S-K 1300 Technical Report Summary Wodgina Operation, Western Australia Albemarle Corporation 4250 Congress St, Suite 900, Charlotte, NC, 28209 Prepared by: SLR USA Advisory Inc. 1658 Cole Blvd, Suite 100, Lakewood, Colorado, 80401 SLR Project No.: 000.V00720.00RP2 Effective Date: June 30, 2025 Signature Date: February 11, 2026 Revision: 0 Exhibit 96.2 Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 i Table of Contents Table of Contents ....................................................................................................................... i 1.0 Executive Summary ...................................................................................................1-1 1.1 Summary ......................................................................................................................1-1 1.2 Report Scope ...............................................................................................................1-1 1.3 Property Description and Location ................................................................................1-2 1.4 Geology and Mineralization ..........................................................................................1-2 1.5 Exploration Status ........................................................................................................1-3 1.6 Development and Operations .......................................................................................1-3 1.7 Mineral Resources and Mineral Reserves ....................................................................1-5 1.8 Market Studies .............................................................................................................1-8 1.9 Environmental, Permitting, and Social Considerations ..................................................1-9 1.10 Economic Evaluation .................................................................................................. 1-10 1.11 Conclusions ................................................................................................................ 1-11 1.12 Recommendations...................................................................................................... 1-12 1.13 Key Risks ................................................................................................................... 1-13 2.0 Introduction ................................................................................................................2-1 2.1 Report Scope ...............................................................................................................2-1 2.2 Site Visits .....................................................................................................................2-1 2.3 Sources of Information .................................................................................................2-2 2.4 Forward-Looking Statements ........................................................................................2-2 2.5 List of Abbreviations .....................................................................................................2-3 2.6 Independence ...............................................................................................................2-8 2.7 Inherent Mining Risks ...................................................................................................2-9 3.0 Property Description ..................................................................................................3-1 3.1 Location ........................................................................................................................3-1 3.2 Land Tenure .................................................................................................................3-4 3.3 Surface Rights and Easement ......................................................................................3-9 3.4 Material Government Consents ....................................................................................3-9 3.5 Significant Limiting Factors and Encumbrances ......................................................... 3-10 3.6 Royalties .................................................................................................................... 3-10 3.7 Required Permits and Status ...................................................................................... 3-10 3.8 Other Significant Factors and Risks ............................................................................ 3-10 4.0 Accessibility, Climate, Local Resources, Infrastructure and Physiography ..........4-1 Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 ii 4.1 Accessibility ..................................................................................................................4-1 4.2 Climate .........................................................................................................................4-1 4.3 Local Resources ...........................................................................................................4-1 4.4 Infrastructure ................................................................................................................4-2 4.5 Physiography ................................................................................................................4-3 5.0 History .........................................................................................................................5-1 5.1 Exploration and Development History ...........................................................................5-1 5.2 Past Production ............................................................................................................5-3 6.0 Geological Setting, Mineralization, and Deposit ......................................................6-1 6.1 Regional Geology .........................................................................................................6-1 6.2 Local Geology ..............................................................................................................6-1 6.3 Pegmatite Geology .......................................................................................................6-4 6.4 Mineralization ...............................................................................................................6-8 6.5 Deposit Types ..............................................................................................................6-9 7.0 Exploration..................................................................................................................7-1 7.1 Exploration ...................................................................................................................7-1 7.2 Drilling ..........................................................................................................................7-3 7.3 Hydrogeology ...............................................................................................................7-8 7.4 Geotechnical Data, Testing, and Analysis .................................................................. 7-10 8.0 Sample Preparation, Analyses, and Security ...........................................................8-1 8.1 Density Determinations ................................................................................................8-1 8.2 Analytical and Test Laboratories...................................................................................8-2 8.3 Sample Preparation and Analysis .................................................................................8-2 8.4 Sample Security ...........................................................................................................8-3 8.5 Quality Assurance and Quality Control .........................................................................8-4 9.0 Data Verification .........................................................................................................9-1 10.0 Mineral Processing and Metallurgical Testing ....................................................... 10-1 10.1 Mineralogy .................................................................................................................. 10-1 10.2 Metallurgical Test Work .............................................................................................. 10-2 10.3 LOM Plan ................................................................................................................... 10-4 11.0 Mineral Resource Estimates .................................................................................... 11-1 11.1 Resource Areas .......................................................................................................... 11-1 11.2 Statement Of Mineral Resources ................................................................................ 11-2 11.3 Initial Assessment ...................................................................................................... 11-4 Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 iii 11.4 Resource Database .................................................................................................... 11-5 11.5 Geological Interpretation ............................................................................................ 11-6 11.6 Resource Assays ..................................................................................................... 11-11 11.7 Block Model .............................................................................................................. 11-20 11.8 Classification ............................................................................................................ 11-27 11.9 Comparison to Previous Mineral Resources Estimates ............................................ 11-30 11.10 Exploration Potential ................................................................................................. 11-31 12.0 Mineral Reserve Estimates ...................................................................................... 12-1 12.1 Summary .................................................................................................................... 12-1 12.2 Statement of Mineral Reserves................................................................................... 12-2 12.3 Approach .................................................................................................................... 12-4 12.4 Planning Status .......................................................................................................... 12-4 12.5 Modifying Factors ....................................................................................................... 12-5 12.6 Comparison to Previous Mineral Reserve Estimate .................................................. 12-11 13.0 Mining Methods ........................................................................................................ 13-1 13.1 Mining Method ............................................................................................................ 13-1 13.2 Mine Design ............................................................................................................... 13-1 13.3 Geotechnical Considerations ...................................................................................... 13-1 13.4 Hydrogeological Considerations ................................................................................. 13-4 13.5 Mining Strategy .......................................................................................................... 13-5 13.6 Life of Mine Plan ......................................................................................................... 13-6 13.7 Mining Equipment ..................................................................................................... 13-14 13.8 Equipment Estimate ................................................................................................. 13-14 14.0 Processing and Recovery Methods ........................................................................ 14-1 14.1 Process Description .................................................................................................... 14-1 14.2 Process Plant Design ............................................................................................... 14-10 15.0 Infrastructure ............................................................................................................ 15-1 15.1 Site Access ................................................................................................................ 15-1 15.2 Airport......................................................................................................................... 15-1 15.3 Port ............................................................................................................................ 15-1 15.4 Site Buildings .............................................................................................................. 15-1 15.5 Power Supply ............................................................................................................. 15-3 15.6 Water Supply .............................................................................................................. 15-3 15.7 Tailings Disposal ........................................................................................................ 15-5

Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 iv 15.8 Production Capacities and Schedule .......................................................................... 15-9 16.0 Market Studies .......................................................................................................... 16-1 16.1 Introduction ................................................................................................................ 16-1 16.2 Lithium Demand ......................................................................................................... 16-1 16.3 Lithium Supply ............................................................................................................ 16-5 16.4 Lithium Supply-Demand Balance ................................................................................ 16-7 16.5 Lithium Prices ............................................................................................................. 16-8 16.6 Contracts .................................................................................................................. 16-11 17.0 Environmental Studies, Permitting, and Plans, Negotiations, or Agreements with Local Individuals or Groups ............................................................................ 17-1 17.1 Environmental and Social Studies .............................................................................. 17-1 17.2 Environmental and Social Management ..................................................................... 17-7 17.3 Operation Permitting and Compliance ...................................................................... 17-11 17.4 Mine Closure Requirements ..................................................................................... 17-17 18.0 Capital and Operating Costs ................................................................................... 18-1 18.1 Capital Costs .............................................................................................................. 18-1 18.2 Mine Closure and Rehabilitation ................................................................................. 18-2 18.3 Operating Costs ......................................................................................................... 18-2 18.4 Safeguard Mechanism ................................................................................................ 18-4 19.0 Economic Analysis ................................................................................................... 19-1 19.1 Economic Criteria ....................................................................................................... 19-1 19.2 Cash Flow Analyses ................................................................................................... 19-1 19.3 Sensitivity Analysis ..................................................................................................... 19-5 20.0 Adjacent Properties .................................................................................................. 20-1 21.0 Other Relevant Data and Information ...................................................................... 21-1 22.0 Interpretation and Conclusions ............................................................................... 22-1 22.1 Geology ...................................................................................................................... 22-1 22.2 Mining......................................................................................................................... 22-1 22.3 Mineral Processing ..................................................................................................... 22-2 22.4 Environmental, Social, and Governance ..................................................................... 22-2 23.0 Recommendations ................................................................................................... 23-1 23.1 Geology and Mineral Resources................................................................................. 23-1 23.2 Mining......................................................................................................................... 23-1 23.3 Mineral Processing ..................................................................................................... 23-1 23.4 Environmental, Social, and Governance ..................................................................... 23-2 Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 v 23.5 Tailings Storage ......................................................................................................... 23-2 24.0 References ................................................................................................................ 24-1 25.0 Reliance on Information Provided by the Registrant ............................................. 25-1 25.1 Macroeconomic Trends .............................................................................................. 25-1 25.2 Marketing ................................................................................................................... 25-1 25.3 Legal Matters .............................................................................................................. 25-1 25.4 Environmental Matters ................................................................................................ 25-1 25.5 Stakeholder Accommodations .................................................................................... 25-2 25.6 Governmental Factors ................................................................................................ 25-2 26.0 Date and Signature Page ......................................................................................... 26-1 Tables Table 1-1: LOM Physicals ................................................................................................. 1-4 Table 1-2: Statement of Mineral Resources at June 30, 2025 (Albemarle Share 50%) ..... 1-6 Table 1-3: Statement of Mineral Reserves as at June 30, 2025 (Albemarle Share 50%) .. 1-8 Table 1-4: Summary of Economic Evaluation ................................................................. 1-11 Table 2-1: Site Visit Summary ........................................................................................... 2-2 Table 2-2: List of Abbreviations ......................................................................................... 2-3 Table 3-1: Land Tenure .................................................................................................... 3-7 Table 5-1: Production History ............................................................................................ 5-4 Table 5-2: Production Since Restart in 2022 ..................................................................... 5-5 Table 7-1: Resource Drilling Summary ............................................................................. 7-8 Table 8-1: Density Values for Material Types at Wodgina ................................................. 8-1 Table 8-2: Density Estimates for TSFs .............................................................................. 8-2 Table 8-3: Elements, Units, and Detection Limits for Wodgina Analyses at NAGROM ...... 8-3 Table 8-4: Comparison of CRM Analysis .......................................................................... 8-5 Table 10-1: Mineralogical Documentation Reviewed ........................................................ 10-1 Table 10-2: Geometallurgy – Mineralogy Sample Texture Selection ................................. 10-2 Table 10-3: Metallurgical Test Work Documentation Reviewed ........................................ 10-3 Table 11-1: Statement of Mineral Resources at June 30, 2025 ......................................... 11-3 Table 11-2: Summary Statistics per Domain ................................................................... 11-12 Table 11-3: Variogram Interpretation .............................................................................. 11-16 Table 11-4: Selected Optimal Parameters ...................................................................... 11-17 Table 11-5: Density Values for Material Types at Wodgina ............................................. 11-18 Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 vi Table 11-6: Density Estimates for TSFs .......................................................................... 11-20 Table 11-7: Block Model Parameters .............................................................................. 11-21 Table 11-8: Search Parameters ...................................................................................... 11-21 Table 11-9: Comparison with Previous Mineral Resources Estimates ............................. 11-30 Table 12-1: Statement of Mineral Reserves as at June 30, 2025 ...................................... 12-3 Table 12-2: Pit Limit Optimization Parameters .................................................................. 12-5 Table 12-3: Applied Ore Recovery Factor ......................................................................... 12-9 Table 12-4: Pit Design Parameters ................................................................................... 12-9 Table 12-5: Pit Ramp Parameters ................................................................................... 12-10 Table 12-6: LOM Plant Feed Yield .................................................................................. 12-10 Table 12-7: Reserves Marginal Cut-off Grade Assumptions ........................................... 12-11 Table 12-8: Comparison with Previous Mineral Reserves ............................................... 12-11 Table 13-1: LOM Physicals ............................................................................................... 13-7 Table 13-2: LOM Schedule as at June 30, 2025 ............................................................. 13-12 Table 13-3: Major Earth Moving Fleet ............................................................................. 13-14 Table 13-4: Major Mining Fleet Summary ....................................................................... 13-15 Table 14-1: Process Design Criteria ............................................................................... 14-11 Table 14-2: Mass Balance .............................................................................................. 14-15 Table 14-3: Mechanical Equipment List .......................................................................... 14-16 Table 15-1: Fine Tailings Storage Capacity .................................................................... 15-10 Table 18-1: LOM Capital Cost Estimate ............................................................................ 18-1 Table 18-2: Annual Capital Costs Summary ..................................................................... 18-2 Table 18-3: Annual Operating Costs Summary ................................................................. 18-3 Table 18-4: LOM Average Annual Cost ............................................................................ 18-4 Table 19-1: Annual Discounted Cash flow ........................................................................ 19-2 Table 19-2: Annual Cash flow ........................................................................................... 19-4 Table 19-3: Sensitivities Applied to NPV Sensitivity Analysis ............................................ 19-5 Figures Figure 1-1: Lithium Supply-Demand Balance (000 tonnes LCE) ........................................ 1-9 Figure 3-1: General Location.............................................................................................. 3-2 Figure 3-2: Regional Location Plan .................................................................................... 3-3 Figure 3-3: Site Layout Plan ............................................................................................... 3-6 Figure 4-1: Overview of the Operation ............................................................................... 4-3 Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 vii Figure 6-1: Geological Map of the Wodgina Greenstone Belt Showing Distribution of Pegmatite Fields .............................................................................................. 6-3 Figure 6-2: Simplified Local Geology Map .......................................................................... 6-4 Figure 6-3: Generalized Cross-Section of the Mt Cassiterite and Mt Tinstone Pegmatites . 6-6 Figure 6-4: Stratigraphic Column of the Pegmatite ............................................................. 6-7 Figure 6-5: Upper Contact of the Basal Zone ..................................................................... 6-9 Figure 7-1: Sample Locations for Re-assayed RC Pulp (black) and New Samples (red) from 2016................................................................................................................. 7-2 Figure 7-2: Drill Hole Locations .......................................................................................... 7-7 Figure 7-3: Foliation Controlling Batter Stability in the East Wall ...................................... 7-11 Figure 10-1: Geometallurgical Program – Metallurgical Testing Flowsheet ........................ 10-3 Figure 11-1: Interpreted Lithology Model ............................................................................ 11-7 Figure 11-2: Geological Interpretation of In situ Pegmatites ............................................... 11-8 Figure 11-3: Wireframe Surfaces of TSF Top and Base ................................................... 11-10 Figure 11-4: Log Probability by Depth of Percentage Lithia in Tailings ............................. 11-11 Figure 11-5: Example Variogram of the Basal Pegmatite for Li2O .................................... 11-15 Figure 11-6: TSF Composite Histogram ........................................................................... 11-19 Figure 11-7: TSF Log Probability Plot .............................................................................. 11-19 Figure 11-8: Plan View of Interpreted Fault Zones ........................................................... 11-22 Figure 11-9: Cross Section Comparison of the Drill Holes Vs the Block Model. ............... 11-23 Figure 11-10: Swath Plots for Basal Pegmatites ................................................................ 11-24 Figure 11-11: 2024 Monthly Reconciliation ........................................................................ 11-25 Figure 11-12: Section through the TSF Rock Model at 7,656,500 mN................................ 11-26 Figure 11-13: Classification of the Mineral Resources ....................................................... 11-29 Figure 11-14: Depth Extension Beneath LOM Pit ............................................................... 11-32 Figure 12-1: Whittle Pit Shell Sensitivity ............................................................................. 12-6 Figure 12-2: Optimized Pit Shell Site Layout ...................................................................... 12-7 Figure 13-1: LOM Pit Design Shell and Waste Rock Formation ......................................... 13-3 Figure 13-2: LOM Total Material Movement (ex-pit + tailings rehandle) ............................. 13-8 Figure 13-3: LOM Active Mining Areas ............................................................................... 13-9 Figure 13-4: LOM EWL Dump Sequence ......................................................................... 13-10 Figure 13-5: LOM Stockpile Inventory .............................................................................. 13-11 Figure 14-1: Processing Overview – Block Flow Diagram .................................................. 14-1 Figure 14-2: Process Plant Overview – Aerial Image ......................................................... 14-2 Figure 14-3: Comminution Circuit – Block Flow Diagram ................................................... 14-3

