after randomization was 36.2 months versus 32.4 months in IgG tumor isotype control-treated patients (P= 0.703; HR= 1.19; 95% CI: 0.472- 3.036) (Figure 8). Cox proportional hazard modeling including the main effects of treatment arm and tumor isotype,, adjusted for FLIPI risk group and the number of chemotherapy cycles received, supports a differential effect of treatment by isotype as indicated by the P value of the interaction term between treatment and tumor Ig isotype (P= 0.062).

Figure 7. Disease free survival in IgM isotype patients

Figure 8. Disease free survival in IgG isotype patients

Our Phase 3 clinical trial had two unique manufacturing features, where: (a) the vaccine consists of the full structure of the idiotype protein (that is, both the variable and the constant regions of the immunoglobulin) and (b) the idiotype of the vaccine matches the idiotype of the patient’s own tumor. These unique features allowed us to be the first to investigate the clinical efficacy implications of the two tumor isotypes. The prior Phase 3 clinical trials of FL idiotype vaccines conducted by Genitope Corporation (“Genitope”) and Favrille, Inc. (“Favrille”) used a manufacturing process known as recombinant manufacturing that universally linked the patient’s variable region of the idiotype into an IgG isotype without regard to the actual isotype of each patient’s tumor. We believe that the use of an IgG isotype was due to the comparative ease of manufacture and purification of IgG proteins as well as to their relatively long half-life. There are two implications of the manufacturing processes used by these prior clinical trials: (1) clinical efficacy cannot be compared by isotype group; and (2) the lack of clinical efficacy observed in these clinical trials may be due to the tolerogenic effect of the universal IgG isotype used in the vaccine manufacturing. As such, we believe that our analysis by tumor isotype may provide profound insight into the efficacy of BiovaxID and may also suggest methods by which cancer vaccines in general could be developed in the future.

BiovaxID Regulatory and Marketing Status

Under our IND for BiovaxID, two Phase 2 clinical trials and one Phase 3 clinical trial have been completed studying BiovaxID for the indications of FL and MCL. We believe that these clinical trials demonstrate the safety and efficacy of BiovaxID and we have presented comprehensive summaries of the clinical development and clinical data to regulatory authorities in the EU, Canada and the U.S.

Based on our scientific advice meetings with multiple EU-Member national medicines agencies, on June 13, 2012, we filed our formal notice of intent to file a MAA with the EMA, which began the EU marketing approval application process. In response to our notice of intent to file for marketing approval, the EMA notified us that we were eligible to submit our planned MAA for BiovaxID under the EMA’s centralized procedure, as an orphan medicinal product for the treatment of FL. Under the EMA centralized procedure, the marketing approval of BiovaxID can be simultaneously obtained throughout all EU-member countries with a single MAA. Also, as part of the EMA’s centralized procedure, our MAA for BiovaxID will be assessed by the EMA’s Committee for Medicinal Products for Human Use (“CHMP”), which designates from within its membership, a Rapporteur and Co-Rapporteur, as well as a Pharmacovigilance Risk Assessment Committee (“PRAC”) Rapporteur and Co-Rapporteur. The Rapporteur and Co-Rapporteur are assigned with the primary responsibility of preparing and delivering an approvability evaluation report, supported by a team of assessors from their National Authority. In 2012, the PRAC Rapporteur and Co-Rapporteur was implemented, after the latest revisions to the EMA safety requirements on Pharmacovigilance and Risk Assessment Plan, with the primary responsibility of preparing and delivering an approvability evaluation report specifically with regards to safety. The EMA has also notified us regarding the EMA’s official designation of the Rapporteur and Co-Rapporteur, and PRAC Rapporteur and Co-Rapporteur to our planned MAA for BiovaxID. We conducted our EMA Pre-submission Meeting for the MAA on September 12, 2012, during which our planned application dossier was validated. Subsequently, on December 3, 2013, we submitted an MAA with the EMA for BiovaxID. We were formally notified the application had been validated by the EMA on January 7, 2014, confirming that the submission was complete, and beginning the formal EMA review process intended to secure approval to market BiovaxID in the EU and to allow prescription and sale of BiovaxID for the treatment of non-Hodgkin’s lymphoma in patients who have achieved a first complete remission.

Additionally, based on a scientific advice meeting conducted with Health Canada, we have announced plans to file a NDS seeking regulatory approval in Canada.

