fcx.com FCX Conference Call 4th Quarter and Year Ended 2025 Results January 22, 2026

Cautionary Statement This presentation contains forward-looking statements in which FCX discusses its potential future performance, operations and projects. Forward-looking statements are all statements other than statements of historical facts, such as plans, projections or expectations relating to business outlook, strategy, goals or targets; repair and remediation efforts, and phased restart and ramp-up of production and downstream processing following the mud rush incident at PT Freeport Indonesia’s (PTFI) Grasberg Block Cave (GBC) underground mine and the anticipated impact on FCX’s business, production, sales, results of operations and operating plans, and recoveries under insurance policies; global market conditions, including trade policies; ore grades and milling rates; production and sales volumes; higher variability between PTFI production and sales; unit net cash costs (credits) and operating costs; capital expenditures; operating plans, including mine sequencing; cash flows; liquidity; potential extension of PTFI’s special mining business license (IUPK) beyond 2041; timing of shipments of inventoried production; FCX’s sustainability-related commitments and targets; FCX’s overarching commitment to deliver responsibly produced copper and molybdenum, including plans to implement, validate and maintain validation of its operating sites under specific frameworks; achievement of FCX’s 2030 climate targets and its 2050 net zero aspiration; improvements in operating procedures and technology innovations and applications; exploration efforts and results; development and production activities, rates and costs; future organic growth opportunities; tax rates; the impact of copper, gold and molybdenum price changes; the impact of deferred intercompany profits on earnings; mineral reserve and mineral resource estimates; final resolution of settlements associated with ongoing legal and environmental proceedings; debt repurchases; and the ongoing implementation of FCX’s financial policy and future returns to shareholders, including dividend payments (base or variable) and share repurchases. The words “anticipates,” “may,” “can,” “plans,” “believes,” “estimates,” “expects,” “projects,” “targets,” “intends,” “likely,” “will,” “should,” “could,” “to be,” “potential,” “assumptions,” “guidance,” “aspirations,” “future,” “commitments,” “pursues,” “initiatives,” “objectives,” “opportunities,” “strategy” and any similar expressions are intended to identify those assertions as forward-looking statements. The declaration and payment of dividends (base or variable), and timing and amount of any share repurchases are at the discretion of the Board of Directors (Board) and management, respectively, and are subject to a number of factors, including not exceeding FCX’s net debt target, capital availability, FCX’s financial results, cash requirements, global economic conditions, changes in laws, contractual restrictions and other factors deemed relevant by the Board or management, as applicable. The share repurchase program may be modified, increased, suspended or terminated at any time at the Board’s discretion. FCX cautions readers that forward-looking statements are not guarantees of future performance and actual results may differ materially from those anticipated, expected, projected or assumed in the forward-looking statements. Important factors that can cause FCX’s actual results to differ materially from those anticipated in the forward-looking statements include, but are not limited to, supply of and demand for, and prices of the commodities FCX produces, primarily copper and gold; changes in export duties and tariff rates; production rates; timing of shipments and sales; PTFI’s ability to repair mud rush incident-related damage, implement enhanced operating procedures, safely restart, phase-in ramp-up and achieve full operating rates of production and downstream processing on the expected timeline and optimize production plans; recover amounts under insurance policies; resolve force majeure declarations and maintain relationships with commercial counterparties; price and availability of consumables and components FCX purchases as well as constraints on supply and logistics, and transportation services; changes in cash requirements, financial position, financing or investment plans; changes in general market, economic, geopolitical, regulatory or industry conditions, including market volatility regarding trade policies and tariff uncertainty; reductions in liquidity and access to capital; changes in tax laws and regulations; political and social risks, including the potential effects of violence in Indonesia, civil unrest in Peru, and relations with local communities and Indigenous Peoples; operational risks inherent in mining, with higher inherent risks in underground mining; mine sequencing; changes in mine plans or operational modifications, delays, deferrals or cancellations, including the ability to smelt and refine or inventory; results of technical, economic or feasibility studies; potential inventory adjustments; potential impairment of long-lived mining assets; satisfaction of requirements in accordance with PTFI’s IUPK to extend mining rights from 2031 through 2041; process relating to the extension of PTFI’s IUPK beyond 2041; cybersecurity risks; any major public health crisis; labor relations, including labor-related work stoppages and increased costs; compliance with applicable environmental, health and safety laws and regulations; weather- and climate-related risks; environmental risks, including availability of secure water supplies; impacts, expenses or results from litigation or investigations; tailings management; FCX’s ability to comply with its responsible production commitments under specific frameworks and any changes to such frameworks and other factors described in more detail under the heading “Risk Factors” in FCX’s Annual Report on Form 10-K for the year ended December 31, 2024, and in FCX’s Current Report on Form 8-K dated November 18, 2025, each filed with the U.S. Securities and Exchange Commission. Investors are cautioned that many of the assumptions upon which FCX’s forward-looking statements are based are likely to change after the date the forward-looking statements are made, including for example commodity prices, which FCX cannot control, and production volumes and costs or technological solutions and innovations, some aspects of which FCX may not be able to control. Further, FCX may make changes to its business plans that could affect its results. FCX undertakes no obligation to update any forward-looking statements, which are as of the date made, notwithstanding any changes in its assumptions, changes in business plans, actual experience or other changes. Estimates of mineral reserves and mineral resources are subject to considerable uncertainty. Such estimates are, to a large extent, based on metal prices for the commodities we produce and interpretations of geologic data, which may not necessarily be indicative of future results or quantities ultimately recovered. This presentation also includes forward-looking statements regarding mineral resources not included in proven and probable mineral reserves. A mineral resource, which includes measured, indicated and inferred mineral resources, is a concentration or occurrence of material of economic interest in or on the Earth’s crust in such form, grade or quality, and quantity that there are reasonable prospects for economic extraction. Such a deposit cannot qualify as recoverable proven and probable mineral reserves until legal and economic feasibility are confirmed based upon a comprehensive evaluation of development and operating costs, grades, recoveries and other material modifying factors. This presentation also includes forward-looking statements regarding mineral potential, which includes exploration targets and mineral resources but will not qualify as mineral reserves until comprehensive engineering studies establish legal and economic feasibility. Significant additional evaluation is required and no assurance can be given that the potential quantities of metal will be produced. Accordingly, no assurance can be given that estimated mineral resources or mineral potential will become proven and probable mineral reserves. This presentation also contains measures such as unit net cash costs (credits) per pound of copper and molybdenum, net debt and Adjusted EBITDA (earnings before interest, taxes, depreciation, amortization and accretion), which are not recognized under U.S. generally accepted accounting principles (GAAP). FCX’s calculation and reconciliation of unit net cash costs (credits) per pound of copper and molybdenum and net debt to amounts reported in FCX’s consolidated financial statements are in the supplemental schedules of FCX’s 4Q25 press release, which is available on FCX’s website, fcx.com. A reconciliation of amounts reported in FCX’s consolidated financial statements to Adjusted EBITDA is included on slide 39. For forward-looking unit net cash costs (credits) per pound of copper and molybdenum measures, FCX is unable to provide a reconciliation to the most comparable GAAP measure without unreasonable effort because estimating such GAAP measures and providing a meaningful reconciliation is extremely difficult and requires a level of precision that is unavailable for these future periods, and the information needed to reconcile these measures is dependent upon future events, many of which are outside of FCX’s control as described above. Forward-looking non-GAAP measures are estimated consistent with the relevant definitions and assumptions. 2

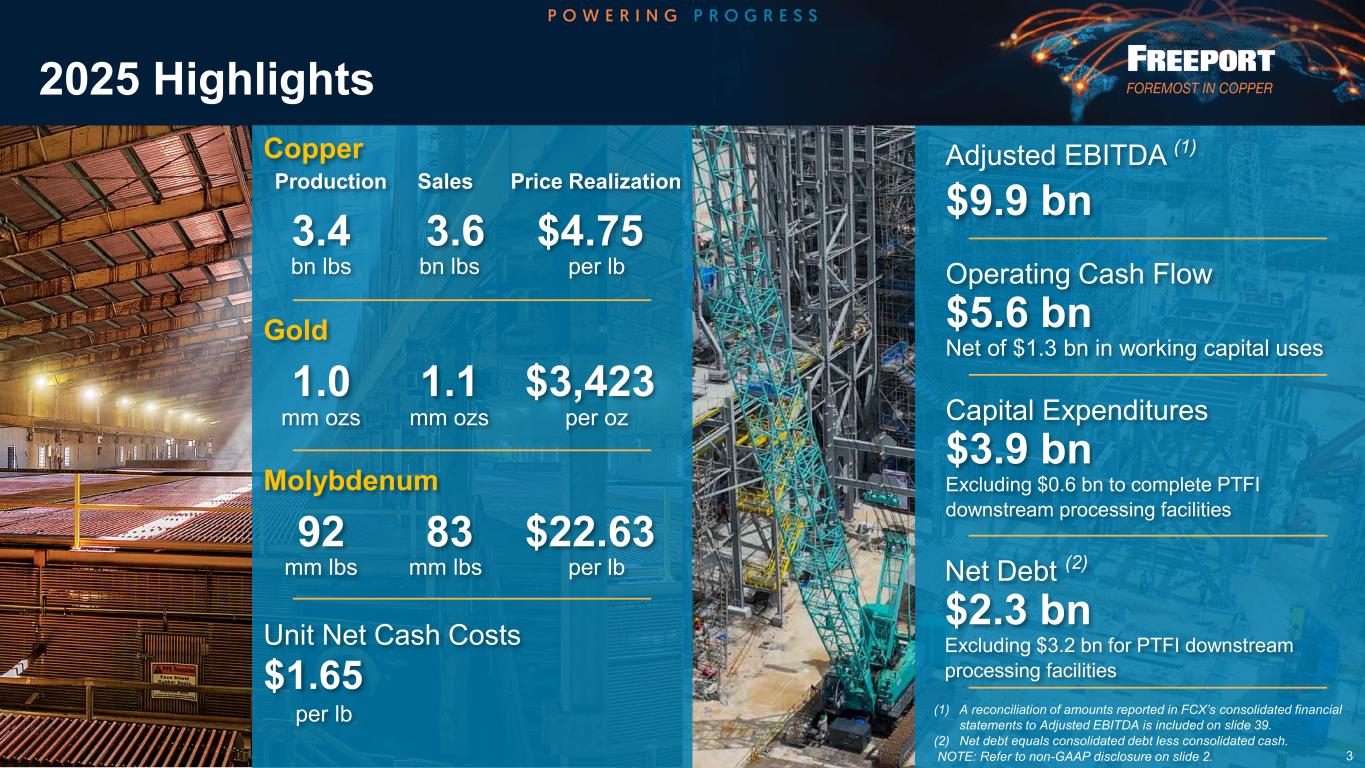

Unit Net Cash Costs $1.65 per lb 3 2025 Highlights Operating Cash Flow $5.6 bn Net of $1.3 bn in working capital uses Capital Expenditures $3.9 bn Excluding $0.6 bn to complete PTFI downstream processing facilities Copper Production Sales Price Realization 3.4 3.6 $4.75 bn lbs bn lbs per lb Gold 1.0 1.1 $3,423 mm ozs mm ozs per oz Molybdenum 92 83 $22.63 mm lbs mm lbs per lb (1) A reconciliation of amounts reported in FCX’s consolidated financial statements to Adjusted EBITDA is included on slide 39. (2) Net debt equals consolidated debt less consolidated cash. NOTE: Refer to non-GAAP disclosure on slide 2. Adjusted EBITDA (1) $9.9 bn Net Debt (2) $2.3 bn Excluding $3.2 bn for PTFI downstream processing facilities

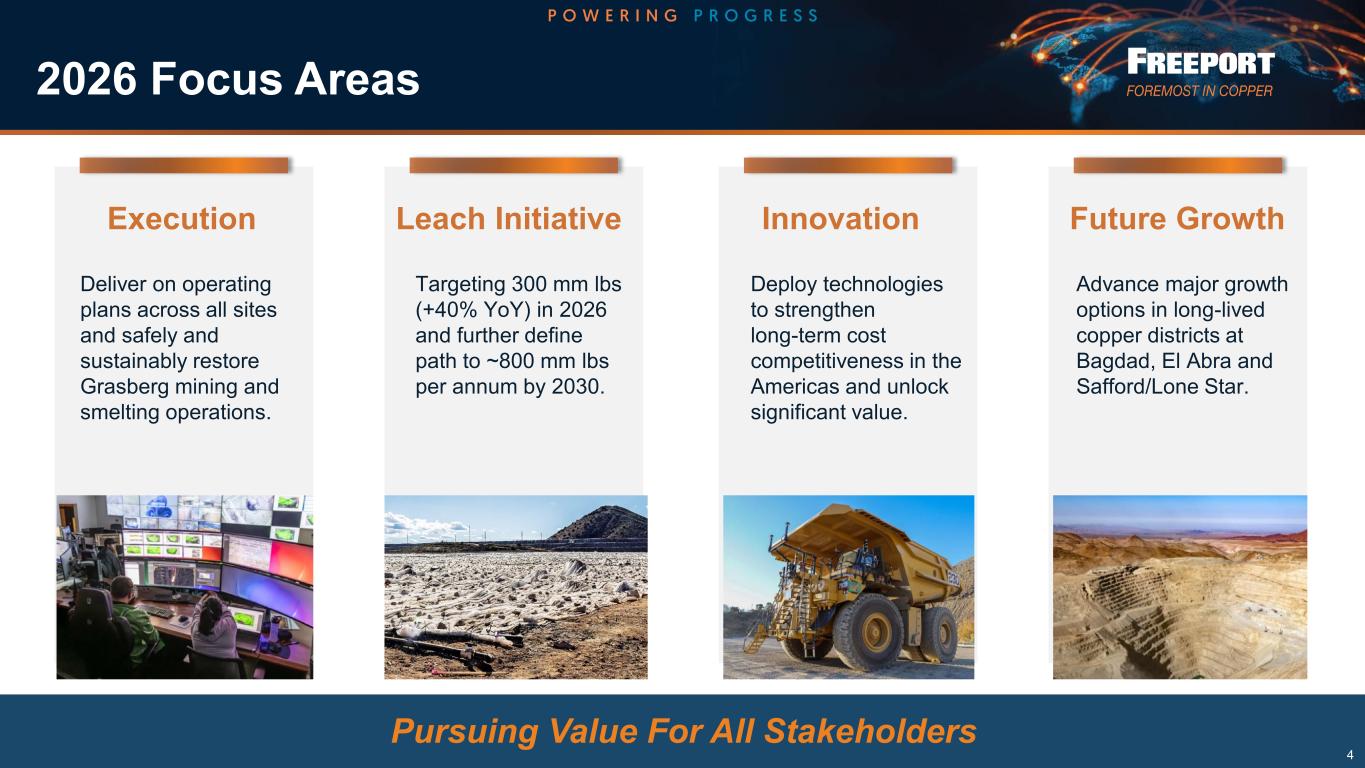

Pursuing Value For All Stakeholders 2026 Focus Areas 4 Leach Initiative Targeting 300 mm lbs (+40% YoY) in 2026 and further define path to ~800 mm lbs per annum by 2030. Innovation Deploy technologies to strengthen long-term cost competitiveness in the Americas and unlock significant value. Future Growth Advance major growth options in long-lived copper districts at Bagdad, El Abra and Safford/Lone Star. Execution Deliver on operating plans across all sites and safely and sustainably restore Grasberg mining and smelting operations.

Copper Commentary $2.00 $2.50 $3.00 $3.50 $4.00 $4.50 $5.00 $5.50 $6.00 $6.50 0 250,000 500,000 750,000 1,000,000 1,250,000 1,500,000 1,750,000 2,000,000 2,250,000 Jan-20 Jan-21 Jan-22 Jan-23 Jan-24 Jan-25 Jan-26 LME Copper Settlement Price Inventories (metric tons) Cu Price ($/lb) Global Copper Exchange Inventories Includes LME, COMEX and Shanghai exchanges Source: Bloomberg as of 1/21/26 Copper added to USGS List of Critical Minerals in November 2025 2025 Low High LME $3.87 $5.68 COMEX $3.99 $5.80 Copper ̶ Metal of Electrification Over 65% of the world’s copper is used in applications that deliver electricity* Infrastructure • Backbone of construction, urbanization and energy infrastructure • Possesses best electrical and thermal conductivity of any industrial metal Technology • Demand expected to benefit from advances in AI, communications and expanding connectivity Transportation • Essential material component of electric vehicles / hybrids • Used in electric motors, batteries, inverters, wiring and charging stations 5 * internationalcopper.org

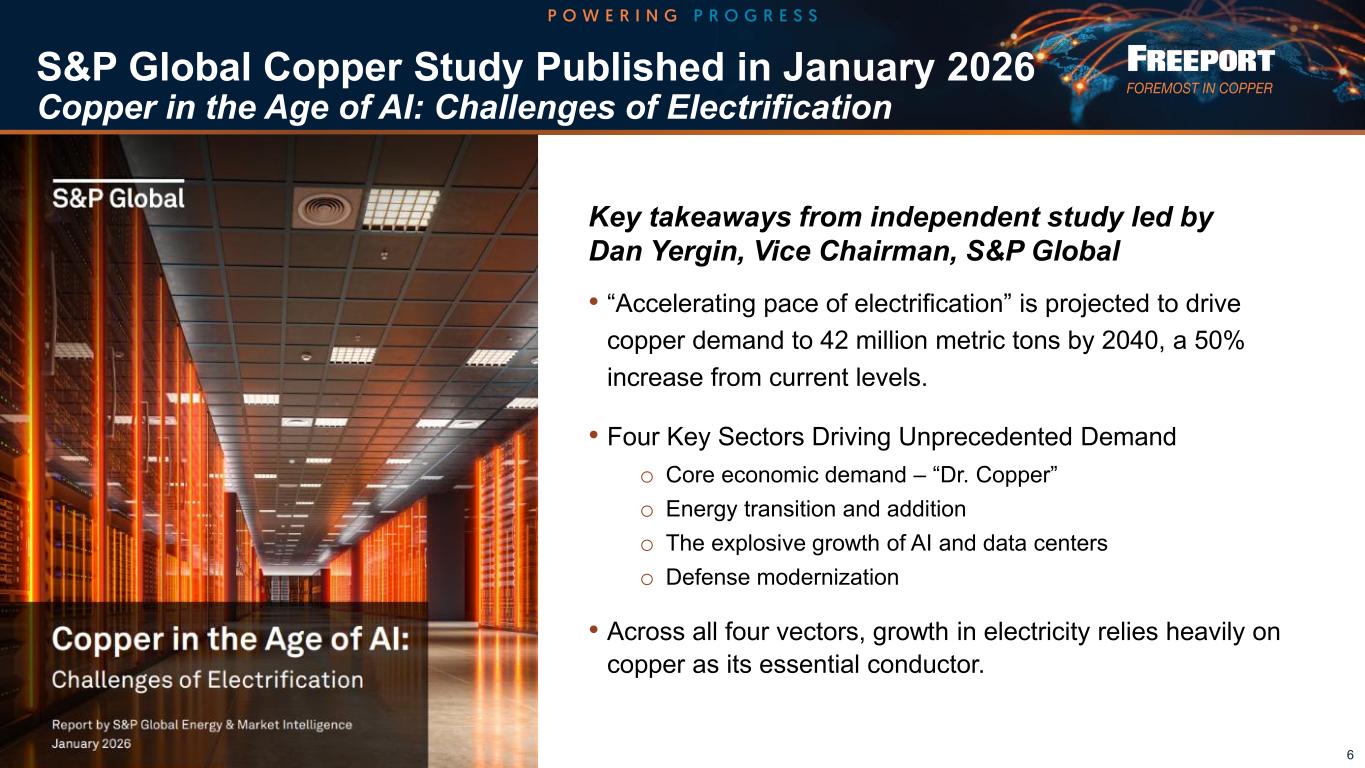

S&P Global Copper Study Published in January 2026 Copper in the Age of AI: Challenges of Electrification 6 Key takeaways from independent study led by Dan Yergin, Vice Chairman, S&P Global • “Accelerating pace of electrification” is projected to drive copper demand to 42 million metric tons by 2040, a 50% increase from current levels. • Four Key Sectors Driving Unprecedented Demand o Core economic demand – “Dr. Copper” o Energy transition and addition o The explosive growth of AI and data centers o Defense modernization • Across all four vectors, growth in electricity relies heavily on copper as its essential conductor.

