Please wait

|

| Technical Report Summary

Hod Maden Project, Türkiye

SSR Mining Inc.

6900 E. Layton Avenue, Suite 1300, Denver, CO 80237

Prepared by:

SLR International Corporation

1658 Cole Blvd, Suite 100, Lakewood, Colorado, 80401

SLR Project No.: 123.000320.00001

Report Date:

January 7, 2026

Revision: 0

|

|

|

| |

| |

| |

Making

Sustainability Happen |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

Cautionary Note Regarding Forward-Looking

Statements:

Certain statements contained in this report are "forward-looking statements" within the meaning of Section 27A of the

Securities Act of 1933, as amended (the “Securities Act”), and Section 21E of the Securities Exchange Act of 1934,

as amended (the “Exchange Act”), and are intended to be covered by the safe harbor provided for under these sections.

Forward looking statements can be identified with words such as “may,” “will,” “could,”

“should,” “expect,” “plan,” “anticipate,” “believe,”

“intend,” “estimate,” “projects,” “predict,” “potential,”

“continue” and similar expressions, as well as statements written in the future tense. Forward-looking statements are

based on information known at such time and/or with a good faith belief with respect to future events. Such statements are subject

to risks and uncertainties that could cause actual performance or results to differ materially from those expressed in the

forward-looking statements. Many of these risks and uncertainties cannot be controlled or predicted. Given these risks and

uncertainties, readers are cautioned not to place undue reliance on forward-looking statements. Forward-looking statements include,

among things: metal price price assumptions, cash flow forecasts, projected capital and operating costs, metal recoveries, mine life

and production rates, and other assumptions used in this report.

Such forward-looking information and statements are based on a number

of material factors and assumptions, including, but not limited to: the inherent speculative nature of exploration results; the ability

to explore; communications with local stakeholders; maintaining community and governmental relations; status of negotiations of joint

ventures; weather conditions at our operations; commodity prices; the ultimate determination of and realization of Mineral Reserves; existence

or realization of Mineral Resources; the development approach; availability and receipt of required approvals, titles, licenses and permits;

sufficient working capital to develop and operate the mines and implement development plans; access to adequate services and supplies;

foreign currency exchange rates; interest rates; access to capital markets and associated cost of funds; availability of a qualified work

force; ability to negotiate, finalize, and execute relevant agreements; lack of social opposition to our mines or facilities; lack of

legal challenges with respect to our properties; the timing and amount of future production; the ability to meet production, cost, and

capital expenditure targets; timing and ability to produce studies and analyses; capital and operating expenditures; economic conditions;

availability of sufficient financing; the ultimate ability to mine, process, and sell mineral products on economically favorable terms;

and any and all other timing, exploration, development, operational, financial, budgetary, economic, legal, social, geopolitical, regulatory

and political factors that may influence future events or conditions. While we consider these factors and assumptions to be reasonable

based on information currently available to us, they may prove to be incorrect.

The above list is not exhaustive list of the factors that may affect

any of the forward-looking statements and information included in this report, and such statements and information will not be updated

to reflect events or circumstances arising after the date of such statements or to reflect the occurrence of anticipated or unanticipated

events.

This technical report summary also contains financial measures which

are not recognized under U.S. generally accepted accounting principles.

| | i |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

Table of Contents

| Cautionary Note Regarding Forward-Looking Statements: |

i |

| Table of Contents |

ii |

| 1.0 Executive Summary |

1-1 |

| 1.1 Summary |

1-1 |

| 1.2 Economic Analysis |

1-12 |

| 1.3 Technical Summary |

1-16 |

| 2.0 Introduction |

2-1 |

| 2.1 Site Visits |

2-1 |

| 2.2 Sources of Information |

2-2 |

| 2.3 Abbreviations, Acronyms and Units of Measure |

2-4 |

| 3.0 Property Description |

3-1 |

| 3.1 Location |

3-1 |

| 3.2 Land Tenure |

3-3 |

| 3.3 Encumbrances |

3-3 |

| 3.4 Royalties |

3-5 |

| 3.5 Required Permits and Status |

3-7 |

| 3.6 Other Significant Factors and Risks |

3-8 |

| 4.0 Accessibility, Climate, Local Resources, Infrastructure and Physiography |

4-1 |

| 4.1 Accessibility |

4-1 |

| 4.2 Climate |

4-4 |

| 4.3 Local Resources |

4-10 |

| 4.4 Infrastructure |

4-10 |

| 4.5 Physiography |

4-11 |

| 5.0 History |

5-1 |

| 5.1 Prior Ownership |

5-1 |

| 5.2 Exploration and Development History |

5-2 |

| 5.3 Past Production |

5-2 |

| 5.4 Previous Mineral Reserve and Mineral Resource Estimates |

5-2 |

| 6.0 Geological Setting, Mineralization, and Deposit |

6-1 |

| 6.1 Regional Geology |

6-1 |

| 6.2 Local Geology |

6-2 |

| 6.3 Property Geology and Mineralization |

6-5 |

| 6.4 Hod Maden Mineral System |

6-13 |

| | ii |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| 6.5 Regional Prospects and Targets |

6-14 |

| 7.0 Exploration |

7-1 |

| 7.1 Exploration Overview |

7-1 |

| 7.2 Drilling |

7-4 |

| 7.3 Hydrogeological Data |

7-7 |

| 7.4 Geotechnical Data |

7-13 |

| 8.0 Sample Preparation, Analysis, and Security |

8-1 |

| 8.1 Sample Preparation |

8-1 |

| 8.2 Sample Analysis |

8-1 |

| 8.3 Sample Security |

8-3 |

| 8.4 Data Quality |

8-3 |

| 8.5 QP Opinion |

8-27 |

| 9.0 Data Verification |

9-1 |

| 9.1 Site Visit |

9-1 |

| 9.2 QP Opinion |

9-5 |

| 10.0 Mineral Processing and Metallurgical Testing |

10-1 |

| 10.1 Overview |

10-1 |

| 10.2 Scoping, PEA, and PFS Test Work |

10-1 |

| 10.3 Feasibility Study Metallurgical Test Work |

10-5 |

| 10.4 Feasibility Study Update Metallurgical Test Work |

10-15 |

| 10.5 Source: Ausenco 2024QP Opinion |

10-25 |

| 11.0 Mineral Resource Estimates |

11-1 |

| 11.1 Summary |

11-1 |

| 11.2 Resource Database |

11-2 |

| 11.3 Database Validation and Verification |

11-5 |

| 11.4 Geological Domains |

11-5 |

| 11.5 Hod Maden Estimation Domaining |

11-15 |

| 11.6 Compositing |

11-22 |

| 11.7 Treatment of High-Grade Assays |

11-25 |

| 11.8 Spatial Analysis |

11-26 |

| 11.9 Block Model |

11-31 |

| 11.10 Search Neighborhood Parameters |

11-31 |

| 11.11 Density Estimation |

11-33 |

| 11.12 Validation |

11-33 |

| | iii |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| 11.13 Classification |

11-40 |

| 11.14 Consideration of Potential for Economic Extraction |

11-42 |

| 11.15 Mineral Resource Reporting |

11-43 |

| 11.16 Comparison with Previous Estimates |

11-44 |

| 11.17 QP Opinion |

11-45 |

| 12.0 Mineral Reserve Estimates |

12-1 |

| 12.1 Summary |

12-1 |

| 12.2 Orebody Description |

12-2 |

| 12.3 Mining Block Model |

12-4 |

| 12.4 Cut-off Value |

12-5 |

| 12.5 Dilution and Recovery Estimates |

12-7 |

| 12.6 Mineral Reserve Reporting |

12-8 |

| 13.0 Mining Methods |

13-1 |

| 13.1 Introduction |

13-1 |

| 13.2 Geotechnical Considerations |

13-2 |

| 13.3 Mining Method Selection |

13-15 |

| 13.4 Stope Design |

13-20 |

| 13.5 Development Design |

13-23 |

| 13.6 Stope Cycle and Sequence |

13-29 |

| 13.7 Ventilation |

13-34 |

| 13.8 Development and Production Schedule |

13-39 |

| 13.9 Material Handling |

13-51 |

| 13.10 Underground Mining Equipment |

13-58 |

| 13.11 Personnel |

13-62 |

| 13.12 Underground Mine Infrastructure |

13-63 |

| 14.0 Processing and Recovery Methods |

14-1 |

| 14.1 Introduction |

14-1 |

| 14.2 Process Design Criteria |

14-5 |

| 14.3 Process Description |

14-7 |

| 14.4 Consumables |

14-12 |

| 14.5 Electricity Supply and Consumption |

14-12 |

| 14.6 Process Plant Personnel |

14-13 |

| 14.7 Equipment Selection |

14-13 |

| 15.0 Infrastructure |

15-1 |

| | iv |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| 15.1 Introduction |

15-1 |

| 15.2 Access Roads |

15-6 |

| 15.3 Power |

15-8 |

| 15.4 Hydrogeological Considerations |

15-9 |

| 15.5 Hydrology and Water Management |

15-21 |

| 15.6 Tailings Storage Facility |

15-37 |

| 15.7 Waste Rock Facilities |

15-45 |

| 16.0 Market Studies |

16-1 |

| 16.1 Markets |

16-1 |

| 16.2 Metal Price Assumptions |

16-1 |

| 16.3 Treatment and Refining Charges |

16-2 |

| 16.4 Expressions of Interest |

16-3 |

| 16.5 Contracts |

16-3 |

| 17.0 Environmental Studies, Permitting, and Plans, Negotiations, or Agreements with Local Individuals or Groups |

17-1 |

| 17.1 Environmental and Social Impacts and Risks |

17-1 |

| 17.2 Waste Management |

17-10 |

| 17.3 Project Permitting |

17-11 |

| 17.4 Mine Closure Planning |

17-12 |

| 18.0 Capital and Operating Costs |

18-1 |

| 18.1 Capital Costs |

18-1 |

| 18.2 Operating Costs |

18-4 |

| 19.0 Economic Analysis |

19-1 |

| 19.1 Economic Criteria |

19-1 |

| 19.2 Cash Flow Analysis |

19-2 |

| 19.3 Sensitivity Analysis |

19-5 |

| 20.0 Adjacent Properties |

20-1 |

| 21.0 Other Relevant Data and Information |

21-1 |

| 21.1 Project Execution |

21-1 |

| 22.0 Interpretation and Conclusions |

22-1 |

| 22.1 Geology and Mineral Resources |

22-1 |

| 22.2 Mining and Mineral Reserves |

22-2 |

| 22.3 Mineral Processing |

22-3 |

| 22.4 Infrastructure |

22-5 |

| 22.5 Marketing Studies |

22-6 |

| | v |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| 22.6 Environment & Social |

22-6 |

| 22.7 Capital and Operating Costs |

22-7 |

| 22.8 Project Execution |

22-7 |

| 23.0 Recommendations |

23-1 |

| 23.1 Geology and Mineral Resources |

23-1 |

| 23.2 Mining and Mineral Reserves |

23-1 |

| 23.3 Mineral Processing |

23-2 |

| 23.4 Infrastructure |

23-2 |

| 23.5 Water Resources |

23-3 |

| 23.6 Marketing Studies |

23-3 |

| 23.7 Environment and Social |

23-3 |

| 23.8 Capital and Operating Costs |

23-4 |

| 23.9 Project Execution |

23-4 |

| 24.0 References |

24-1 |

| 25.0 Reliance on Information Provided by the Registrant |

25-1 |

| 26.0 Date and Signature Page |

26-1 |

| 27.0 Appendix 1 |

27-1 |

Tables

| Table 1-1: After-Tax Cash Flow Summary |

1-14 |

| Table 1-2: AISC Composition |

1-15 |

| Table 1-3: Summary of Hod Maden Mineral Resources, exclusive of Mineral Reserves, as of August 31, 2025 (SSR’s

Attributable Share) |

1-20 |

| Table 1-4: Mineral Reserve Estimate as of August 31, 2025 (SSR’s Attributable Ownership Basis) |

1-21 |

| Table 1-5: Grade and Recovery Values Over Life of Mine |

1-22 |

| Table 1-6: Capital Cost Summary |

1-26 |

| Table 1-7: Average Operating Costs Unit Rates |

1-26 |

| Table 1-8: Hod Maden Schedule Milestones |

1-28 |

| Table 2-1: Consulting Companies Which Acted as Qualified Persons in Preparing this Report |