We conducted a formal guidance meeting with the FDA in order to discuss the path for our filing of a BLA for BiovaxID’s U.S. regulatory/marketing approval. As a result of this guidance meeting, we plan to conduct a second Phase 3 clinical trial to complete the clinical data gained through our first Phase 3 clinical trial and our BiovaxID development program to support our filing of our BLA for BiovaxID. We are preparing to initiate this second Phase 3 clinical trial subject to required funding.

As we continue to advance our efforts to comply with various regulatory validations and comparability requirements related to our manufacturing process and facility, no assurances can be given that substantial additional requirements will not be imposed by any regulatory agencies, including the EMA, Health Canada, and the FDA for the regulatory/marketing approval of BiovaxID.

Subsequent regulatory/marketing approval of BiovaxID, if any, may require us to perform additional clinical studies as a condition to approval or continued marketing of BiovaxID, which may result in additional clinical trial expenses. Once received, there can be no assurances that we will receive continued regulatory/marketing approval. Our ability to timely access required financing will continue to be essential to support the ongoing efforts to pursue the development and potential regulatory/marketing approval and commercialization efforts of BiovaxID.

Proprietary Rights to BiovaxID

As a result of the FDA’s Orphan Drug designation of BiovaxID for the treatment of FL, MCL and Waldenstrom's Macroglobulinemia, a rare B-cell subtype of NHL, we have 7 years of market exclusivity in the U.S. from the date of the FDA’s marketing approval for these three B-cell subtypes of NHL. We also have 10 years of market exclusivity in the EU as a result of EMA’s Orphan Medicinal Product designation of BiovaxID for the treatment of FL and MCL.

In addition, the regulations adopted in both the U.S. and the EU governing “biosimilar” products (the term adopted to describe generic biologic pharmaceutical products) provide us with “data exclusivity” (i.e., no biosimilar could reference the BiovaxID clinical data) for 12 years in the U.S. and 8 years in the EU. Those same biosimilar regulations make it extremely difficult to qualify as a “biosimilar”, and even for those products which can clear that hurdle independent clinical data is required prior to licensure.

In addition to market exclusivity based on governmental regulation, we rely on proprietary rights provided by a combination of an exclusive world-wide license to the cell line that is used in the production of BiovaxID, patent protection, trade secret protection, and our ongoing innovation. Although the composition of BiovaxID, in its current form, is not patentable, we have filed U.S. and foreign patent applications relating to methods of treatment using BiovaxID. We have also filed an international patent application (“PCT”) and a provisional application relating to methods for producing and selecting idiotype vaccines for treatment of B-cell cancers. Also, we have filed a provisional application covering the use of a biomarker for predicting cancer vaccine effectiveness and patient outcomes. In addition, we have filed U.S. and foreign patent applications relating to certain features of the AutovaxID® instrument used in the production of BiovaxID. The AutovaxID instrument is our proprietary production system which is fully enclosed, automated and has disposable components for each patient’s personalized vaccine. We believe that, without the availability of an automated production system, the methods used to produce a patient-specific immunotherapy are time-consuming and labor-intensive, resulting in a very expensive process that would be difficult to scale up. Following the findings related to the apparent role of the IgM isotype in clinical benefit from the vaccine, we filed a broad range of patent applications covering various applications of these findings. We have re-filed for U.S. registration of the trademark BiovaxID and have registered BiovaxID® as a Community Trademark in the EU. BiovaxID is manufactured with a proprietary cell line, which we have licensed on a worldwide exclusive basis from Stanford University (“Stanford”). We believe that the use of any cell line other than our exclusively licensed cell line, in the production of a similar idiotype vaccine would require filing a separate IND application and undergoing clinical testing evaluation by the FDA.

BiovaxID Manufacturing Process and Facility

Manufacturing Process

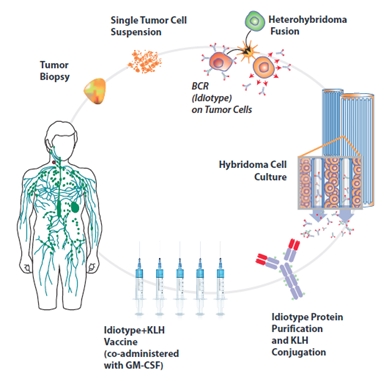

The BiovaxID manufacturing production process begins when a sample of the patient’s tumor is extracted by a biopsy and the sample is shipped refrigerated to our facility in Minneapolis (Coon Rapids), Minnesota. At our facility, we identify the idiotype that is expressed on the surface of the patient’s tumor cells through laboratory analysis. Additionally, we identify whether the isotype is IgM or IgG. In NHL, the tumor B-cells bear the surface idiotype (immunoglobulin or antibody) derived from the original transformed malignant B-cell, but do not typically secrete it in an amount suitable for vaccine production. In order to make sufficient quantities of idiotype for vaccination, the patient’s tumor cells are then fused with an exclusively licensed cell line (mouse/human heterohybridoma cell line, K6H6) from Stanford to create a hybridoma or hybrid cell.