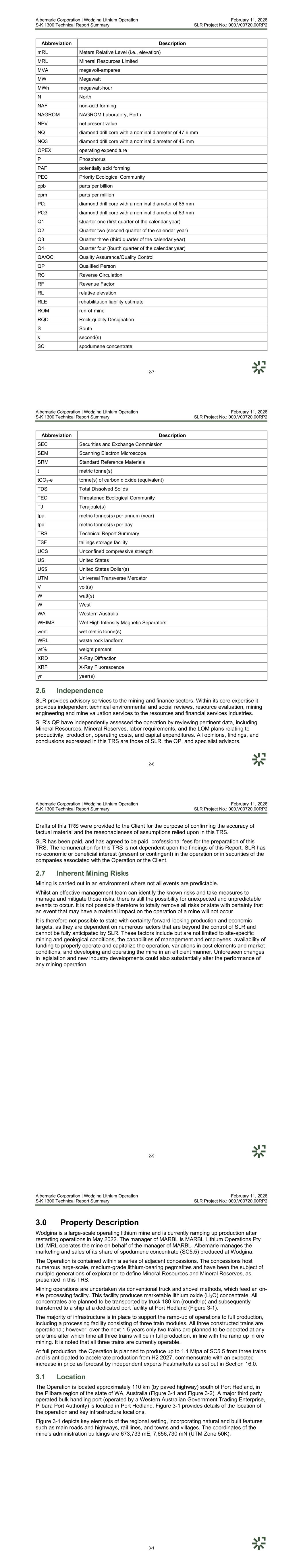

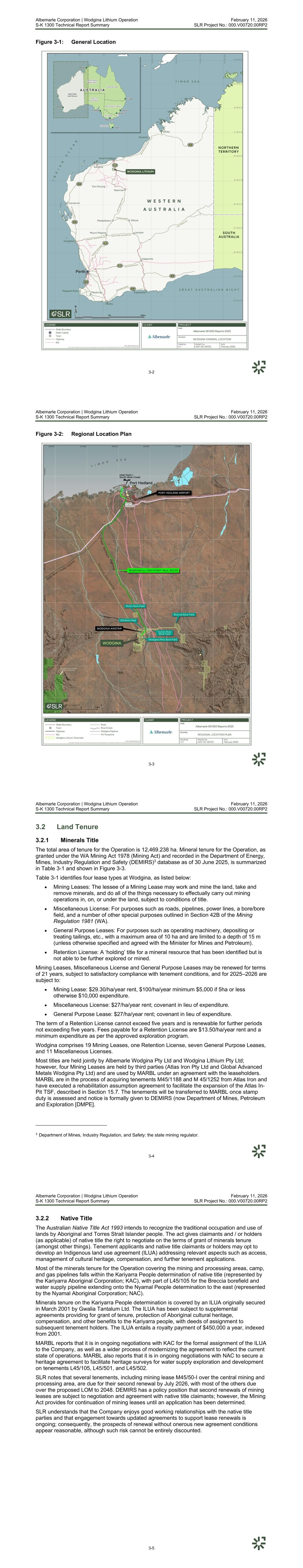

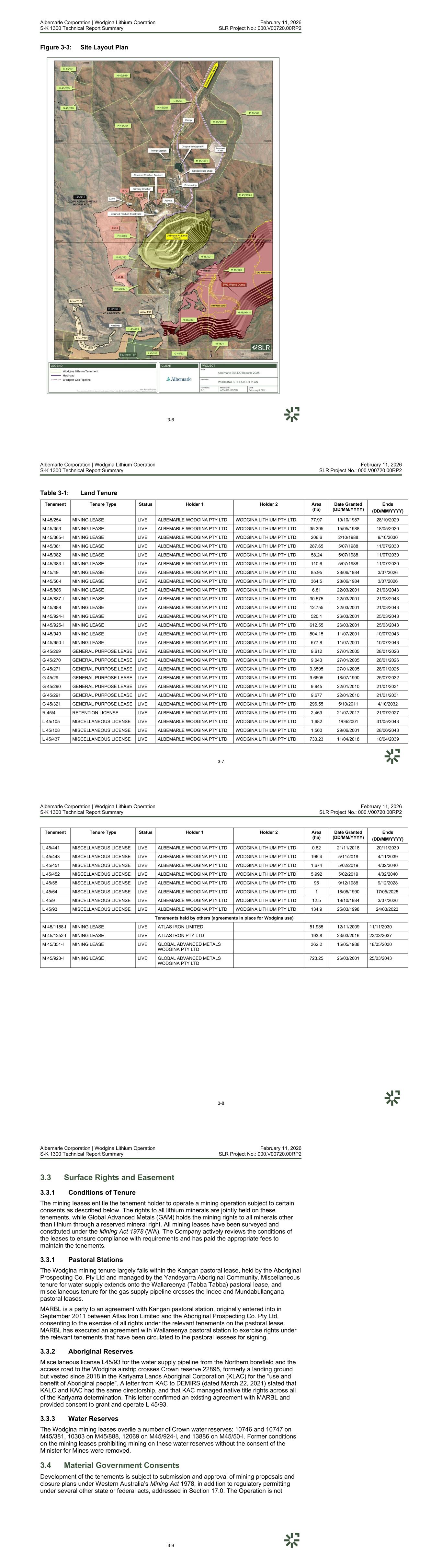

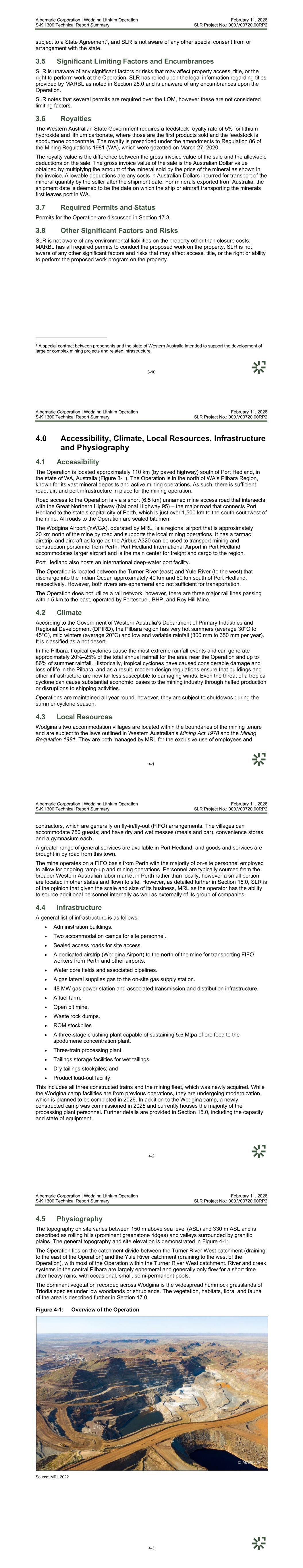

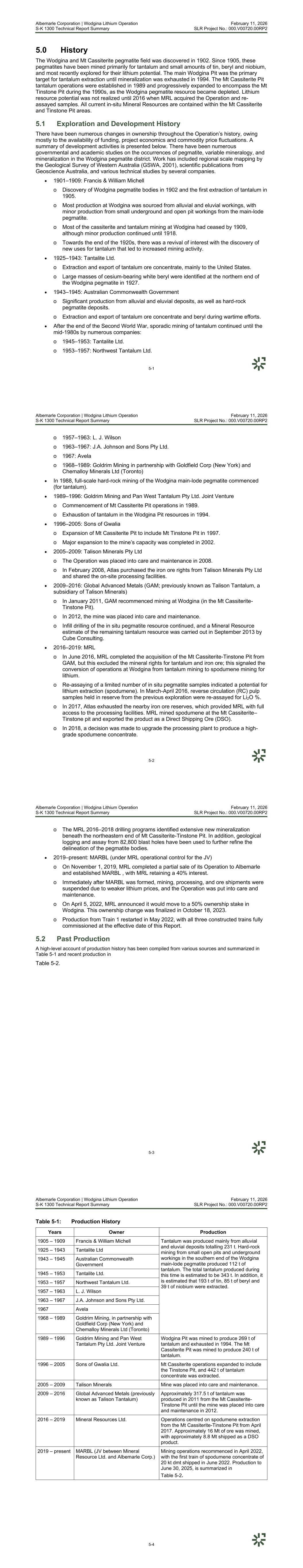

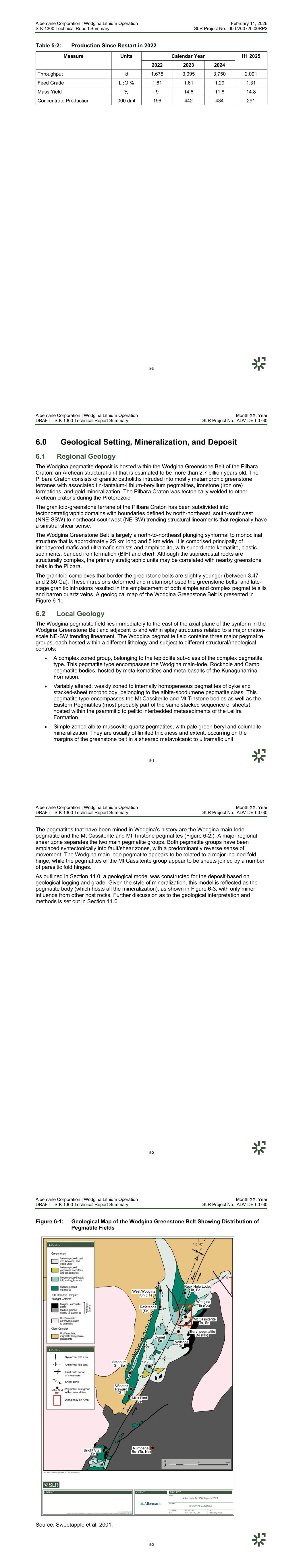

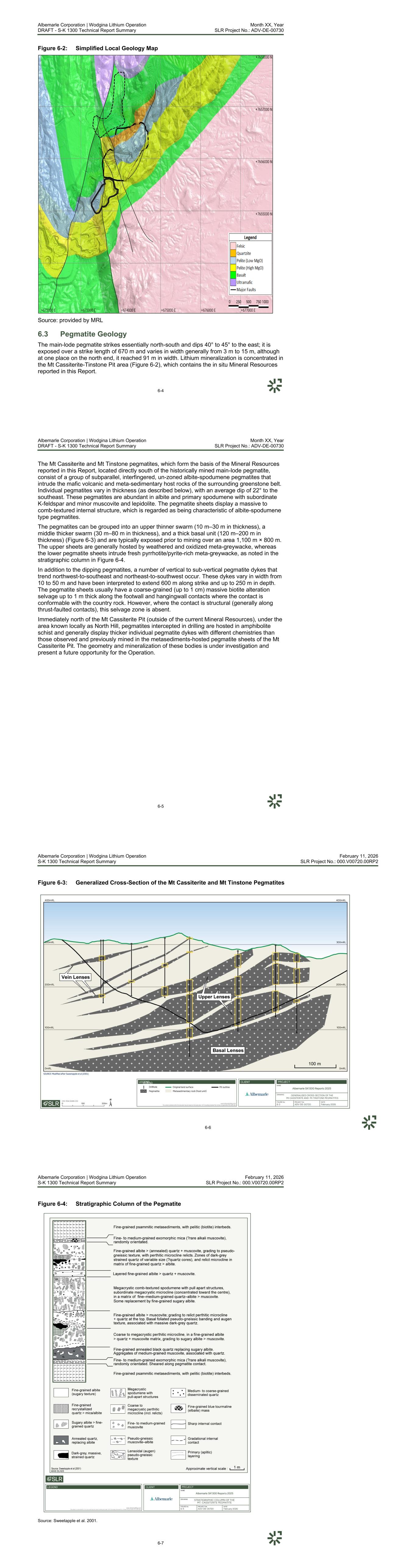

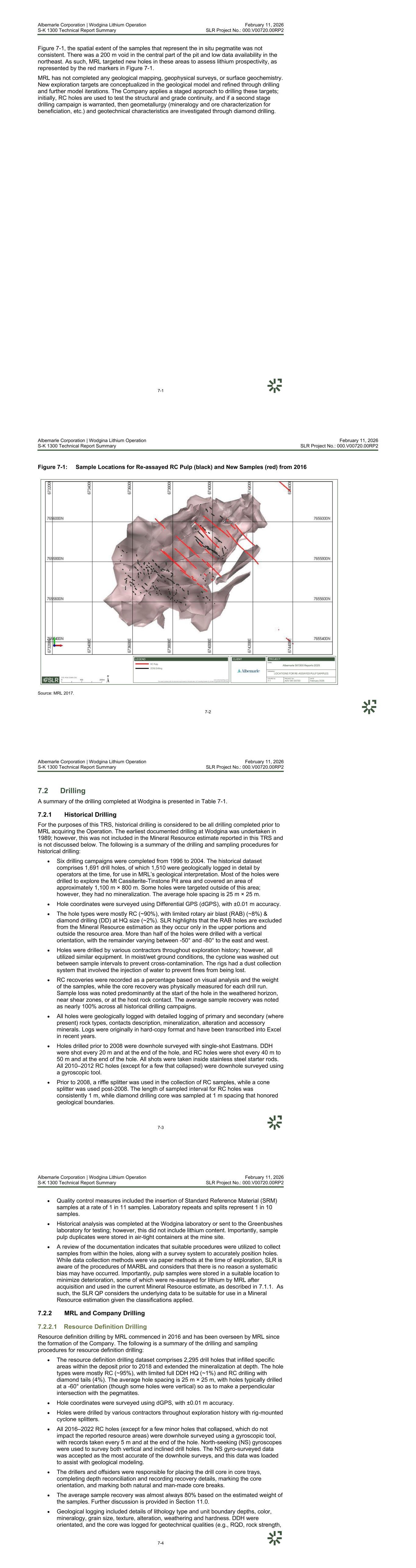

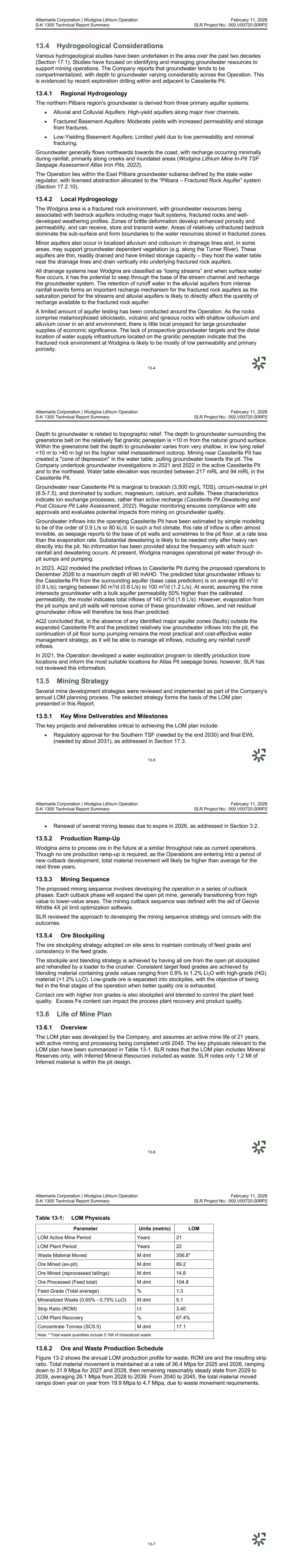

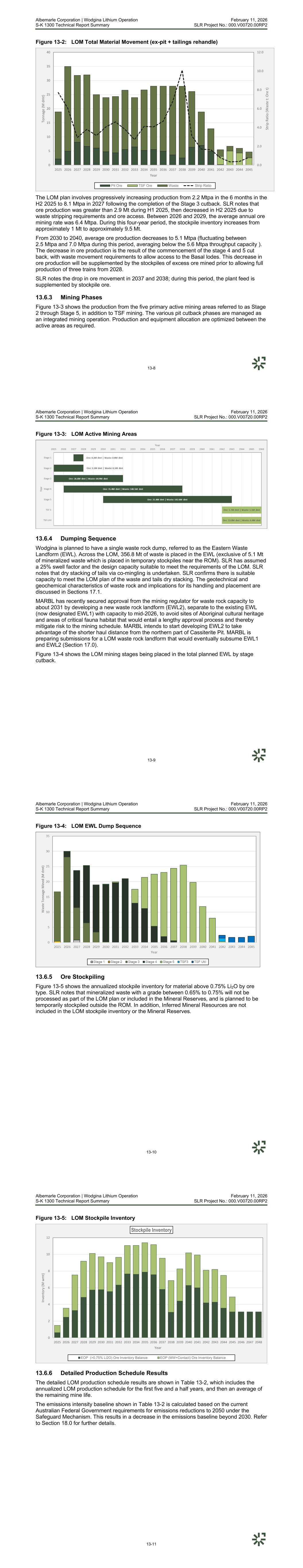

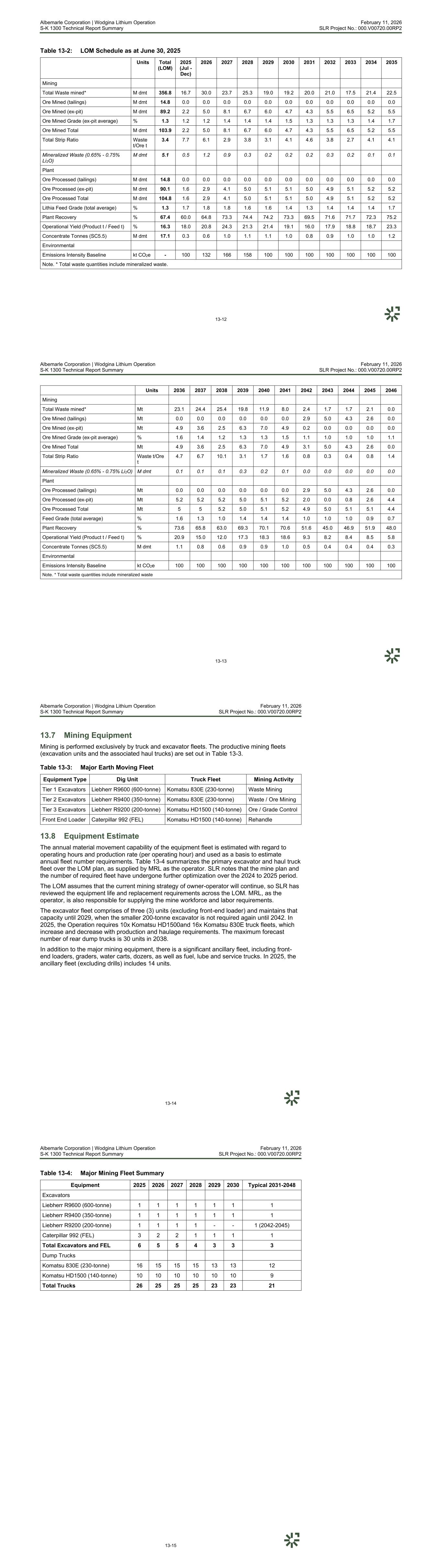

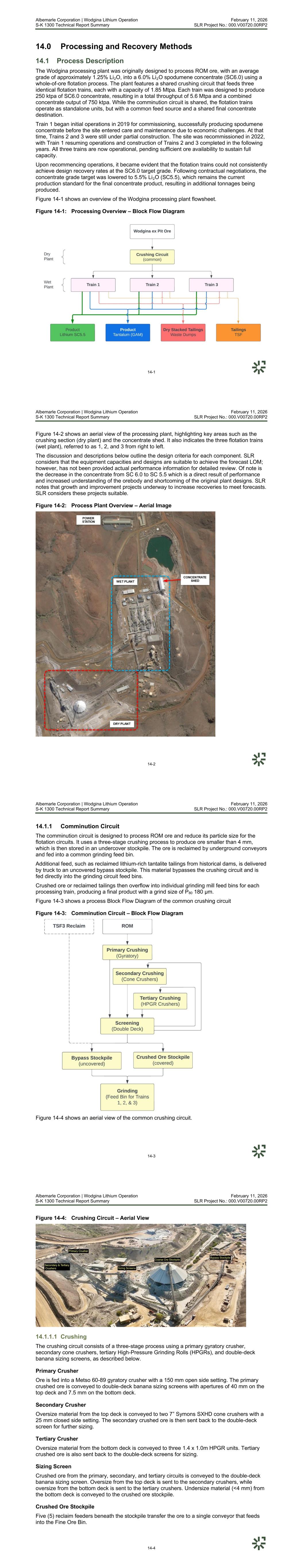

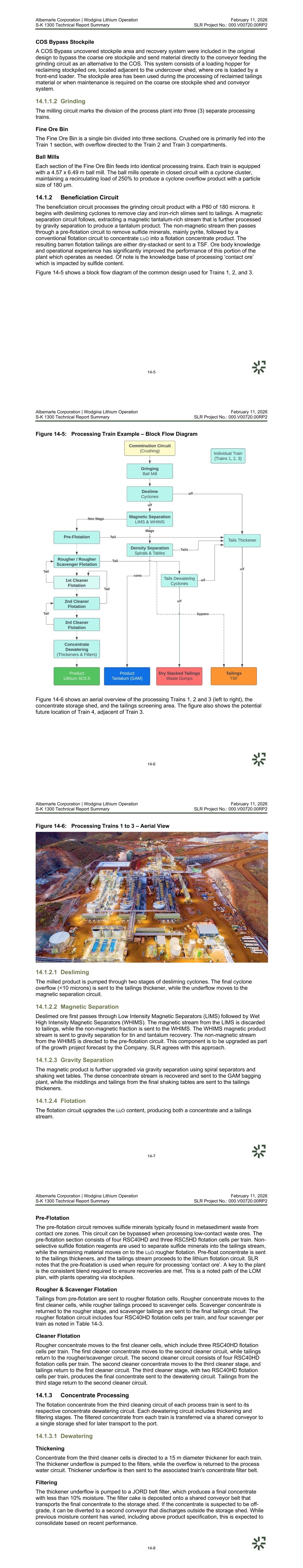

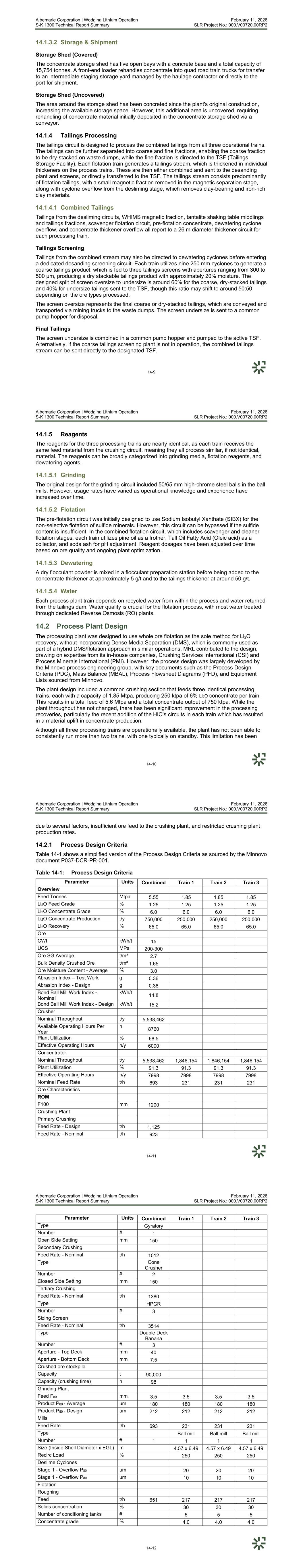

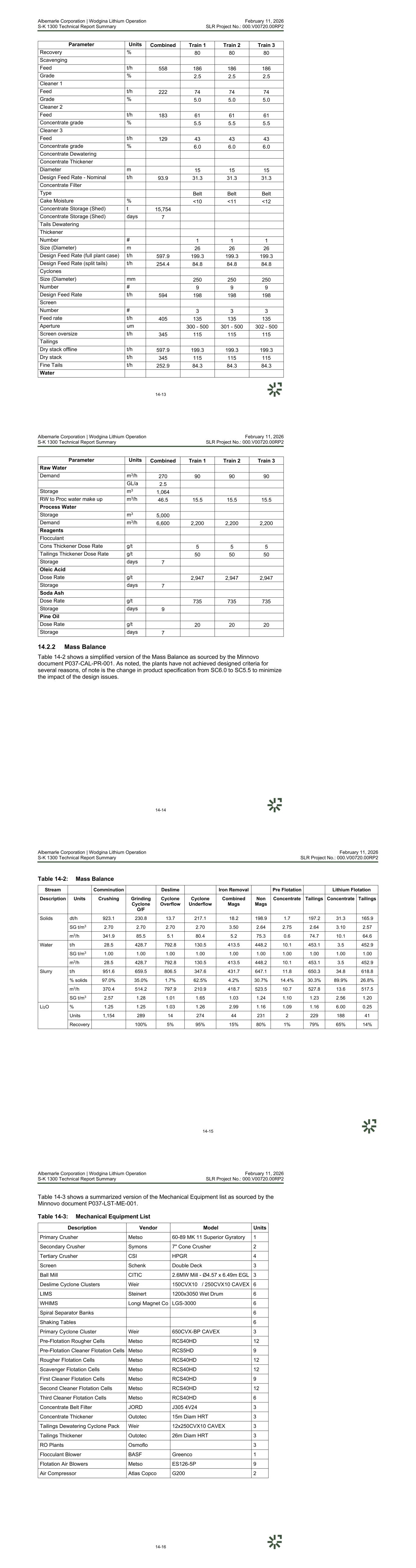

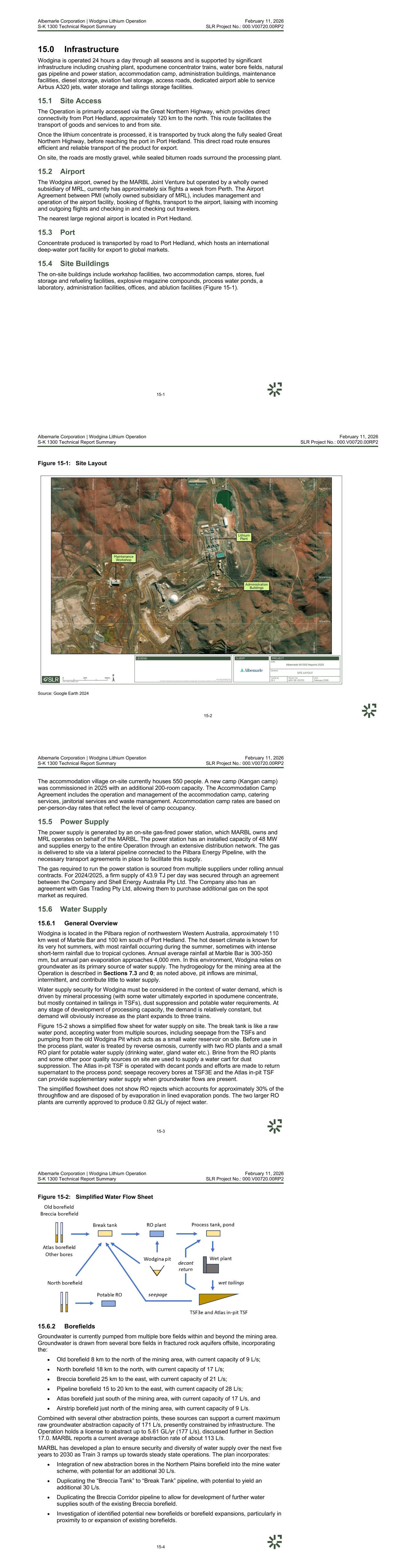

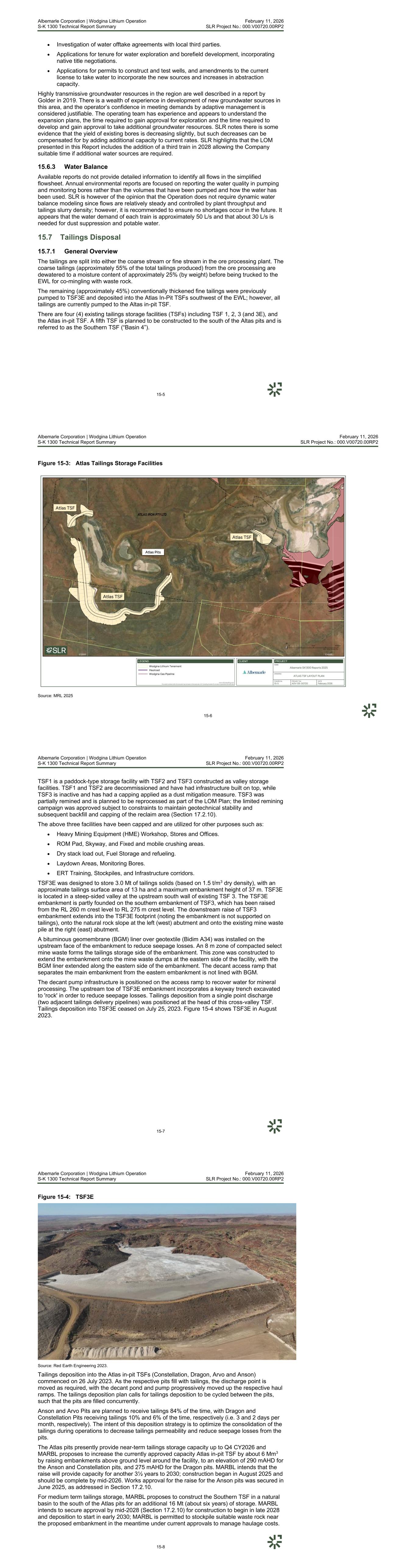

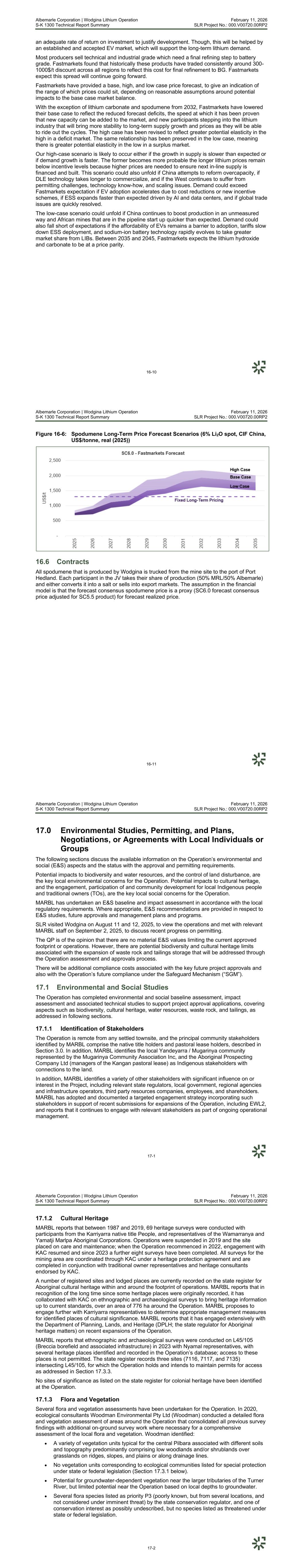

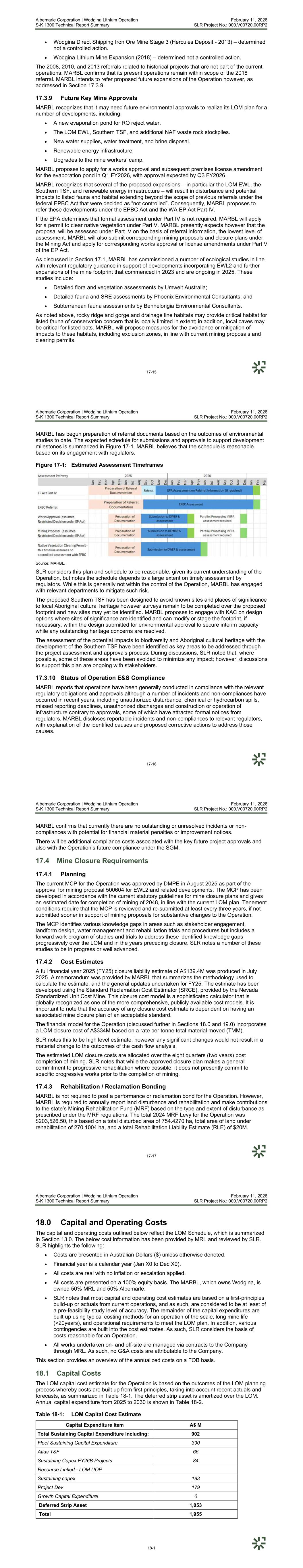

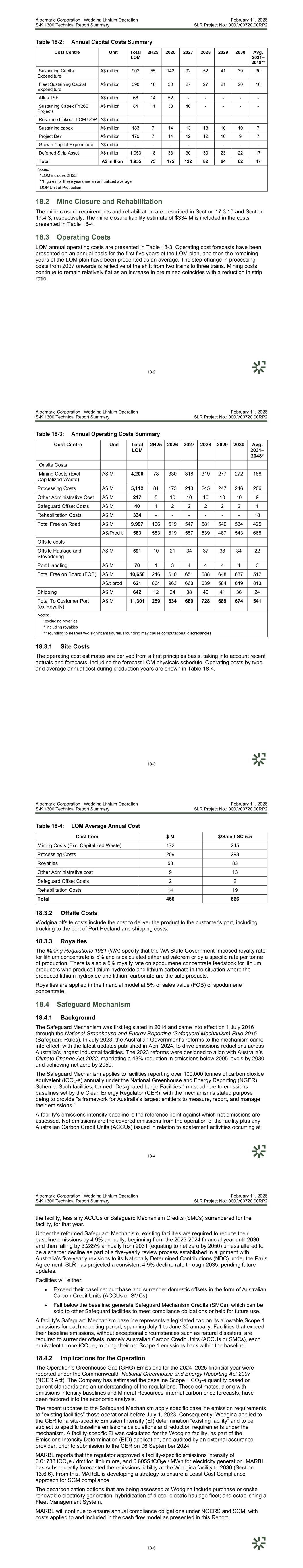

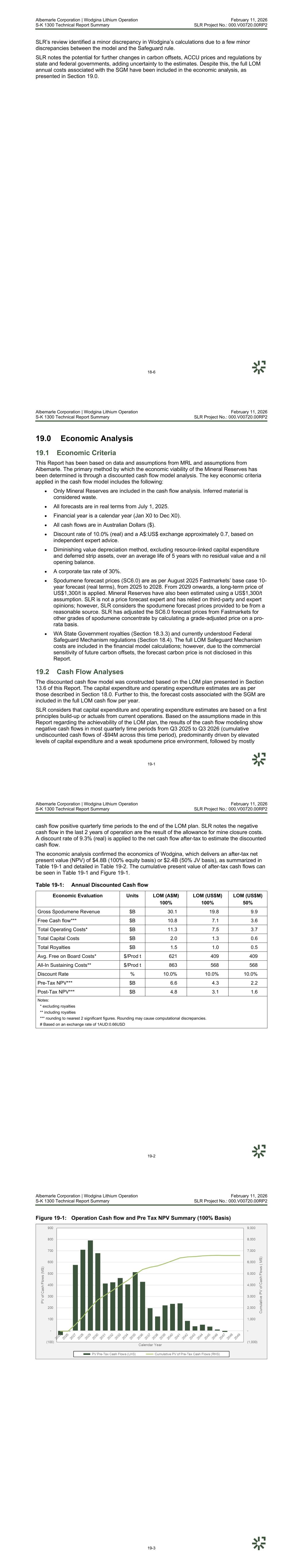

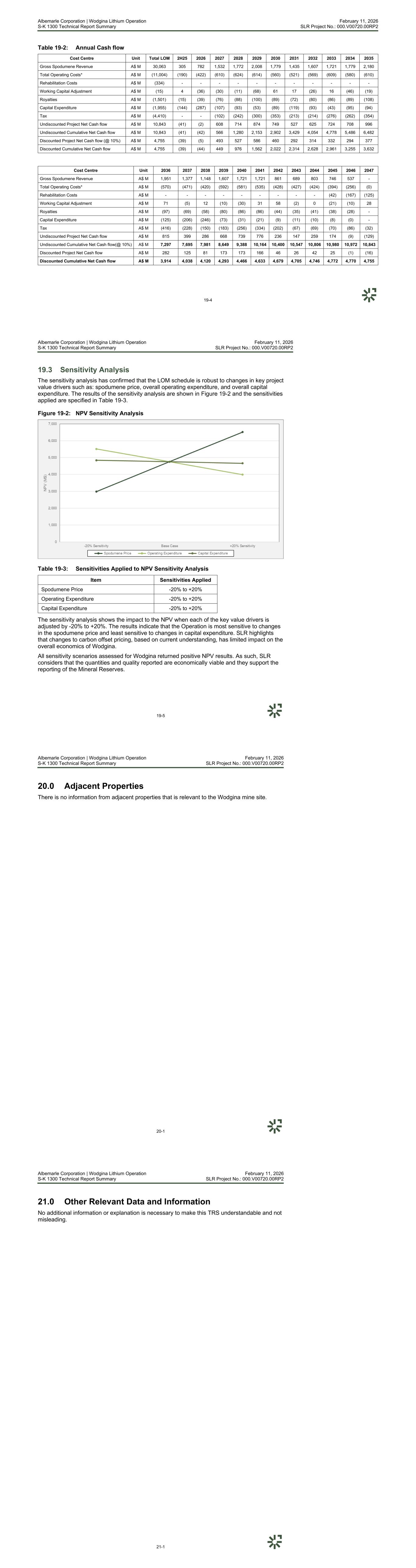

Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 viii Figure 14-4: Crushing Circuit – Aerial View ........................................................................ 14-4 Figure 14-5: Processing Train Example – Block Flow Diagram .......................................... 14-6 Figure 14-6: Processing Trains 1 to 3 – Aerial View ........................................................... 14-7 Figure 15-1: Site Layout ..................................................................................................... 15-2 Figure 15-2: Simplified Water Flow Sheet .......................................................................... 15-4 Figure 15-3: Atlas Tailings Storage Facilities ..................................................................... 15-6 Figure 15-4: TSF3E ........................................................................................................... 15-8 Figure 15-5: Southern Sites 1 and 2 ................................................................................ 15-11 Figure 16-1: Global EV Sales and Penetration Rates (000 vehicles, %) ............................. 16-2 Figure 16-2: Global Lithium Demand in Key Sectors (000 LCE tonnes) ............................. 16-3 Figure 16-3: Forecast Mine Supply (000 tonnes LCE) ........................................................ 16-6 Figure 16-4: Lithium Supply-Demand Balance (000 tonnes LCE) ...................................... 16-8 Figure 16-5: Spodumene Prices (6% lithia, spot, CIF China, US$/tonne) ........................... 16-9 Figure 16-6: Spodumene Long-Term Price Forecast Scenarios (6% Li2O spot, CIF China, US$/tonne, real (2025))................................................................................ 16-11 Figure 17-1: Estimated Assessment Timeframes ............................................................. 17-16 Figure 19-1: Operation Cash flow and Pre Tax NPV Summary (100% Basis) .................... 19-3 Figure 19-2: NPV Sensitivity Analysis ................................................................................ 