2-2 |

| Table 3-1: Hod Maden Project, Licenses Details |

3-3 |

| Table 3-2: Royalty Rates for Gold and Copper |

3-6 |

| Table 3-3: Operating License Fee and Forestry Land Fees for 2020 |

3-7 |

| Table 4-1: On-Site Meteorological Station Information |

4-4 |

| | vi |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

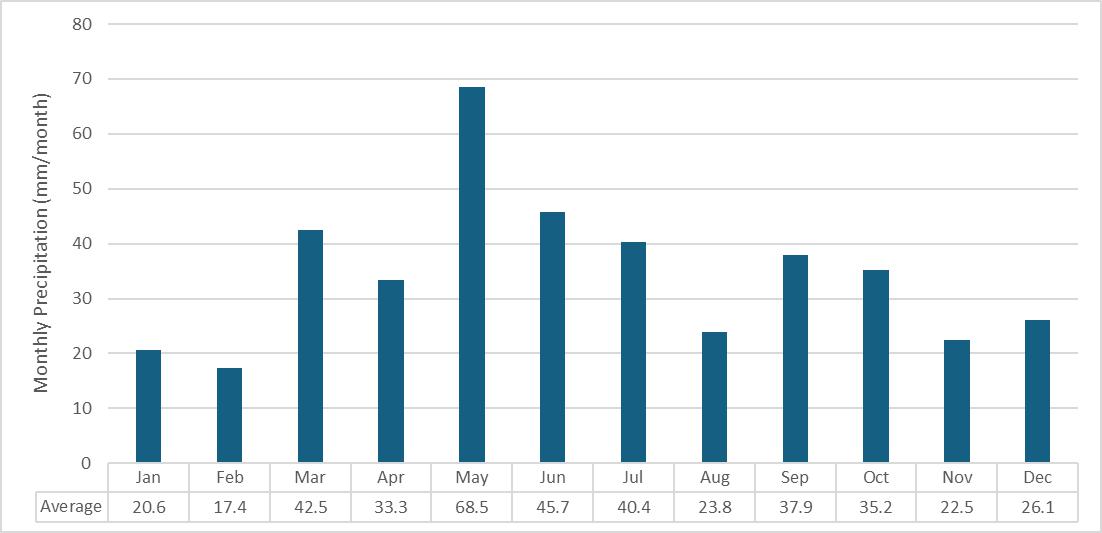

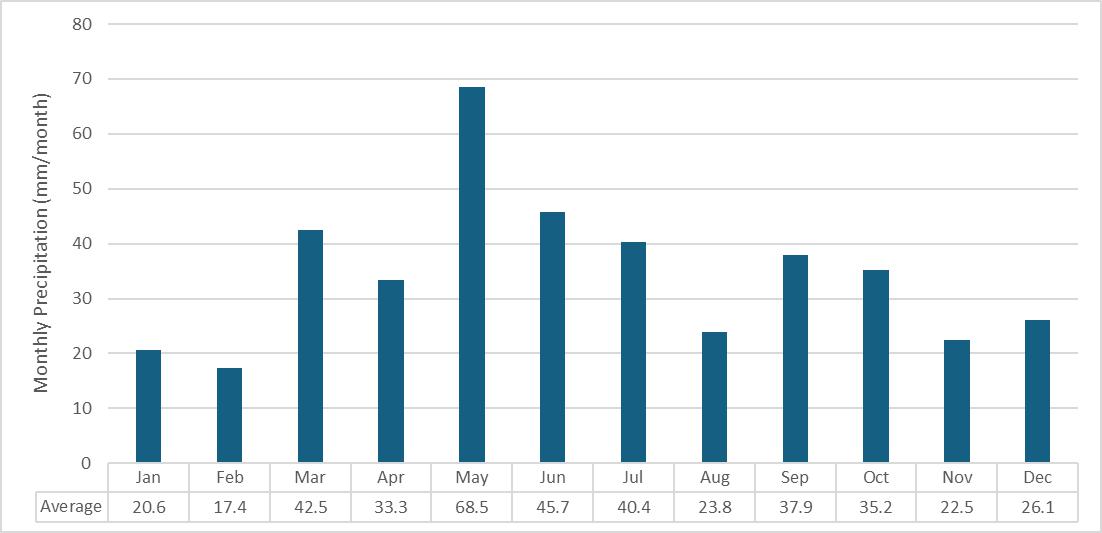

| Table 4-2: On-Site Station Monthly Average Precipitation (mm) |

4-5 |

| Table 4-3: On-Site Station Temperature Summary (2017–2024) |

4-7 |

| Table 4-4: Monthly

Reference Evapotranspiration (ET0) Data (mm) |

4-8 |

| Table 4-5: Climate Change Projection for 2031 to 2060 Period |

4-9 |

| Table 5-1: Previous Hod Maden Reserves as of December 31, 2024 |

5-4 |

| Table 5-2: Previous Hod Maden Resources as of December 31, 2024 |

5-4 |

| Table 7-1: Overview of Exploration by Artmin at Hod Maden |

7-1 |

| Table 7-2: Overview of Diamond Drilling with Assay Results by Artmin Madençilik at Hod Maden Deposit |

7-5 |

| Table 7-3: Pumping and Slug Test Information and Analysis Results (2017–2025) |