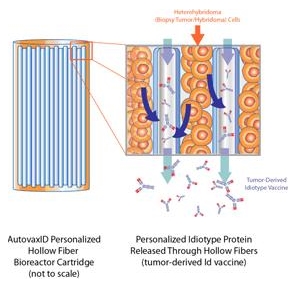

After the creation of the hybridoma, we determine which hybridoma cells display the same antigen idiotype as the patient’s tumor cells, and those cells are selected to produce the vaccine. The selected hybridoma cells are then seeded into our proprietary hollow fiber bioreactors, where they are cultured and where they secrete or produce idiotype antigen. The secreted idiotype is then collected from the cells growing in the hollow fiber bioreactor. After a sufficient amount of idiotype is collected for the production of an appropriate amount of the vaccine, the patient’s idiotype is purified using multi-step purification processes (see Figure 10a).

Figure 10a. Individualized Manufacturing Process for BiovaxID Immunotherapy: (Clockwise) Beginning with an excisional (>2cm) lymph node biopsy, tumor cells are fused with our proprietary mouse/human heterohybridoma in order to induce secretion of normally surface-bound tumor immunoglobulin (idiotype). Id-secreting clones are identified by comparing their unique idiotype sequence to the tumor’s after which they are cultured (expanded) in a proprietary hollow fiber bioreactor system (not shown). During culture, supernatant (containing idiotype) is collected until sufficient amounts have been produced to yield adequate dosage of vaccine. This supernatant is purified by affinity chromatography and conjugated (bonded) to KLH carrier protein, resulting in a finished vaccine that can be shipped and administered to patients. In our Phase 3 clinical trial, manufacturing success was approximately 95% of treated patients. (Fig. reprinted from Neelapu, et al. Exp. Opin Biol Ther 2007).

Figure 10b. Hollow fiber perfusion to produce the cell cultures used in the manufacture of BiovaxID.

We use a method known as “hollow fiber perfusion” to produce the cell cultures used in the manufacture of BiovaxID (see Figure 10b). Hollow fiber perfusion, as compared to other cell culture methods, seeks to grow cells to higher densities more closely approaching the density of cells naturally occurring in body tissue. The hollow fiber perfusion method involves using hair-like plastic fibers with hollow centers which are intended to simulate human capillaries. Thousands of these fibers are inserted in a cartridge, which we refer to as a bioreactor. The cells are grown on the outside of the hollow fibers while nutrient media used to support cell growth is delivered through the hollow centers of the fibers. The fiber walls have small pores, allowing nutrients to pass from the hollow center to the cells. The fibers act as filters and yield concentrated secreted products. Because the cells are immobilized in the bioreactor, the concentrated product can be harvested during the ongoing cell growth process. We believe that hollow fiber technology permits the harvest of cell culture products with generally higher purities than stirred-tank fermentation, a common alternative cell culture method, thereby reducing the cost of purification as compared to stirred tank fermentation. Additionally, the technology associated with the hollow fiber process generally minimizes the amount of costly nutrient media required for cell growth as opposed to other cell culturing techniques.

After manufacture and purification, the resulting purified idiotype is then conjugated, or joined together, with KLH, to create the vaccine. KLH is a foreign carrier protein that is used to improve the immunogenicity, or ability to evoke an immune response, of the tumor-specific idiotype. The BiovaxID vaccine is then frozen and shipped to the treating physician. At the treating physician’s office, the vaccine is thawed and injected into the patient.

BiovaxID is administered in conjunction with GM-CSF, a natural immune system growth factor that is administered with the idiotype vaccine to stimulate the immune system and increase the response to the idiotype vaccine. In the Phase 2 and Phase 3 clinical trials FL patients were administered 5 monthly BiovaxID injections in the amount of 0.5 milligram of idiotype per injection, with the injections being given over a 6-month period of time in which the fifth month is skipped. Through this process, the patient-specific idiotype is used to stimulate the patient’s immune system into targeting and destroying malignant B-cells bearing the same idiotype.