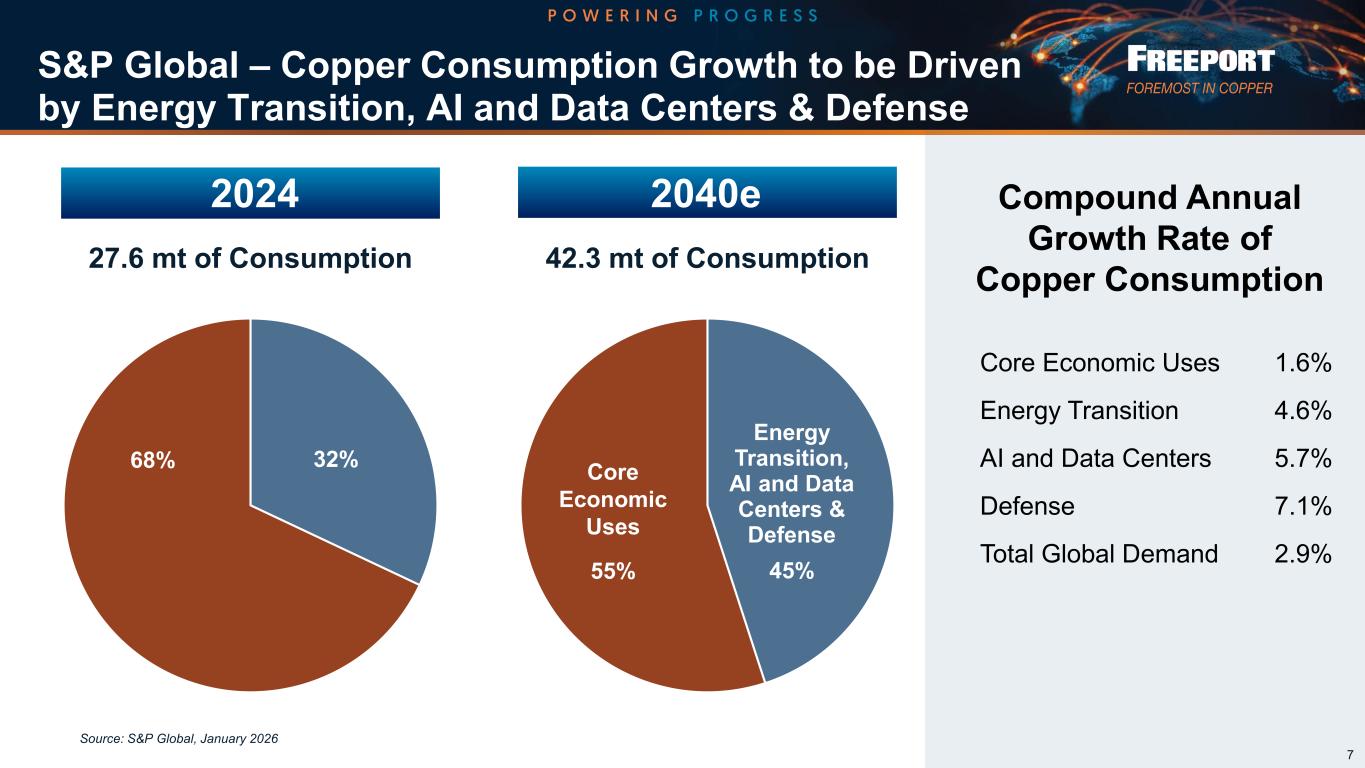

7 S&P Global – Copper Consumption Growth to be Driven by Energy Transition, AI and Data Centers & Defense 2024 68% 32% Energy Transition, AI and Data Centers & Defense 45% 2040e Source: S&P Global, January 2026 27.6 mt of Consumption 42.3 mt of Consumption Core Economic Uses 55% Compound Annual Growth Rate of Copper Consumption Core Economic Uses 1.6% Energy Transition 4.6% AI and Data Centers 5.7% Defense 7.1% Total Global Demand 2.9%

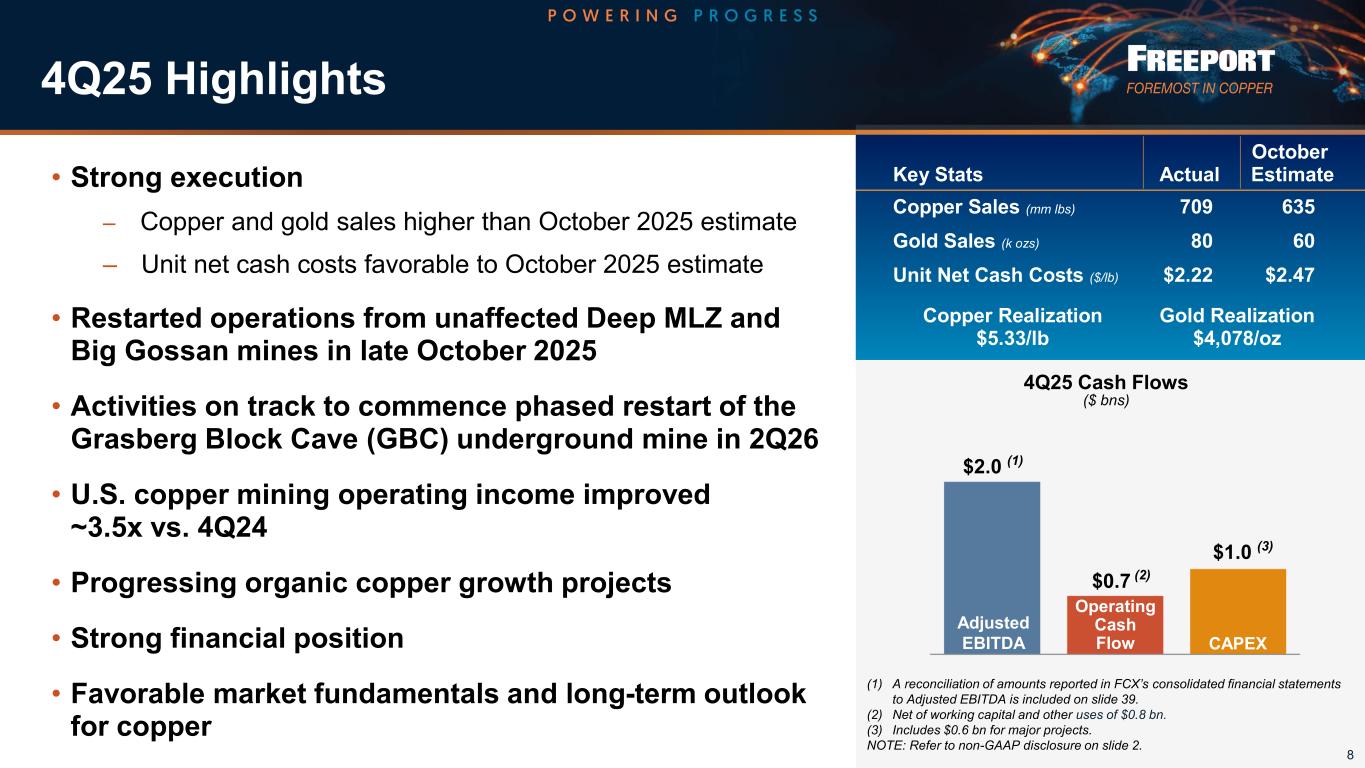

8 4Q25 Highlights • Strong execution – Copper and gold sales higher than October 2025 estimate – Unit net cash costs favorable to October 2025 estimate • Restarted operations from unaffected Deep MLZ and Big Gossan mines in late October 2025 • Activities on track to commence phased restart of the Grasberg Block Cave (GBC) underground mine in 2Q26 • U.S. copper mining operating income improved ~3.5x vs. 4Q24 • Progressing organic copper growth projects • Strong financial position • Favorable market fundamentals and long-term outlook for copper October Key Stats Actual Estimate Copper Sales (mm lbs) 709 635 Gold Sales (k ozs) 80 60 Unit Net Cash Costs ($/lb) $2.22 $2.47 Copper Realization Gold Realization $5.33/lb $4,078/oz Operating Cash Flow CAPEX $1.0 (3) $0.7 (2) 4Q25 Cash Flows ($ bns) (1) A reconciliation of amounts reported in FCX’s consolidated financial statements to Adjusted EBITDA is included on slide 39. (2) Net of working capital and other uses of $0.8 bn. (3) Includes $0.6 bn for major projects. NOTE: Refer to non-GAAP disclosure on slide 2. $2.0 (1) Adjusted EBITDA

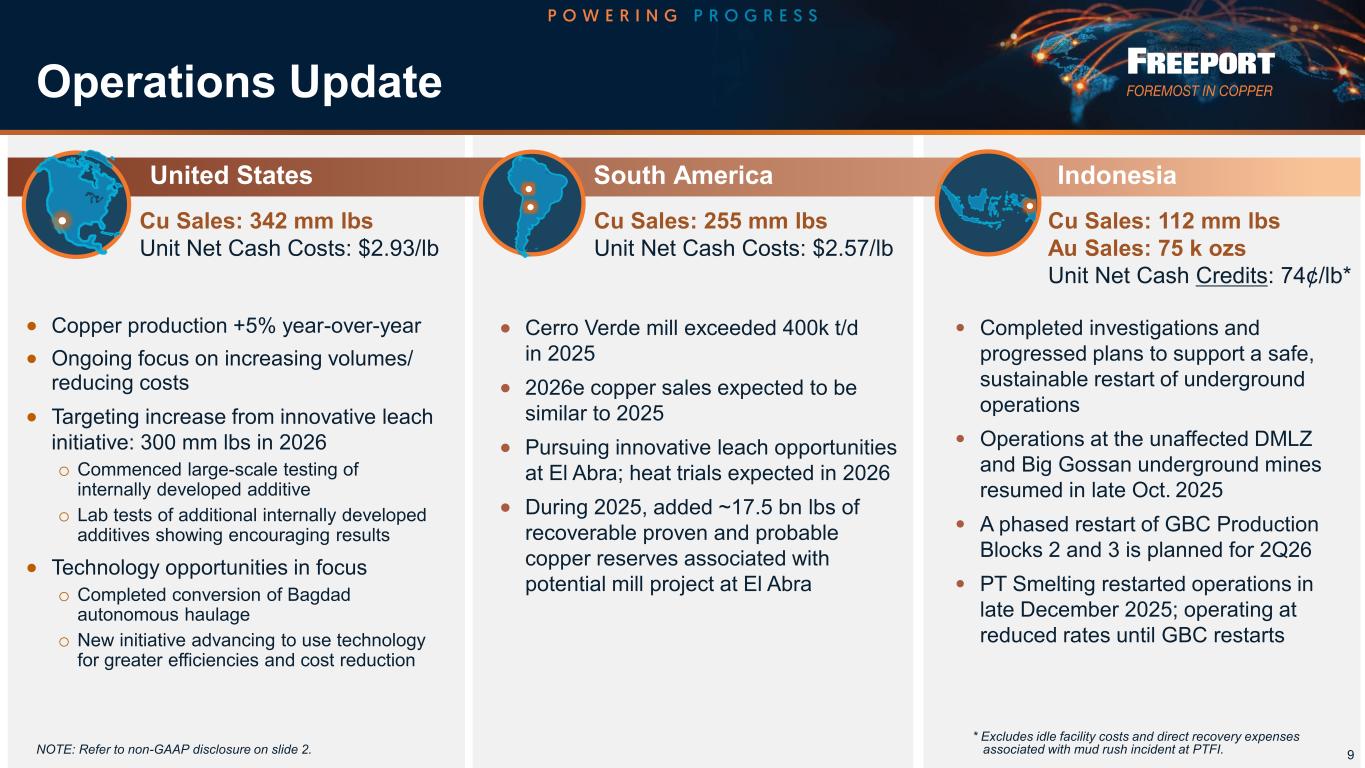

Operations Update • Copper production +5% year-over-year • Ongoing focus on increasing volumes/ reducing costs • Targeting increase from innovative leach initiative: 300 mm lbs in 2026 o Commenced large-scale testing of internally developed additive o Lab tests of additional internally developed additives showing encouraging results • Technology opportunities in focus o Completed conversion of Bagdad autonomous haulage o New initiative advancing to use technology for greater efficiencies and cost reduction • Cerro Verde mill exceeded 400k t/d in 2025 • 2026e copper sales expected to be similar to 2025 • Pursuing innovative leach opportunities at El Abra; heat trials expected in 2026 • During 2025, added ~17.5 bn lbs of recoverable proven and probable copper reserves associated with potential mill project at El Abra • Completed investigations and progressed plans to support a safe, sustainable restart of underground operations • Operations at the unaffected DMLZ and Big Gossan underground mines resumed in late Oct. 2025 • A phased restart of GBC Production Blocks 2 and 3 is planned for 2Q26 • PT Smelting restarted operations in late December 2025; operating at reduced rates until GBC restarts NOTE: Refer to non-GAAP disclosure on slide 2. 9 United States South America Indonesia Cu Sales: 342 mm lbs Unit Net Cash Costs: $2.93/lb Cu Sales: 255 mm lbs Unit Net Cash Costs: $2.57/lb Cu Sales: 112 mm lbs Au Sales: 75 k ozs Unit Net Cash Credits: 74¢/lb* * Excludes idle facility costs and direct recovery expenses associated with mud rush incident at PTFI.

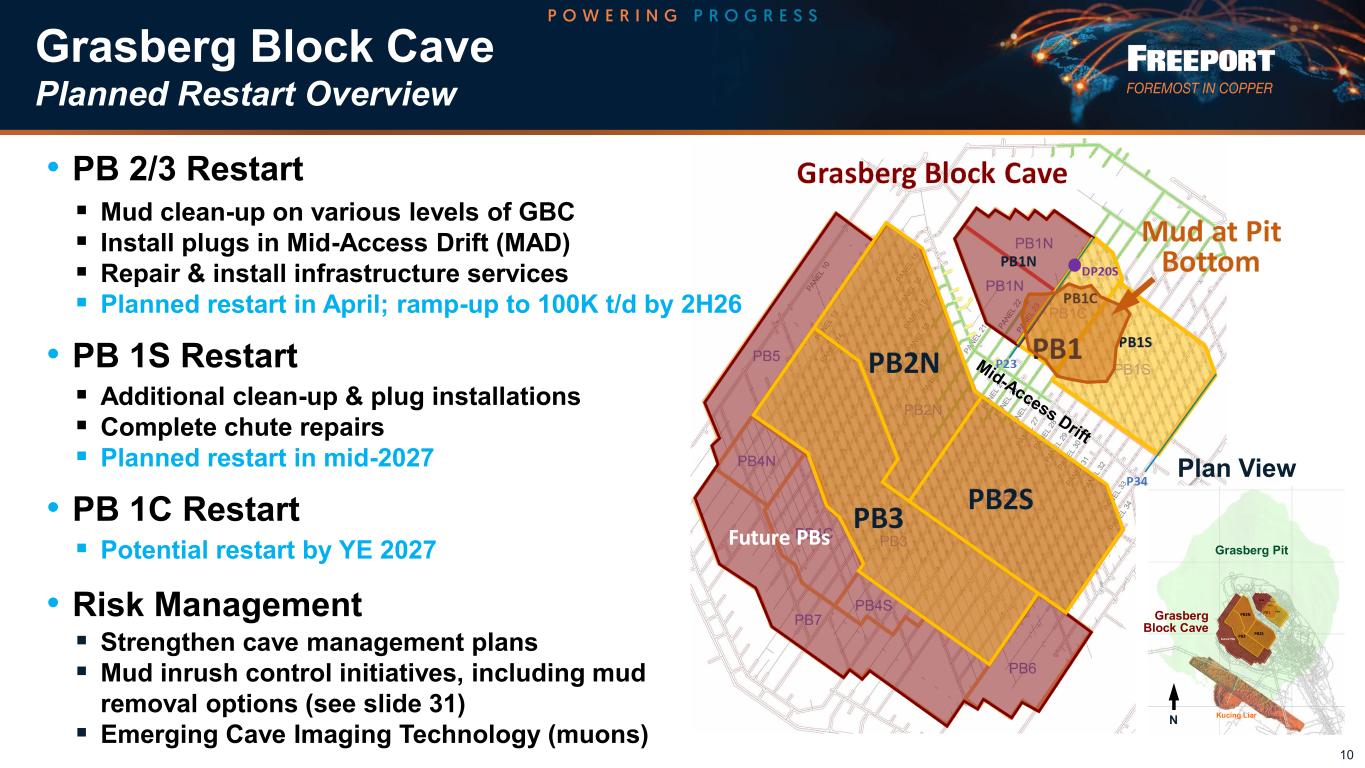

Grasberg Block Cave ▪ Mud clean-up on various levels of GBC ▪ Install plugs in Mid-Access Drift (MAD) ▪ Repair & install infrastructure services ▪ Planned restart in April; ramp-up to 100K t/d by 2H26 ▪ Additional clean-up & plug installations ▪ Complete chute repairs ▪ Planned restart in mid-2027 ▪ Potential restart by YE 2027 ▪ Strengthen cave management plans ▪ Mud inrush control initiatives, including mud removal options (see slide 31) ▪ Emerging Cave Imaging Technology (muons) 10 Planned Restart Overview Plan View Grasberg Pit Grasberg Block Cave Kucing Liar N Future PBs PB3 PB2N PB2S PB1 PB1N PB1C PB1S P23 P34 DP20S • PB 2/3 Restart • PB 1S Restart • PB 1C Restart • Risk Management