19-5 Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 1-1 1.0 Executive Summary 1.1 Summary SLR USA Advisory Inc. (SLR), formerly RPMGlobal USA, Inc. (RPM), was retained by Albemarle Corporation (Albemarle or the Client) to prepare an independent Technical Report Summary (TRS) on the Wodgina Lithium Operation (the Operation or Wodgina), located approximately 110 km (by paved highway) south-southeast of Port Hedland, in the Pilbara region of the state of Western Australia (WA), Australia. The purpose of this Report is to provide a Technical Report Summary (TRS or the Report) including an updated Mineral Resource and Mineral Reserves estimate in accordance with the guidelines of Regulation S-K Subpart 1300 (“S-K 1300”). The Operation is owned by an unincorporated Joint Venture between Mineral Resources Limited (MRL) (50%) and Albemarle (50%), known as the MARBL Lithium Joint Venture (MARBL JV, MARBL, or the Company). MRL, through various wholly owned subsidiaries, operates Wodgina on behalf of MARBL including life of mine (LOM) crushing services contracts. Each party individually manages the marketing and sales of its attributable share of spodumene concentrate. SLR’s technical team (the Team) consisted of senior, principal, and executive level Consultants across geology, mining, processing, infrastructure, and environment, health, safety and social (EHSS) with relevant experience in the styles of mineralization, mining method, and regional setting of the Operation. SLR, as the Qualified Person (QP), was responsible for overseeing the compilation of this TRS and the statements of Mineral Resources and Mineral Reserves stated within. Two site visits were conducted by several of the Team members to familiarize themselves with the Operation, as part of the compilation of the TRS, which included the mine site and surface operations. The Team also held several meetings with key operational staff in the areas of geology, mining, reconciliation, processing and EHSS during the undertaking of the TRS. During the site visits and meetings, the Team had open discussions with operational personnel on technical aspects relating to the relevant issues. The personnel were cooperative and open in facilitating SLR’s work. It is highlighted that all costs and cash flow within this TRS are presented in Australian Dollars (A$ or $) (unless otherwise stated), the financial analysis have been detailed and evaluated on a 100% equity basis (compared to Albemarle’s 50%), and no adjustment has been made for inflation (real terms basis). 1.2 Report Scope The purpose of this TRS is to update the Mineral Resources and Mineral Reserves estimates for Wodgina as at June 30, 2025 (the Effective Date), reported to reflect the 50% Albemarle ownership in the relevant holding companies that own the Operation. This TRS conforms to the United States Securities and Exchange Commission’s (SEC) Modernized Property Disclosure Requirements for Mining Registrants as described in Title 17 Subpart 229.1300 of Regulation S- K, Disclosure by Registrants Engaged in Mining Operations (S-K 1300) and Item 601 (b)(96) Technical Report Summary. The TRS was prepared by SLR as a third-party firm in accordance with S-K 1300. References to the QP are references to SLR and not to any individual employed or engaged by SLR. Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 1-2 In addition to work undertaken to generate independent Mineral Resources and Mineral Reserves estimates, the TRS relies largely on information provided by the Company, MRL, or the Client, either directly from the site and other offices or from reports by other organizations whose work is the property of the Company or the Client or its subsidiaries. The data relied upon for the Mineral Resources and Mineral Reserves estimates independently completed by SLR have been compiled primarily by the Client and/or the Company and subsequently reviewed and verified as well as reasonably possible by SLR. The TRS is based on information made available to SLR as of June 30, 2025. Neither the Client nor MRL has advised SLR of any material change, or event likely to cause material change, to the underlying data, designs, or forecasts since the date of asset inspections. It is noted that references to quarterly, half-yearly or annual time periods are based on a calendar year commencing January 1 each year, unless otherwise noted. 1.3 Property Description and Location Wodgina is a large-scale operating lithium mine that is located within a series of adjacent concessions that contain numerous large-scale, medium-grade lithium-bearing pegmatites. The pegmatites have been the subject of multiple generations of exploration to define Mineral Resources and Mineral Reserves, as presented in this TRS. Mining operations are undertaken via conventional truck and shovel methods, which feed an on-site processing facility consisting of three identical train modules. This facility produces a 5.5% lithium oxide (Li2O) concentrate (spodumene concentrate [SC]5.5), which is subsequently transported to a third-party port facility in Port Hedland. MRL, and subsequently the Company, has a history of operating in the Pilbara, acquiring the Operation in 2016 and commencing Direct Shipping Ore (DSO) production and sales in 2017, prior to the establishment of MARBL in 2019. The Operation is currently ramping up production after restarting operations in May 2022. Wodgina has undergone several expansions to its current total nominal processing capacity of 5.6 million tonnes per annum (Mtpa) and is forecast to produce 828 thousand tonnes (kt) of SC5.5 in 2026. Wodgina operates under tenure issued by the State Government of Western Australia and granted under the provisions of the Mining Act 1978. Wodgina has a combined surface extent of approximately 12,469 hectares (ha) with a total of 19 Mining Leases, one Retention License, seven General Purpose Leases, and 11 Miscellaneous License. Most titles are held jointly by Albemarle Wodgina Pty Ltd and Wodgina Lithium Pty Ltd; however, four Mining Leases are held by third parties (Atlas Iron Pty Ltd and Global Advanced Metals Wodgina Pty Ltd) and used by MARBL under an agreement with the lease holders. The Operation is accessible year-round via sealed bitumen roads, and there is sufficient road, air, and port infrastructure in place with sufficient capacity to support the planned mining operations. SLR considers there to be no limitations on mining or exploration at the site due to the climate other than cyclonic events typical for the region. 1.4 Geology and Mineralization The Wodgina pegmatite deposit is hosted within the Wodgina Greenstone Belt of the Pilbara Craton, an Archean structural unit that is estimated to be more than 2.7 billion years old. The Pilbara Craton consists of granitic batholiths intruded into mostly metamorphic greenstone terranes with associated tin-tantalum-lithium-beryllium pegmatites, ironstone (iron ore) formations, and gold mineralization. Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 1-3 The Mt Cassiterite-Tinstone pegmatite sheets of Wodgina Greenstone Belt are mostly zoned, which appears to increase in complexity at depth, with mineralogy dominated by phenocrysts of spodumene (10 cm to 30 cm long) and K-feldspar in a matrix of fine- to medium-grained albite, quartz, and muscovite. Veins of quartz up to 10 cm thick are common, as are 1 mm thick veinlets of green sericite-albite. Some mineralized zoning of the pegmatites has been observed, with higher concentrations of spodumene occurring close to the upper contact, and near- perpendicular alignment of crystals to the pegmatite contact exhibiting distinctive 'pull apart' structures. In the massive basal pegmatite, the spodumene is distributed within fine-grained quartz, feldspar, spodumene, and muscovite matrix. A weak zonation is evident in the development of finer-grained border units and occasionally in areas rich in microcline crystals. However, there is no obvious zoning associated with the minor occurrences of other minerals, including lepidolite, biotite, fluorite, white beryl, and lithium phosphate minerals. 1.5 Exploration Status The Wodgina deposit is well explored and understood with ongoing mining, and exploration drilling programs completing 2,295 holes since drilling commenced in the early 1980s. Exploration has been continuous throughout the life of the operation, with recent exploration focused on the mining areas within and below the LOM pit limits. These exploration programs have gathered geology and geochemical data, with all of this data collected from surface drilling activities. Wodgina’s current and future exploration strategy focuses on increasing the geological confidence within and below the current LOM pit. 1.6 Development and Operations The Operation utilizes conventional open-cut mining techniques optimized for the deposit's geological characteristics, with targeted extraction from the pegmatites. Mining is forecast to be sourced from a single open pit with the final pit design incorporating staged cutbacks to balance cost efficiency, recovery and safety. The mining fleet is expected to remain fully owner-operated. It is managed by MRL and consists of a mixed fleet of backhoe hydraulic excavators and 230-t and 140-t haul trucks. Contractors manage equipment supply, maintenance, replacement, and workforce logistics, and, subsequently, most mining costs are based on unit rates. Wodgina is operated 24 hours per day through all seasons and is supported by infrastructure including a crushing plant, three floatation trains, laboratory, process water ponds, water bore fields, gas fired power station, natural gas pipeline, accommodation villages, administration buildings, maintenance facilities, diesel storage and refueling, aviation fuel storage, access roads, dedicated airport able to service A320 jets, water storage, and tailings storage facilities (TSFs). The Operation features a single crushing circuit that feeds three identical flotation trains with a combined throughput capacity of 5.6 Mtpa that target a SC5.5 concentrate resulting in a >1 Mtpa concentrate capacity. While the comminution circuit is shared, a recently installed crushed ore stacker allows significant improvements in feed blending for the flotation trains, which operate as standalone units with a shared final concentrate destination. This provides the Operation with significant flexibility and the ability to adjust processing throughput as required. Of note a key change to the design flowsheet was the installation of high intensity conditioning (HIC) in each of the three trains.