We estimate that an average of 2 to 3 months is required to manufacture each vaccine, which for most patients may overlap the time period when induction chemotherapy is being administered. While the manufacturing process for BiovaxID is highly personalized to each patient, we consider it to be highly controlled and predictable. The most common reason for a failure to successfully produce a patient’s vaccine was the presence of rare idiotype variants as opposed to the failure of a step in the manufacturing process. During the Phase 3 clinical trial, we experienced approximately 95% success rate in manufacturing our BiovaxID vaccines.

Manufacturing Facility

BiovaxID is a personalized medicine which is produced separately for each individual patient through a laboratory-type process based on the patient’s own tumor cells derived by biopsy. Following regulatory/marketing approval of BiovaxID, we plan to initially produce BiovaxID in our existing leasehold space in Minneapolis (Coon Rapids), Minnesota. In order to facilitate the regulatory/marketing approval process, we have completed a dedicated pilot scale suite of laboratory clean rooms especially designed to produce BiovaxID. As the regulatory/marketing approval process advances toward completion and subject to availability of funding, we anticipate expanding our current leasehold space or adding new manufacturing facilities as required to, meet the anticipated commercialization requirements. During our Phase 3 clinical trial, BiovaxID was produced at our facility in Worcester, Massachusetts. Because, we have relocated the site of the manufacturing process to our Minneapolis (Coon Rapids), Minnesota facility following the Phase 3 clinical trials and because we are expanding this facility, we are currently in the process of demonstrating to the national and/or international regulatory agencies that the BiovaxID vaccine produced under these new conditions is comparable to the BiovaxID vaccine that was the produced subject of earlier clinical testing. This requirement will also apply to future expansions of the facility, such as the possible expansion to additional facilities that may be required for successful commercialization of BiovaxID. There is also a requirement for validation of the manufacturing process for BiovaxID utilizing our AutovaxID® instrument. A showing of comparability requires data demonstrating that the BiovaxID vaccine produced continues to be safe, pure, and potent and may be based on chemical, physical, and biological assays and, in some cases, other non-clinical data.

INSTRUMENTS AND DISPOSABLES

We provide a range of cell culture systems that are used to produce small, research and development-scale through large, production-scale quantities of cell culture products. Our cell culture systems all incorporate perfusion technology and hollow fiber cartridges. This segment of our business represented approximately $1.6 million (approximately 39%) and $0.8 million (approximately 22%) of our tatal revenues for the years ended September 30, 2013 and 2012, respectively. Because of these shared characteristics, all of our cell culture systems listed below can be used to culture a variety of cell lines (hybridomas, CHO, MDCK, BHK and others) to produce a range of cell-based products, such as monoclonal antibodies, other secreted proteins, virus, virus-like particles, vaccines, and whole cells. Our smaller cell culture systems can be scaled-up to any of our larger cell culture systems. Our cell culture system product line, in order of increasing capacity, includes:

HF PRIMER™: The HF Primer is a low-cost cell culture system capable of producing small, research and development quantities of the cell culture products from mammalian cell lines. The HF Primer also provides a relatively inexpensive option to evaluate the efficacy of new cell lines or applications in perfusion technology that can then be scaled-up to any of our larger cell culture systems. HF Primer is a single-use, fully disposable product that requires no investment in custom equipment.

MULTI-6™: The Multi-6 is a low-cost cell culture system capable of simultaneously producing small, research and development -scale quantities of six different cell culture products. Optionally, the Multi-6 can be used to produce one cell culture product at a rate that is six-fold higher than the HF Primer. This flexibility allows a researcher to operate one Multi-6 instead of managing six separate HF Primer systems running side-by-side. Multi-6 applications can be scaled-up to our larger AutovaxID® or other cell culture systems listed below, if the need arises. Multi-6 is a single-use, fully disposable product that requires no investment in custom equipment.