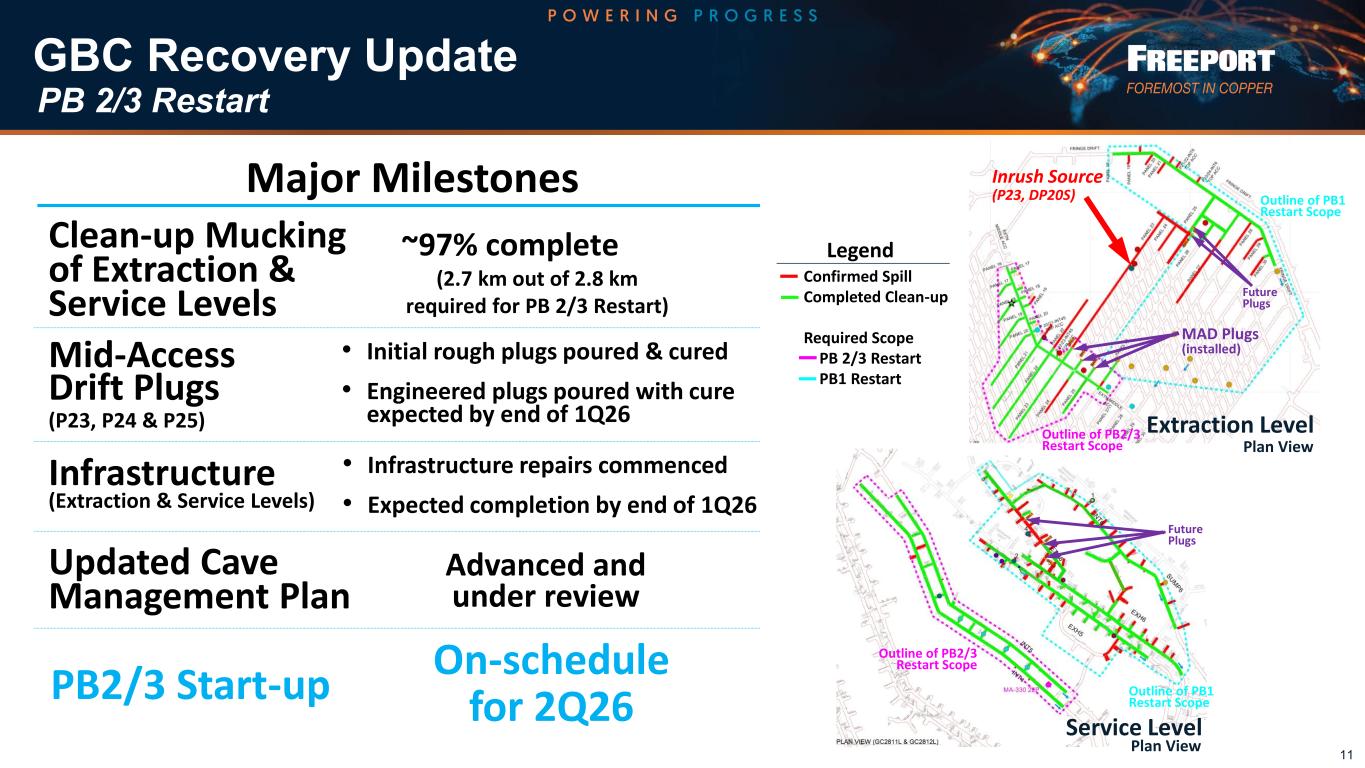

11 GBC Recovery Update Clean-up Mucking of Extraction & Service Levels Infrastructure (Extraction & Service Levels) Updated Cave Management Plan PB2/3 Start-up Mid-Access Drift Plugs (P23, P24 & P25) PB 2/3 Restart ~97% complete (2.7 km out of 2.8 km required for PB 2/3 Restart) • Infrastructure repairs commenced • Expected completion by end of 1Q26 Advanced and under review On-schedule for 2Q26 Major Milestones Plan View Extraction Level Plan View Service Level Inrush Source (P23, DP20S) MAD Plugs (installed) Outline of PB2/3 Restart Scope Outline of PB1 Restart Scope Outline of PB2/3 Restart Scope Future Plugs Future Plugs Outline of PB1 Restart Scope Legend Confirmed Spill Completed Clean-up Required Scope PB 2/3 Restart PB1 Restart • Initial rough plugs poured & cured • Engineered plugs poured with cure expected by end of 1Q26

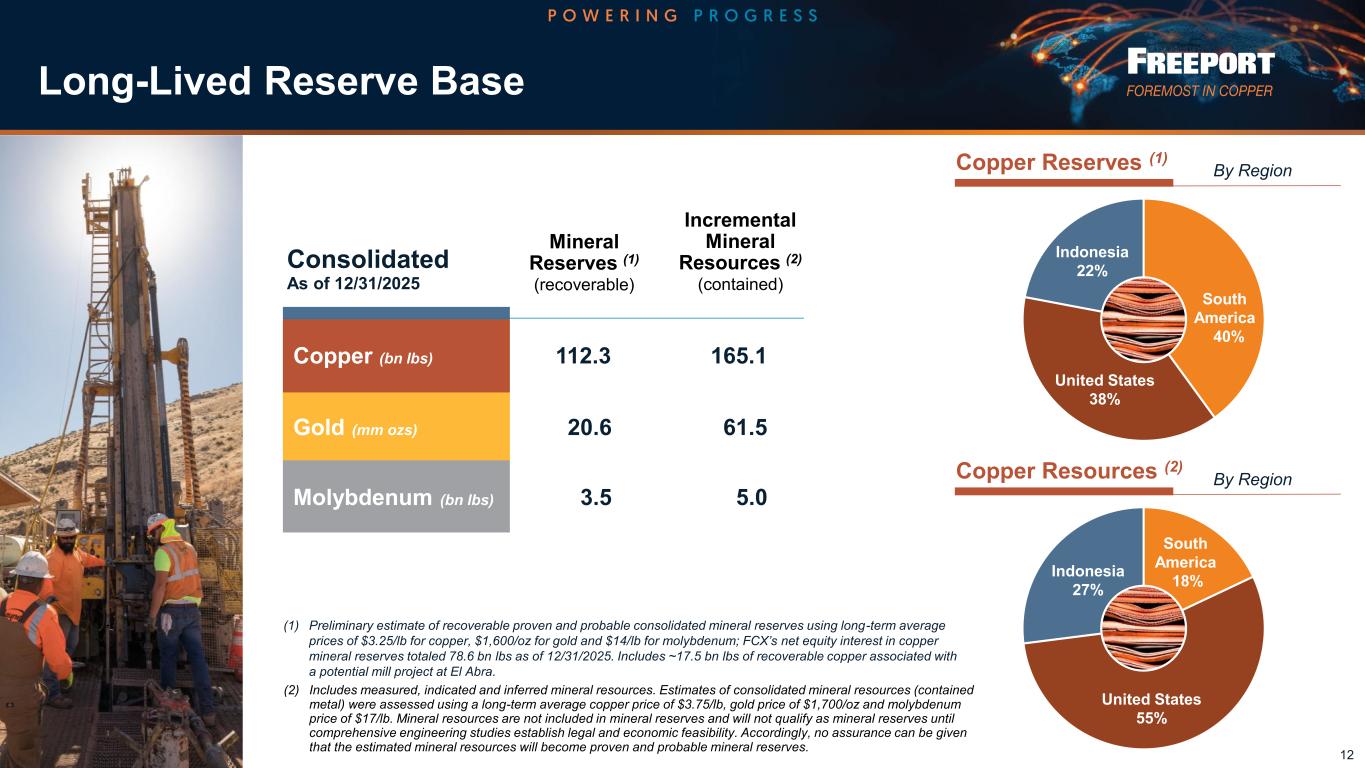

12 Long-Lived Reserve Base Copper (bn lbs) 112.3 165.1 Gold (mm ozs) 20.6 61.5 Molybdenum (bn lbs) 3.5 5.0 Mineral Reserves (1) (recoverable) Incremental Mineral Resources (2) (contained) (2) Includes measured, indicated and inferred mineral resources. Estimates of consolidated mineral resources (contained metal) were assessed using a long-term average copper price of $3.75/lb, gold price of $1,700/oz and molybdenum price of $17/lb. Mineral resources are not included in mineral reserves and will not qualify as mineral reserves until comprehensive engineering studies establish legal and economic feasibility. Accordingly, no assurance can be given that the estimated mineral resources will become proven and probable mineral reserves. (1) Preliminary estimate of recoverable proven and probable consolidated mineral reserves using long-term average prices of $3.25/lb for copper, $1,600/oz for gold and $14/lb for molybdenum; FCX’s net equity interest in copper mineral reserves totaled 78.6 bn lbs as of 12/31/2025. Includes ~17.5 bn lbs of recoverable copper associated with a potential mill project at El Abra. Consolidated As of 12/31/2025 South America 40% United States 38% Indonesia 22% South America 18% United States 55% Indonesia 27% Copper Reserves (1) By Region Copper Resources (2) By Region

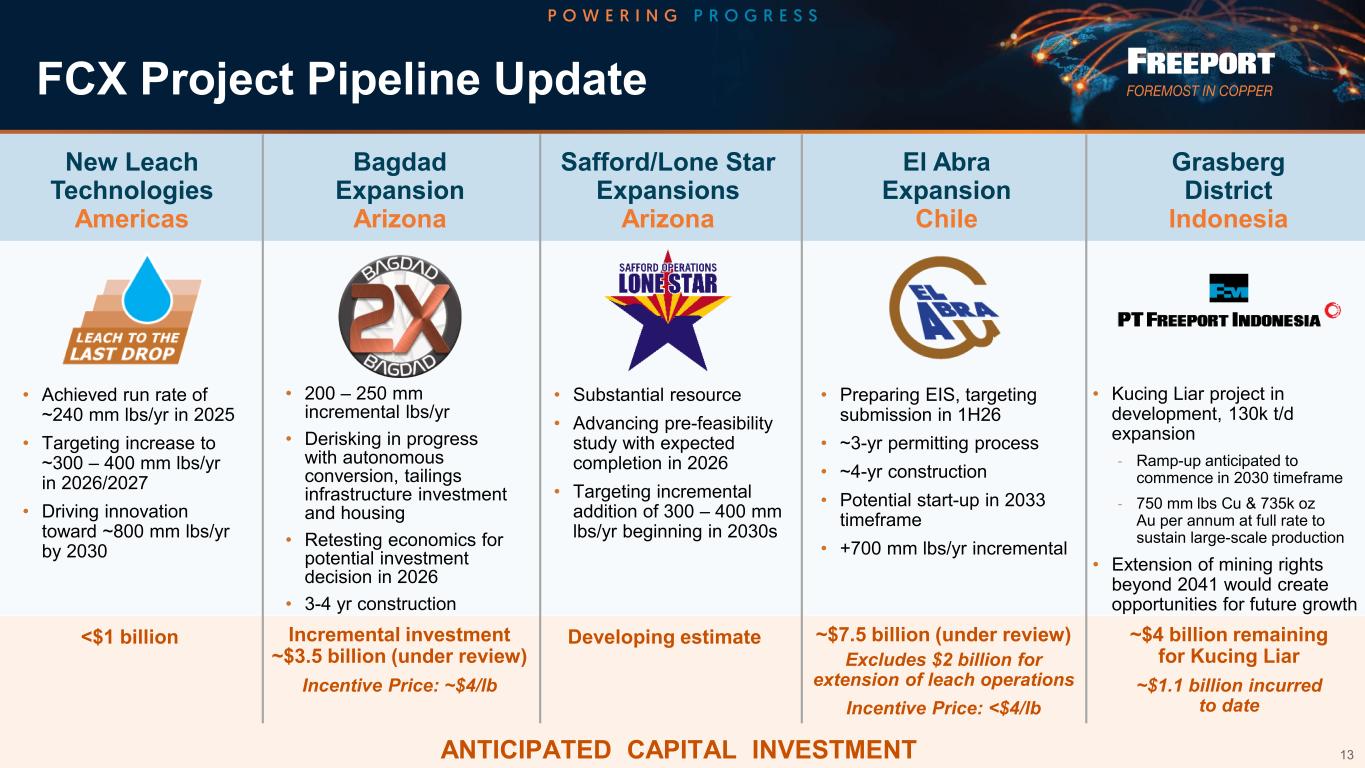

FCX Project Pipeline Update 13 El Abra Expansion Chile Safford/Lone Star Expansions Arizona Grasberg District Indonesia Bagdad Expansion Arizona New Leach Technologies Americas • Achieved run rate of ~240 mm lbs/yr in 2025 • Targeting increase to ~300 – 400 mm lbs/yr in 2026/2027 • Driving innovation toward ~800 mm lbs/yr by 2030 • 200 – 250 mm incremental lbs/yr • Derisking in progress with autonomous conversion, tailings infrastructure investment and housing • Retesting economics for potential investment decision in 2026 • 3-4 yr construction • Substantial resource • Advancing pre-feasibility study with expected completion in 2026 • Targeting incremental addition of 300 – 400 mm lbs/yr beginning in 2030s • Kucing Liar project in development, 130k t/d expansion - Ramp-up anticipated to commence in 2030 timeframe - 750 mm lbs Cu & 735k oz Au per annum at full rate to sustain large-scale production • Extension of mining rights beyond 2041 would create opportunities for future growth • Preparing EIS, targeting submission in 1H26 • ~3-yr permitting process • ~4-yr construction • Potential start-up in 2033 timeframe • +700 mm lbs/yr incremental <$1 billion Incremental investment ~$3.5 billion (under review) Incentive Price: ~$4/lb Developing estimate ~$4 billion remaining for Kucing Liar ~$1.1 billion incurred to date ~$7.5 billion (under review) Excludes $2 billion for extension of leach operations Incentive Price: <$4/lb ANTICIPATED CAPITAL INVESTMENT

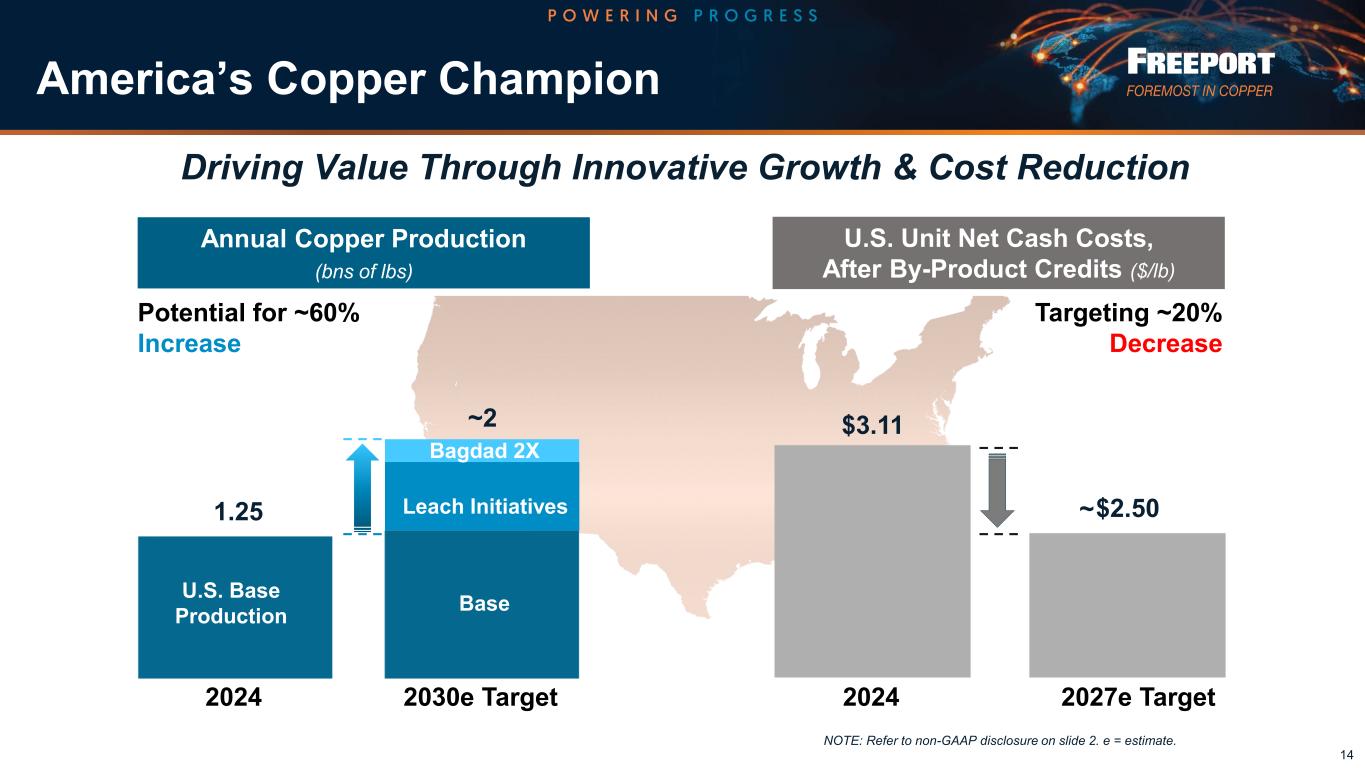

14 America’s Copper Champion $3.11 $2.50 2024 2027e Target ~ Annual Copper Production (bns of lbs) Targeting ~20% Decrease Potential for ~60% Increase ~2 1.25 U.S. Base Production Base Leach Initiatives Bagdad 2X U.S. Unit Net Cash Costs, After By-Product Credits ($/lb) Driving Value Through Innovative Growth & Cost Reduction NOTE: Refer to non-GAAP disclosure on slide 2. e = estimate. 2024 2030e Target