7-12 |

| Table 8-1: Summary of Sample Preparation and Analysis Methods |

8-2 |

| Table 8-2: Summary of QA and SOP Review |

8-4 |

| Table 8-3: Summary of Hod Maden QC Review |

8-8 |

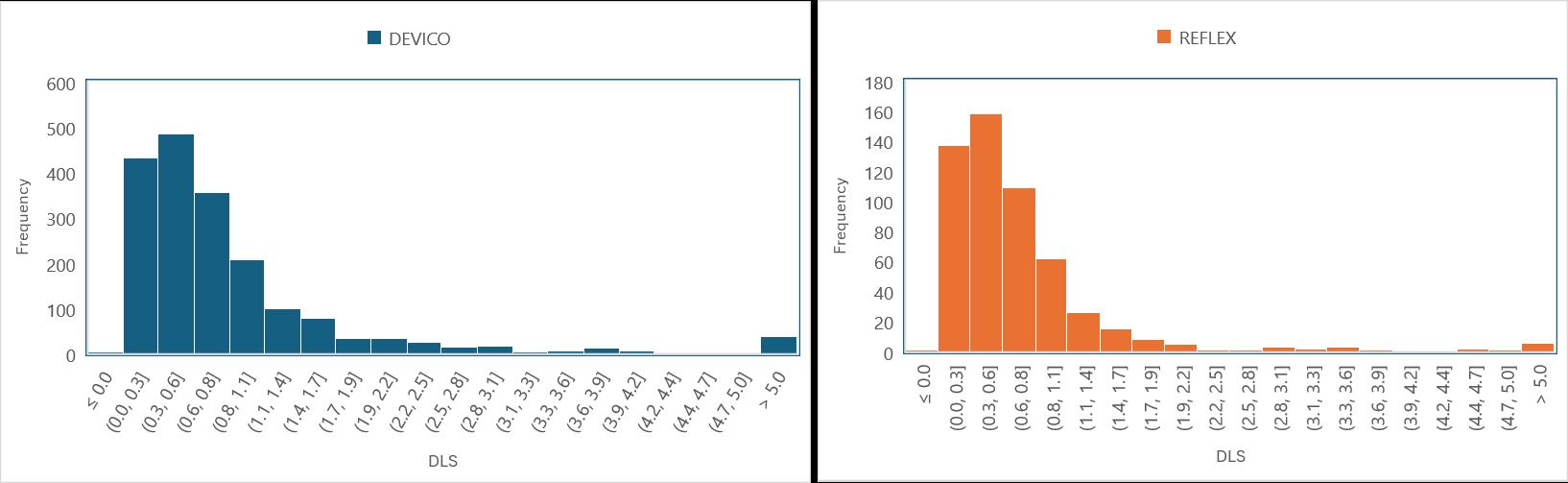

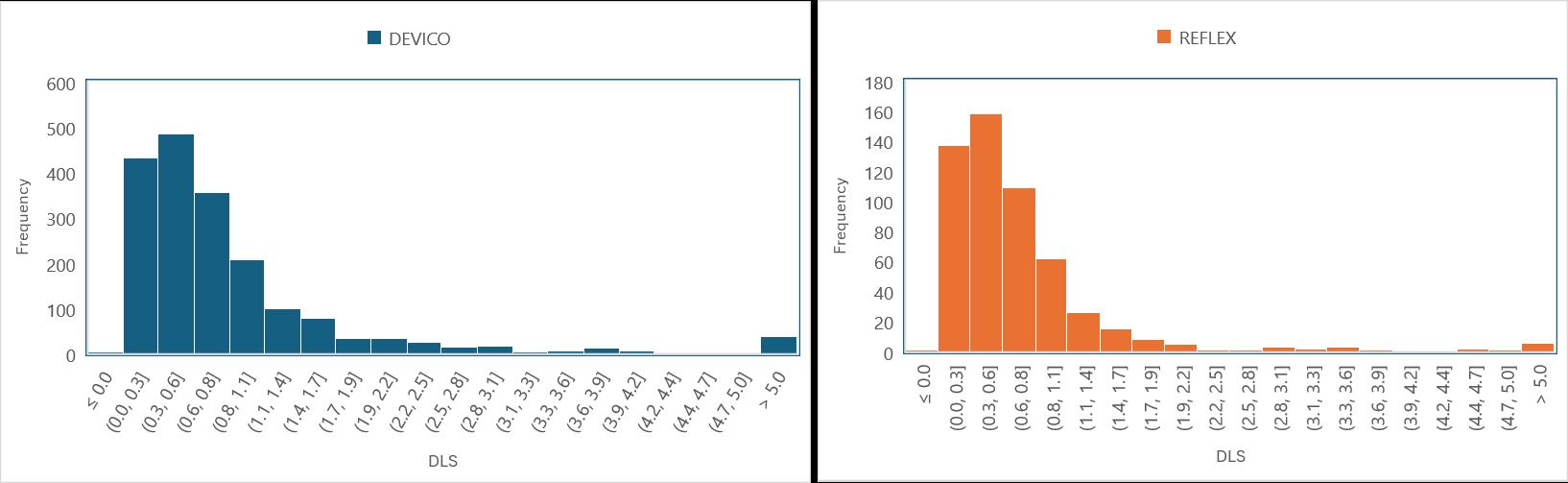

| Table 8-4: Dog-leg Severity of Downhole Surveys |

8-10 |

| Table 8-5: Summary of Hod Maden Quality Acceptance Testing |

8-16 |

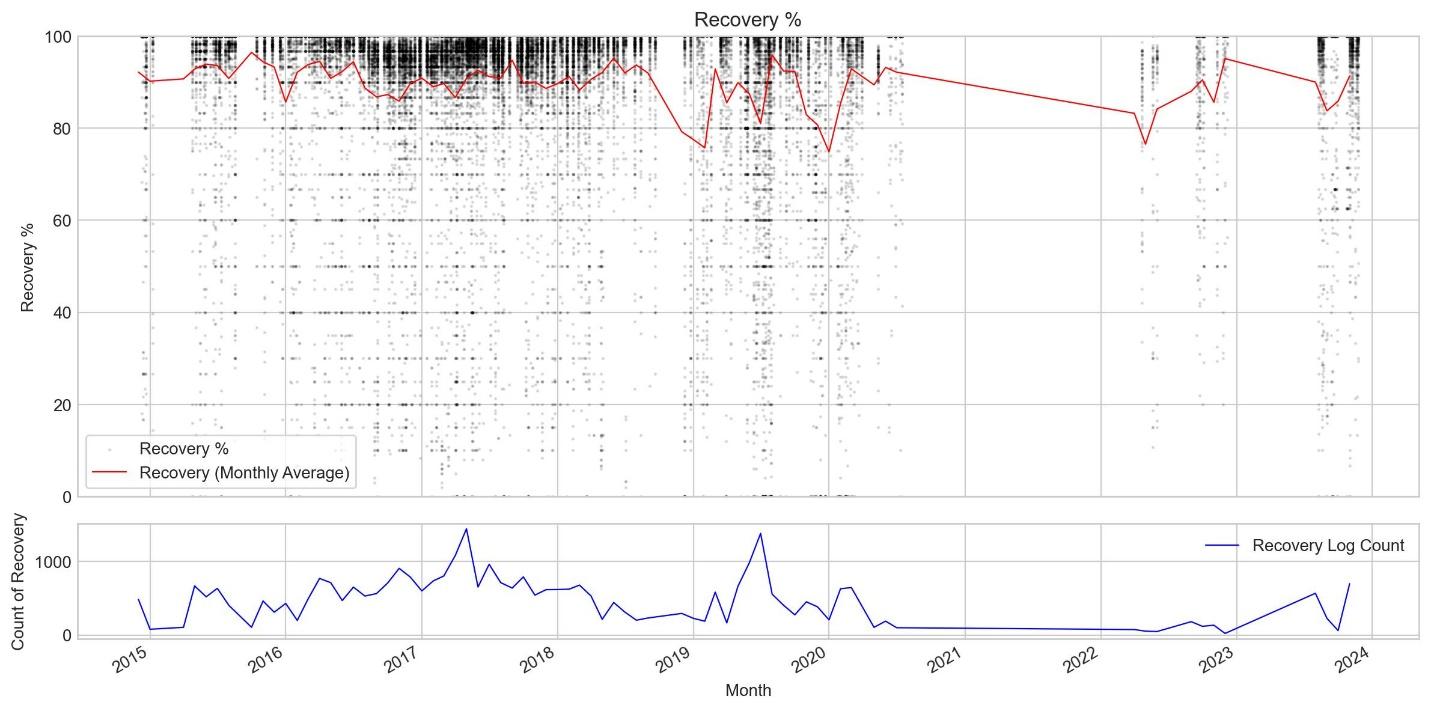

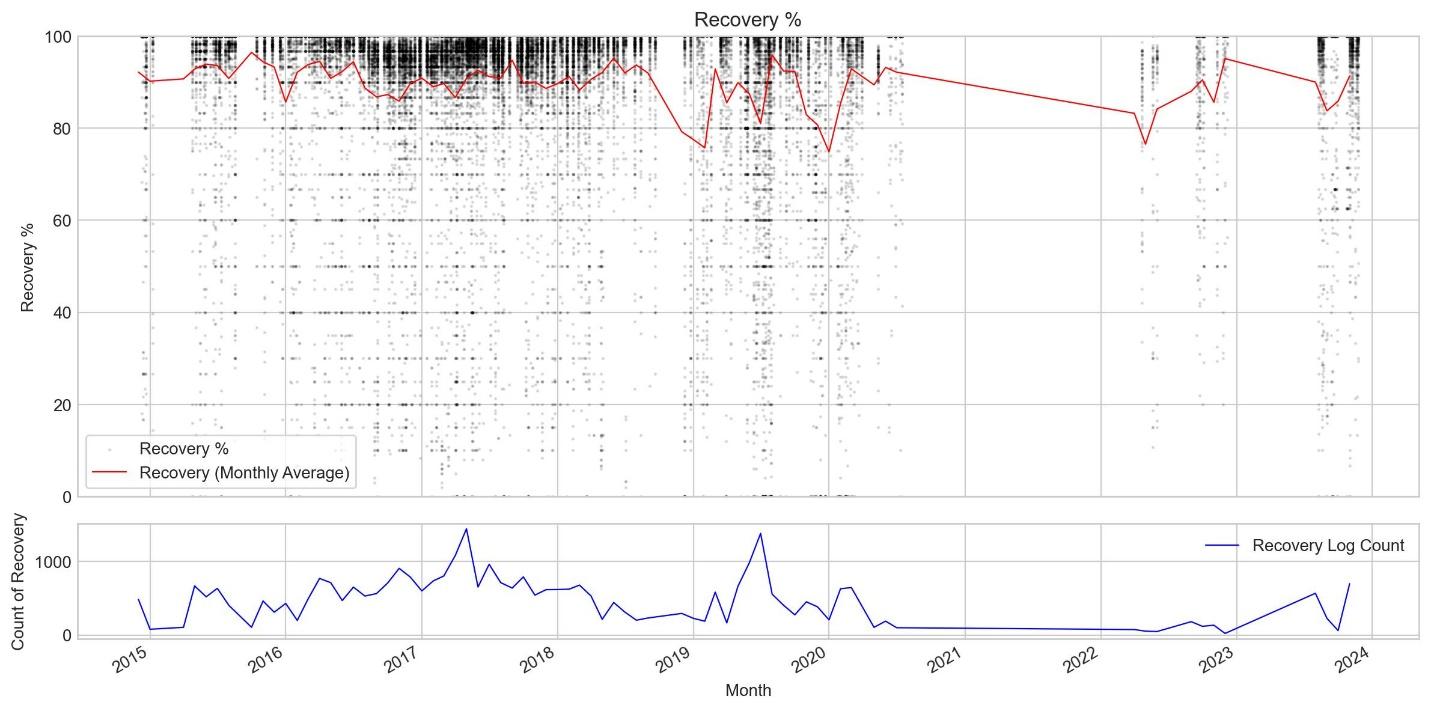

| Table 8-6: Recovery Statistics for Hod Maden, 2014–2024 |

8-19 |

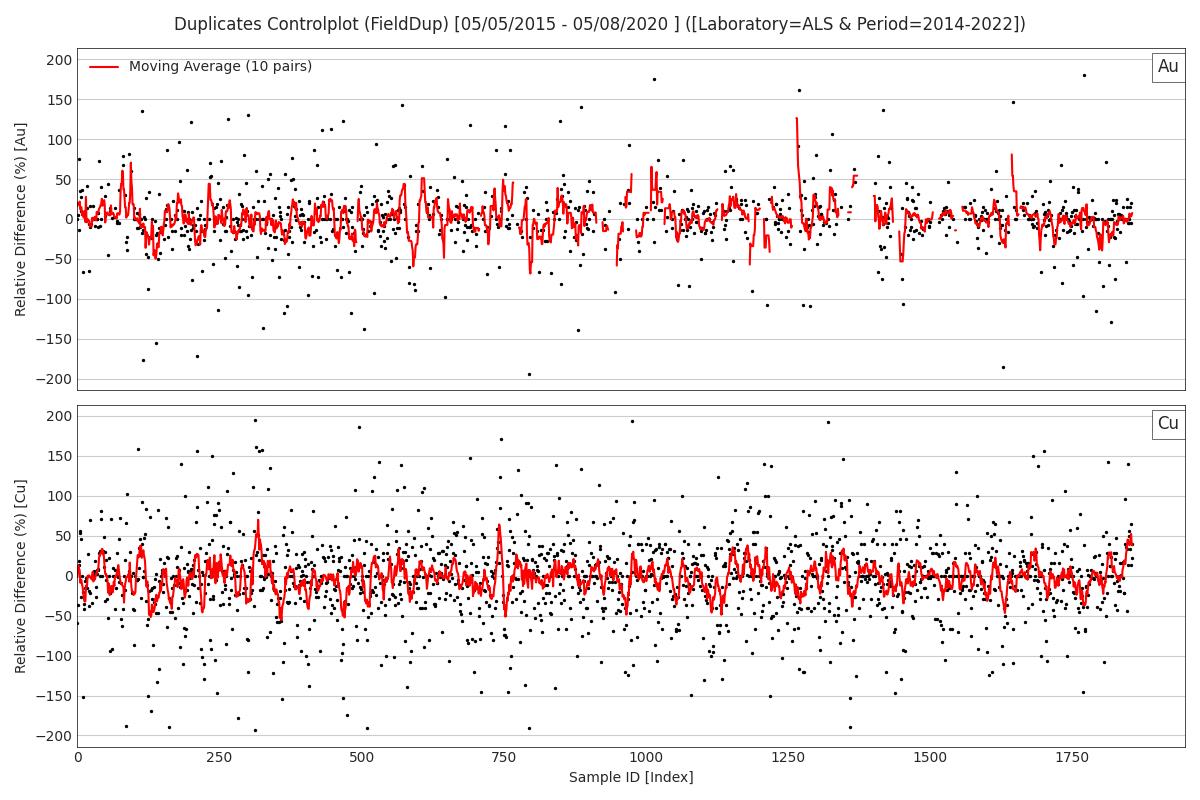

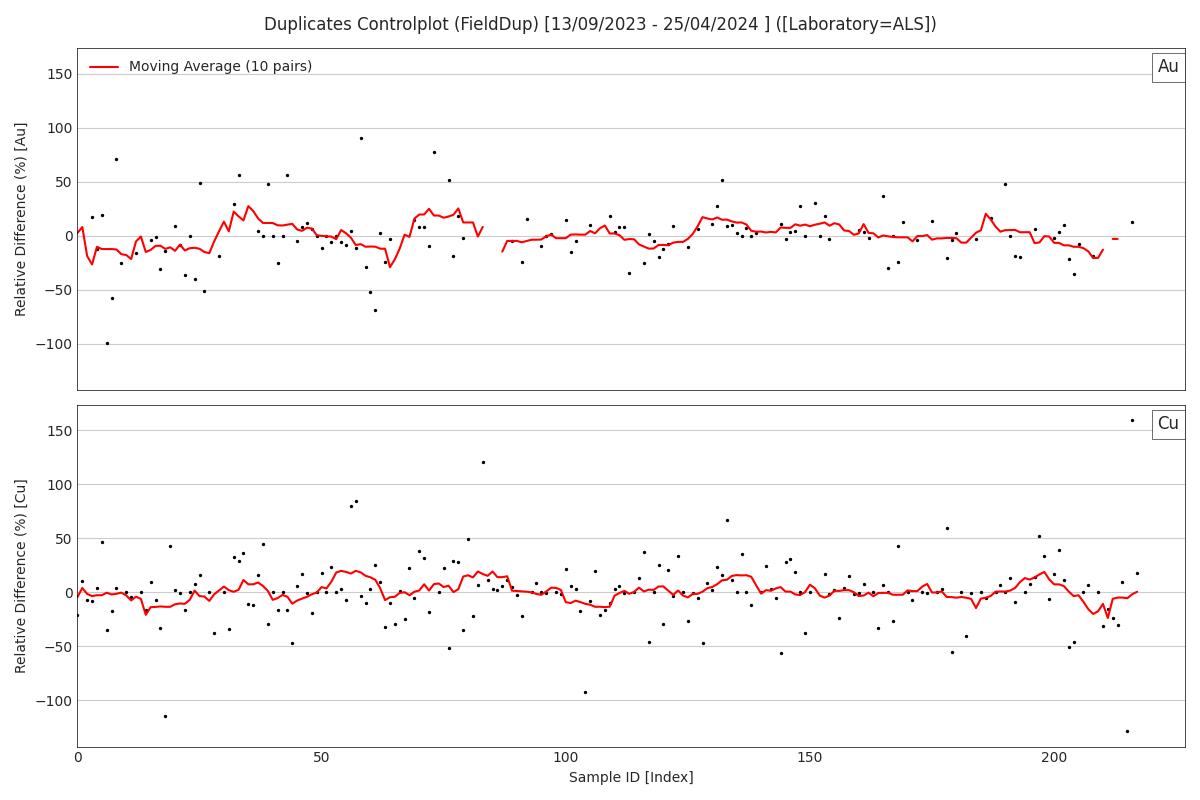

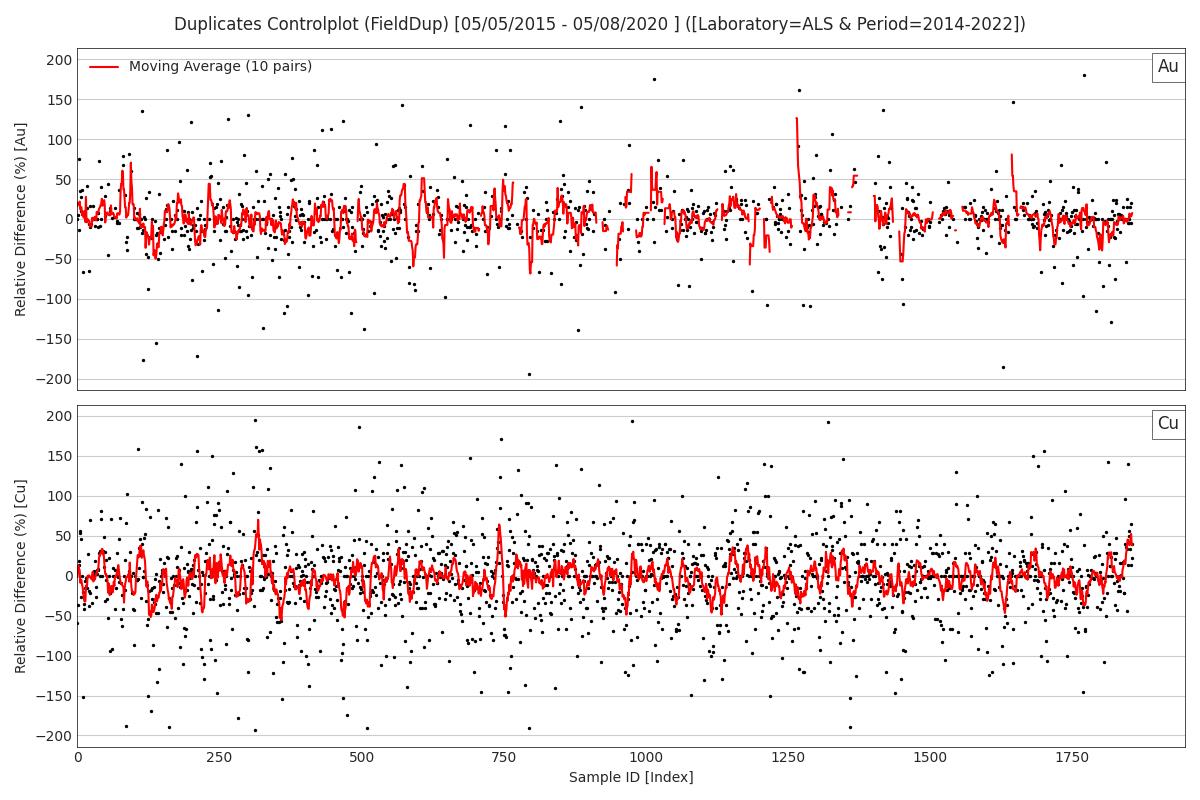

| Table 8-7: Summary of Hod Maden First-Split (“Field Duplicate”) QAT from 2014–2024 |