AUTOVAXID®: The AutovaxID is our most advanced, fully automated cell culture system. Its setup and operation requires very little technician expertise and labor in comparison to competing cell culture system technologies and even our other cell culture systems listed below. The AutovaxID was designed from the beginning to: enable multi-product facilities, capture most all production information into its CFR 21 Part 11-compliant electronic records system, and operate as a fully closed-system biologics-manufacturing platform. The AutovaxID allows supervisors to implement built-in software controls to ensure technicians adhere to strictly defined production protocols for cGMP environments or remove this feature when it is not needed, such as in research and development operations. There are four single-use AutovaxID disposables to provide researchers the needed flexibility to go from research and development- through pilot-scale production. One of the disposable options even allows the simultaneous culturing of three different cell lines to produce three different products in small quantities. When needed, one cell line can then be scaled-up to AutovaxID’s larger-capacity disposables. We plan to utilize AutovaxID’s advanced capabilities to streamline commercial manufacture of BiovaxID. AutovaxID is the first cell culture system that enables production of personalized cell-based treatments economically and in compliance with cGMP standards. Additionally, we have contracted with the DoD and others to further develop the AutovaxID and related hollow fiber bioreactor systems to explore potential production of additional vaccines, including vaccines for viral indications such as influenza and other contagious diseases.

ACUSYST-MINIMAX®: The miniMAX is an economical system that provides the flexibility and technology needed to support optimization studies and research- through pilot-scale production of the cell culture products listed above. The miniMax is a tabletop instrument that uses simple, but robust, microprocessors to automatically control pH, incubator temperature, fluid-flow dynamics, and seven process pumps. This system offers two single-use disposables options to meet varying production requirements. Optimization results determined in the miniMAX can be transferred to our larger systems listed below. The production capacity is equivalent to an AutovaxID, but the miniMAX does not have the advanced features, controls, simpler setup and ease of operation available through the AutovaxID.

ACUSYST-MAXIMIZER®: The Maximizer is an economical system with a design that is similar to the miniMAX system. This system has all of the features of miniMAX, using single-use disposables that either match or double the production capacity of the miniMAX system. The Maximizer is an economical system for process development and routine productions. The Maximizer offers the flexibility of four single-use disposables to meet varying production requirements. Production processes determined in the Maximizer can be scaled-up to our largest cell culture system, AcuSyst-Xcellerator®.

ACUSYST-XCELLERATOR®: The Xcellerator is a freestanding, production-scale cell culture system that has been used for production of a FDA-licensed biologic. The Xcellerator contains an incubator, a refrigerator, a built-in computer that has a CFR 21 Part 11-compliant electronic records system, numerous process pumps, and a touch screen for local control. The Xcellerator supports remote monitoring and/or control via standard web browsers. The system supports two independent single-use disposables and, therefore, can simultaneously culture two different cell lines to produce two products. The Xcellerator has a production capacity that is equivalent to a 20x scale-up of AutovaxID’s capacity.

In addition to instrument and disposables sales, we have recurring revenue from the sale of hollow fiber bioreactors, cultureware, tubing sets and other disposable products and supplies for use with our cell culture system instrument product line.

Currently, we assemble, validate and package the instruments and disposables, cell culture products and services which we sell. Customers for our instruments and disposables are the same potential customers targeted for our contract cell culture products and services which include biopharmaceutical and biotechnology companies, medical schools, universities, research facilities, hospitals and public and private laboratories.

Proprietary Rights to Instruments and Disposables

We own several patents covering various aspects of our hollow fiber perfusion process, instruments and proprietary cell culturing methods. We own U.S. Patent No. 6,001,585, which protects the HF Primer™ cell culture system and its use in screening cell lines and process conditions. Although the HF Primer is impractical for large-scale vaccine production, it may be used as an efficient screening tool to cost-effectively determine how well a cell line will perform in a hollow fiber system, such as the AutovaxID® instrument, which is used in the production of BiovaxID. U.S. Patent No. 6,001,585 will expire in November 2017.

We have also filed U.S. and foreign patent applications relating to certain features of the AutovaxID instrument. Several patents have been granted in the EU covering the AutovaxID’s extra-capillary (“EC”) fluid cycling system, which enables control of fluid volumes in the hollow fiber bioreactor during manufacture of BiovaxID in a closed, contamination-free environment. These EU patents will remain in force until 2027.

We have filed (a) a PCT application covering the use of AutovaxID instrumentation for rapid, large-scale production of virus, virus-like particles, and viral vaccines at a high yield, (b) a PCT application concerning an integrated apparatus and method for production and purification of antibodies, and (c) a provisional application concerning cultureware modules and biomanufacturing suites for large-scale production of cells and cell-derived products such as antibodies, proteins, virus, and virus-like particles.