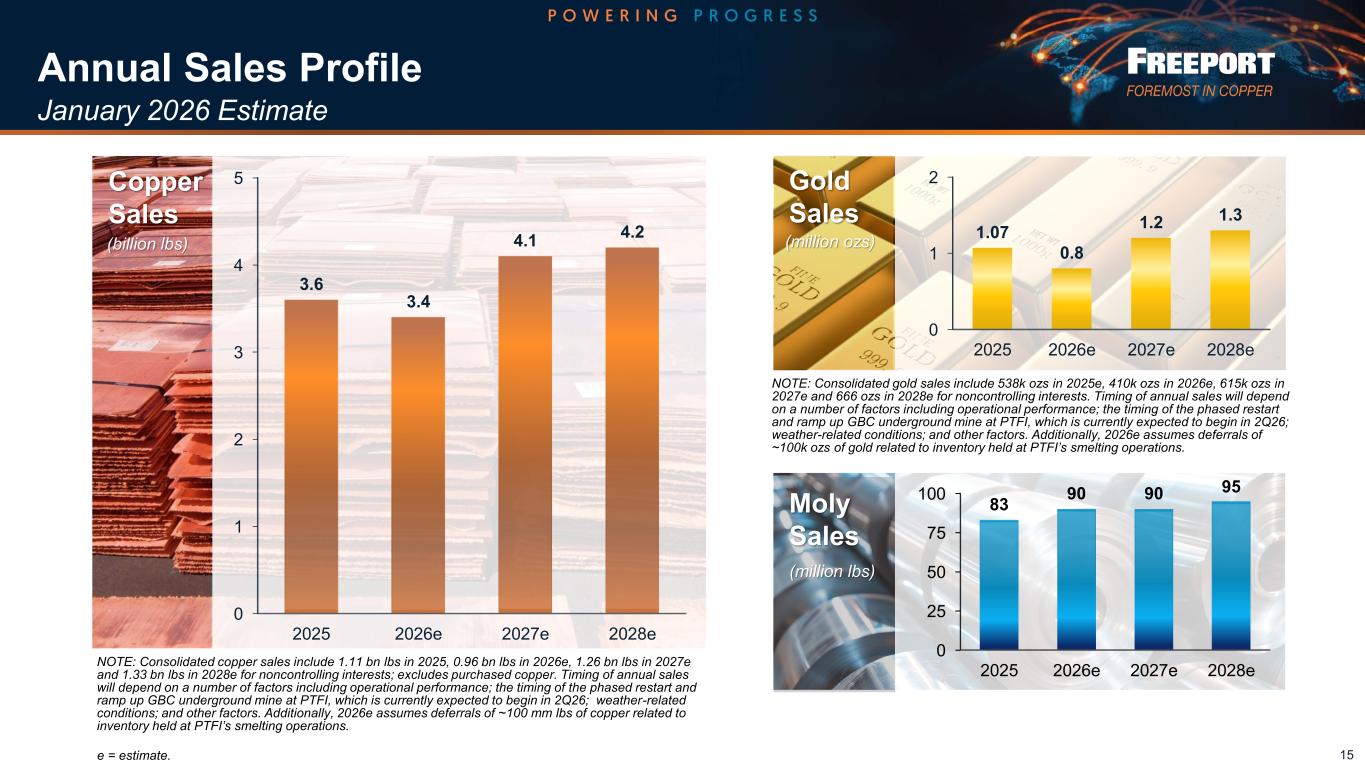

Annual Sales Profile January 2026 Estimate 15 NOTE: Consolidated copper sales include 1.11 bn lbs in 2025, 0.96 bn lbs in 2026e, 1.26 bn lbs in 2027e and 1.33 bn lbs in 2028e for noncontrolling interests; excludes purchased copper. Timing of annual sales will depend on a number of factors including operational performance; the timing of the phased restart and ramp up GBC underground mine at PTFI, which is currently expected to begin in 2Q26; weather-related conditions; and other factors. Additionally, 2026e assumes deferrals of ~100 mm lbs of copper related to inventory held at PTFI’s smelting operations. e = estimate. NOTE: Consolidated gold sales include 538k ozs in 2025e, 410k ozs in 2026e, 615k ozs in 2027e and 666 ozs in 2028e for noncontrolling interests. Timing of annual sales will depend on a number of factors including operational performance; the timing of the phased restart and ramp up GBC underground mine at PTFI, which is currently expected to begin in 2Q26; weather-related conditions; and other factors. Additionally, 2026e assumes deferrals of ~100k ozs of gold related to inventory held at PTFI’s smelting operations. (million lbs) Moly Sales (billion lbs) Copper Sales 0 1 2 3 4 5 2025 2026e 2027e 2028e 3.6 3.4 4.1 4.2 0 25 50 75 100 2025 2026e 2027e 2028e 83 90 90 95 0 1 2 2025 2026e 2027e 2028e 1.07 0.8 1.2 1.3 Gold Sales (million ozs)

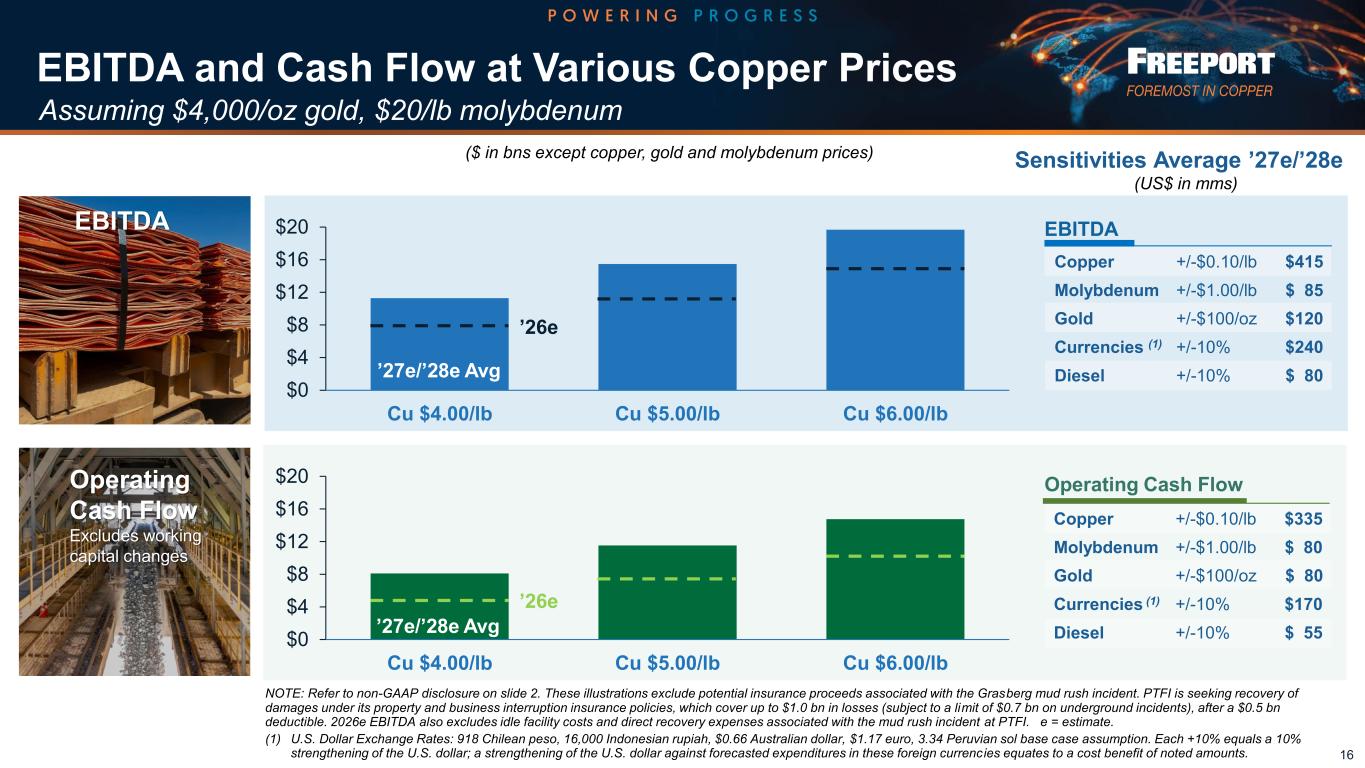

$0 $4 $8 $12 $16 $20 Cu $4.00/lb Cu $5.00/lb Cu $6.00/lb ’27e/’28e Avg EBITDA and Cash Flow at Various Copper Prices Assuming $4,000/oz gold, $20/lb molybdenum 16 NOTE: Refer to non-GAAP disclosure on slide 2. These illustrations exclude potential insurance proceeds associated with the Grasberg mud rush incident. PTFI is seeking recovery of damages under its property and business interruption insurance policies, which cover up to $1.0 bn in losses (subject to a limit of $0.7 bn on underground incidents), after a $0.5 bn deductible. 2026e EBITDA also excludes idle facility costs and direct recovery expenses associated with the mud rush incident at PTFI. e = estimate. (1) U.S. Dollar Exchange Rates: 918 Chilean peso, 16,000 Indonesian rupiah, $0.66 Australian dollar, $1.17 euro, 3.34 Peruvian sol base case assumption. Each +10% equals a 10% strengthening of the U.S. dollar; a strengthening of the U.S. dollar against forecasted expenditures in these foreign currencies equates to a cost benefit of noted amounts. ($ in bns except copper, gold and molybdenum prices) Operating Cash Flow Excludes working capital changes EBITDA Sensitivities Average ’27e/’28e (US$ in mms) EBITDA Operating Cash Flow Copper +/-$0.10/lb $335 Molybdenum +/-$1.00/lb $ 80 Gold +/-$100/oz $ 80 Currencies (1) +/-10% $170 Diesel +/-10% $ 55 Copper +/-$0.10/lb $415 Molybdenum +/-$1.00/lb $ 85 Gold +/-$100/oz $120 Currencies (1) +/-10% $240 Diesel +/-10% $ 80 ’26e $0 $4 $8 $12 $16 $20 Cu $4.00/lb Cu $5.00/lb Cu $6.00/lb ’27e/’28e Avg ’26e

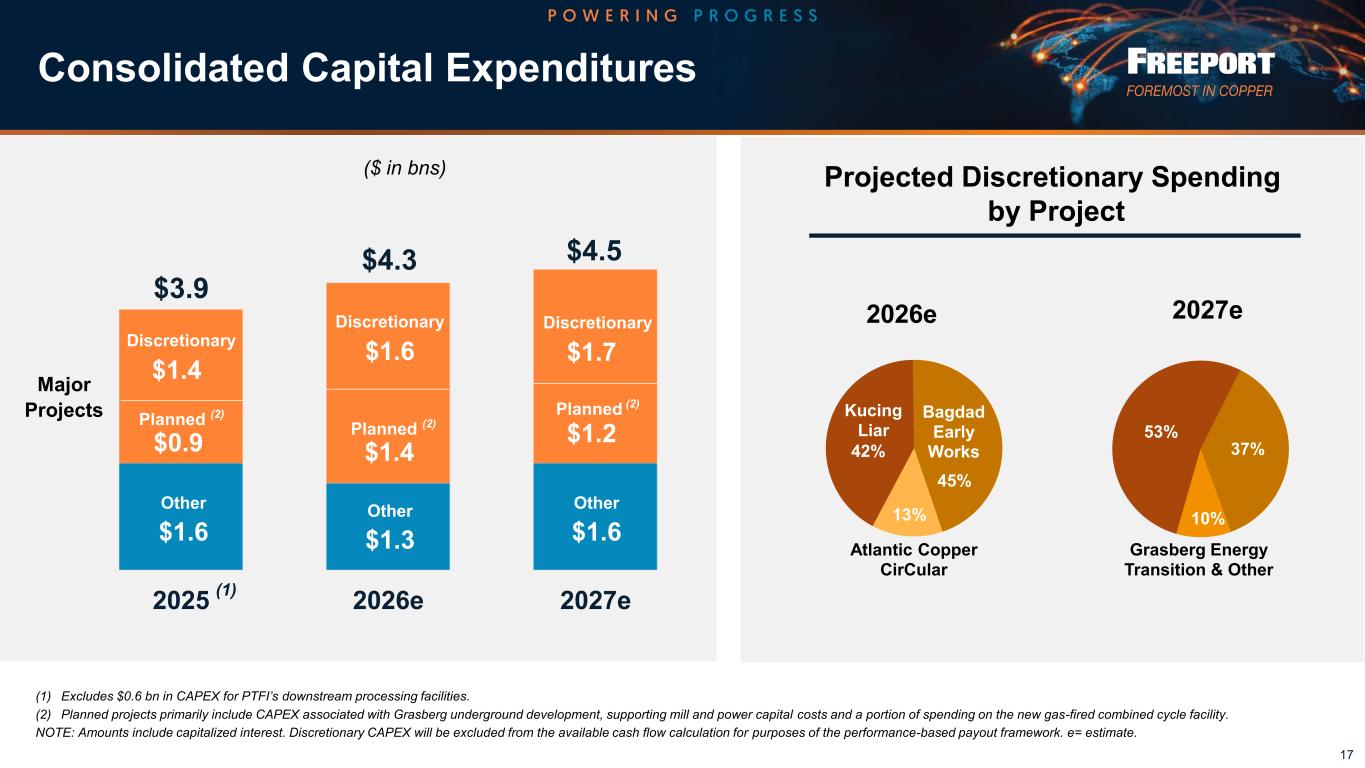

Consolidated Capital Expenditures 2025 2026e 2027e Major Projects (1) Excludes $0.6 bn in CAPEX for PTFI’s downstream processing facilities. (2) Planned projects primarily include CAPEX associated with Grasberg underground development, supporting mill and power capital costs and a portion of spending on the new gas-fired combined cycle facility. NOTE: Amounts include capitalized interest. Discretionary CAPEX will be excluded from the available cash flow calculation for purposes of the performance-based payout framework. e= estimate. $1.6 $0.9 Planned (2) Discretionary $1.4 $3.9 Other Other $1.6 Planned (2) Discretionary $4.5 Other $1.3 $1.4 $1.6 $4.3 53% 37% 10% Grasberg Energy Transition & Other Atlantic Copper CirCular 2027e Projected Discretionary Spending by Project 2026e ($ in bns) 17 42% 45% 13% (1) Planned (2) Discretionary $1.2 $1.7 Kucing Liar Bagdad Early Works

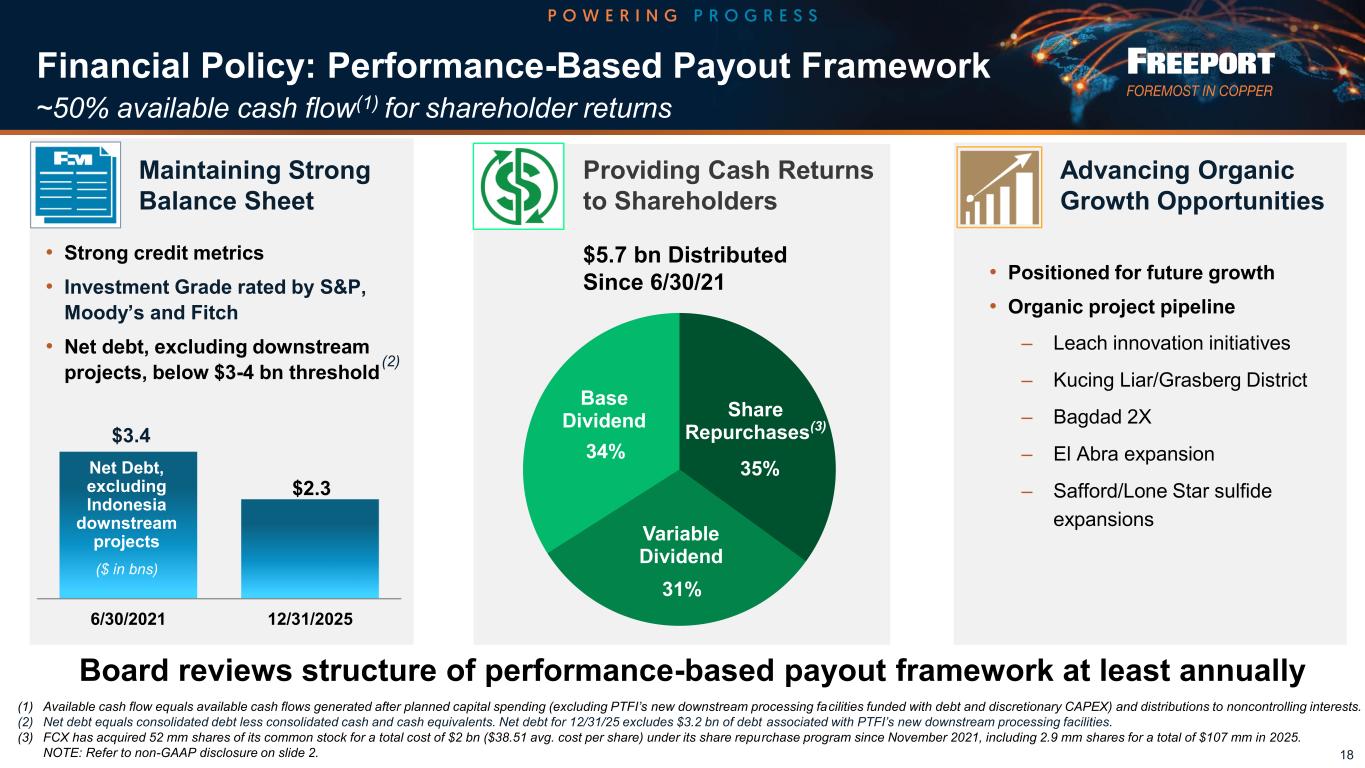

Financial Policy: Performance-Based Payout Framework ~50% available cash flow(1) for shareholder returns 18 (1) Available cash flow equals available cash flows generated after planned capital spending (excluding PTFI’s new downstream processing facilities funded with debt and discretionary CAPEX) and distributions to noncontrolling interests. (2) Net debt equals consolidated debt less consolidated cash and cash equivalents. Net debt for 12/31/25 excludes $3.2 bn of debt associated with PTFI’s new downstream processing facilities. (3) FCX has acquired 52 mm shares of its common stock for a total cost of $2 bn ($38.51 avg. cost per share) under its share repurchase program since November 2021, including 2.9 mm shares for a total of $107 mm in 2025. NOTE: Refer to non-GAAP disclosure on slide 2. Board reviews structure of performance-based payout framework at least annually Maintaining Strong Balance Sheet 6/30/2021 12/31/2025 $2.3 $3.4 Net Debt, excluding Indonesia downstream projects ($ in bns) Providing Cash Returns to Shareholders $5.7 bn Distributed Since 6/30/21 35% Share Repurchases(3) Variable Dividend Base Dividend 34% 31% Advancing Organic Growth Opportunities • Positioned for future growth • Organic project pipeline – Leach innovation initiatives – Kucing Liar/Grasberg District – Bagdad 2X – El Abra expansion – Safford/Lone Star sulfide expansions (2) • Strong credit metrics • Investment Grade rated by S&P, Moody’s and Fitch • Net debt, excluding downstream projects, below $3-4 bn threshold

19 Freeport – Store of Value Significant Gold Producer Organic Growth Pipeline Leadership Position in Critical Metal Large Scale Producer Strong Global Leader with Valuable U.S. Franchise