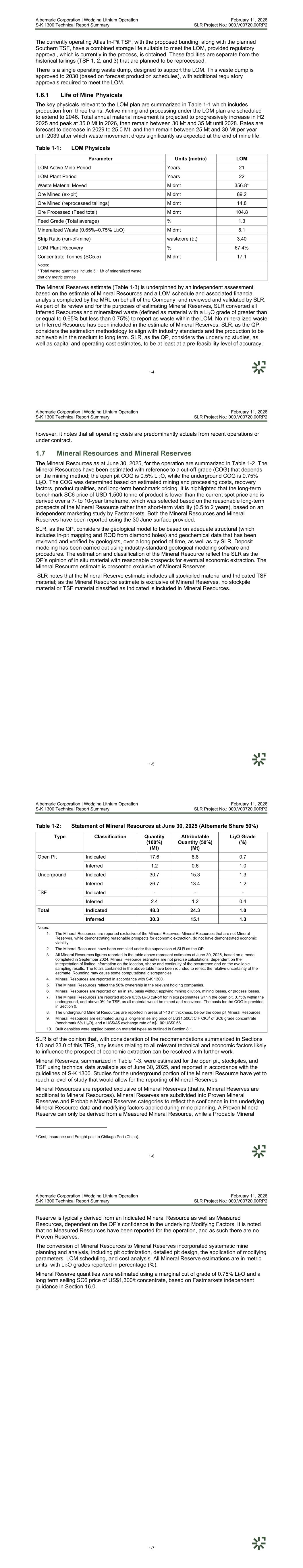

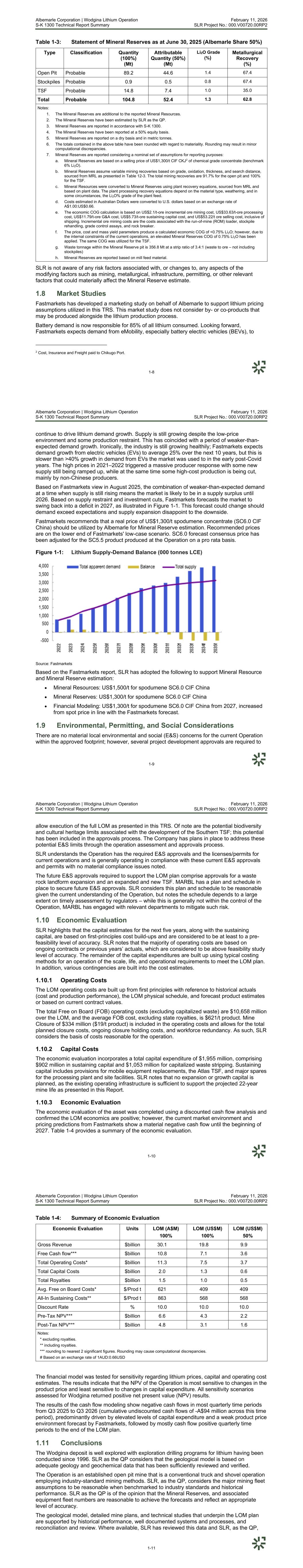

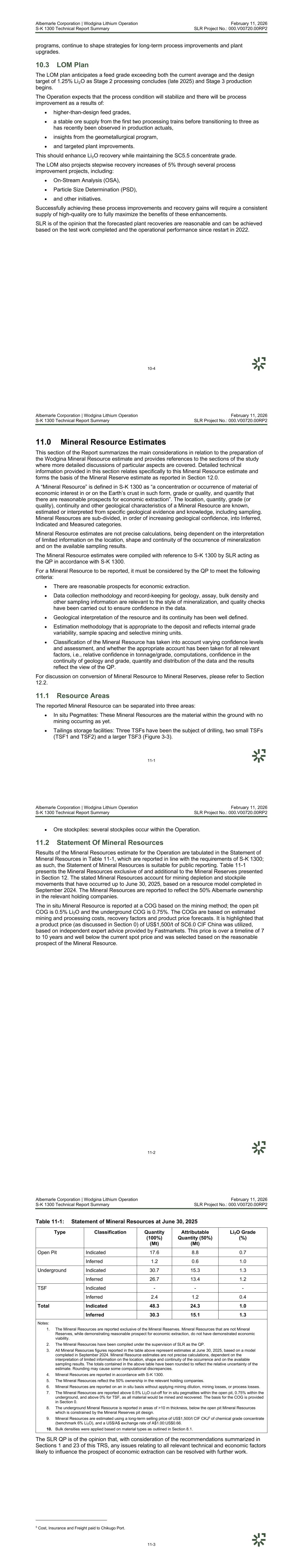

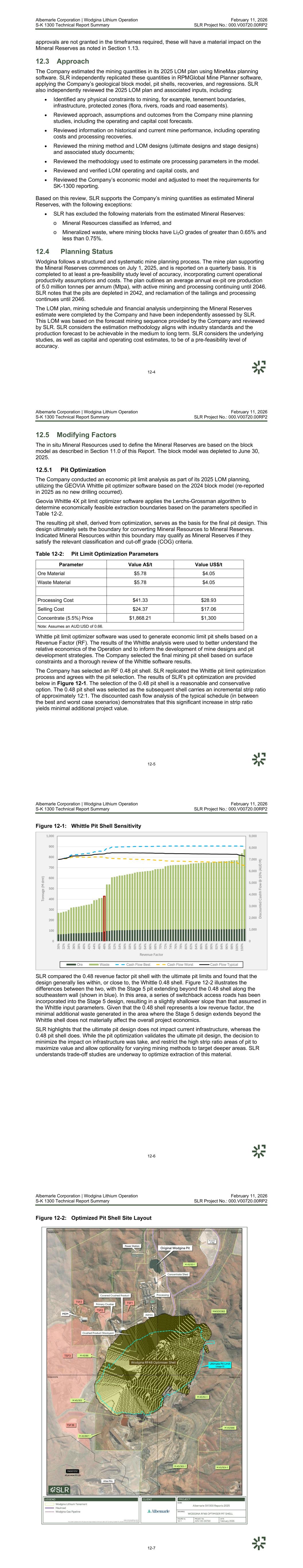

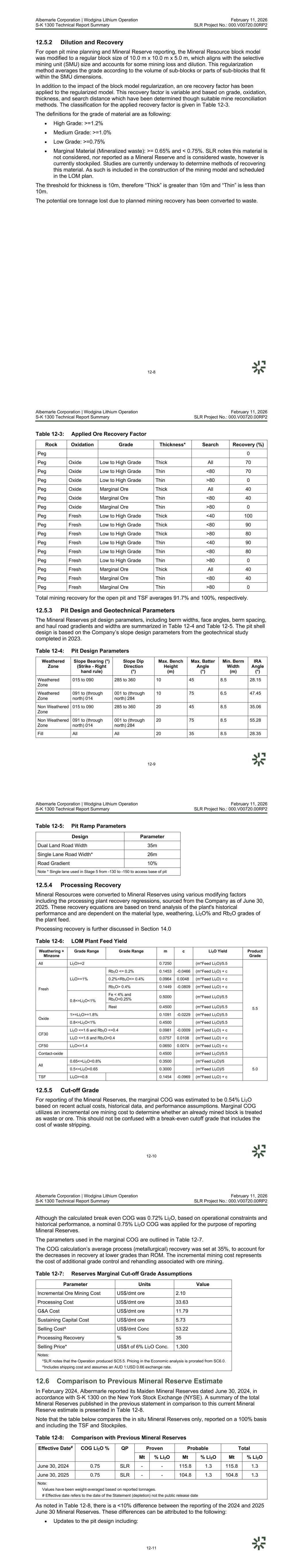

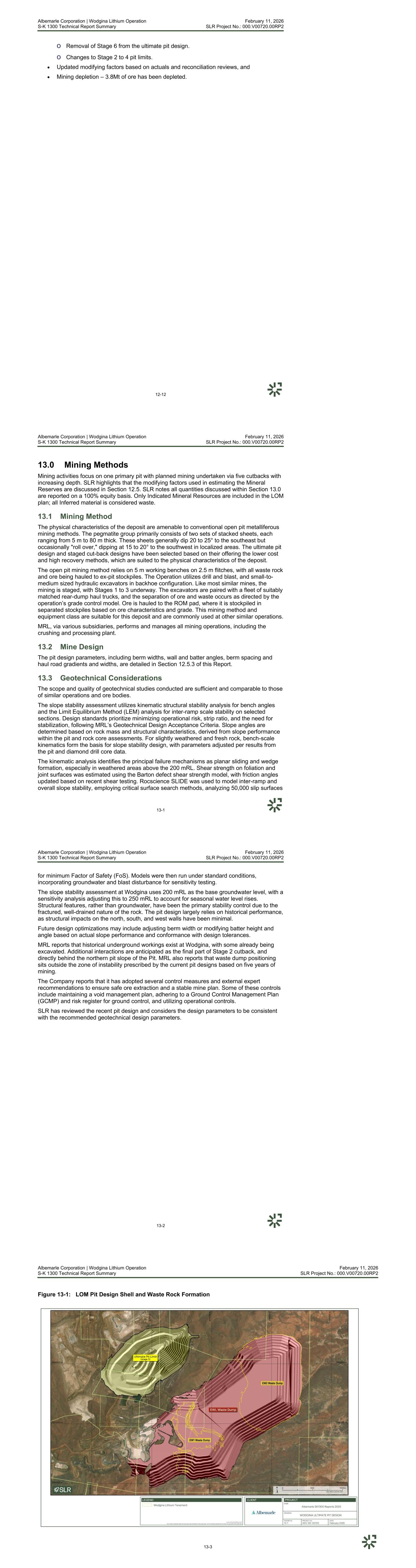

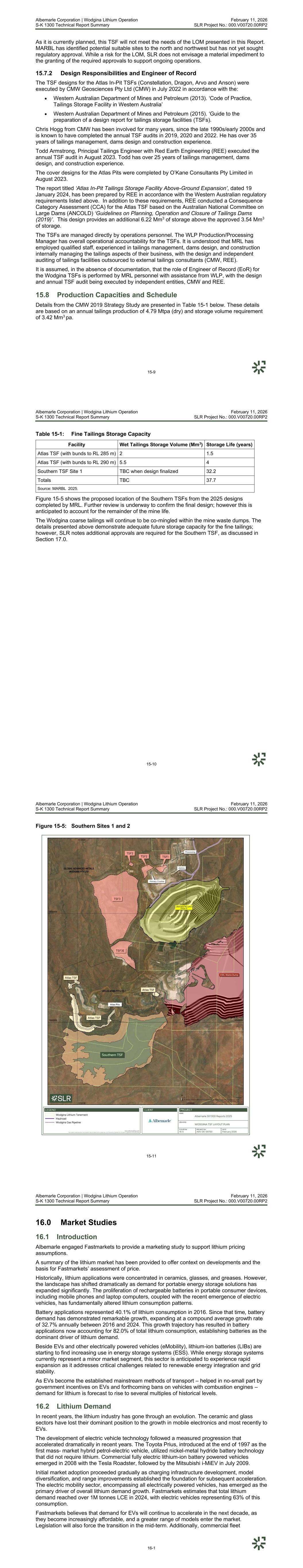

Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 1-4 The currently operating Atlas In-Pit TSF, with the proposed bunding, along with the planned Southern TSF, have a combined storage life suitable to meet the LOM, provided regulatory approval, which is currently in the process, is obtained. These facilities are separate from the historical tailings (TSF 1, 2, and 3) that are planned to be reprocessed. There is a single operating waste dump, designed to support the LOM. This waste dump is approved to 2030 (based on forecast production schedules), with additional regulatory approvals required to meet the LOM. 1.6.1 Life of Mine Physicals The key physicals relevant to the LOM plan are summarized in Table 1-1 which includes production from three trains. Active mining and processing under the LOM plan are scheduled to extend to 2046. Total annual material movement is projected to progressively increase in H2 2025 and peak at 35.0 Mt in 2026, then remain between 30 Mt and 35 Mt until 2028. Rates are forecast to decrease in 2029 to 25.0 Mt, and then remain between 25 Mt and 30 Mt per year until 2039 after which waste movement drops significantly as expected at the end of mine life. Table 1-1: LOM Physicals Parameter Units (metric) LOM LOM Active Mine Period Years 21 LOM Plant Period Years 22 Waste Material Moved M dmt 356.8* Ore Mined (ex-pit) M dmt 89.2 Ore Mined (reprocessed tailings) M dmt 14.8 Ore Processed (Feed total) M dmt 104.8 Feed Grade (Total average) % 1.3 Mineralized Waste (0.65%–0.75% Li2O) M dmt 5.1 Strip Ratio (run-of-mine) waste:ore (t:t) 3.40 LOM Plant Recovery % 67.4% Concentrate Tonnes (SC5.5) M dmt 17.1 Notes: * Total waste quantities include 5.1 Mt of mineralized waste dmt dry metric tonnes The Mineral Reserves estimate (Table 1-3) is underpinned by an independent assessment based on the estimate of Mineral Resources and a LOM schedule and associated financial analysis completed by the MRL on behalf of the Company, and reviewed and validated by SLR. As part of its review and for the purposes of estimating Mineral Reserves, SLR converted all Inferred Resources and mineralized waste (defined as material with a Li2O grade of greater than or equal to 0.65% but less than 0.75%) to report as waste within the LOM. No mineralized waste or Inferred Resource has been included in the estimate of Mineral Reserves. SLR, as the QP, considers the estimation methodology to align with industry standards and the production to be achievable in the medium to long term. SLR, as the QP, considers the underlying studies, as well as capital and operating cost estimates, to be at least at a pre-feasibility level of accuracy; Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 1-5 however, it notes that all operating costs are predominantly actuals from recent operations or under contract. 1.7 Mineral Resources and Mineral Reserves The Mineral Resources as at June 30, 2025, for the operation are summarized in Table 1-2. The Mineral Resources have been estimated with reference to a cut-off grade (COG) that depends on the mining method; the open pit COG is 0.5% Li2O, while the underground COG is 0.75% Li2O. The COG was determined based on estimated mining and processing costs, recovery factors, product qualities, and long-term benchmark pricing. It is highlighted that the long-term benchmark SC6 price of USD 1,500 tonne of product is lower than the current spot price and is derived over a 7- to 10-year timeframe, which was selected based on the reasonable long-term prospects of the Mineral Resource rather than short-term viability (0.5 to 2 years), based on an independent marketing study by Fastmarkets. Both the Mineral Resources and Mineral Reserves have been reported using the 30 June surface provided. SLR, as the QP, considers the geological model to be based on adequate structural (which includes in-pit mapping and RQD from diamond holes) and geochemical data that has been reviewed and verified by geologists, over a long period of time, as well as by SLR. Deposit modeling has been carried out using industry-standard geological modeling software and procedures. The estimation and classification of the Mineral Resource reflect the SLR as the QP’s opinion of in situ material with reasonable prospects for eventual economic extraction. The Mineral Resource estimate is presented exclusive of Mineral Reserves. SLR notes that the Mineral Reserve estimate includes all stockpiled material and Indicated TSF material; as the Mineral Resource estimate is exclusive of Mineral Reserves, no stockpile material or TSF material classified as Indicated is included in Mineral Resources. Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 1-6 Table 1-2: Statement of Mineral Resources at June 30, 2025 (Albemarle Share 50%) Type Classification Quantity (100%) (Mt) Attributable Quantity (50%) (Mt) Li2O Grade (%) Open Pit Indicated 17.6 8.8 0.7 Inferred 1.2 0.6 1.0 Underground Indicated 30.7 15.3 1.3 Inferred 26.7 13.4 1.2 TSF Indicated - - - Inferred 2.4 1.2 0.4 Total Indicated 48.3 24.3 1.0 Inferred 30.3 15.1 1.3 Notes: 1. The Mineral Resources are reported exclusive of the Mineral Reserves. Mineral Resources that are not Mineral Reserves, while demonstrating reasonable prospects for economic extraction, do not have demonstrated economic viability. 2. The Mineral Resources have been compiled under the supervision of SLR as the QP. 3. All Mineral Resources figures reported in the table above represent estimates at June 30, 2025, based on a model completed in September 2024. Mineral Resource estimates are not precise calculations, dependent on the interpretation of limited information on the location, shape and continuity of the occurrence and on the available sampling results. The totals contained in the above table have been rounded to reflect the relative uncertainty of the estimate. Rounding may cause some computational discrepancies. 4. Mineral Resources are reported in accordance with S-K 1300. 5. The Mineral Resources reflect the 50% ownership in the relevant holding companies. 6. Mineral Resources are reported on an in situ basis without applying mining dilution, mining losses, or process losses. 7. The Mineral Resources are reported above 0.5% Li2O cut-off for in situ pegmatites within the open pit, 0.75% within the underground, and above 0% for TSF, as all material would be mined and recovered. The basis for the COG is provided in Section 0. 8. The underground Mineral Resources are reported in areas of >10 m thickness, below the open pit Mineral Resources. 9. Mineral Resources are estimated using a long-term selling price of US$1,500/t CIF CKJ1 of SC6 grade concentrate (benchmark 6% Li2O), and a US$/A$ exchange rate of A$1.00:US$0.66. 10. Bulk densities were applied based on material types as outlined in Section 8.1. SLR is of the opinion that, with consideration of the recommendations summarized in Sections 1.0 and 23.0 of this TRS, any issues relating to all relevant technical and economic factors likely to influence the prospect of economic extraction can be resolved with further work. Mineral Reserves, summarized in Table 1-3, were estimated for the open pit, stockpiles, and TSF using technical data available as of June 30, 2025, and reported in accordance with the guidelines of S-K 1300. Studies for the underground portion of the Mineral Resource have yet to reach a level of study that would allow for the reporting of Mineral Reserves. Mineral Resources are reported exclusive of Mineral Reserves (that is, Mineral Reserves are additional to Mineral Resources). Mineral Reserves are subdivided into Proven Mineral Reserves and Probable Mineral Reserves categories to reflect the confidence in the underlying Mineral Resource data and modifying factors applied during mine planning. A Proven Mineral Reserve can only be derived from a Measured Mineral Resource, while a Probable Mineral 1 Cost, Insurance and Freight paid to Chikugo Port (China). Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 1-7 Reserve is typically derived from an Indicated Mineral Resource as well as Measured Resources, dependent on the QP’s confidence in the underlying Modifying Factors. It is noted that no Measured Resources have been reported for the operation, and as such there are no Proven Reserves. The conversion of Mineral Resources to Mineral Reserves incorporated systematic mine planning and analysis, including pit optimization, detailed pit design, the application of modifying parameters, LOM scheduling, and cost analysis. All Mineral Reserve estimations are in metric units, with Li2O grades reported in percentage (%). Mineral Reserve quantities were estimated using a marginal cut of grade of 0.75% Li2O and a long term selling SC6 price of US$1,300/t concentrate, based on Fastmarkets independent guidance in Section 16.0.