8-22 |

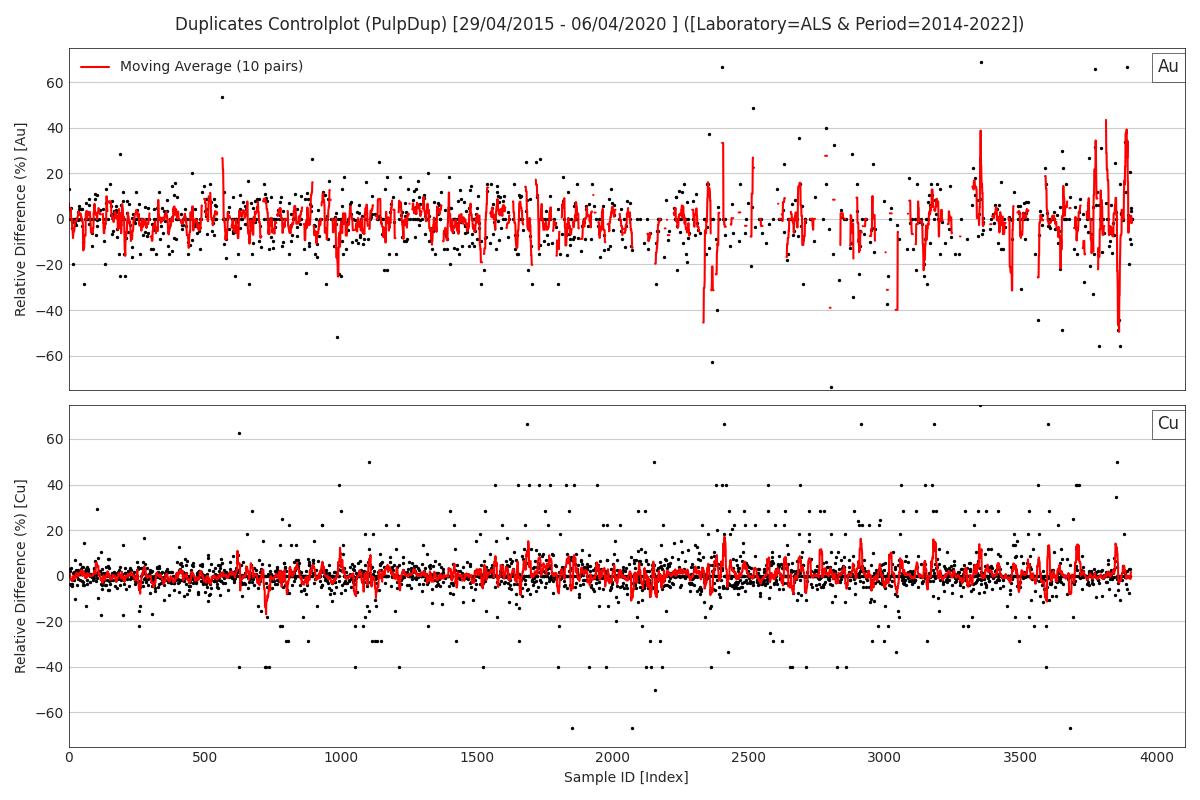

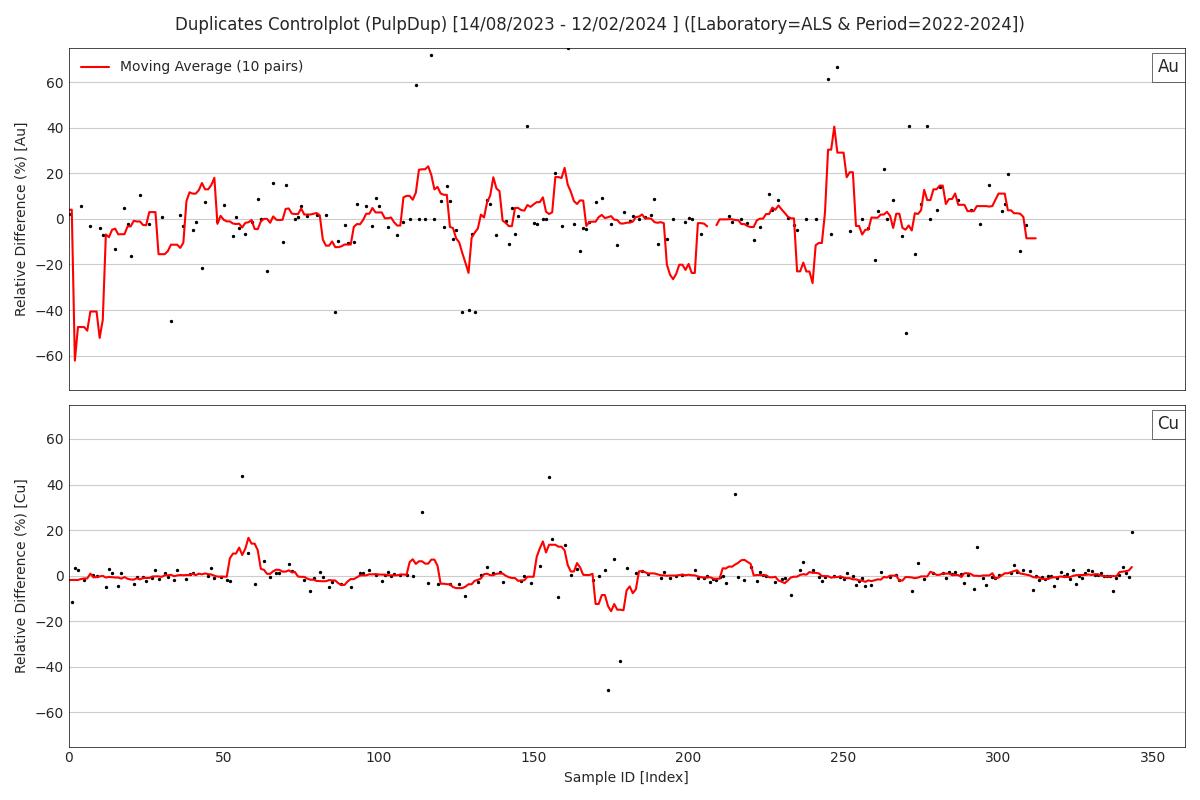

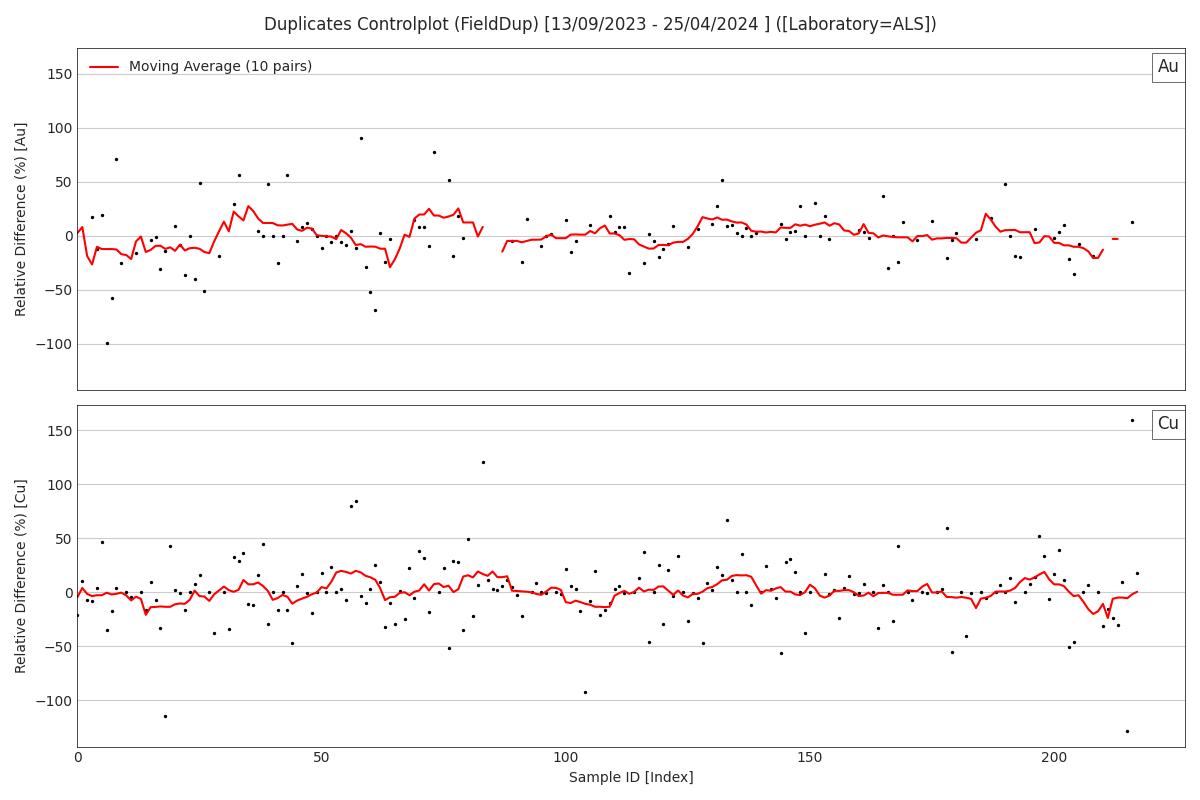

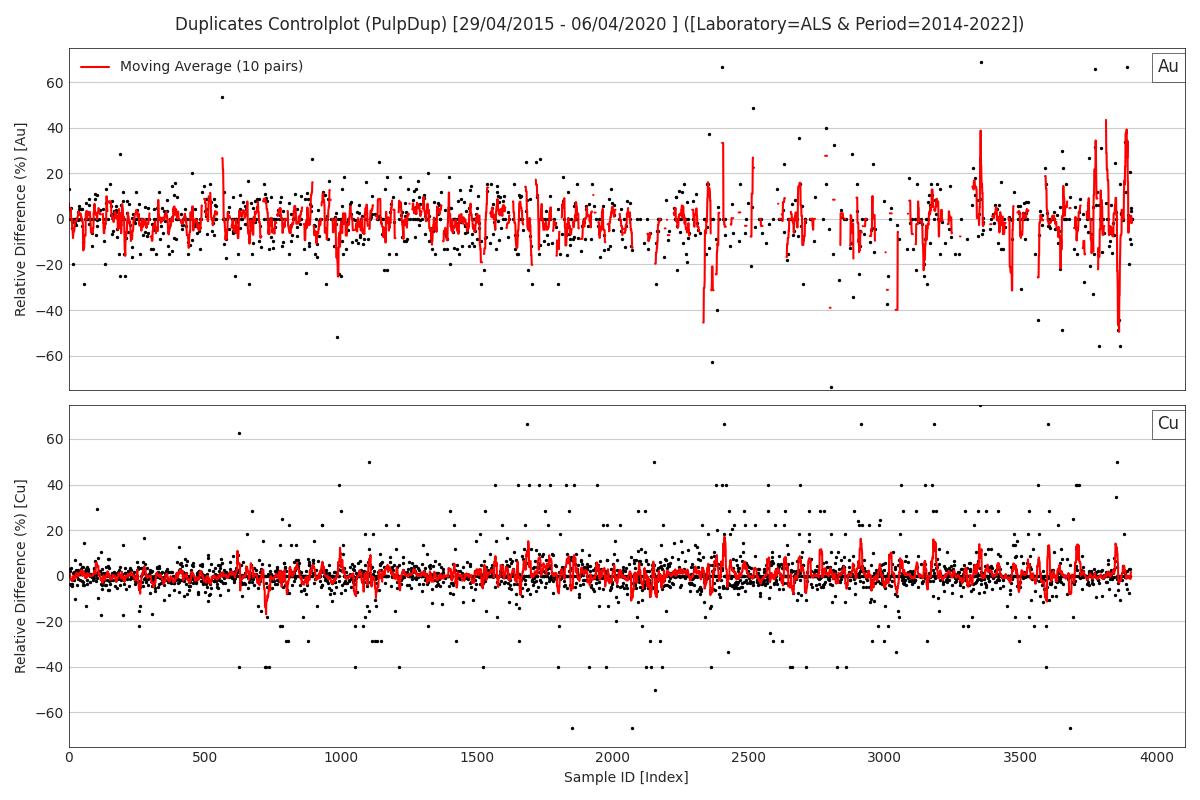

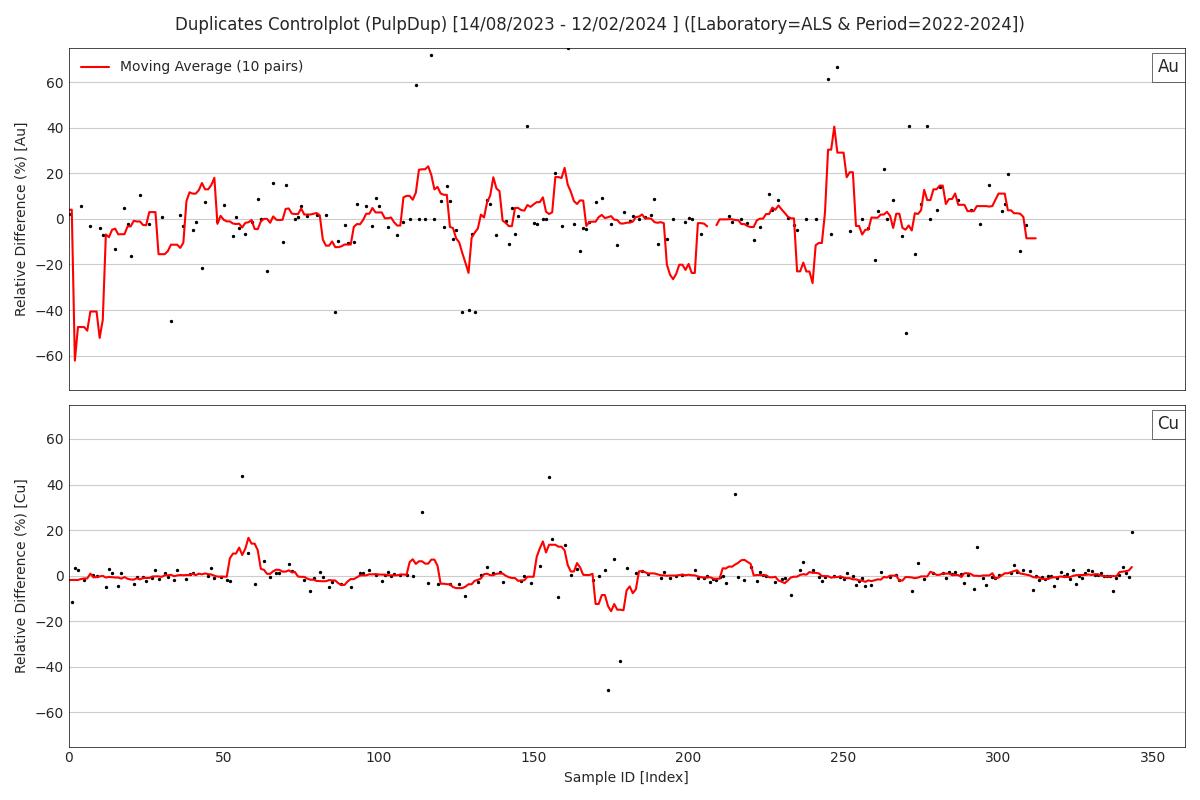

| Table 8-8: Summary of Hod Maden Third Split (“Pulp Duplicate”) QAT from 2014–2024 |

8-24 |

| Table 8-9: QAT Summary for Hod Maden CRMs (2014–2024) |

8-26 |

| Table 9-1: Summary of Check Analyses for HTD-077 |

9-3 |

| Table 9-2: Results of Check Measurements for Bulk Density Requested by the RSC QP |

9-5 |

| Table 10-1: Average Grade and Recoveries of the LCT Conducted at HMT |

10-4 |

| Table 10-2: Average Grade and Recoveries of the LCT Conducted at WAI |

10-5 |

| Table 10-3: Samples Selected for the Ore Variability Flotation Tests |

10-7 |

| Table 10-4: Comminution Test Samples |

10-8 |

| Table 10-5: Comminution Test Results of the Variability Samples |

10-13 |

| Table 10-6: Rougher/Scavenger tests (2024) |

10-16 |

| Table 10-7: OCT and LCT Test Results |

10-18 |

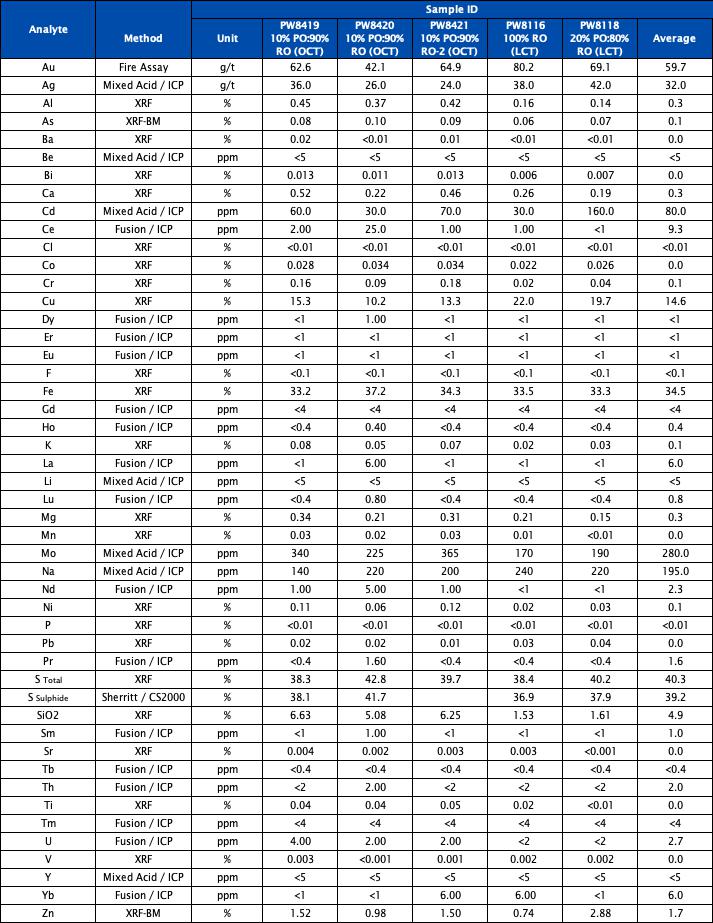

| Table 10-8: Detailed Analysis of OCT and LCT Concentrates |

10-22 |

| Table 11-1: Summary of Hod Maden Mineral Resources, exclusive of Mineral Reserves, as of August 31, 2025 (SSR’s

Attributable Share) |

11-1 |

| Table 11-2: Summary of Drill Hole Data Informing the MRE |

11-2 |

| Table 11-3: Summary of Available Data for all Elements Included in the MRE |

11-3 |

| Table 11-4: Summary of Remaining Core |

11-3 |

| Table 11-5: Grouped Lithology Column Used to Support the Lithology Model |

11-6 |

| | vii |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| Table 11-6: Summary of the Sub-Domaining Strategy for Hod Maden |

11-18 |

| Table 11-7: Declustered Composite Statistics for Au and Cu Inside the Estimation Domains |

11-22 |

| Table 11-8: Declustered Composite Statistics for Fe, SS and C Inside the Estimation Domains |

11-25 |

| Table 11-9: Variogram Parameters for All Domains (Au, Cu) |

11-30 |

| Table 11-10: Block Model Description |

11-31 |

| Table 11-11: Kriging Neighborhood Settings for All Domains (Au, Cu) |

11-32 |

| Table 11-12: Hod Maden Density Statistics for Lithology Domains |

11-33 |

| Table 11-13: Summary of Hod Maden Mineral Resource Cut-off Value |

11-42 |

| Table 11-14: Summary of Hod Maden Mineral Resources, exclusive of Mineral Reserves as of August 31, 2025 (SSR’s

Attributable Share) |

11-43 |

| Table 11-: Summary of Hod Maden Mineral Resources, exclusive of Mineral Reserves as of August 31, 2025 (100%) |

11-43 |

| Table 12-1: Mineral Reserve Estimate as of August 31, 2025 (SSR’s Attributable Ownership Basis) |