20 Reference Slides

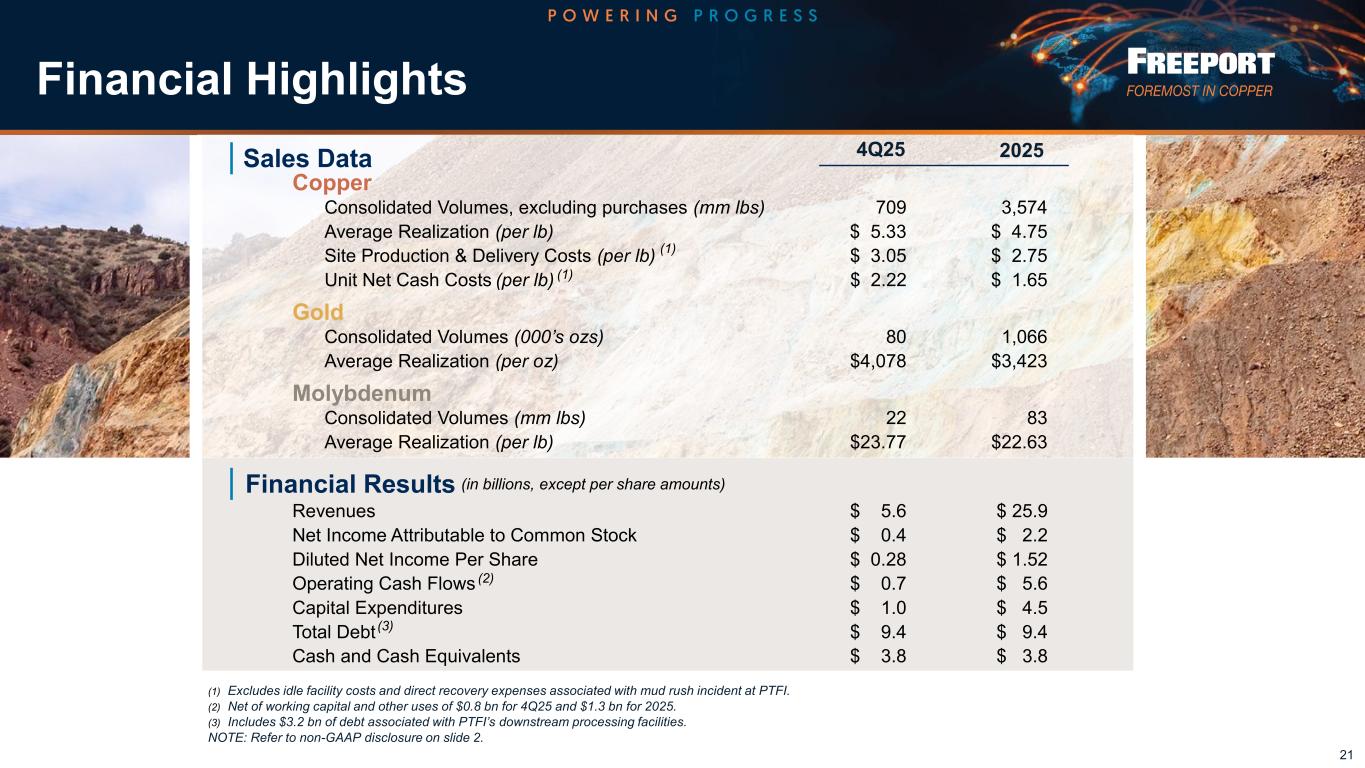

Financial Highlights 21 Copper Consolidated Volumes, excluding purchases (mm lbs) 709 3,574 Average Realization (per lb) $ 5.33 $ 4.75 Site Production & Delivery Costs (per lb) $ 3.05 $ 2.75 Unit Net Cash Costs (per lb) $ 2.22 $ 1.65 Gold Consolidated Volumes (000’s ozs) 80 1,066 Average Realization (per oz) $4,078 $3,423 Molybdenum Consolidated Volumes (mm lbs) 22 83 Average Realization (per lb) $23.77 $22.63 4Q25 (1) Excludes idle facility costs and direct recovery expenses associated with mud rush incident at PTFI. (2) Net of working capital and other uses of $0.8 bn for 4Q25 and $1.3 bn for 2025. (3) Includes $3.2 bn of debt associated with PTFI’s downstream processing facilities. NOTE: Refer to non-GAAP disclosure on slide 2. Revenues $ 5.6 $ 25.9 Net Income Attributable to Common Stock $ 0.4 $ 2.2 Diluted Net Income Per Share $ 0.28 $ 1.52 Operating Cash Flows $ 0.7 $ 5.6 Capital Expenditures $ 1.0 $ 4.5 Total Debt $ 9.4 $ 9.4 Cash and Cash Equivalents $ 3.8 $ 3.8 (in billions, except per share amounts) | Sales Data | Financial Results 2025 (3) (1) (2) (1)

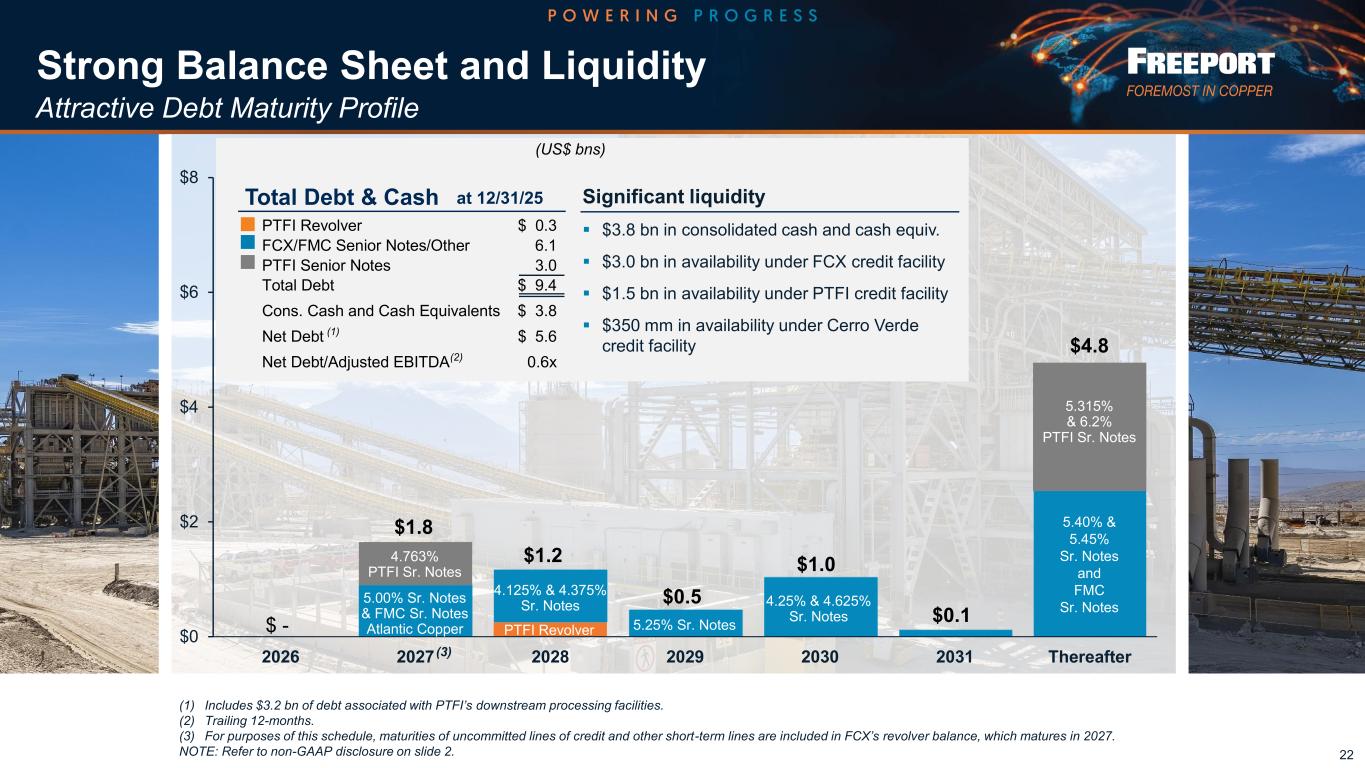

Strong Balance Sheet and Liquidity Attractive Debt Maturity Profile 22 $0 $2 $4 $6 $8 2026 2027 2028 2029 2030 2031 Thereafter (US$ bns) $4.8 5.40% & 5.45% Sr. Notes and FMC Sr. Notes PTFI Revolver $ 0.3 FCX/FMC Senior Notes/Other 6.1 PTFI Senior Notes 3.0 Total Debt $ 9.4 Cons. Cash and Cash Equivalents $ 3.8 Net Debt (1) $ 5.6 Net Debt/Adjusted EBITDA(2) 0.6x $ - at 12/31/25Total Debt & Cash $1.8 (3) 5.00% Sr. Notes & FMC Sr. Notes 4.763% PTFI Sr. Notes 5.315% & 6.2% PTFI Sr. Notes Significant liquidity ▪ $3.8 bn in consolidated cash and cash equiv. ▪ $3.0 bn in availability under FCX credit facility ▪ $1.5 bn in availability under PTFI credit facility ▪ $350 mm in availability under Cerro Verde credit facility 4.125% & 4.375% Sr. Notes $1.2 $0.5 5.25% Sr. Notes 4.25% & 4.625% Sr. Notes $1.0 PTFI Revolver (1) Includes $3.2 bn of debt associated with PTFI’s downstream processing facilities. (2) Trailing 12-months. (3) For purposes of this schedule, maturities of uncommitted lines of credit and other short-term lines are included in FCX’s revolver balance, which matures in 2027. NOTE: Refer to non-GAAP disclosure on slide 2. Atlantic Copper $0.1

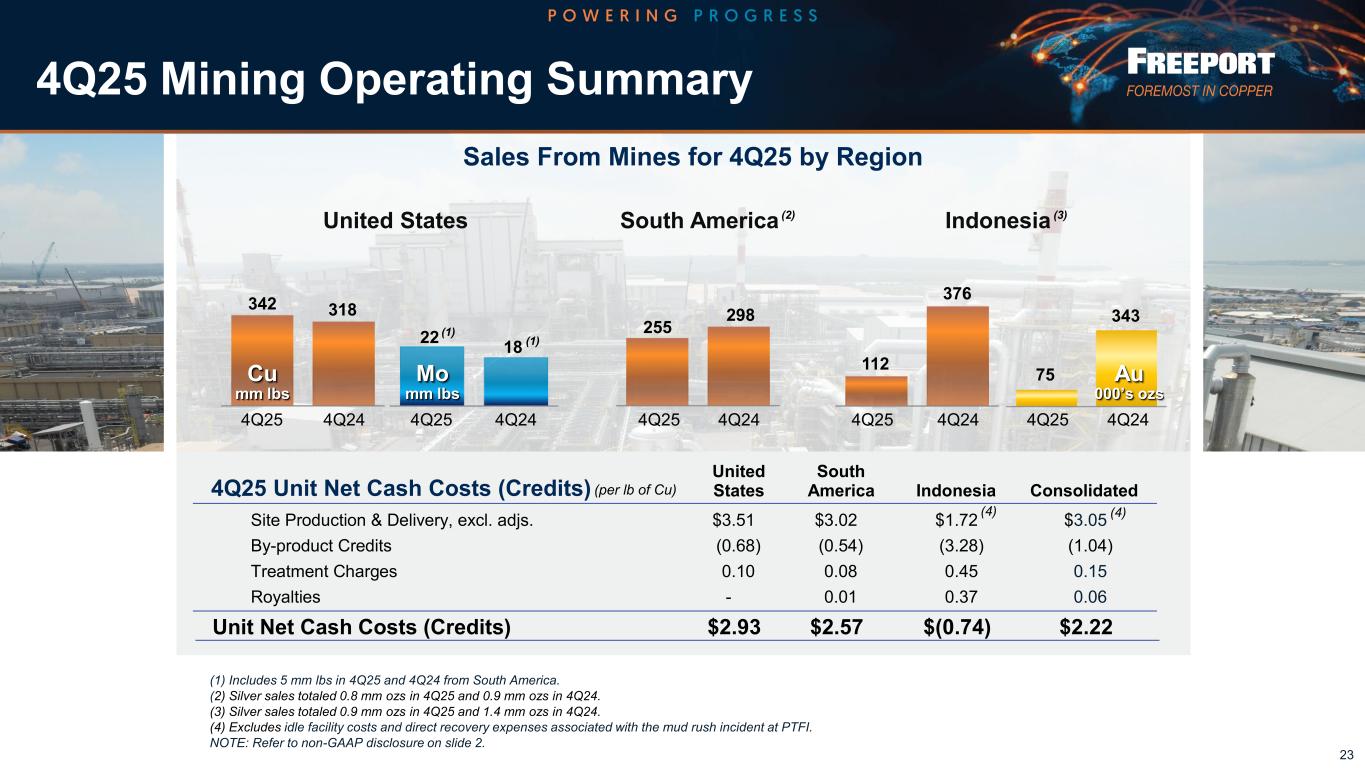

4Q25 Mining Operating Summary 23 (1) Includes 5 mm lbs in 4Q25 and 4Q24 from South America. (2) Silver sales totaled 0.8 mm ozs in 4Q25 and 0.9 mm ozs in 4Q24. (3) Silver sales totaled 0.9 mm ozs in 4Q25 and 1.4 mm ozs in 4Q24. (4) Excludes idle facility costs and direct recovery expenses associated with the mud rush incident at PTFI. NOTE: Refer to non-GAAP disclosure on slide 2. Site Production & Delivery, excl. adjs. $3.51 $3.02 $1.72 $3.05 By-product Credits (0.68) (0.54) (3.28) (1.04) Treatment Charges 0.10 0.08 0.45 0.15 Royalties - 0.01 0.37 0.06 Unit Net Cash Costs (Credits) $2.93 $2.57 $(0.74) $2.22 United South States America Indonesia Consolidated (per lb of Cu)4Q25 Unit Net Cash Costs (Credits) United States 18 22 (1) 318342 4Q25 4Q24 Indonesia 376 112 343 75 South America 255 298 Sales From Mines for 4Q25 by Region 4Q25 4Q24 4Q25 4Q24 4Q25 4Q244Q25 4Q24 (2) (1) Au 000’s ozs Mo mm lbs Cu mm lbs (4) (4) (3)

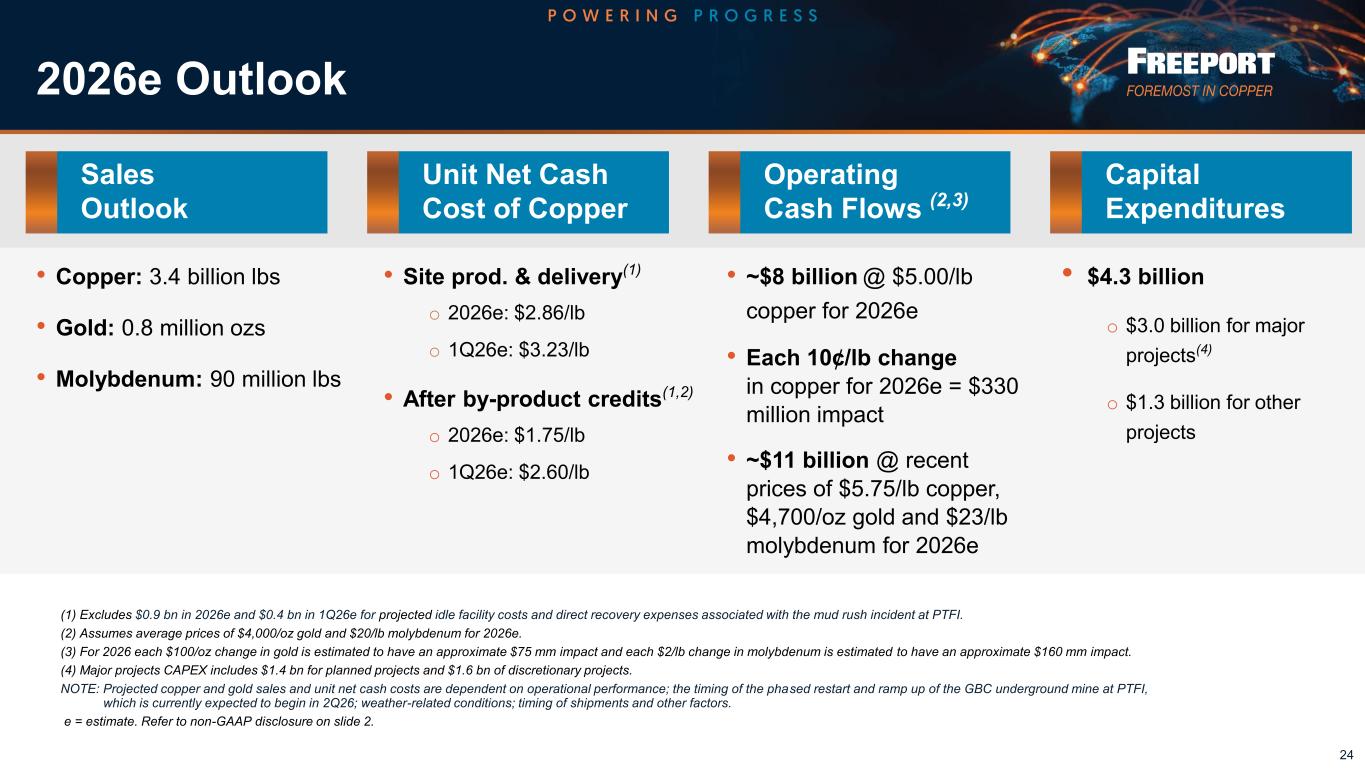

2026e Outlook 24 (1) Excludes $0.9 bn in 2026e and $0.4 bn in 1Q26e for projected idle facility costs and direct recovery expenses associated with the mud rush incident at PTFI. (2) Assumes average prices of $4,000/oz gold and $20/lb molybdenum for 2026e. (3) For 2026 each $100/oz change in gold is estimated to have an approximate $75 mm impact and each $2/lb change in molybdenum is estimated to have an approximate $160 mm impact. (4) Major projects CAPEX includes $1.4 bn for planned projects and $1.6 bn of discretionary projects. NOTE: Projected copper and gold sales and unit net cash costs are dependent on operational performance; the timing of the phased restart and ramp up of the GBC underground mine at PTFI, which is currently expected to begin in 2Q26; weather-related conditions; timing of shipments and other factors. e = estimate. Refer to non-GAAP disclosure on slide 2. • Copper: 3.4 billion lbs • Gold: 0.8 million ozs • Molybdenum: 90 million lbs • Site prod. & delivery(1) o 2026e: $2.86/lb o 1Q26e: $3.23/lb • After by-product credits(1,2) o 2026e: $1.75/lb o 1Q26e: $2.60/lb • $4.3 billion o $3.0 billion for major projects(4) o $1.3 billion for other projects • ~$8 billion @ $5.00/lb copper for 2026e • Each 10¢/lb change in copper for 2026e = $330 million impact • ~$11 billion @ recent prices of $5.75/lb copper, $4,700/oz gold and $23/lb molybdenum for 2026e Sales Outlook Unit Net Cash Cost of Copper Operating Cash Flows (2,3) Capital Expenditures