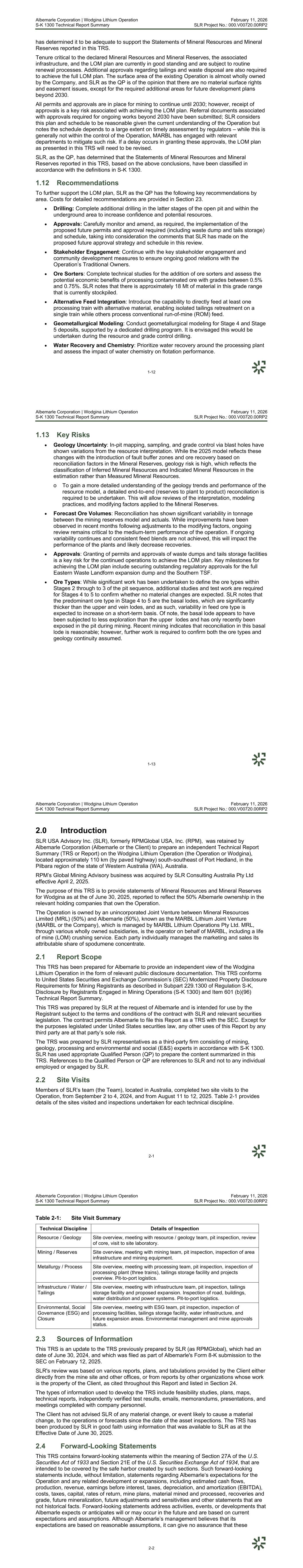

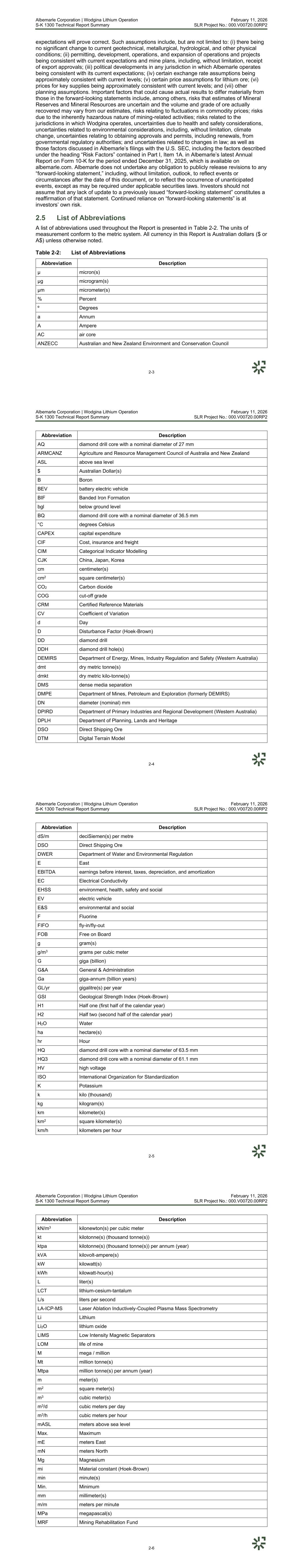

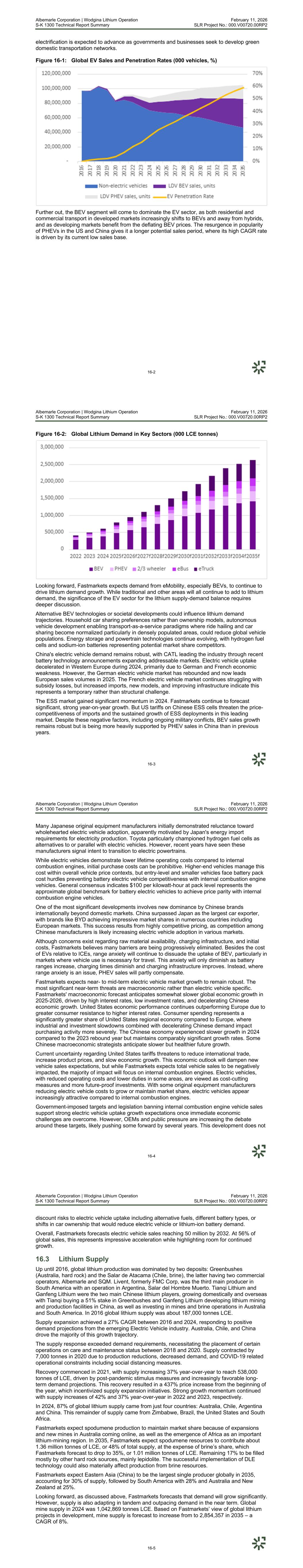

Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 1-8 Table 1-3: Statement of Mineral Reserves as at June 30, 2025 (Albemarle Share 50%) Type Classification Quantity (100%) (Mt) Attributable Quantity (50%) (Mt) Li2O Grade (%) Metallurgical Recovery (%) Open Pit Probable 89.2 44.6 1.4 67.4 Stockpiles Probable 0.9 0.5 0.8 67.4 TSF Probable 14.8 7.4 1.0 35.0 Total Probable 104.8 52.4 1.3 62.8 Notes: 1. The Mineral Reserves are additional to the reported Mineral Resources. 2. The Mineral Reserves have been estimated by SLR as the QP. 3. Mineral Reserves are reported in accordance with S-K 1300. 4. The Mineral Reserves have been reported at a 50% equity basis. 5. Mineral Reserves are reported on a dry basis and in metric tonnes. 6. The totals contained in the above table have been rounded with regard to materiality. Rounding may result in minor computational discrepancies. 7. Mineral Reserves are reported considering a nominal set of assumptions for reporting purposes: a. Mineral Reserves are based on a selling price of US$1,300/t CIF CKJ2 of chemical grade concentrate (benchmark 6% Li2O). b. Mineral Reserves assume variable mining recoveries based on grade, oxidation, thickness, and search distance, sourced from MRL as presented in Table 12-3. The total mining recoveries are 91.7% for the open pit and 100% for the TSF. c. Mineral Resources were converted to Mineral Reserves using plant recovery equations, sourced from MRL and based on plant data. The plant processing recovery equations depend on the material type, weathering, and in some circumstances, the Li2O% grade of the plant feed. d. Costs estimated in Australian Dollars were converted to U.S. dollars based on an exchange rate of A$1.00:US$0.66. e. The economic COG calculation is based on US$2.1/t-ore incremental ore mining cost, US$33.63/t-ore processing cost, US$11.79/t-ore G&A cost, US$5.73/t-ore sustaining capital cost, and US$53.22/t ore selling cost, inclusive of shipping. Incremental ore mining costs are the costs associated with the run-of-mine (ROM) loader, stockpile rehandling, grade control assays, and rock breaker. f. The price, cost and mass yield parameters produce a calculated economic COG of <0.75% Li2O; however, due to the internal constraints of the current operations, an elevated Mineral Reserves COG of 0.75% Li2O has been applied. The same COG was utilized for the TSF. g. Waste tonnage within the Mineral Reserve pit is 356.8 Mt at a strip ratio of 3.4:1 (waste to ore – not including stockpiles) h. Mineral Reserves are reported based on mill feed material. SLR is not aware of any risk factors associated with, or changes to, any aspects of the modifying factors such as mining, metallurgical, infrastructure, permitting, or other relevant factors that could materially affect the Mineral Reserve estimate. 1.8 Market Studies Fastmarkets has developed a marketing study on behalf of Albemarle to support lithium pricing assumptions utilized in this TRS. This market study does not consider by- or co-products that may be produced alongside the lithium production process. Battery demand is now responsible for 85% of all lithium consumed. Looking forward, Fastmarkets expects demand from eMobility, especially battery electric vehicles (BEVs), to 2 Cost, Insurance and Freight paid to Chikugo Port. Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 1-9 continue to drive lithium demand growth. Supply is still growing despite the low-price environment and some production restraint. This has coincided with a period of weaker-than- expected demand growth. Ironically, the industry is still growing healthily; Fastmarkets expects demand growth from electric vehicles (EVs) to average 25% over the next 10 years, but this is slower than >40% growth in demand from EVs the market was used to in the early post-Covid years. The high prices in 2021–2022 triggered a massive producer response with some new supply still being ramped up, while at the same time some high-cost production is being cut, mainly by non-Chinese producers. Based on Fastmarkets view in August 2025, the combination of weaker-than-expected demand at a time when supply is still rising means the market is likely to be in a supply surplus until 2026. Based on supply restraint and investment cuts, Fastmarkets forecasts the market to swing back into a deficit in 2027, as illustrated in Figure 1-1. This forecast could change should demand exceed expectations and supply expansion disappoint to the downside. Fastmarkets recommends that a real price of US$1,300/t spodumene concentrate (SC6.0 CIF China) should be utilized by Albemarle for Mineral Reserve estimation. Recommended prices are on the lower end of Fastmarkets' low-case scenario. SC6.0 forecast consensus price has been adjusted for the SC5.5 product produced at the Operation on a pro rata basis. Figure 1-1: Lithium Supply-Demand Balance (000 tonnes LCE) Source: Fastmarkets Based on the Fastmarkets report, SLR has adopted the following to support Mineral Resource and Mineral Reserve estimation: • Mineral Resources: US$1,500/t for spodumene SC6.0 CIF China • Mineral Reserves: US$1,300/t for spodumene SC6.0 CIF China • Financial Modeling: US$1,300/t for spodumene SC6.0 CIF China from 2027, increased from spot price in line with the Fastmarkets forecast. 1.9 Environmental, Permitting, and Social Considerations There are no material local environmental and social (E&S) concerns for the current Operation within the approved footprint; however, several project development approvals are required to Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 1-10 allow execution of the full LOM as presented in this TRS. Of note are the potential biodiversity and cultural heritage limits associated with the development of the Southern TSF; this potential has been included in the approvals process. The Company has plans in place to address these potential E&S limits through the operation assessment and approvals process. SLR understands the Operation has the required E&S approvals and the licenses/permits for current operations and is generally operating in compliance with these current E&S approvals and permits with no material compliance issues noted. The future E&S approvals required to support the LOM plan comprise approvals for a waste rock landform expansion and an expanded and new TSF. MARBL has a plan and schedule in place to secure future E&S approvals. SLR considers this plan and schedule to be reasonable given the current understanding of the Operation, but notes the schedule depends to a large extent on timely assessment by regulators – while this is generally not within the control of the Operation, MARBL has engaged with relevant departments to mitigate such risk. 1.10 Economic Evaluation SLR highlights that the capital estimates for the next five years, along with the sustaining capital, are based on first-principles cost build-ups and are considered to be at least to a pre- feasibility level of accuracy. SLR notes that the majority of operating costs are based on ongoing contracts or previous years’ actuals, which are considered to be above feasibility study level of accuracy. The remainder of the capital expenditures are built up using typical costing methods for an operation of the scale, life, and operational requirements to meet the LOM plan. In addition, various contingencies are built into the cost estimates. 1.10.1 Operating Costs The LOM operating costs are built up from first principles with reference to historical actuals (cost and production performance), the LOM physical schedule, and forecast product estimates or based on current contract values. The total Free on Board (FOB) operating costs (excluding capitalized waste) are $10,658 million over the LOM, and the average FOB cost, excluding state royalties, is $621/t product. Mine Closure of $334 million ($19/t product) is included in the operating costs and allows for the total planned closure costs, ongoing closure holding costs, and workforce redundancy. As such, SLR considers the basis of costs reasonable for the operation. 1.10.2 Capital Costs The economic evaluation incorporates a total capital expenditure of $1,955 million, comprising $902 million in sustaining capital and $1,053 million for capitalized waste stripping. Sustaining capital includes provisions for mobile equipment replacements, the Atlas TSF, and major spares for the processing plant and site facilities. SLR notes that no expansion or growth capital is planned, as the existing operating infrastructure is sufficient to support the projected 22-year mine life as presented in this Report. 1.10.3 Economic Evaluation The economic evaluation of the asset was completed using a discounted cash flow analysis and confirmed the LOM economics are positive; however, the current market environment and pricing predictions from Fastmarkets show a material negative cash flow until the beginning of 2027. Table 1-4 provides a summary of the economic evaluation. Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 1-11 Table 1-4: Summary of Economic Evaluation Economic Evaluation Units LOM (A$M) 100% LOM (US$M) 100% LOM (US$M) 50% Gross Revenue $billion 30.1 19.8 9.9 Free Cash flow*** $billion 10.8 7.1 3.6 Total Operating Costs* $billion 11.3 7.5 3.7 Total Capital Costs $billion 2.0 1.3 0.6 Total Royalties $billion 1.5 1.0 0.5 Avg. Free on Board Costs* $/Prod t 621 409 409 All-In Sustaining Costs** $/Prod t 863 568 568 Discount Rate % 10.0 10.0 10.0 Pre-Tax NPV*** $billion 6.6 4.3 2.2 Post-Tax NPV*** $billion 4.8 3.1 1.6 Notes: * excluding royalties. ** including royalties. *** rounding to nearest 2 significant figures. Rounding may cause computational discrepancies. # Based on an exchange rate of 1AUD:0.66USD The financial model was tested for sensitivity regarding lithium prices, capital and operating cost estimates. The results indicate that the NPV of the Operation is most sensitive to changes in the product price and least sensitive to changes in capital expenditure. All sensitivity scenarios assessed for Wodgina returned positive net present value (NPV) results. The results of the cash flow modeling show negative cash flows in most quarterly time periods from Q3 2025 to Q3 2026 (cumulative undiscounted cash flows of -A$94 million across this time period), predominantly driven by elevated levels of capital expenditure and a weak product price environment forecast by Fastmarkets, followed by mostly cash flow positive quarterly time periods to the end of the LOM plan. 1.11 Conclusions The Wodgina deposit is well explored with exploration drilling programs for lithium having been conducted since 1996. SLR as the QP considers that the geological model is based on adequate geology and geochemical data that has been sufficiently reviewed and verified. The Operation is an established open pit mine that is a conventional truck and shovel operation employing industry-standard mining methods. SLR, as the QP, considers the major mining fleet assumptions to be reasonable when benchmarked to industry standards and historical performance. SLR as the QP is of the opinion that the Mineral Reserves, and associated equipment fleet numbers are reasonable to achieve the forecasts and reflect an appropriate level of accuracy. The geological model, detailed mine plans, and technical studies that underpin the LOM plan are supported by historical performance, well documented systems and processes, and reconciliation and review. Where available, SLR has reviewed this data and SLR, as the QP,