12-1 |

| Table 12-2: NSR Input Parameters |

12-5 |

| Table 12-3 Cut-off Values Used for 2025 Mineral Reserve Estimation |

12-6 |

| Table 12-4: Hod Maden - Mining Recovery and Dilution Factors by Mining Method |

12-8 |

| Table 12-5: Comparison Mining Recovery and Dilution Factors for Long Hole Stoping |

12-8 |

| Table 12-6: Mineral Reserve Estimate as of August 31, 2025 (100% Ownership Basis) |

12-9 |

| Table 12-7: Mineral Reserve Estimate as of August 31, 2025 (SSR’s Attributable Ownership Basis) |

12-9 |

| Table 12-8 Previous Mineral Reserve Estimate (December 31, 2024) Compared to Current Mineral Reserve Estimate –August

31, 2025 (10% Basis) |

12-11 |

| Table 13-1: Intact Rock Properties and Laboratory Test Results (UCS with Elastic Constants) |

13-5 |

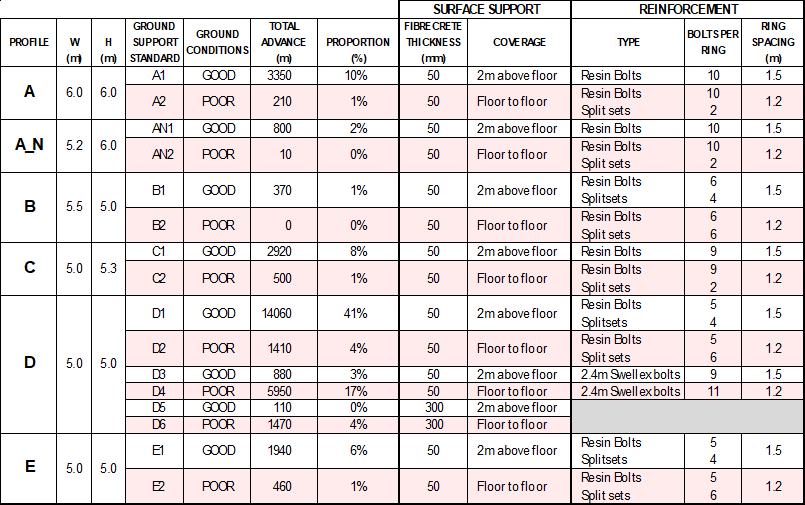

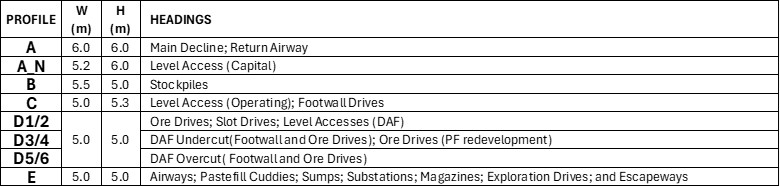

| Table 13-2: Estimated Development Ground Support Requirements – LHS |

13-9 |

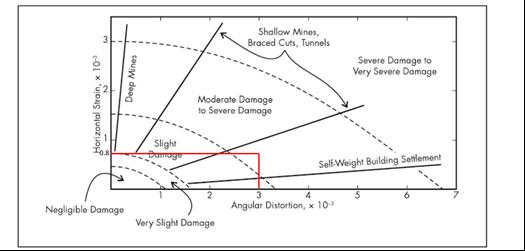

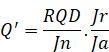

| Table 13-3: Rock Mass Classification Based on the Q’ |

13-12 |

| Table 13-4: Stope Stability Assessment Results |

13-14 |

| Table 13-5: Stope Sizing |

13-15 |

| Table 13-6 Hod Maden Stope Optimizer Settings |

13-20 |

| Table 13-7: Hod Maden LHS Lateral Development Quantities |

13-27 |

| Table 13-8: Hod Maden Mine Lateral Development Quantities – Heading Type |

13-28 |

| Table 13-9: Hod Maden Vertical Development Types and Profiles |

13-28 |

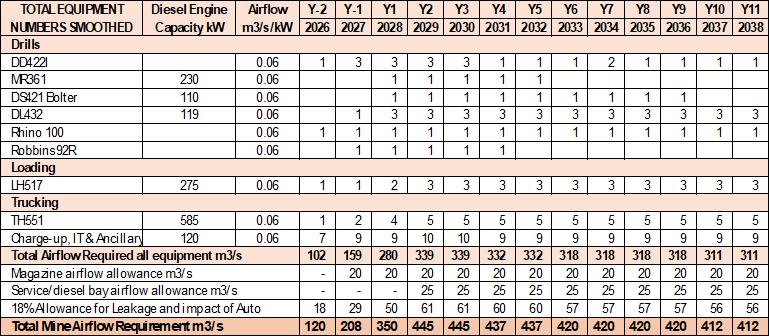

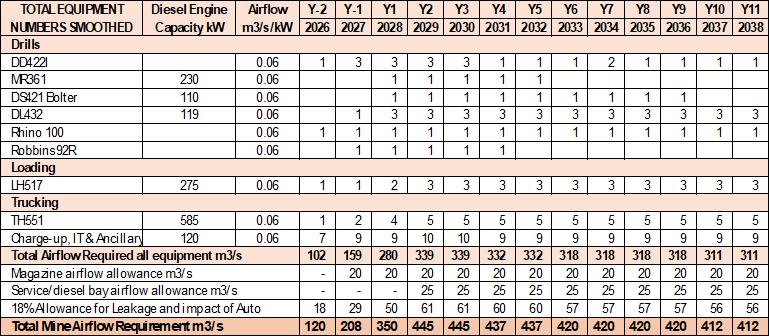

| Table 13-10: Hod Maden Ventilation Design Criteria |

13-35 |

| Table 13-11: Total Airflow Requirements – Primary |

13-36 |

| | viii |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| Table 13-12: DAF Lateral Development Peak Scheduled Advance Rates |

13-39 |

| Table 13-13: LHS Lateral Development Peak Scheduled Advance Rates |

13-39 |

| Table 13-14: Life of Mine Lateral Development Schedule – DAF and LHS |

13-40 |

| Table 13-15: Cable Drilling Summary |

13-41 |

| Table 13-16: LHS Vertical Development Peak Scheduled Advance Rates |

13-41 |

| Table 13-17: LHS Vertical Development Resource Assignments |

13-41 |

| Table 13-18: Life of Mine Vertical Development Summary |

13-42 |

| Table 13-19: Life of Mine Production Drilling Summary |

13-42 |

| Table 13-20: Life of Mine Production by Level Summary |

13-43 |

| Table 13-21: Production Schedule Assumptions |

13-44 |

| Table 13-22: Production Resource Assignments |

13-45 |

| Table 13-23: Hod Maden Life of Mine Production Schedule |

13-46 |

| Table 13-24: Hod Maden Process Schedule |

13-49 |

| Table 13-25: Paste Line and Service Hole Summary |

13-53 |

| Table 13-26: Summary of LOM Paste Backfill Requirements |

13-54 |

| Table 13-27: UCS Results for Various Binder Contents and Cure Times - PF with CUF Tailings |