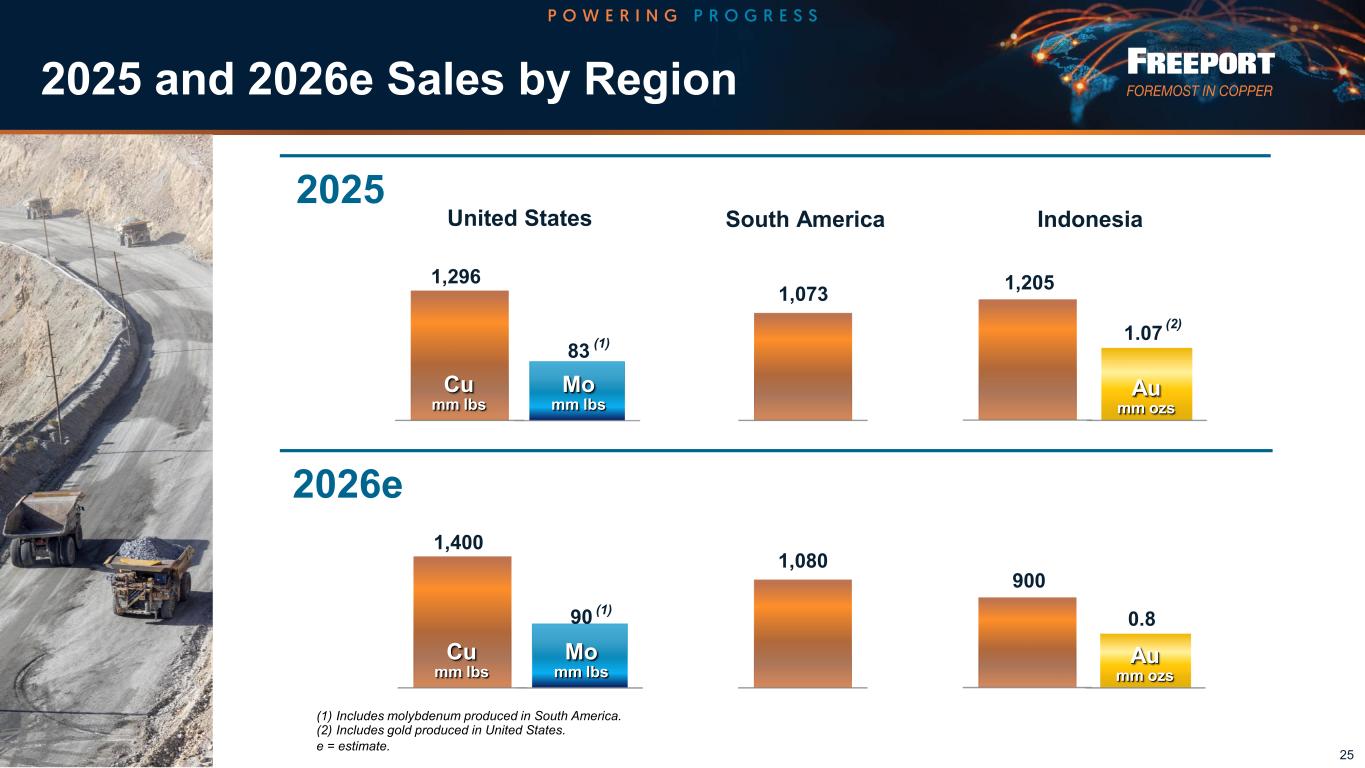

2025 2026e 2025 and 2026e Sales by Region 25 (1) Includes molybdenum produced in South America. (2) Includes gold produced in United States. e = estimate. (1) 1,073 83 1,296 1,205 1.07 United States IndonesiaSouth America Au mm ozs Mo mm lbs Cu mm lbs (1) 1,080 90 1,400 900 0.8 Au mm ozs Mo mm lbs Cu mm lbs (2)

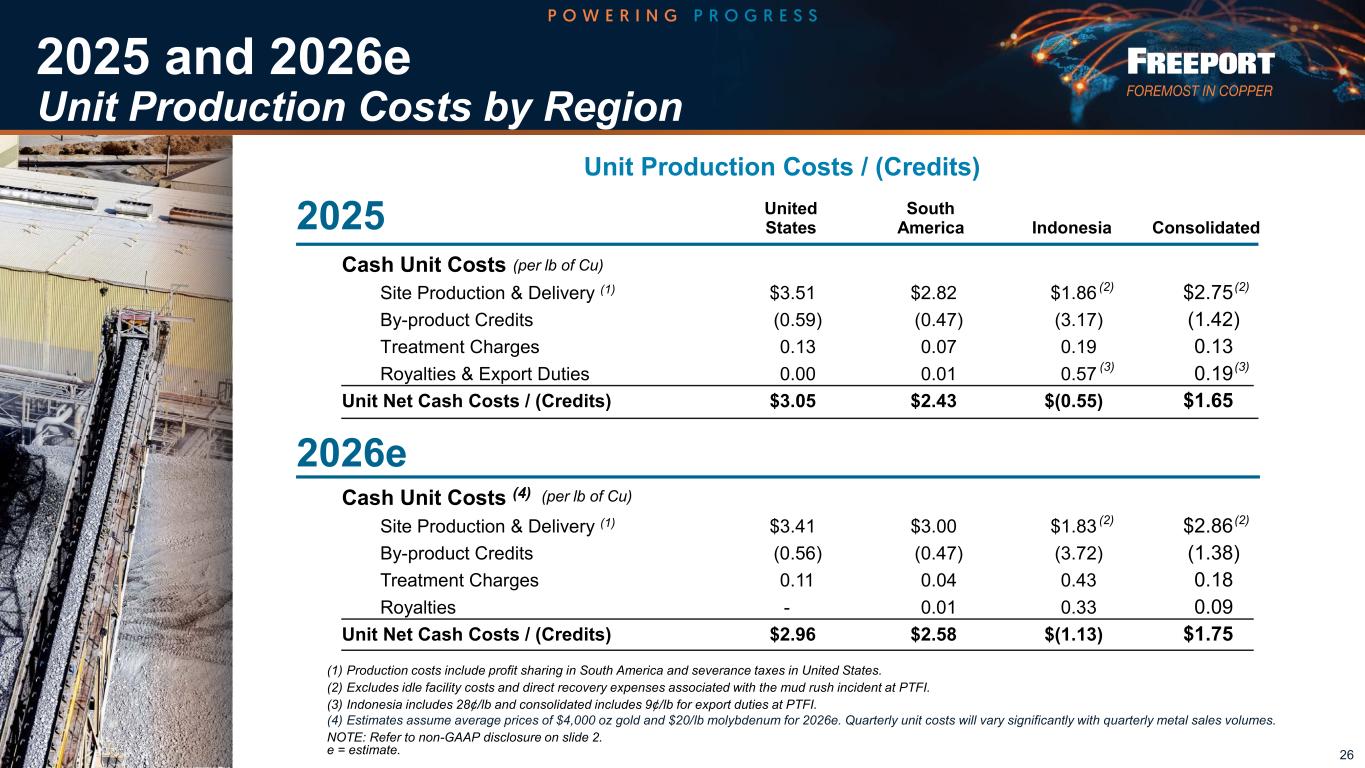

2025 2025 and 2026e Unit Production Costs by Region 26 (per lb of Cu) United South States America Indonesia Consolidated Unit Production Costs / (Credits) e = estimate. (per lb of Cu) (1) Production costs include profit sharing in South America and severance taxes in United States. (2) Excludes idle facility costs and direct recovery expenses associated with the mud rush incident at PTFI. (3) Indonesia includes 28¢/lb and consolidated includes 9¢/lb for export duties at PTFI. (4) Estimates assume average prices of $4,000 oz gold and $20/lb molybdenum for 2026e. Quarterly unit costs will vary significantly with quarterly metal sales volumes. NOTE: Refer to non-GAAP disclosure on slide 2. 2026e Cash Unit Costs Site Production & Delivery (1) $3.51 $2.82 $1.86 $2.75 By-product Credits (0.59) (0.47) (3.17) (1.42) Treatment Charges 0.13 0.07 0.19 0.13 Royalties & Export Duties 0.00 0.01 0.57 0.19 Unit Net Cash Costs / (Credits) $3.05 $2.43 $(0.55) $1.65 Cash Unit Costs (4) Site Production & Delivery (1) $3.41 $3.00 $1.83 $2.86 By-product Credits (0.56) (0.47) (3.72) (1.38) Treatment Charges 0.11 0.04 0.43 0.18 Royalties - 0.01 0.33 0.09 Unit Net Cash Costs / (Credits) $2.96 $2.58 $(1.13) $1.75 (2) (2) (3) (3) (2) (2)

2026e Quarterly Sales 27e = estimate. (million lbs) Moly Sales (million lbs) Copper Sales Gold Sales (000’s ozs) 0 100 200 300 400 1Q26e 2Q26e 3Q26e 4Q26e 60 140 290 310 0 200 400 600 800 1000 1200 1Q26e 2Q26e 3Q26e 4Q26e 640 740 980 1,020 0 5 10 15 20 25 1Q26e 2Q26e 3Q26e 4Q26e 22 23 22 23 NOTE: Consolidated copper sales include 145 mm lbs in 1Q26e, 190 mm lbs in 2Q26e, 303 mm lbs in 3Q26e and 317 mm lbs in 4Q26e for noncontrolling interests; excludes purchased copper. Estimates are dependent on operational performance; the timing of the phased restart and ramp up of the GBC underground mine at PTFI, which is currently expected to begin in 2Q26; weather- related conditions; timing of shipments and other factors. NOTE: Consolidated gold sales include 30k ozs in 1Q26e, 72k ozs in 2Q26e, 149k ozs in 3Q26e and 159k ozs in 4Q26e for noncontrolling interests. Estimates are dependent on operational performance; the timing of the phased restart and ramp up of the GBC underground mine at PTFI, which is currently expected to begin in 2Q26; weather-related conditions; timing of shipments and other factors.

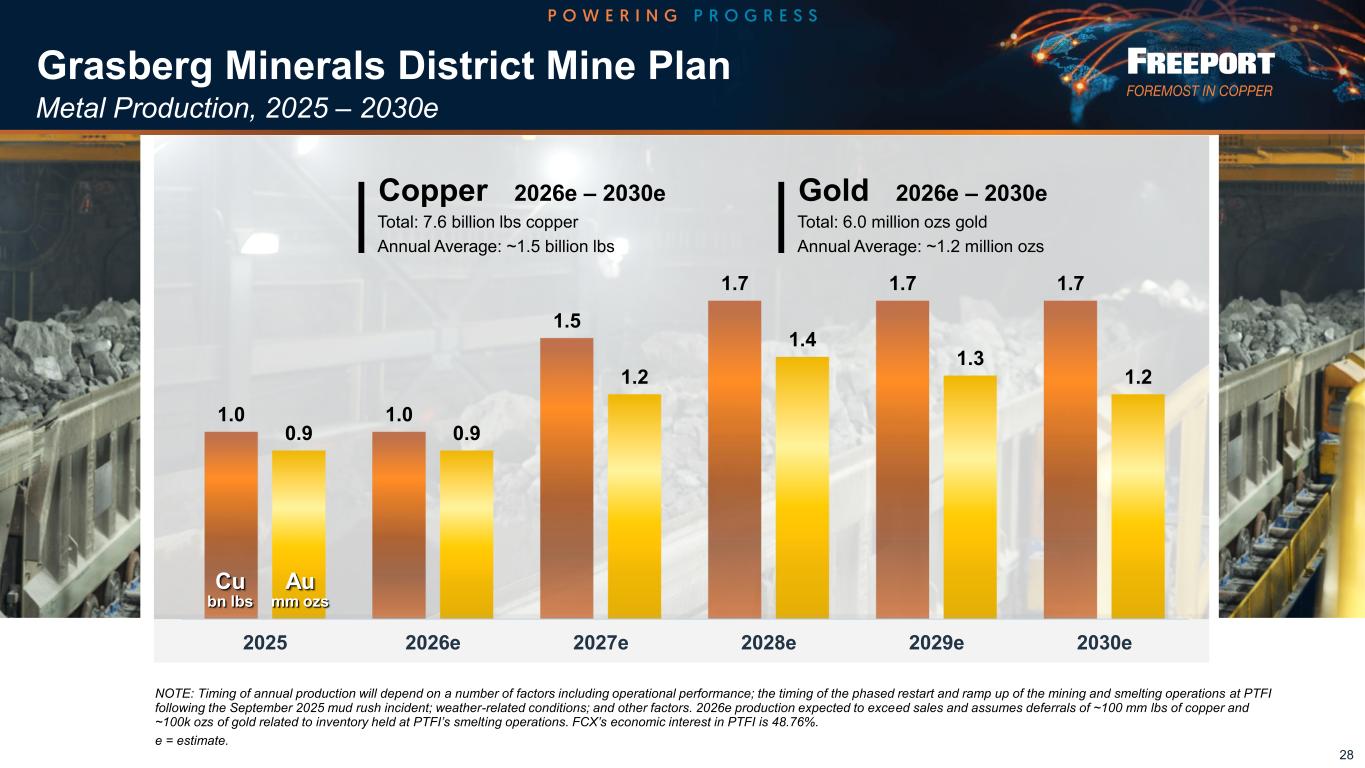

Grasberg Minerals District Mine Plan Metal Production, 2025 – 2030e 28 1.0 1.0 1.5 1.7 1.7 1.7 0.9 0.9 1.2 1.4 1.3 1.2 2025 2026e 2027e 2028e 2029e 2030e | Copper 2026e – 2030e Total: 7.6 billion lbs copper Annual Average: ~1.5 billion lbs | Gold 2026e – 2030e Total: 6.0 million ozs gold Annual Average: ~1.2 million ozs Cu bn lbs Au mm ozs NOTE: Timing of annual production will depend on a number of factors including operational performance; the timing of the phased restart and ramp up of the mining and smelting operations at PTFI following the September 2025 mud rush incident; weather-related conditions; and other factors. 2026e production expected to exceed sales and assumes deferrals of ~100 mm lbs of copper and ~100k ozs of gold related to inventory held at PTFI’s smelting operations. FCX’s economic interest in PTFI is 48.76%. e = estimate.

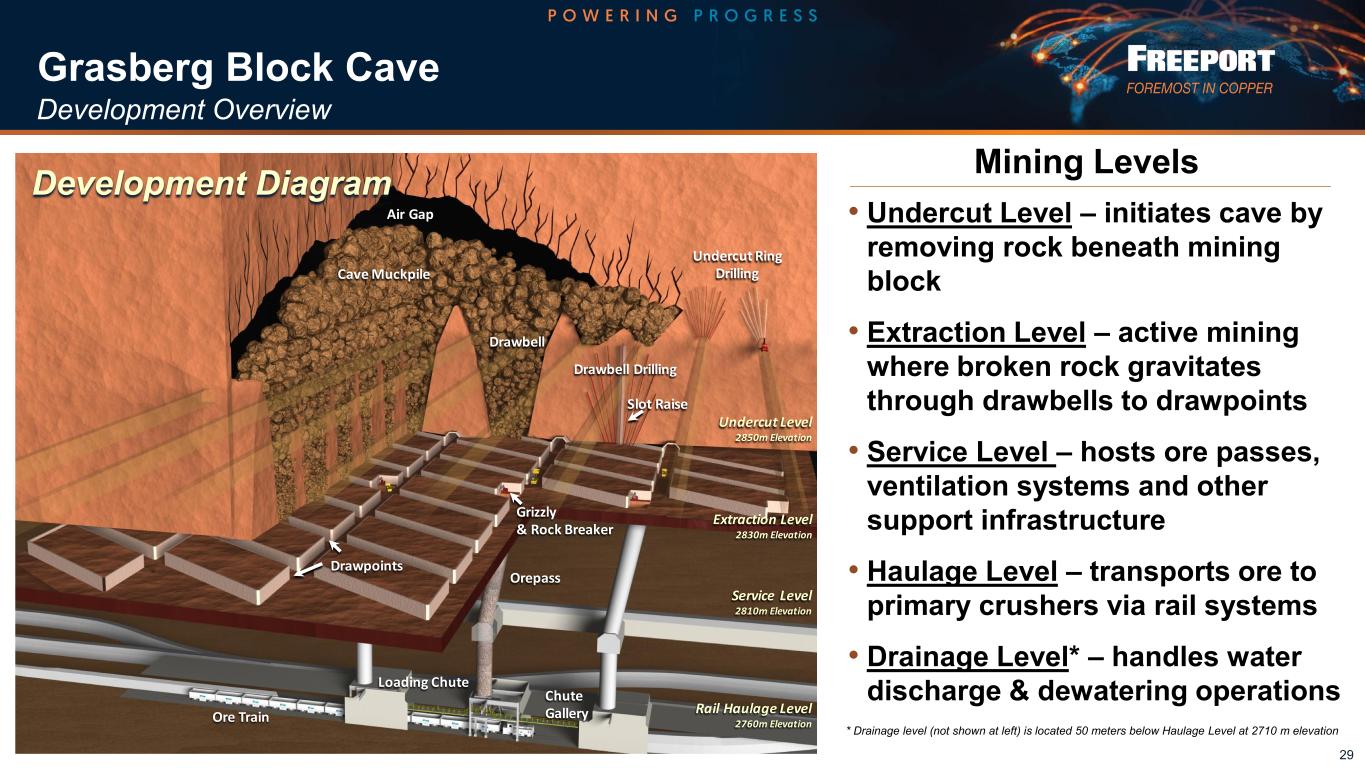

Grasberg Block Cave Drawbell Drilling Undercut Ring DrillingCave Muckpile Air Gap Undercut Level 2850m Elevation Extraction Level 2830m Elevation Service Level 2810m Elevation Rail Haulage Level 2760m Elevation Orepass Chute GalleryOre Train Slot Raise Grizzly & Rock Breaker Drawpoints Loading Chute Drawbell Development Diagram • Undercut Level – initiates cave by removing rock beneath mining block • Extraction Level – active mining where broken rock gravitates through drawbells to drawpoints • Service Level – hosts ore passes, ventilation systems and other support infrastructure • Haulage Level – transports ore to primary crushers via rail systems • Drainage Level* – handles water discharge & dewatering operations Mining Levels 29 Development Overview * Drainage level (not shown at left) is located 50 meters below Haulage Level at 2710 m elevation

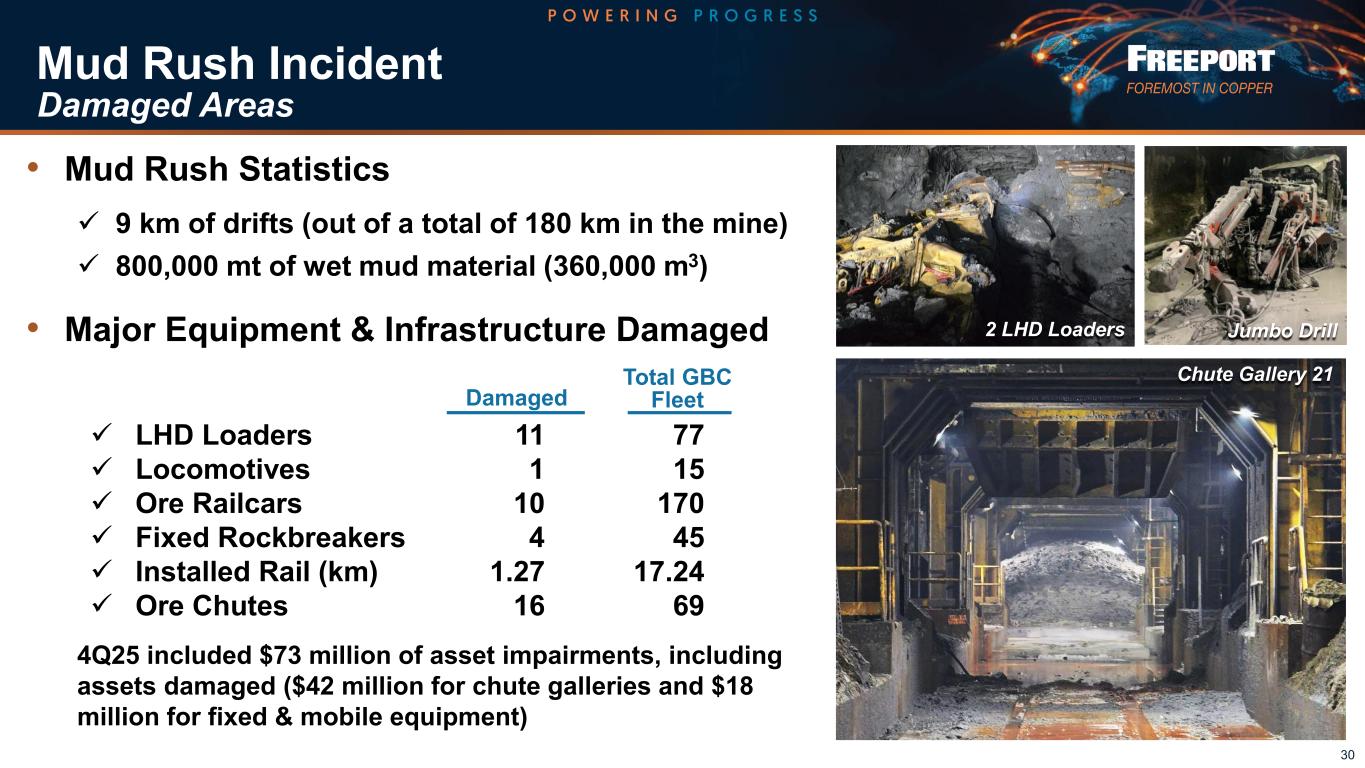

Mud Rush Incident • Mud Rush Statistics ✓ 9 km of drifts (out of a total of 180 km in the mine) ✓ 800,000 mt of wet mud material (360,000 m3) • Major Equipment & Infrastructure Damaged ✓ LHD Loaders 11 77 ✓ Locomotives 1 15 ✓ Ore Railcars 10 170 ✓ Fixed Rockbreakers 4 45 ✓ Installed Rail (km) 1.27 17.24 ✓ Ore Chutes 16 69 4Q25 included $73 million of asset impairments, including assets damaged ($42 million for chute galleries and $18 million for fixed & mobile equipment) 30 Total GBC FleetDamaged Damaged Areas Jumbo Drill2 LHD Loaders Chute Gallery 21