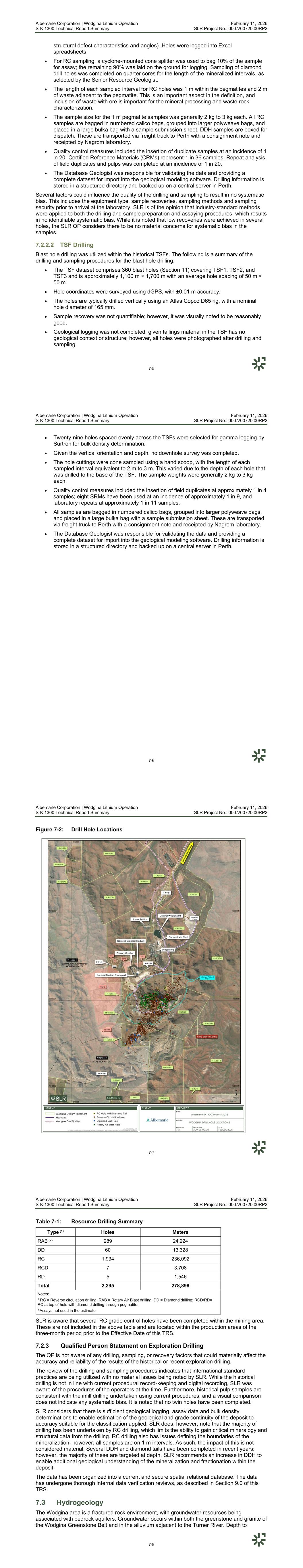

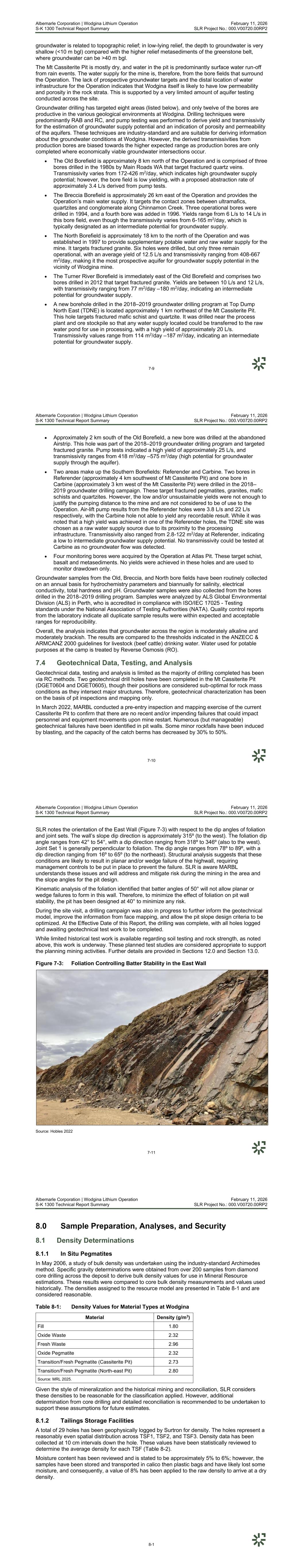

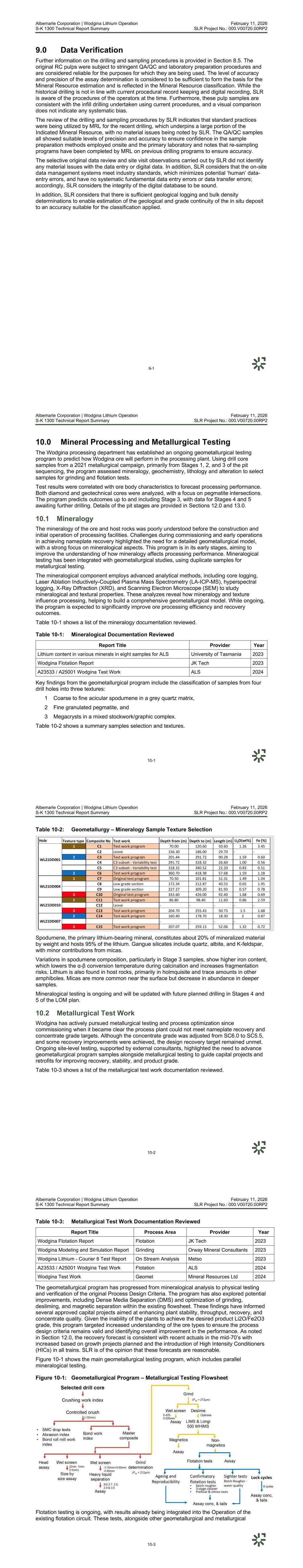

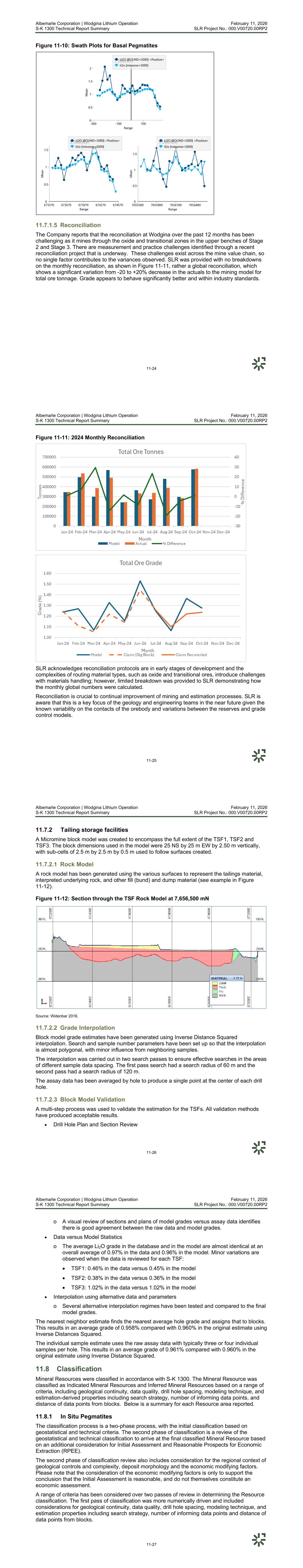

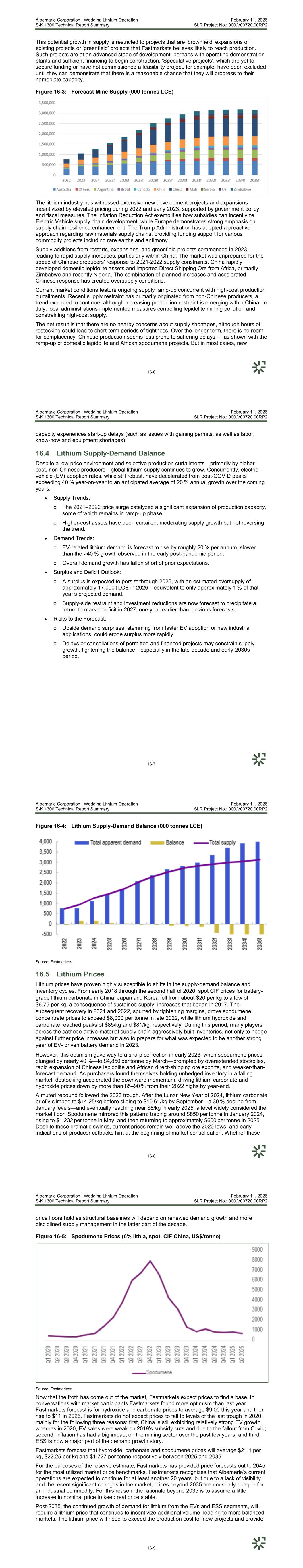

Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 1-12 has determined it to be adequate to support the Statements of Mineral Resources and Mineral Reserves reported in this TRS. Tenure critical to the declared Mineral Resources and Mineral Reserves, the associated infrastructure, and the LOM plan are currently in good standing and are subject to routine renewal processes. Additional approvals regarding tailings and waste disposal are also required to achieve the full LOM plan. The surface area of the existing Operation is almost wholly owned by the Company, and SLR as the QP is of the opinion that there are no material surface rights and easement issues, except for the required additional areas for future development plans beyond 2030. All permits and approvals are in place for mining to continue until 2030; however, receipt of approvals is a key risk associated with achieving the LOM plan. Referral documents associated with approvals required for ongoing works beyond 2030 have been submitted; SLR considers this plan and schedule to be reasonable given the current understanding of the Operation but notes the schedule depends to a large extent on timely assessment by regulators – while this is generally not within the control of the Operation, MARBL has engaged with relevant departments to mitigate such risk. If a delay occurs in granting these approvals, the LOM plan as presented in this TRS will need to be revised. SLR, as the QP, has determined that the Statements of Mineral Resources and Mineral Reserves reported in this TRS, based on the above conclusions, have been classified in accordance with the definitions in S-K 1300. 1.12 Recommendations To further support the LOM plan, SLR as the QP has the following key recommendations by area. Costs for detailed recommendations are provided in Section 23. • Drilling: Complete additional drilling in the latter stages of the open pit and within the underground area to increase confidence and potential resources. • Approvals: Carefully monitor and amend, as required, the implementation of the proposed future permits and approval required (including waste dump and tails storage) and schedule, taking into consideration the comments that SLR has made on the proposed future approval strategy and schedule in this review. • Stakeholder Engagement: Continue with the key stakeholder engagement and community development measures to ensure ongoing good relations with the Operation’s Traditional Owners. • Ore Sorters: Complete technical studies for the addition of ore sorters and assess the potential economic benefits of processing contaminated ore with grades between 0.5% and 0.75%. SLR notes that there is approximately 18 Mt of material in this grade range that is currently stockpiled. • Alternative Feed Integration: Introduce the capability to directly feed at least one processing train with alternative material, enabling isolated tailings retreatment on a single train while others process conventional run-of-mine (ROM) feed. • Geometallurgical Modeling: Conduct geometallurgical modeling for Stage 4 and Stage 5 deposits, supported by a dedicated drilling program. It is envisaged this would be undertaken during the resource and grade control drilling. • Water Recovery and Chemistry: Prioritize water recovery around the processing plant and assess the impact of water chemistry on flotation performance. Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 1-13 1.13 Key Risks • Geology Uncertainty: In-pit mapping, sampling, and grade control via blast holes have shown variations from the resource interpretation. While the 2025 model reflects these changes with the introduction of fault buffer zones and ore recovery based on reconciliation factors in the Mineral Reserves, geology risk is high, which reflects the classification of Inferred Mineral Resources and Indicated Mineral Resources in the estimation rather than Measured Mineral Resources. o To gain a more detailed understanding of the geology trends and performance of the resource model, a detailed end-to-end (reserves to plant to product) reconciliation is required to be undertaken. This will allow reviews of the interpretation, modeling practices, and modifying factors applied to the Mineral Reserves. • Forecast Ore Volumes: Reconciliation has shown significant variability in tonnage between the mining reserves model and actuals. While improvements have been observed in recent months following adjustments to the modifying factors, ongoing review remains critical to the medium-term performance of the operation. If ongoing variability continues and consistent feed blends are not achieved, this will impact the performance of the plants and likely decrease recoveries. • Approvals: Granting of permits and approvals of waste dumps and tails storage facilities is a key risk for the continued operations to achieve the LOM plan. Key milestones for achieving the LOM plan include securing outstanding regulatory approvals for the full Eastern Waste Landform expansion dump and the Southern TSF. • Ore Types: While significant work has been undertaken to define the ore types within Stages 2 through to 3 of the pit sequence, additional studies and test work are required for Stages 4 to 5 to confirm whether no material changes are expected. SLR notes that the predominant ore type in Stage 4 to 5 are the basal lodes, which are significantly thicker than the upper and vein lodes, and as such, variability in feed ore type is expected to increase on a short-term basis. Of note, the basal lode appears to have been subjected to less exploration than the upper lodes and has only recently been exposed in the pit during mining. Recent mining indicates that reconciliation in this basal lode is reasonable; however, further work is required to confirm both the ore types and geology continuity assumed. Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 2-1 2.0 Introduction SLR USA Advisory Inc. (SLR), formerly RPMGlobal USA, Inc. (RPM), was retained by Albemarle Corporation (Albemarle or the Client) to prepare an independent Technical Report Summary (TRS or Report) on the Wodgina Lithium Operation (the Operation or Wodgina), located approximately 110 km (by paved highway) south-southeast of Port Hedland, in the Pilbara region of the state of Western Australia (WA), Australia. RPM’s Global Mining Advisory business was acquired by SLR Consulting Australia Pty Ltd effective April 2, 2025. The purpose of this TRS is to provide statements of Mineral Resources and Mineral Reserves for Wodgina as at the of June 30, 2025, reported to reflect the 50% Albemarle ownership in the relevant holding companies that own the Operation. The Operation is owned by an unincorporated Joint Venture between Mineral Resources Limited (MRL) (50%) and Albemarle (50%), known as the MARBL Lithium Joint Venture (MARBL or the Company), which is managed by MARBL Lithium Operations Pty Ltd. MRL, through various wholly owned subsidiaries, is the operator on behalf of MARBL, including a life of mine (LOM) crushing service. Each party individually manages the marketing and sales its attributable share of spodumene concentrate. 2.1 Report Scope This TRS has been prepared for Albemarle to provide an independent view of the Wodgina Lithium Operation in the form of relevant public disclosure documentation. This TRS conforms to United States Securities and Exchange Commission’s (SEC) Modernized Property Disclosure Requirements for Mining Registrants as described in Subpart 229.1300 of Regulation S-K, Disclosure by Registrants Engaged in Mining Operations (S-K 1300) and Item 601 (b)(96) Technical Report Summary. This TRS was prepared by SLR at the request of Albemarle and is intended for use by the Registrant subject to the terms and conditions of the contract with SLR and relevant securities legislation. The contract permits Albemarle to file this Report as a TRS with the SEC. Except for the purposes legislated under United States securities law, any other uses of this Report by any third party are at that party’s sole risk. The TRS was prepared by SLR representatives as a third-party firm consisting of mining, geology, processing and environmental and social (E&S) experts in accordance with S-K 1300. SLR has used appropriate Qualified Person (QP) to prepare the content summarized in this TRS. References to the Qualified Person or QP are references to SLR and not to any individual employed or engaged by SLR. 2.2 Site Visits Members of SLR’s team (the Team), located in Australia, completed two site visits to the Operation, from September 2 to 4, 2024, and from August 11 to 12, 2025. Table 2-1 provides details of the sites visited and inspections undertaken for each technical discipline. Albemarle Corporation | Wodgina Lithium Operation S-K 1300 Technical Report Summary February 11, 2026 SLR Project No.: 000.V00720.00RP2 2-2 Table 2-1: Site Visit Summary Technical Discipline Details of Inspection Resource / Geology Site overview, meeting with resource / geology team, pit inspection, review of core, visit to site laboratory. Mining / Reserves Site overview, meeting with mining team, pit inspection, inspection of area infrastructure and mining equipment. Metallurgy / Process Site overview, meeting with processing team, pit inspection, inspection of processing plant (three trains), tailings storage facility and projects overview. Pit-to-port logistics. Infrastructure / Water / Tailings Site overview, meeting with infrastructure team, pit inspection, tailings storage facility and proposed expansion. Inspection of road, buildings, water distribution and power systems. Pit-to-port logistics. Environmental, Social Governance (ESG) and Closure Site overview, meeting with ESG team, pit inspection, inspection of processing facilities, tailings storage facility, water infrastructure, and future expansion areas. Environmental management and mine approvals status. 2.3 Sources of Information This TRS is an update to the TRS previously prepared by SLR (as RPMGlobal), which had an date of June 30, 2024, and which was filed as part of Albemarle's Form 8-K submission to the SEC on February 12, 2025. SLR's review was based on various reports, plans, and tabulations provided by the Client either directly from the mine site and other offices, or from reports by other organizations whose work is the property of the Client, as cited throughout this Report and listed in Section 24. The types of information used to develop the TRS include feasibility studies, plans, maps, technical reports, independently verified test results, emails, memorandums, presentations, and meetings completed with company personnel. The Client has not advised SLR of any material change, or event likely to cause a material change, to the operations or forecasts since the date of the asset inspections. The TRS has been produced by SLR in good faith using information that was available to SLR as at the Effective Date of June 30, 2025. 2.4 Forward-Looking Statements This TRS contains forward-looking statements within the meaning of Section 27A of the U.S. Securities Act of 1933 and Section 21E of the U.S. Securities Exchange Act of 1934, that are intended to be covered by the safe harbor created by such sections. Such forward-looking statements include, without limitation, statements regarding Albemarle‘s expectations for the Operation and any related development or expansions, including estimated cash flows, production, revenue, earnings before interest, taxes, depreciation, and amortization (EBITDA), costs, taxes, capital, rates of return, mine plans, material mined and processed, recoveries and grade, future mineralization, future adjustments and sensitivities and other statements that are not historical facts. Forward-looking statements address activities, events, or developments that Albemarle expects or anticipates will or may occur in the future and are based on current expectations and assumptions. Although Albemarle’s management believes that its expectations are based on reasonable assumptions, it can give no assurance that these