13-55 |

| Table 13-28: PF Design Strengths for Vertical Exposures – 30 m Wide Stopes |

13-55 |

| Table 13-29: Life of Mine Equipment Fleet (Year 2, 2029) |

13-58 |

| Table 13-30: Proposed Mobile Equipment Fleet Availability and Utilization |

13-59 |

| Table 13-31: Mining Personnel Summary |

13-63 |

| Table 13-32: Typical Underground Electrical Consumption, kW |

13-67 |

| Table 14-1: Planned Mill Feed Data from Mine Plan – LOM Average |

14-5 |

| Table 14-2: Design Criteria |

14-6 |

| Table 14-3: Reagents Used |

14-11 |

| Table 14-4: Major Consumables with Expected Consumption Rates |

14-12 |

| Table 14-5: Electrical Loads and Electrical Energy Consumption |

14-13 |

| Table 14-6: Major Equipment List |

14-14 |

| Table 14-7: Regrind Mill Selection |

14-15 |

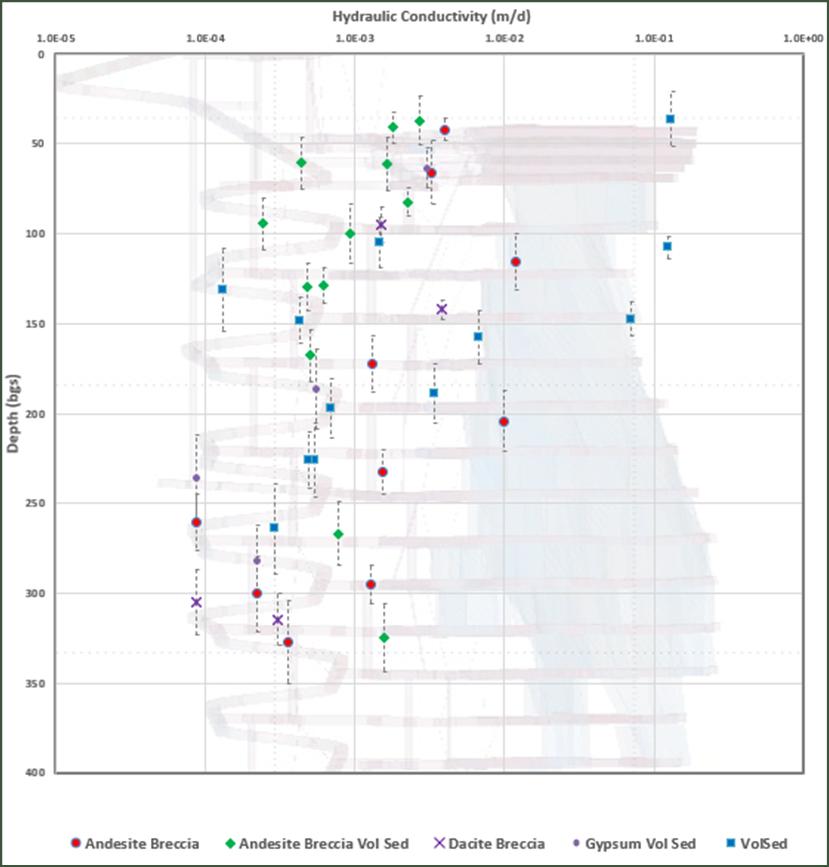

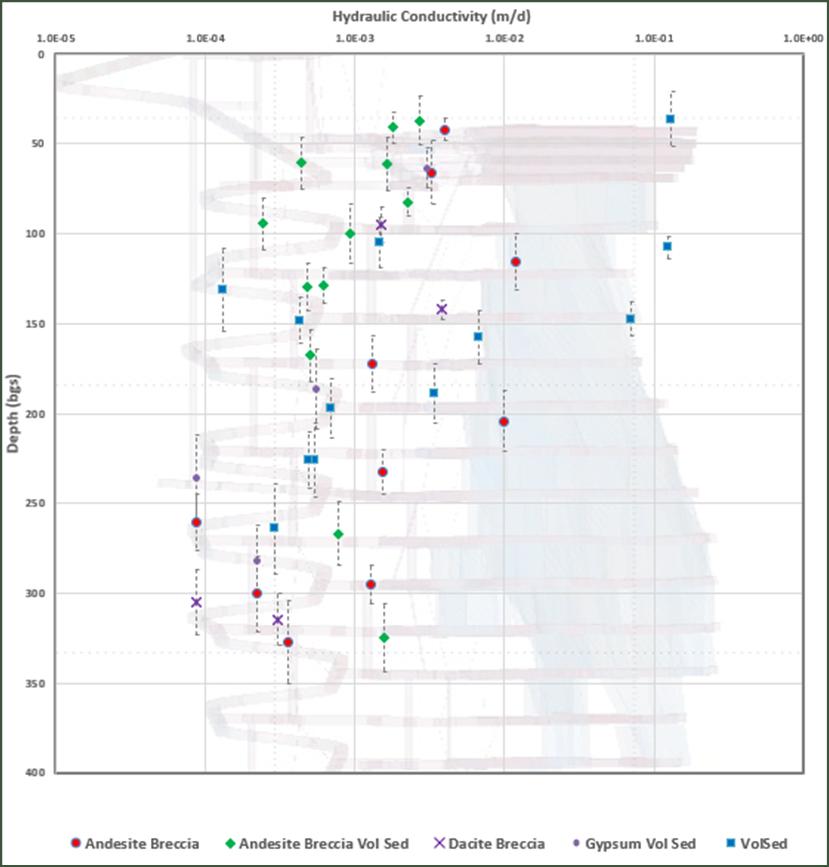

| Table 15-1: Hydraulic Parameters used for Hydrogeological Units |

15-7 |

| Table 15-2: Summary of Planned Sensitivity Analysis |

15-20 |

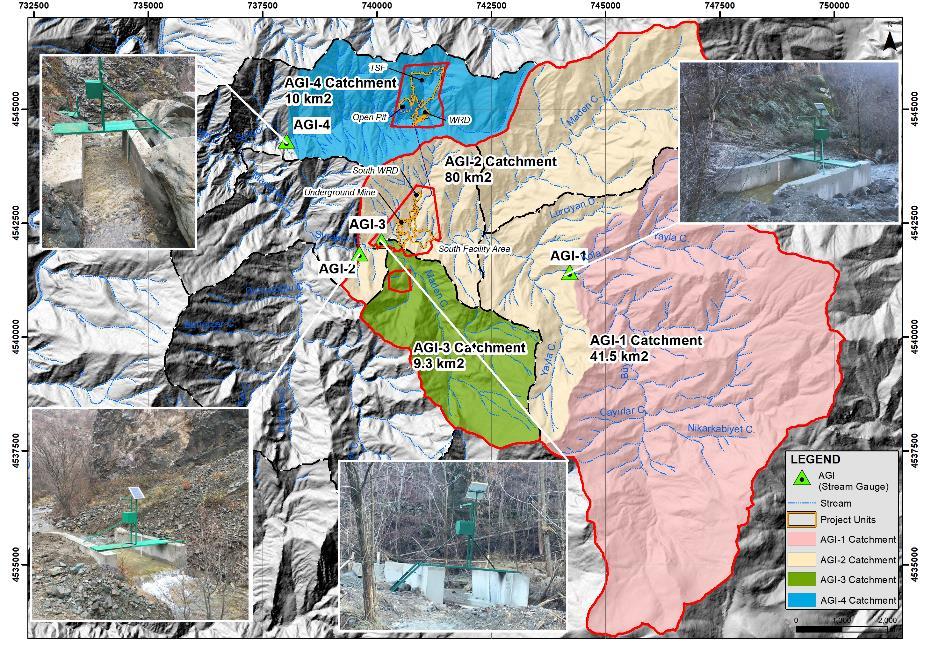

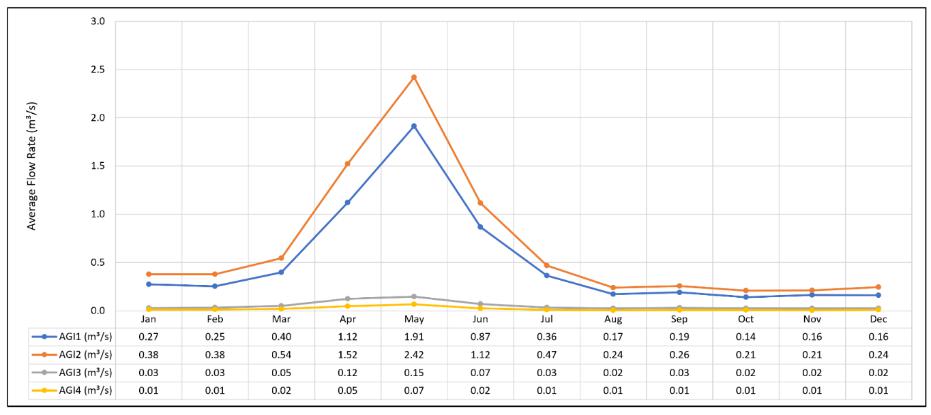

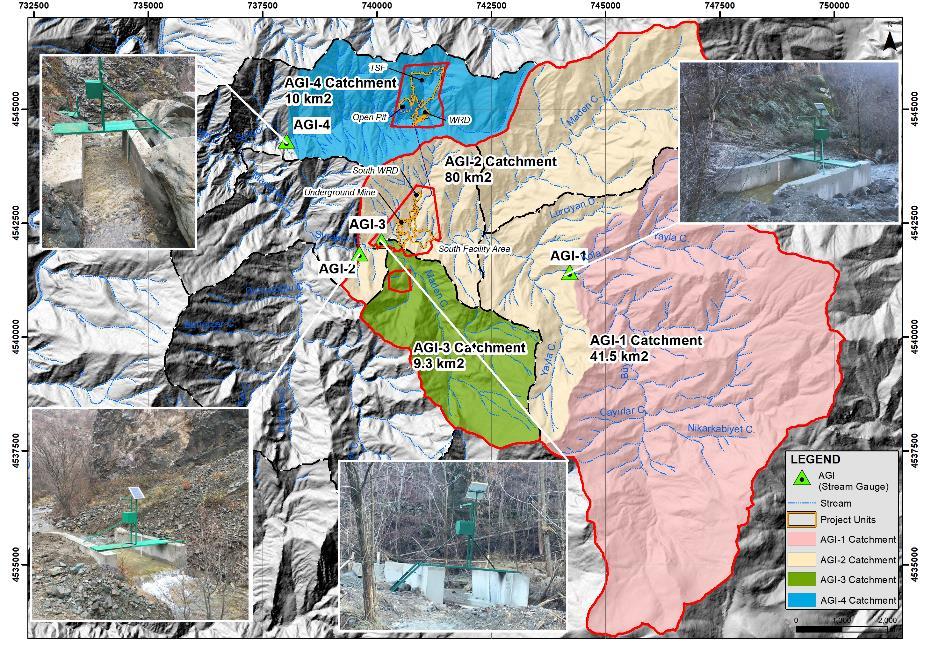

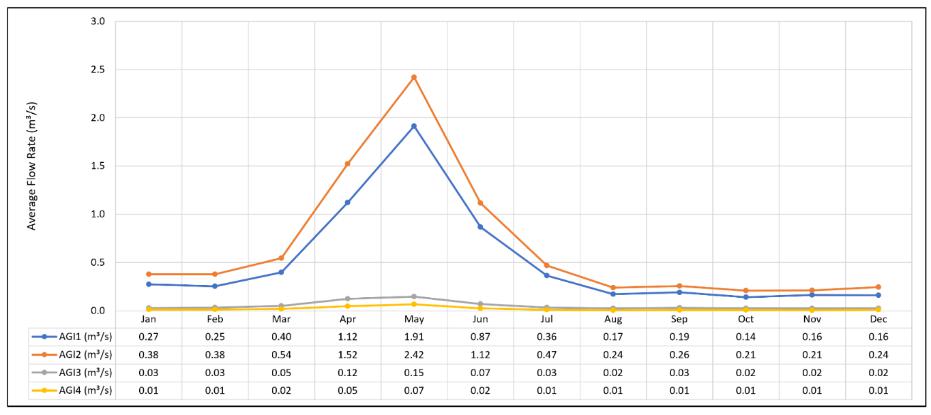

| Table 15-3: Summary Information of Stream Gauges (AGI) |

15-22 |

| Table 15-4: Descriptive

Statistics of Daily Streamflow Records (m3/s) (2018-2021) |

15-23 |

| Table 15-5: Summary of TSF Phases |

15-38 |

| Table 16-1: Metal Price Assumptions |

16-2 |

| | ix |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| Table 16-2: Historical Gold and Copper Prices for the Preceding Five Years |