CELL CULTURE PRODUCTS AND SERVICES

We manufacture mammalian cell culture products such as, whole cells, recombinant and secreted proteins, and monoclonal antibodies. Additionally, we provide related services as a contract resource to assist our customers in developing cell production process protocols, cell line optimization, cell culture production optimization, media evaluation and other related services. This segment of our business represented approximately $1.6 million (approximately 39%) and $0.8 million (approximately 22%) of our total revenues for the years ended September 30, 2013 and 2012, respectively.

With our focus on pre-launch therapeutics and marketed diagnostics production, we serve all the manufacturing needs of our customers. From process development to regulatory support, our one-stop comprehensive approach provides solutions for clients that have chosen to temporarily or permanently outsource any or all stages of drug development. If needed, commercial production capacity for product launch is seamless, we provide all the required regulatory support, including biocompatibility studies.

With nearly 30 years of expert experience in cell culture, we formulate the optimal strategy for our customers’ biologics manufacturing. By accurately matching the level of hollow fiber bioreactor production technology to our customers’ phase of product development, our customers can manage their overall investment risk. Only as products advance to the next stage of development do we scale to higher-output production systems. Customers of our cell culture products and services are biopharmaceutical and biotechnology companies, medical schools, universities, research facilities, hospitals and public and private laboratories. We generally produce cell culture products pursuant to contracts which specify the customer’s requirements for the cell culture products to be produced or the services to be performed.

There are various processes commonly used to expand mammalian cells generally used for the production of antibodies. These may include hollow fiber bioreactor perfusion, stirred tank fermentation, roller bottle and other processes. We primarily use hollow fiber bioreactor technology to expand customer provided cell lines and produce the respective monoclonal antibodies. This technology grows cells to higher densities which more closely mimics mammalian physiology. We have significant expertise with in vitro (outside the living body) cell culture methods for a wide variety of mammalian cells. Mammalian cells are complicated and dynamic, with constantly changing needs. A primary component of hollow fiber bioreactors is fibers made of plastic polymers. The fibers are hair-like with hollow centers which simulate human capillaries. Thousands of these fibers are inserted in a cartridge, which we refer to as a bioreactor. The cells are grown on the outside of the hollow fibers while nutrient media used to support cell growth is perfused through the lumen of the fibers. The fiber walls have small pores, allowing nutrients to pass from the hollow center to the cells. The fibers act as filters and yield concentrated secreted products. Because the cells are immobilized in the bioreactor, the concentrated product can be harvested during the ongoing cell growth process. Hollow fiber technology permits harvests of cell culture products with generally higher purities thereby reducing the cost of downstream purification processes. This technology generally minimizes the amount of costly nutrient media required for cell growth.

The most generally used process for mammalian cell production is stirred tank fermentation. Hollow fiber bioreactor technology can be contrasted with the competitive stirred tank fermentation process which takes place in tanks of various sizes. Cells are grown inside the tanks in culture medium which is maintained under controlled conditions and continuously stirred to stimulate growth. At the end of the growing process, as opposed to incrementally during the growth process, cells are separated from the medium and the protein of interest is isolated through a series of complex purification processes. The size of the tanks generally result in stirred tank fermentation facilities requiring significantly more start-up costs, space and infrastructure than comparable production facilities using hollow fiber technology. While stirred tank fermentation and hollow fiber technology are both used for cell production of various quantities, we believe that the stirred tank fermentation process is currently more commonly used for larger scale commercial production requirements. We believe that hollow fiber technology has advantages in scalability, start-up time and cost in the early development of antibody production.

Our patented hollow fiber technology is the key to optimizing our customers’ biologics manufacturing. For Phase I, Phase II and Phase III cGMP production, our hollow fiber bioreactor perfusion technology provides economic advantages through largely automated culture of a relatively large, densely packed population of cells in a small space. Additionally, the low molecular weight cut-off of the fiber membrane allows more expensive media components to be conserved, while less expensive basal media is continuously perfused through the bioreactor. As a result, this automated approach can be more cost-effective than conventional platforms generally used for maintenance of large cell populations. In the expanding field of personalized medicine where patient specific drugs and therapeutics are frequently envisioned, such as BiovaxID, we believe that hollow fiber technology may be the appropriate cell culture production technology.

COMPETITION FOR BIOVAXID