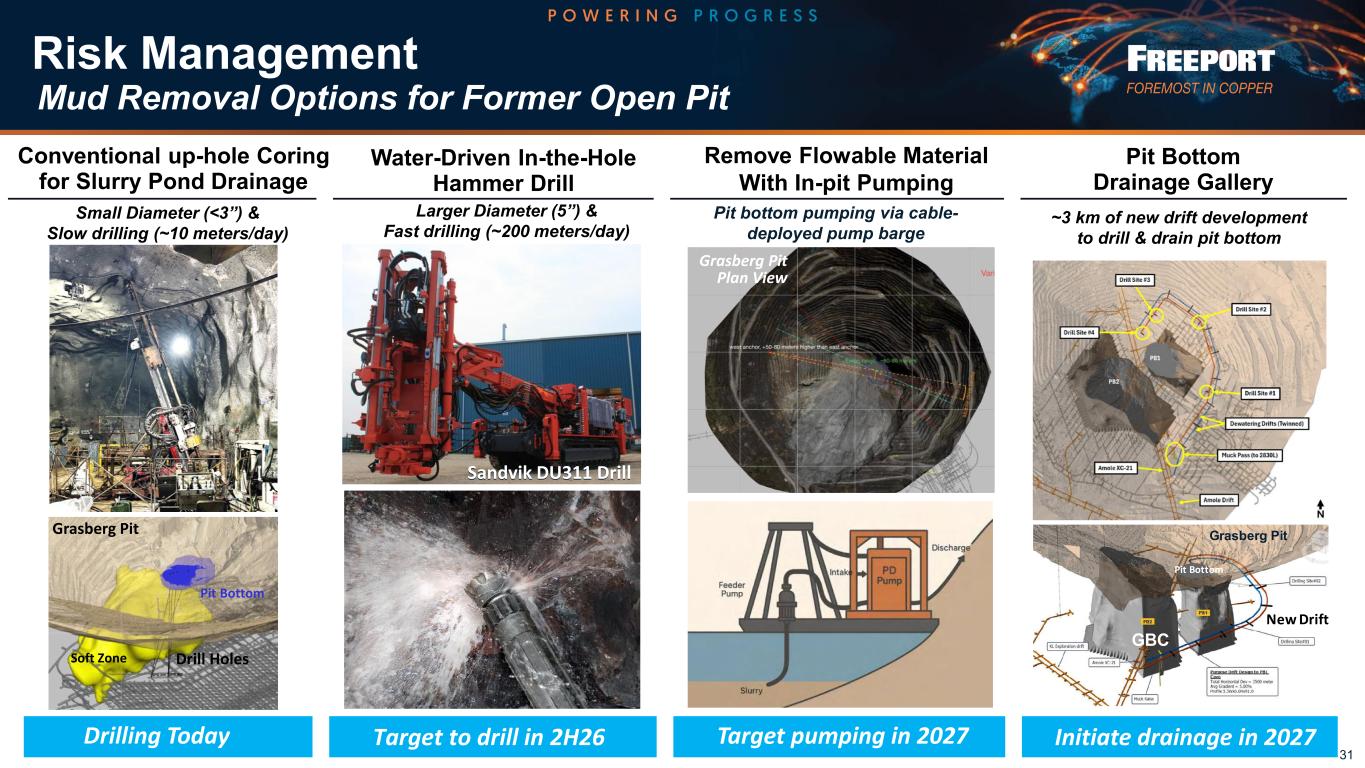

Risk Management Sandvik DU311 Drill Remove Flowable Material With In-pit Pumping Conventional up-hole Coring for Slurry Pond Drainage Soft Zone Grasberg Pit Water-Driven In-the-Hole Hammer Drill Pit Bottom Drill Holes Pit Bottom Drainage Gallery Grasberg Pit Plan View 31 ~3 km of new drift development to drill & drain pit bottom Larger Diameter (5”) & Fast drilling (~200 meters/day) Small Diameter (<3”) & Slow drilling (~10 meters/day) Mud Removal Options for Former Open Pit New Drift Grasberg Pit GBC Pit Bottom Drilling Today Target to drill in 2H26 Target pumping in 2027 Initiate drainage in 2027 Pit bottom pumping via cable- deployed pump barge

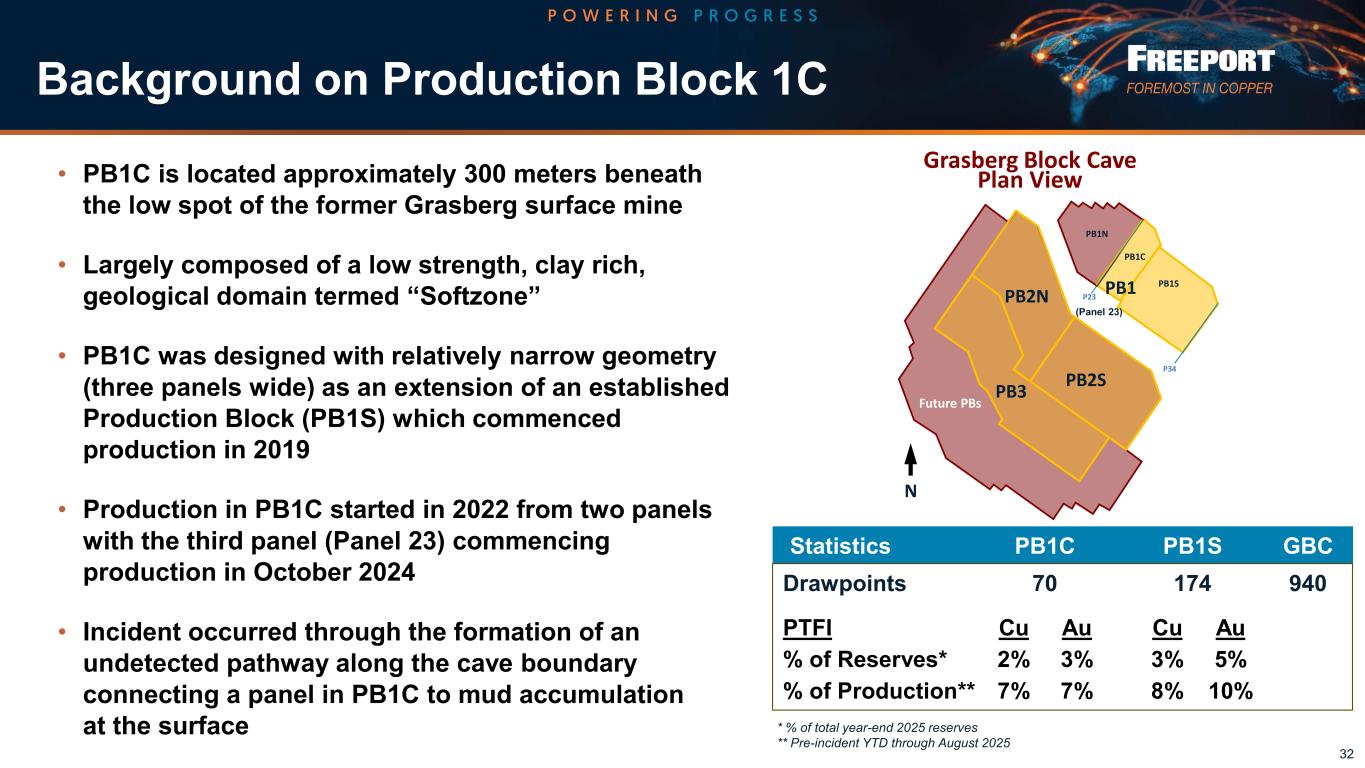

32 Background on Production Block 1C • PB1C is located approximately 300 meters beneath the low spot of the former Grasberg surface mine • Largely composed of a low strength, clay rich, geological domain termed “Softzone” • PB1C was designed with relatively narrow geometry (three panels wide) as an extension of an established Production Block (PB1S) which commenced production in 2019 • Production in PB1C started in 2022 from two panels with the third panel (Panel 23) commencing production in October 2024 • Incident occurred through the formation of an undetected pathway along the cave boundary connecting a panel in PB1C to mud accumulation at the surface * % of total year-end 2025 reserves ** Pre-incident YTD through August 2025 Statistics PB1C PB1S GBC Drawpoints 70 174 940 PTFI Cu Au Cu Au % of Reserves* 2% 3% 3% 5% % of Production** 7% 7% 8% 10% Grasberg Block Cave Plan View Future PBs PB3 PB2N PB2S PB1 PB1N PB1C PB1S P23 P34 N (Panel 23)

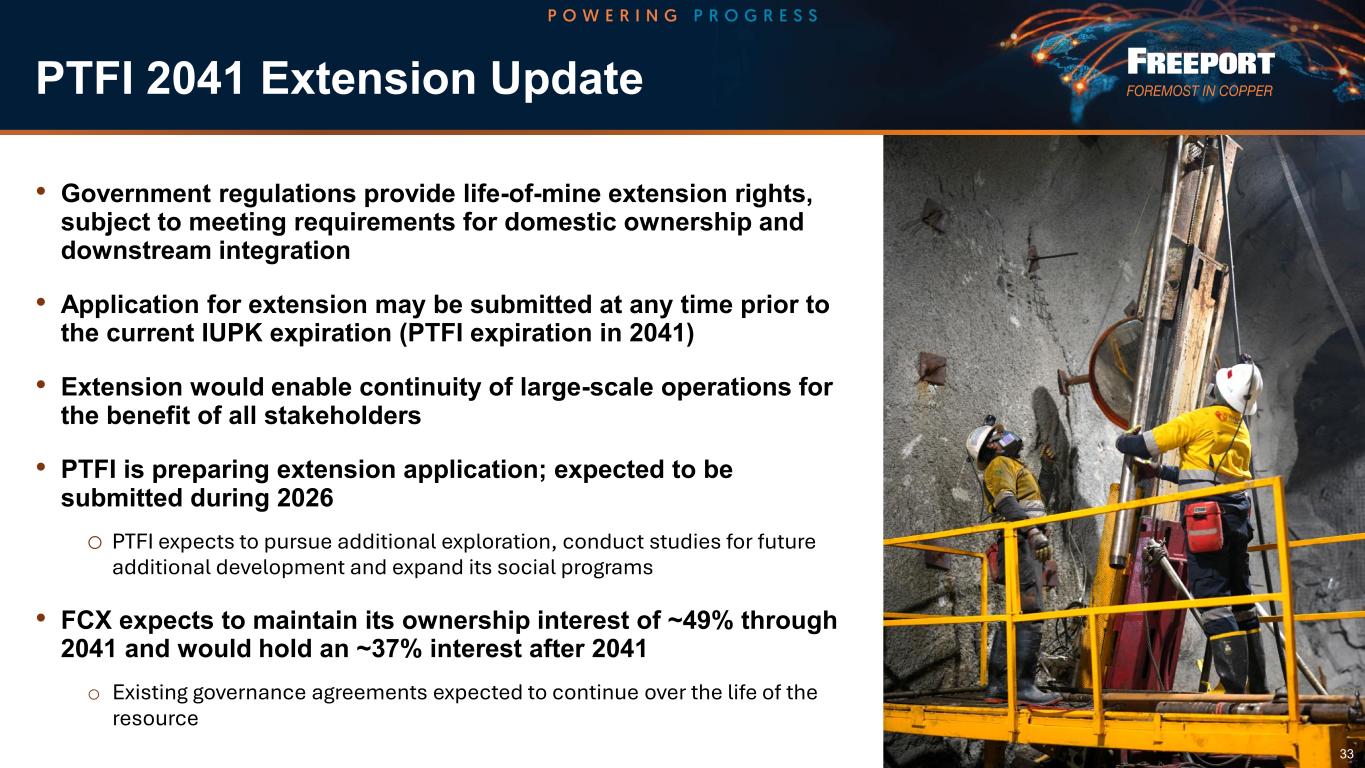

PTFI 2041 Extension Update • Government regulations provide life-of-mine extension rights, subject to meeting requirements for domestic ownership and downstream integration • Application for extension may be submitted at any time prior to the current IUPK expiration (PTFI expiration in 2041) • Extension would enable continuity of large-scale operations for the benefit of all stakeholders • PTFI is preparing extension application; expected to be submitted during 2026 o PTFI expects to pursue additional exploration, conduct studies for future additional development and expand its social programs • FCX expects to maintain its ownership interest of ~49% through 2041 and would hold an ~37% interest after 2041 o Existing governance agreements expected to continue over the life of the resource 33

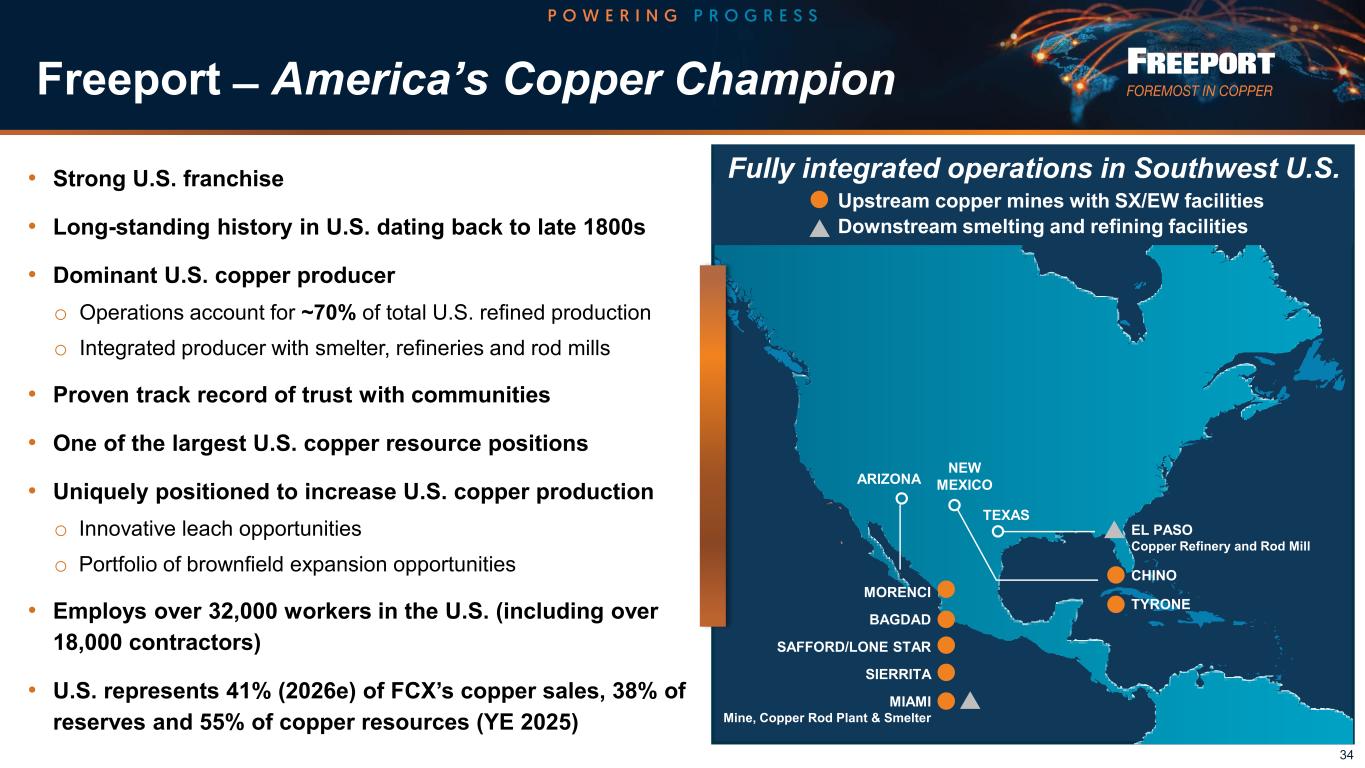

Freeport ̶ America’s Copper Champion 34 • Strong U.S. franchise • Long-standing history in U.S. dating back to late 1800s • Dominant U.S. copper producer o Operations account for ~70% of total U.S. refined production o Integrated producer with smelter, refineries and rod mills • Proven track record of trust with communities • One of the largest U.S. copper resource positions • Uniquely positioned to increase U.S. copper production o Innovative leach opportunities o Portfolio of brownfield expansion opportunities • Employs over 32,000 workers in the U.S. (including over 18,000 contractors) • U.S. represents 41% (2026e) of FCX’s copper sales, 38% of reserves and 55% of copper resources (YE 2025) Upstream copper mines with SX/EW facilities Downstream smelting and refining facilities EL PASO Copper Refinery and Rod Mill CHINO TYRONE MORENCI BAGDAD SAFFORD/LONE STAR SIERRITA MIAMI Mine, Copper Rod Plant & Smelter Fully integrated operations in Southwest U.S. ARIZONA NEW MEXICO TEXAS