16-2 |

| Table 17-1: Land Acquisition Status |

17-9 |

| Table 17-2: Approval and Permit Status |

17-11 |

| Table 18-1: LOM Capital Cost Summary |

18-1 |

| Table 18-2: Sunk Costs as of November 30, 2025 |

18-1 |

| Table 18-3: LOM Capital Cost Estimate December 2025 – Level 1 Summary |

18-2 |

| Table 18-4: Key Capital Cost Metrics |

18-3 |

| Table 18-5: Capital Cost Estimate Percentage by Currency |

18-4 |

| Table 18-6: Average Operating Costs Unit Rates |

18-5 |

| Table 18-7: Mine Operating Cost Summary |

18-5 |

| Table 18-8: Process Operating Cost Summary |

18-6 |

| Table 18-9: G&A Operating Cost Summary |

18-6 |

| Table 18-10: Proposed Workforce |

18-6 |

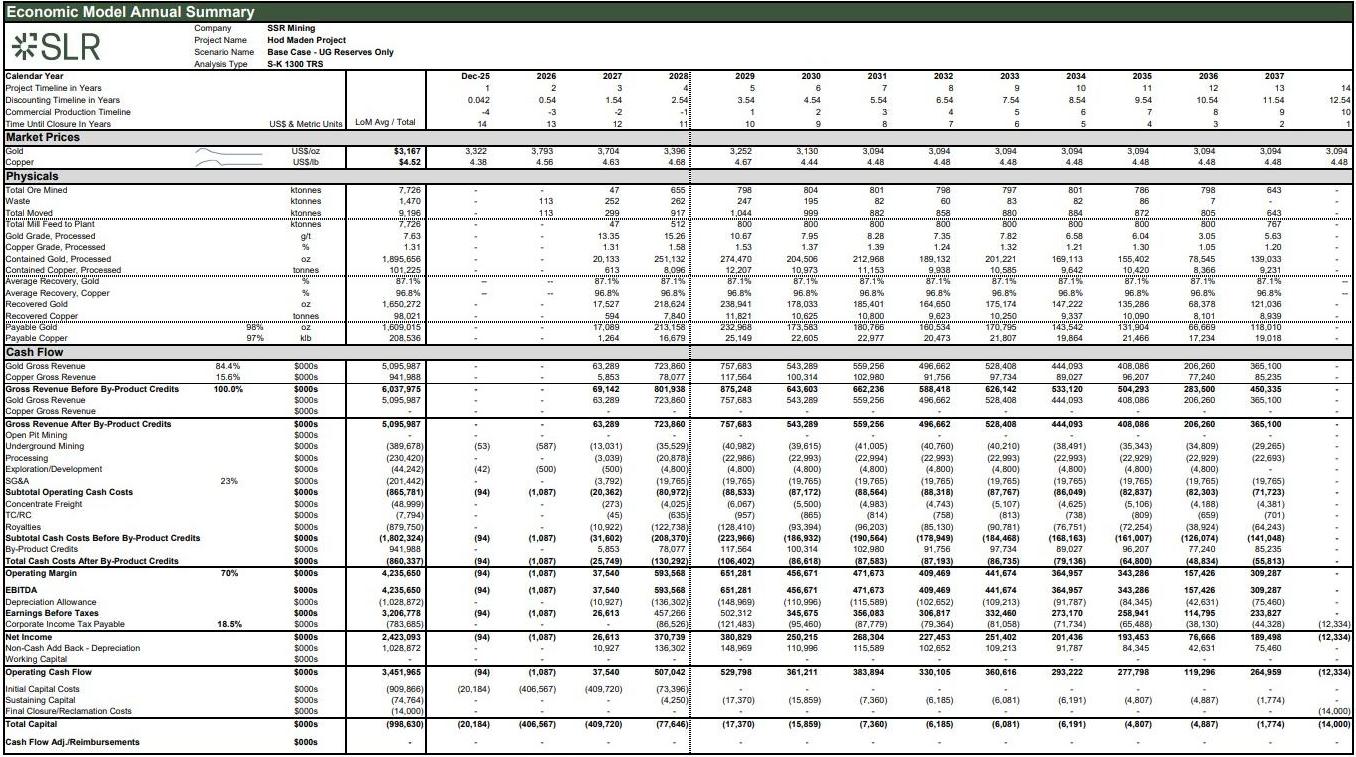

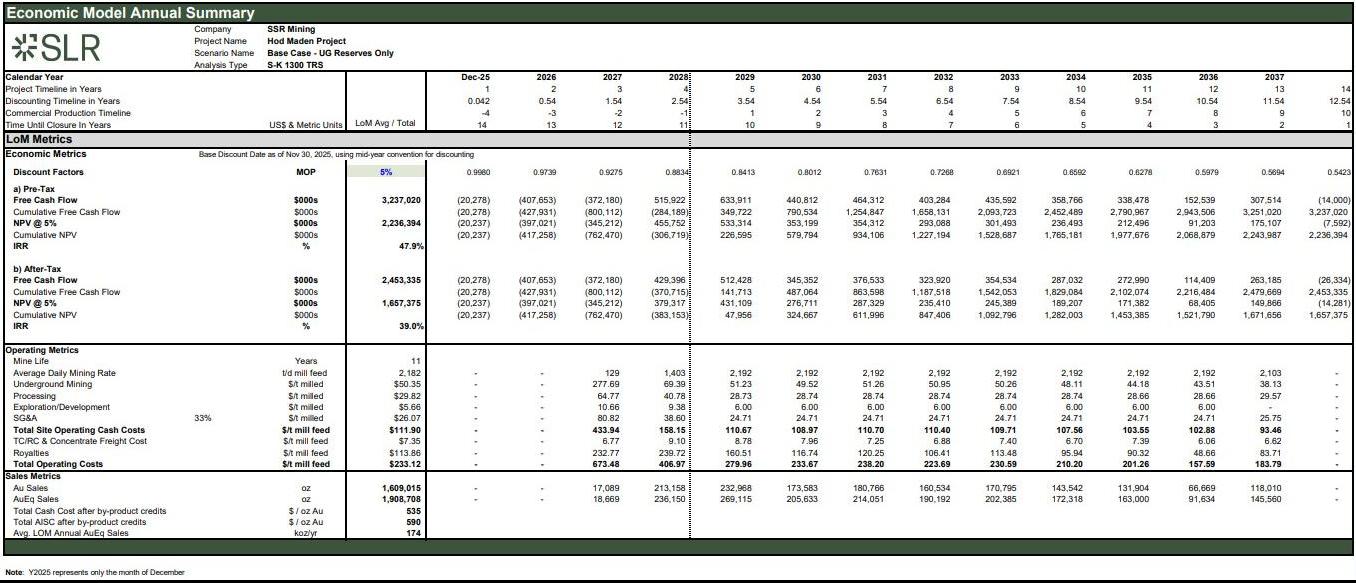

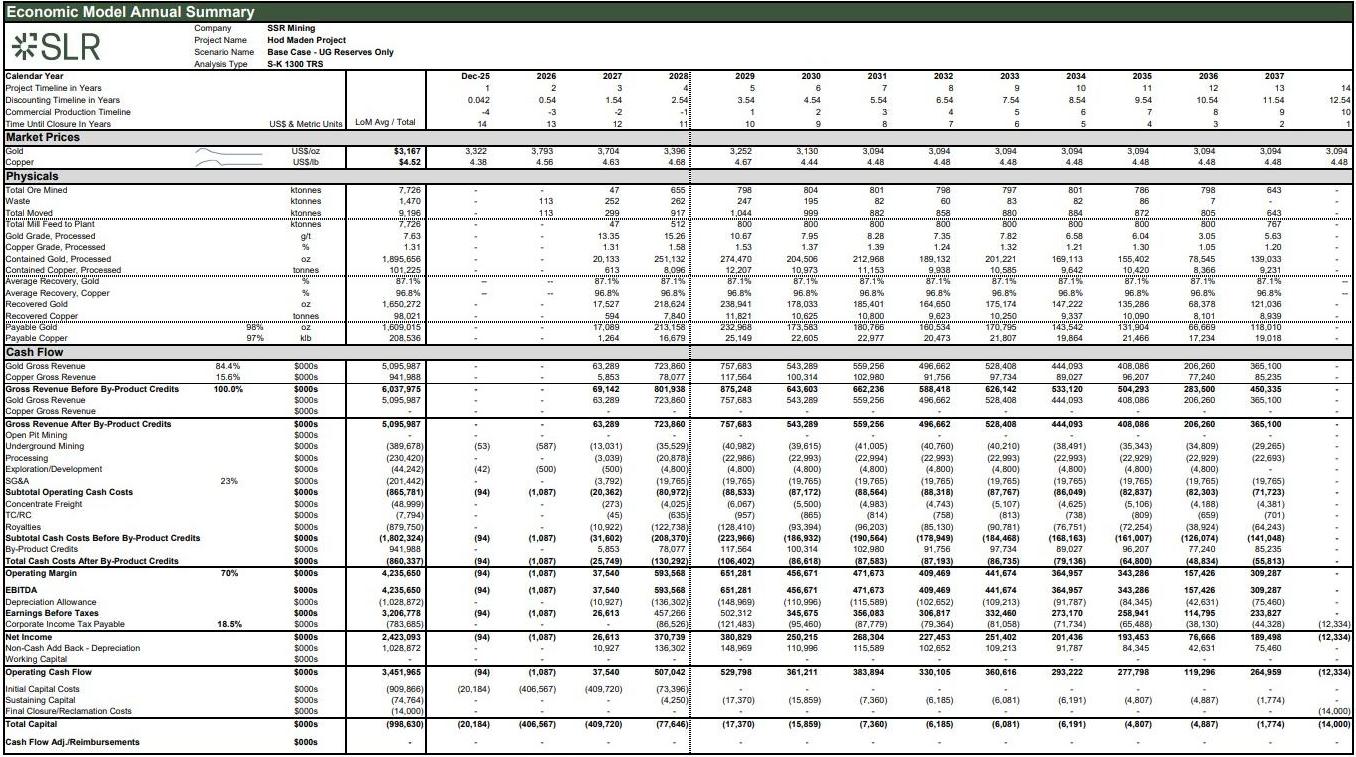

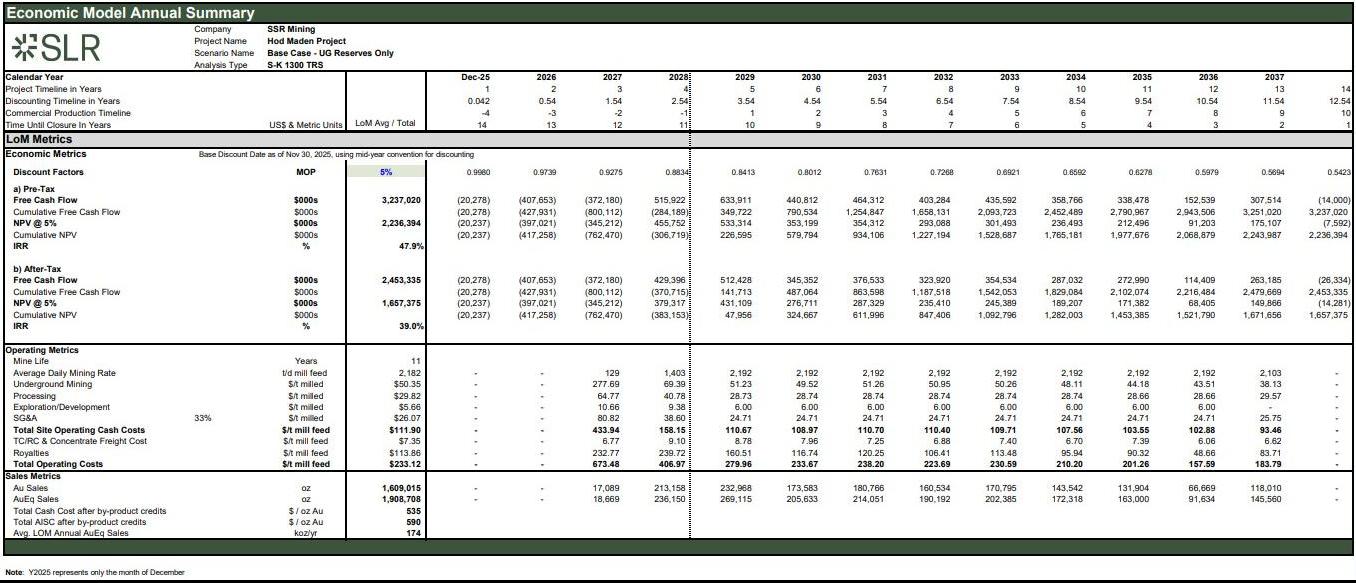

| Table 19-1: After-Tax Cash Flow Summary |

19-3 |

| Table 19-2: AISC Composition |