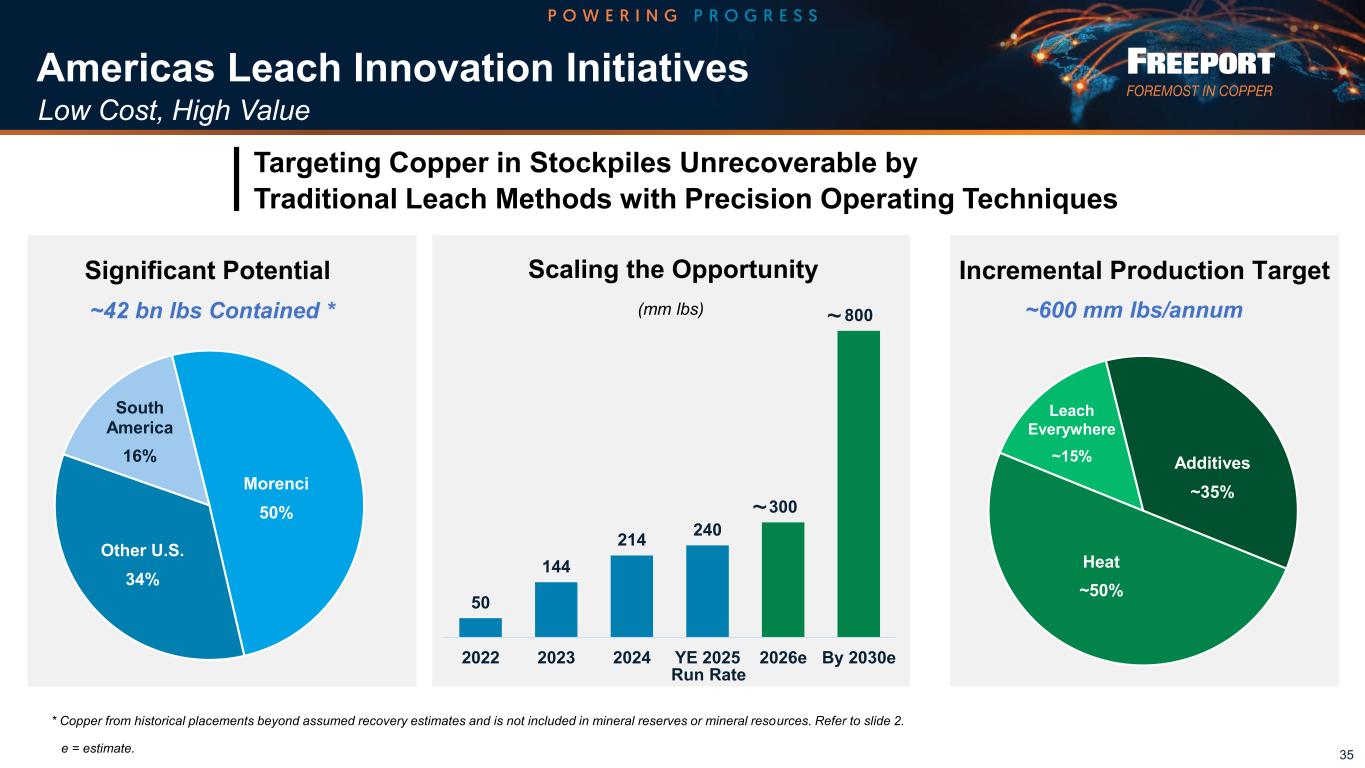

Americas Leach Innovation Initiatives Low Cost, High Value 35 * Copper from historical placements beyond assumed recovery estimates and is not included in mineral reserves or mineral resources. Refer to slide 2. South America 16% Other U.S. 34% Morenci 50% Significant Potential ~42 bn lbs Contained * Leach Everywhere ~15% Heat ~50% Additives ~35% ~600 mm lbs/annum Incremental Production Target | Targeting Copper in Stockpiles Unrecoverable by Traditional Leach Methods with Precision Operating Techniques 50 144 214 240 300 800 2022 2023 2024 YE 2025 2026e By 2030e Scaling the Opportunity (mm lbs) ~ ~ e = estimate. Run Rate

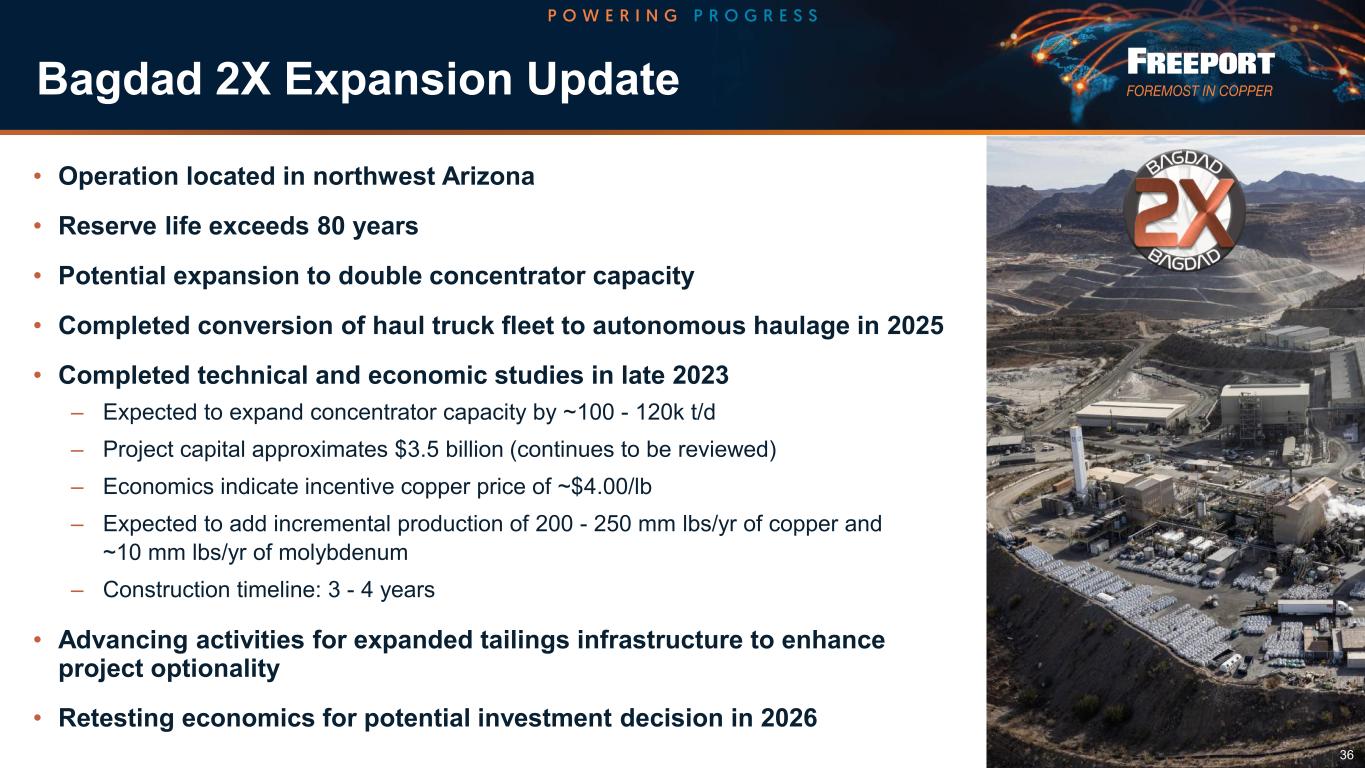

Bagdad 2X Expansion Update 36 • Operation located in northwest Arizona • Reserve life exceeds 80 years • Potential expansion to double concentrator capacity • Completed conversion of haul truck fleet to autonomous haulage in 2025 • Completed technical and economic studies in late 2023 – Expected to expand concentrator capacity by ~100 - 120k t/d – Project capital approximates $3.5 billion (continues to be reviewed) – Economics indicate incentive copper price of ~$4.00/lb – Expected to add incremental production of 200 - 250 mm lbs/yr of copper and ~10 mm lbs/yr of molybdenum – Construction timeline: 3 - 4 years • Advancing activities for expanded tailings infrastructure to enhance project optionality • Retesting economics for potential investment decision in 2026

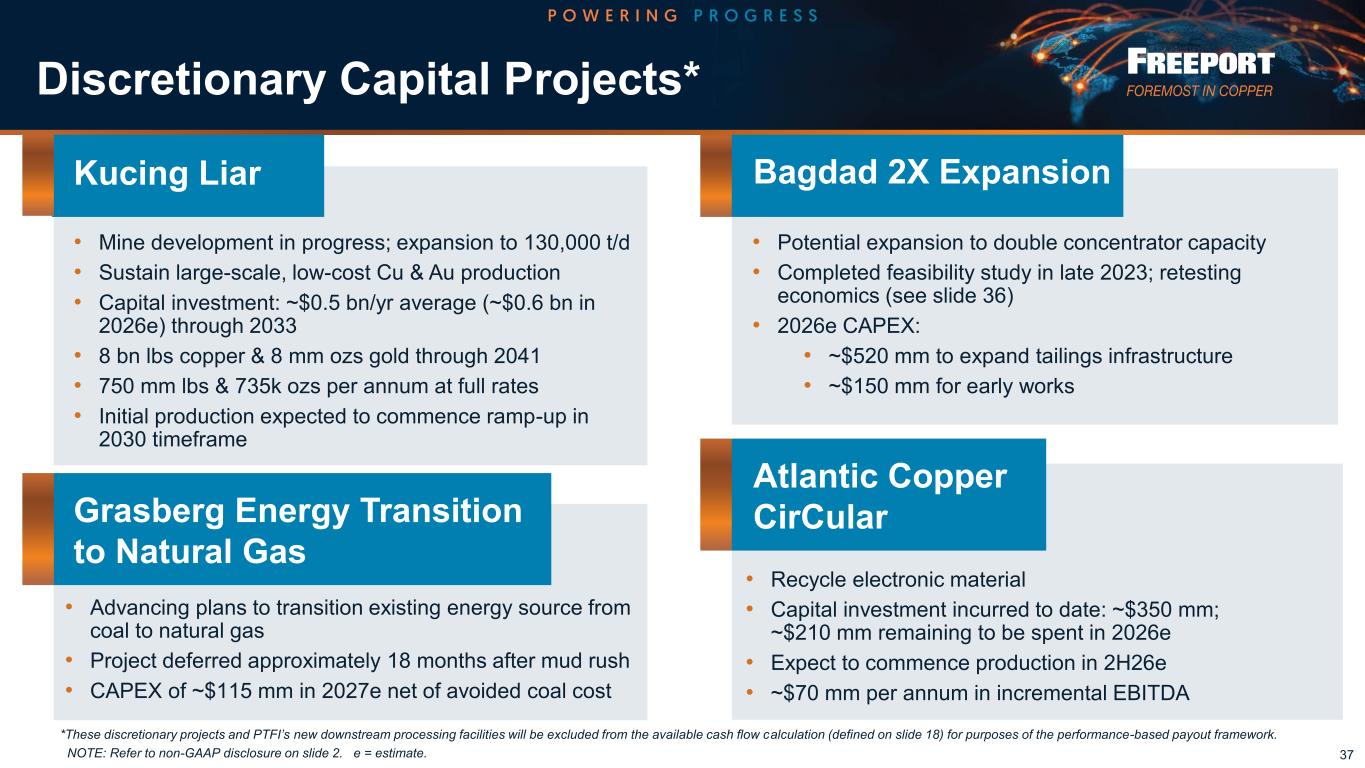

Discretionary Capital Projects* 37 • Mine development in progress; expansion to 130,000 t/d • Sustain large-scale, low-cost Cu & Au production • Capital investment: ~$0.5 bn/yr average (~$0.6 bn in 2026e) through 2033 • 8 bn lbs copper & 8 mm ozs gold through 2041 • 750 mm lbs & 735k ozs per annum at full rates • Initial production expected to commence ramp-up in 2030 timeframe • Recycle electronic material • Capital investment incurred to date: ~$350 mm; ~$210 mm remaining to be spent in 2026e • Expect to commence production in 2H26e • ~$70 mm per annum in incremental EBITDA *These discretionary projects and PTFI’s new downstream processing facilities will be excluded from the available cash flow calculation (defined on slide 18) for purposes of the performance-based payout framework. NOTE: Refer to non-GAAP disclosure on slide 2. e = estimate. • Potential expansion to double concentrator capacity • Completed feasibility study in late 2023; retesting economics (see slide 36) • 2026e CAPEX: • ~$520 mm to expand tailings infrastructure • ~$150 mm for early works Bagdad 2X Expansion • Advancing plans to transition existing energy source from coal to natural gas • Project deferred approximately 18 months after mud rush • CAPEX of ~$115 mm in 2027e net of avoided coal cost Atlantic Copper CirCular Kucing Liar Grasberg Energy Transition to Natural Gas

The Copper Mark Recognition for Responsible Production • The Copper Mark is an assurance framework developed to demonstrate the copper industry’s responsible production practices • FCX has achieved, and is committed to maintaining, the Copper Mark and Molybdenum Mark at all operating sites globally, as applicable • Producers participating in the Copper Mark and Molybdenum Mark are committed to adhering to internationally recognized responsible operating practices; the framework currently includes 33 issue areas across 5 ESG categories • Requires third-party assurance of site performance and independent Copper Mark validation every three years • The Copper Mark 2.0 assurance process in progress • The Copper Mark is governed by an independent board including NGO participation and multi-stakeholder advisory council FCX AWARDED SITES Atlantic Copper smelter & refinery (Spain) Bagdad mine (AZ) Cerro Verde mine (Peru) Chino mine (NM) Climax mine (CO) El Abra mine (Chile) El Paso refinery & rod mill (TX) Fort Madison (IA) Henderson mine (CO) Miami smelter, mine & rod mill (AZ) Morenci mine (AZ) PTFI mine (Indonesia) Rotterdam (Netherlands) Safford mine (AZ) Sierrita mine (AZ) Stowmarket (UK) Tyrone mine (NM) Note: FCX’s copper producing sites that produce by-product molybdenum have received both the Copper Mark and the Molybdenum Mark. 38

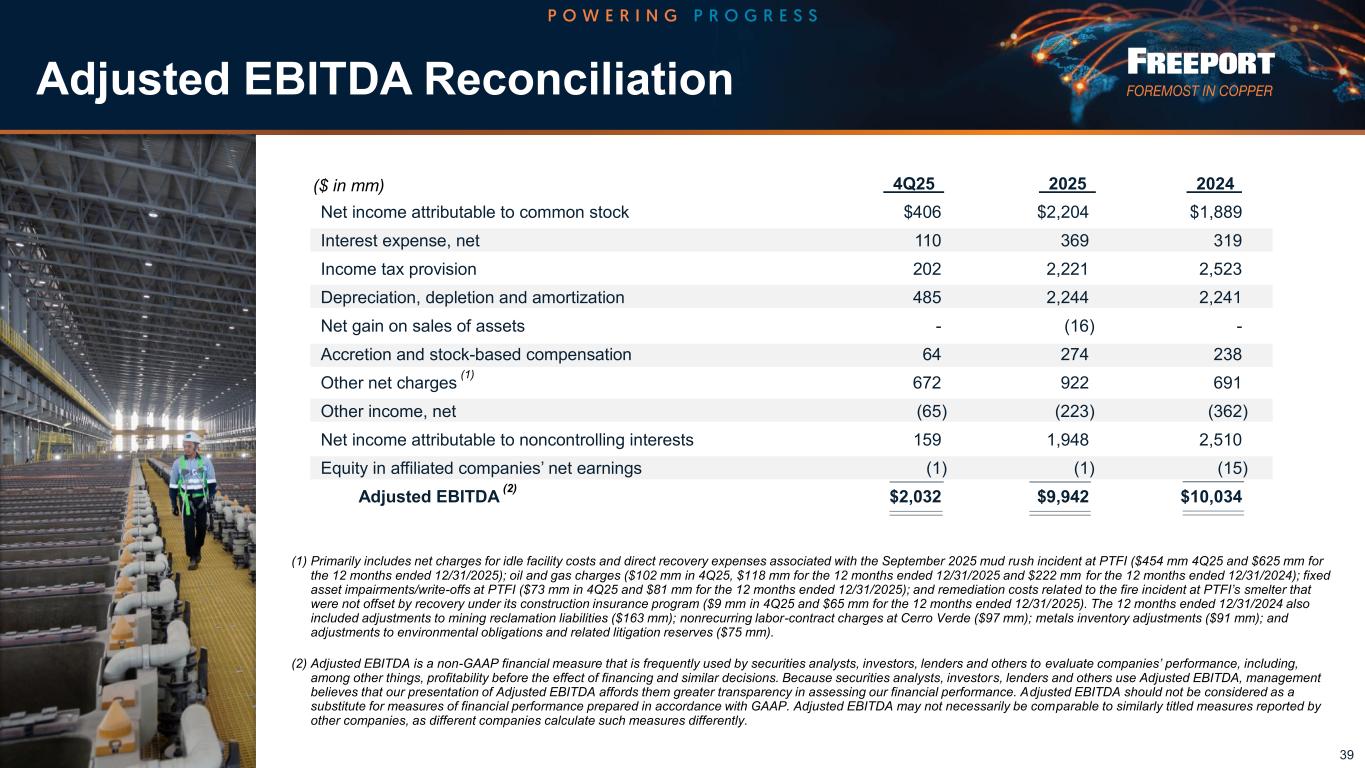

Adjusted EBITDA Reconciliation 39 ($ in mm) 4Q25 2025 2024 Net income attributable to common stock $406 $2,204 $1,889 Interest expense, net 110 369 319 Income tax provision 202 2,221 2,523 Depreciation, depletion and amortization 485 2,244 2,241 Net gain on sales of assets - (16) - Accretion and stock-based compensation 64 274 238 Other net charges (1) 672 922 691 Other income, net (65) (223) (362) Net income attributable to noncontrolling interests 159 1,948 2,510 Equity in affiliated companies’ net earnings (1) (1) (15) Adjusted EBITDA (2) $2,032 $9,942 $10,034 (1) Primarily includes net charges for idle facility costs and direct recovery expenses associated with the September 2025 mud rush incident at PTFI ($454 mm 4Q25 and $625 mm for the 12 months ended 12/31/2025); oil and gas charges ($102 mm in 4Q25, $118 mm for the 12 months ended 12/31/2025 and $222 mm for the 12 months ended 12/31/2024); fixed asset impairments/write-offs at PTFI ($73 mm in 4Q25 and $81 mm for the 12 months ended 12/31/2025); and remediation costs related to the fire incident at PTFI’s smelter that were not offset by recovery under its construction insurance program ($9 mm in 4Q25 and $65 mm for the 12 months ended 12/31/2025). The 12 months ended 12/31/2024 also included adjustments to mining reclamation liabilities ($163 mm); nonrecurring labor-contract charges at Cerro Verde ($97 mm); metals inventory adjustments ($91 mm); and adjustments to environmental obligations and related litigation reserves ($75 mm). (2) Adjusted EBITDA is a non-GAAP financial measure that is frequently used by securities analysts, investors, lenders and others to evaluate companies’ performance, including, among other things, profitability before the effect of financing and similar decisions. Because securities analysts, investors, lenders and others use Adjusted EBITDA, management believes that our presentation of Adjusted EBITDA affords them greater transparency in assessing our financial performance. Adjusted EBITDA should not be considered as a substitute for measures of financial performance prepared in accordance with GAAP. Adjusted EBITDA may not necessarily be comparable to similarly titled measures reported by other companies, as different companies calculate such measures differently.

40