19-4 |

| Table 19-3: After-Tax Sensitivity Analysis |

19-6 |

| Table 21-1: Hod Maden Schedule Current Overview |

21-1 |

| Table 21-2: Hod Maden Schedule Milestones |

21-3 |

| Table 21-3: Permitting Schedule Current Status |

21-4 |

| Table 21-4: Direct Labor Hours for Construction by Area |

21-7 |

| Table 21-5: Contracting Strategy |

21-12 |

| Table 21-6: Summary of Project Progress as at November 30, 2025 |

21-14 |

Figures

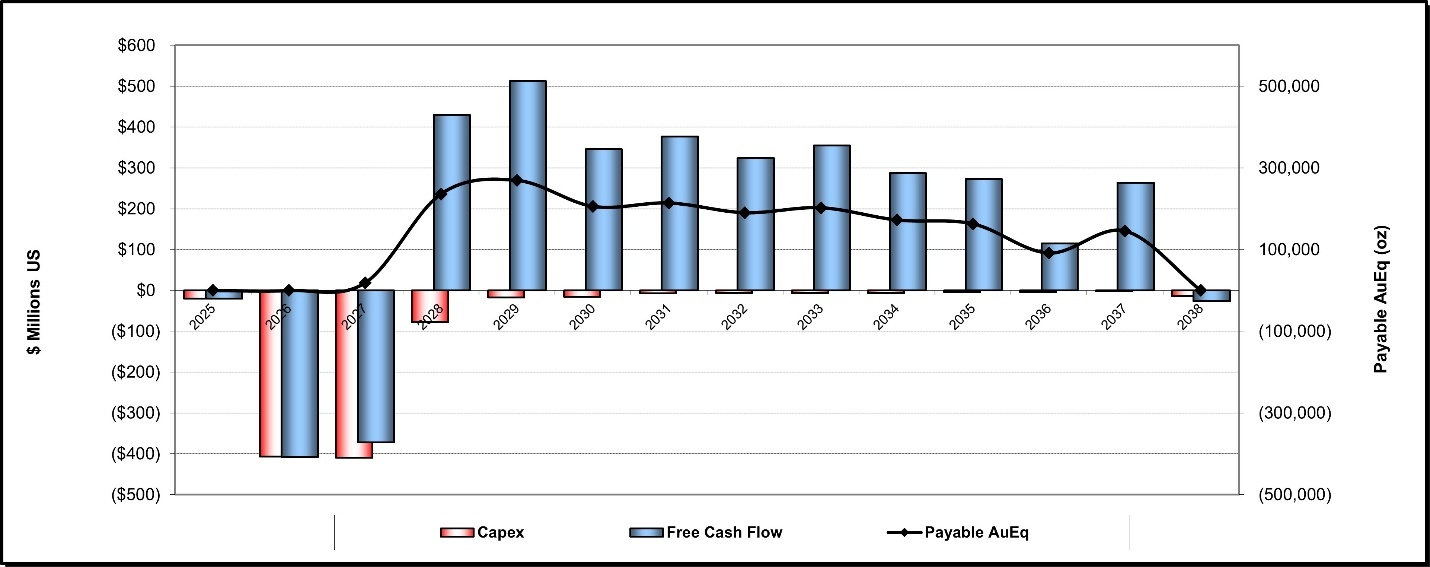

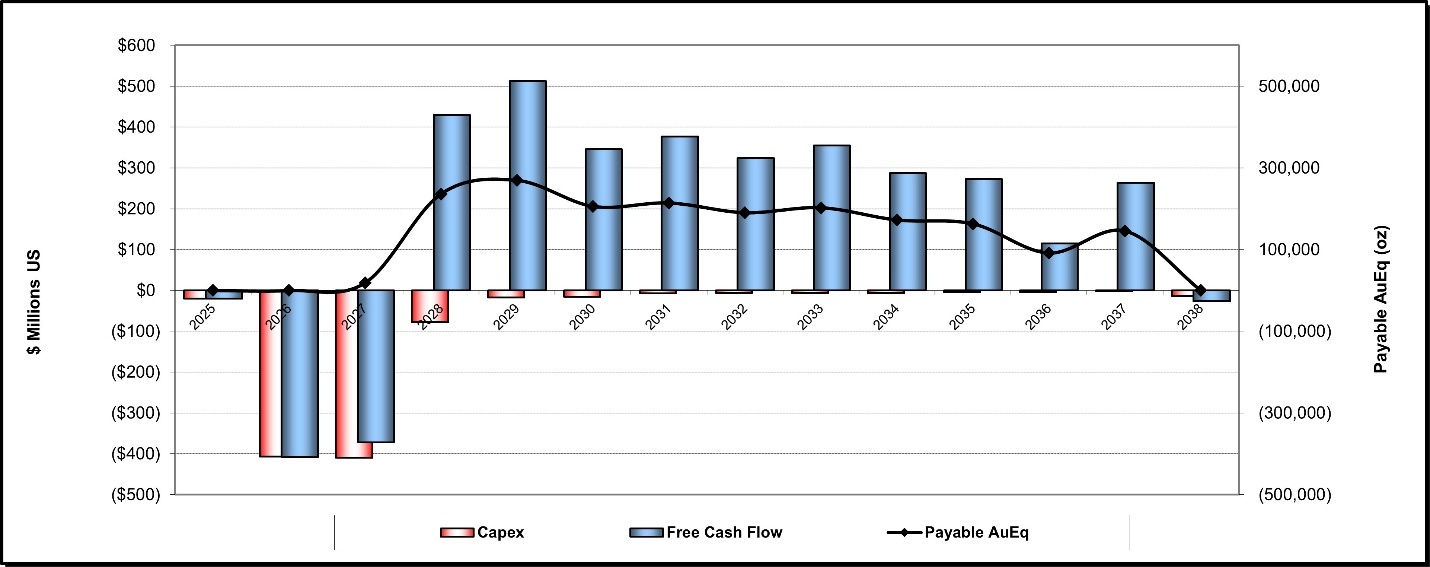

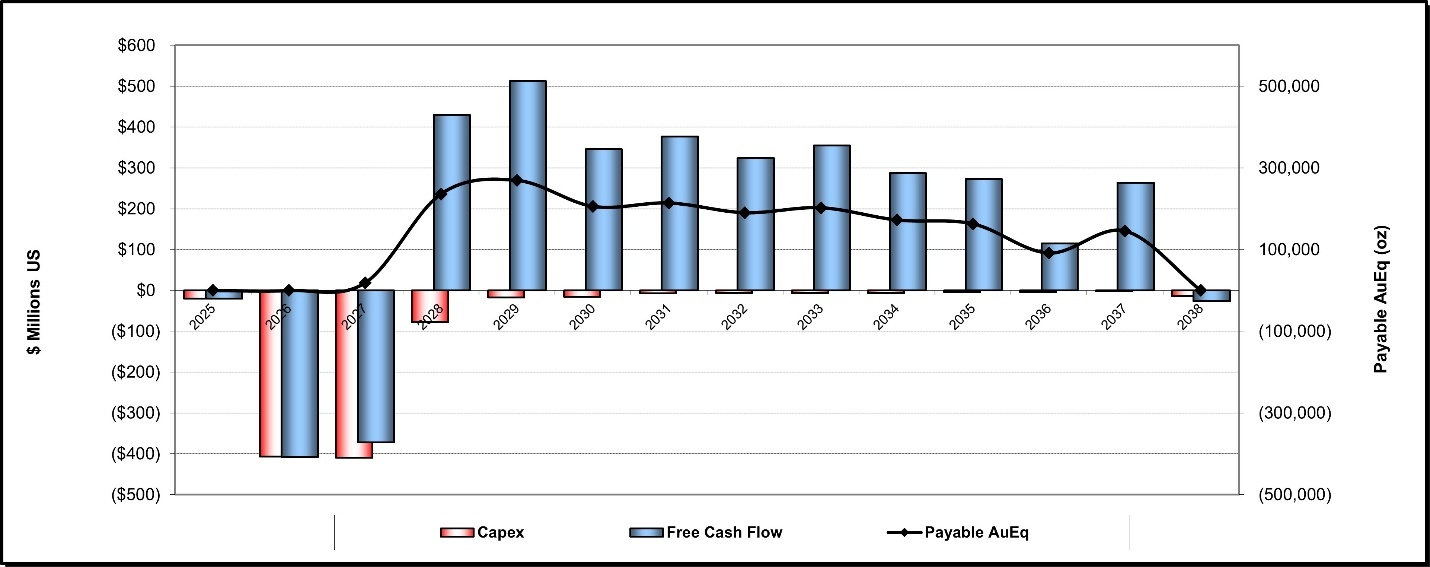

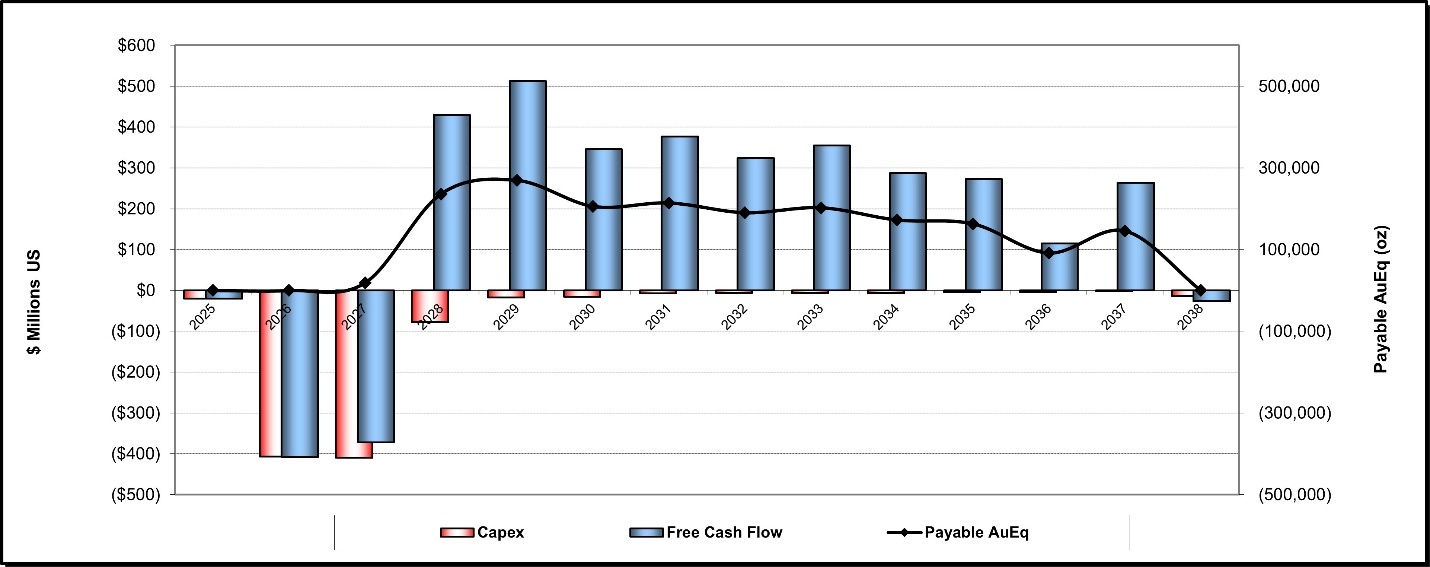

| Figure 1-1: After-Tax Annual Cash Flow Metrics |

1-14 |

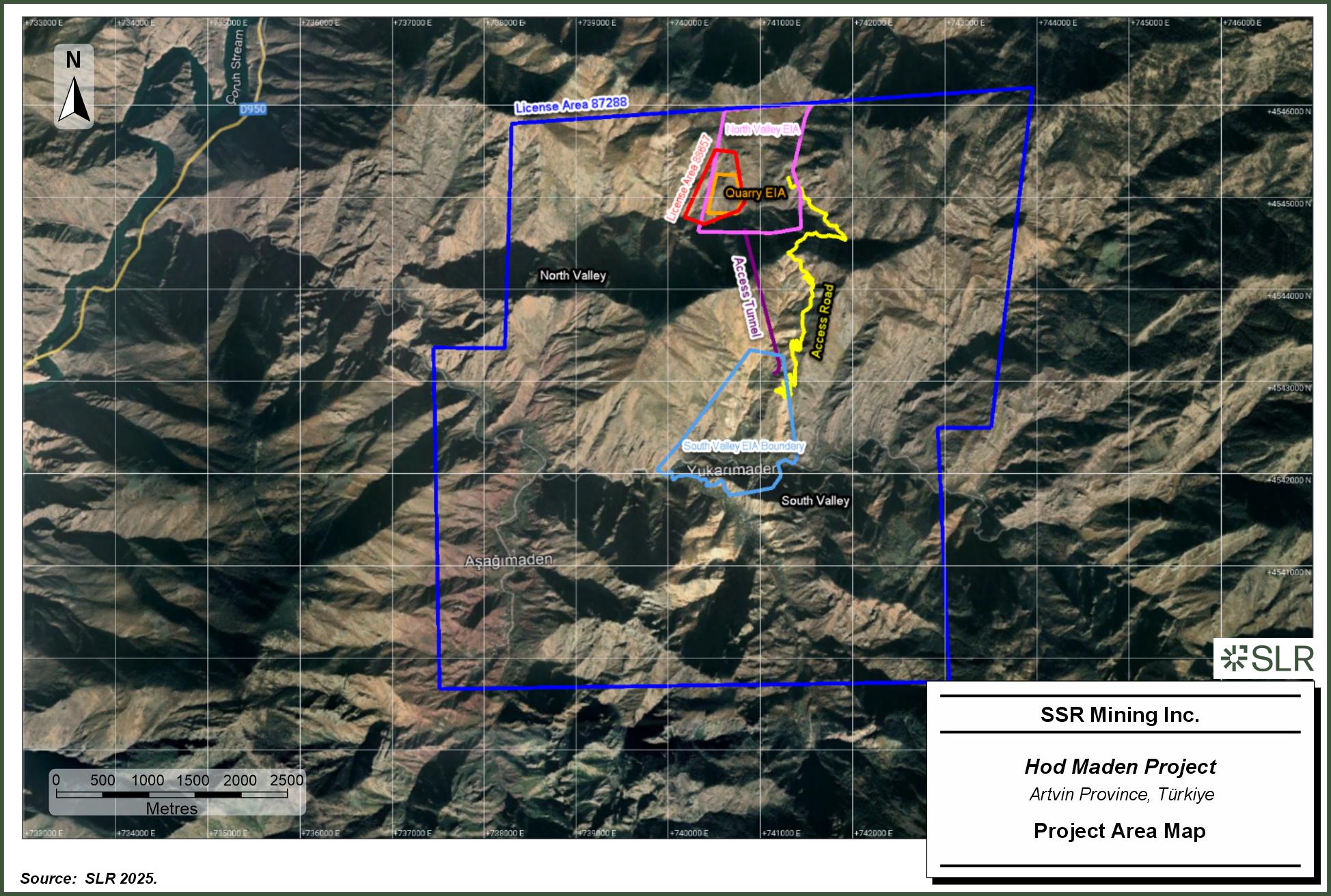

| Figure 3-1: Location Map |

3-2 |

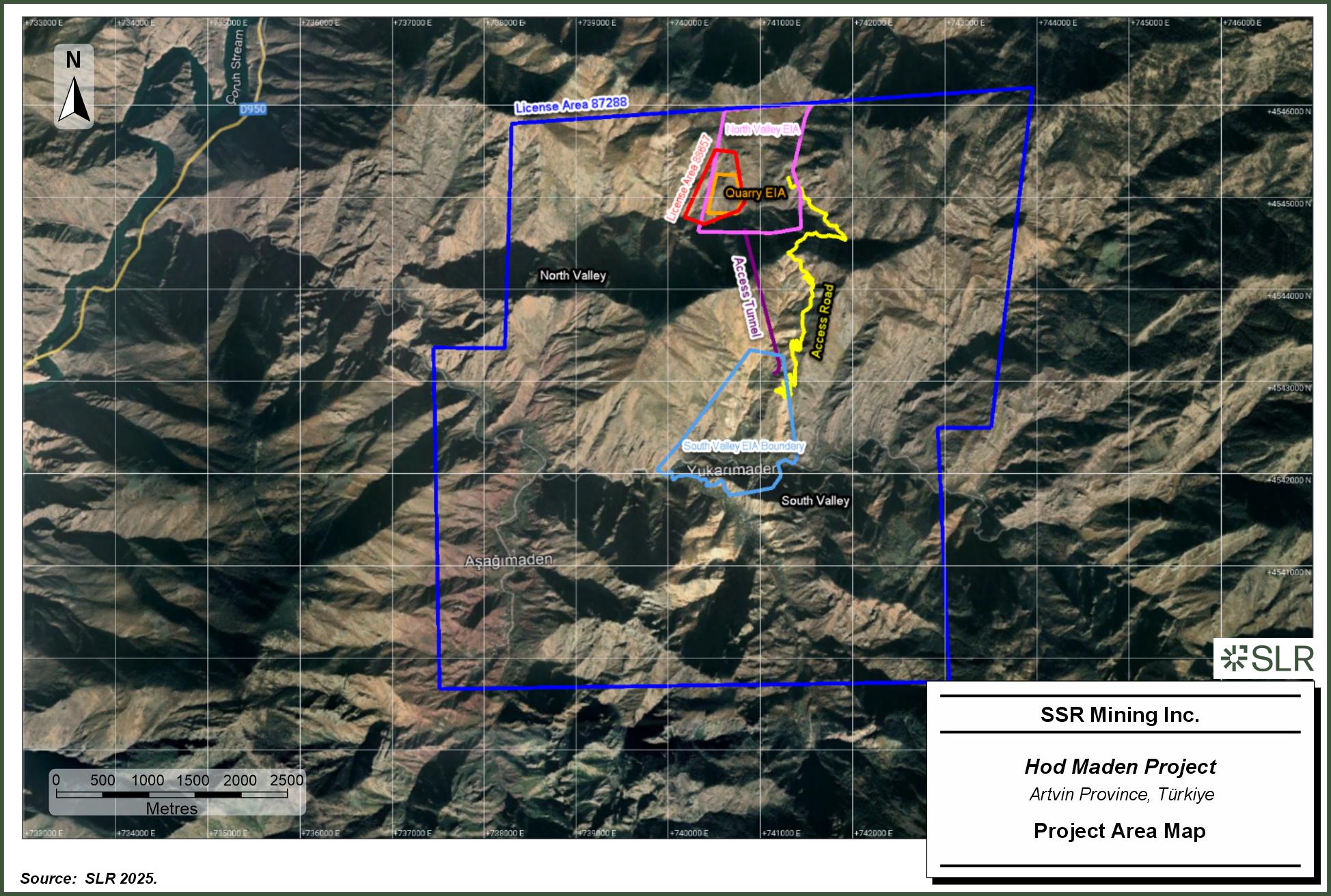

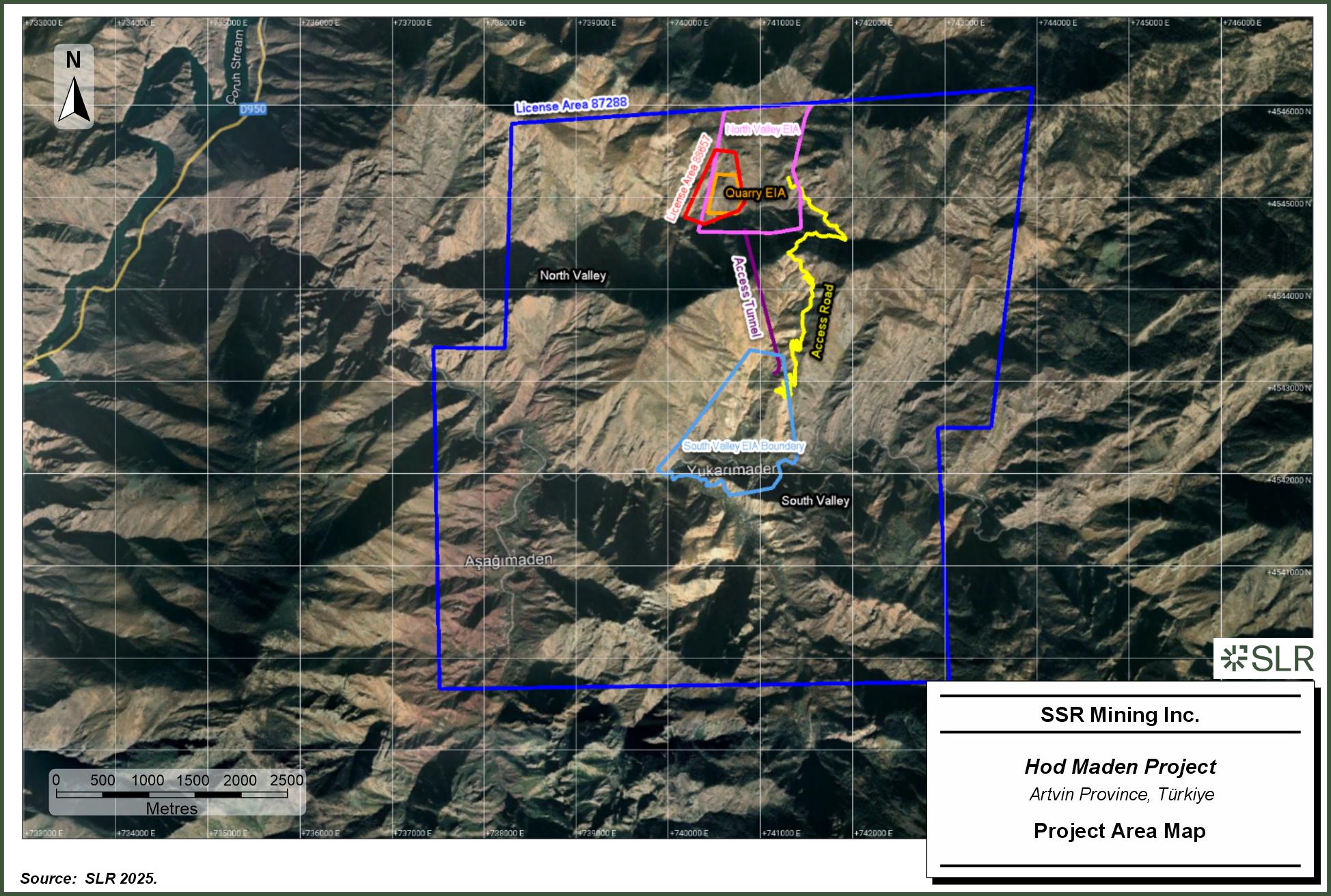

| Figure 3-2: Project Area Map |

3-4 |

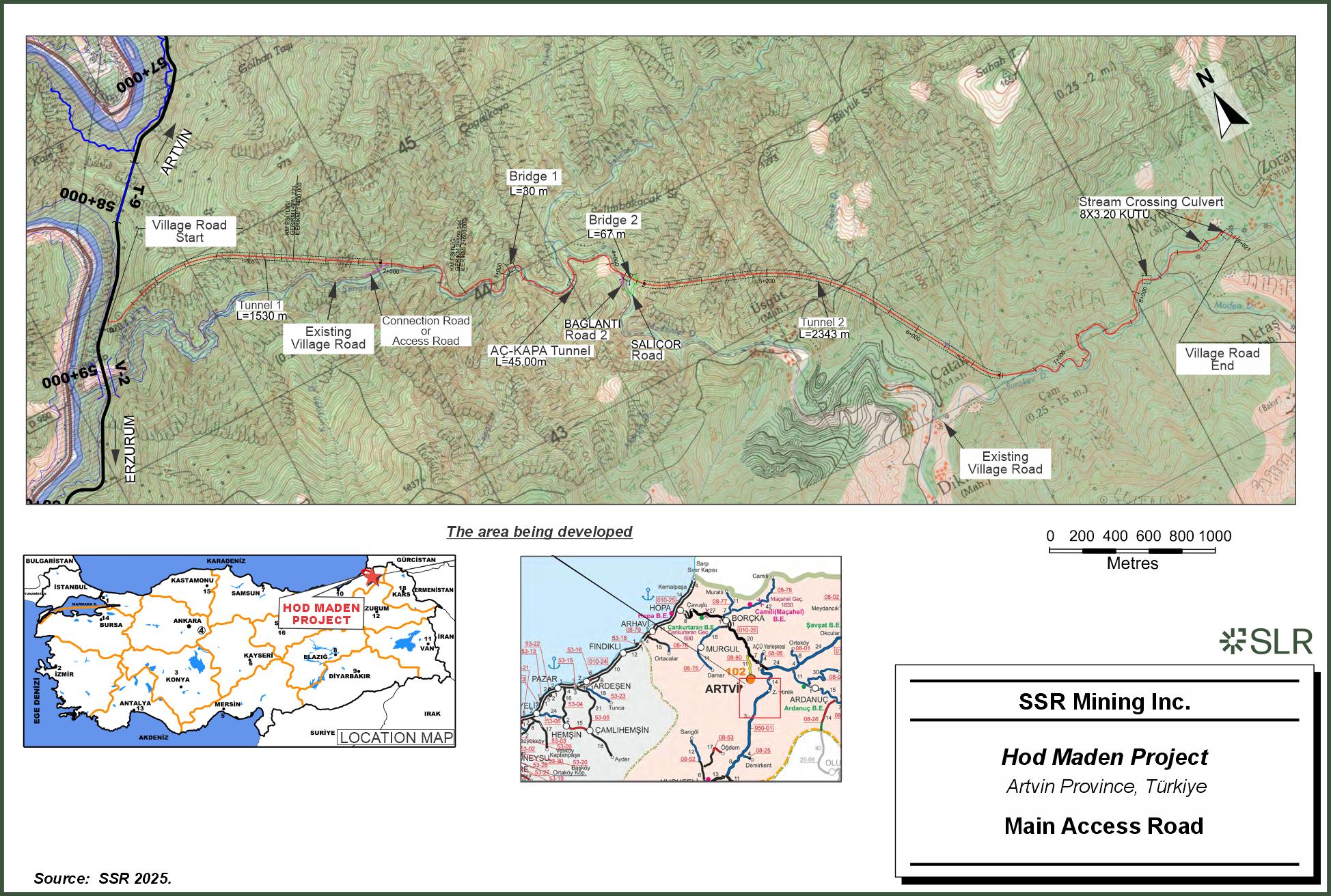

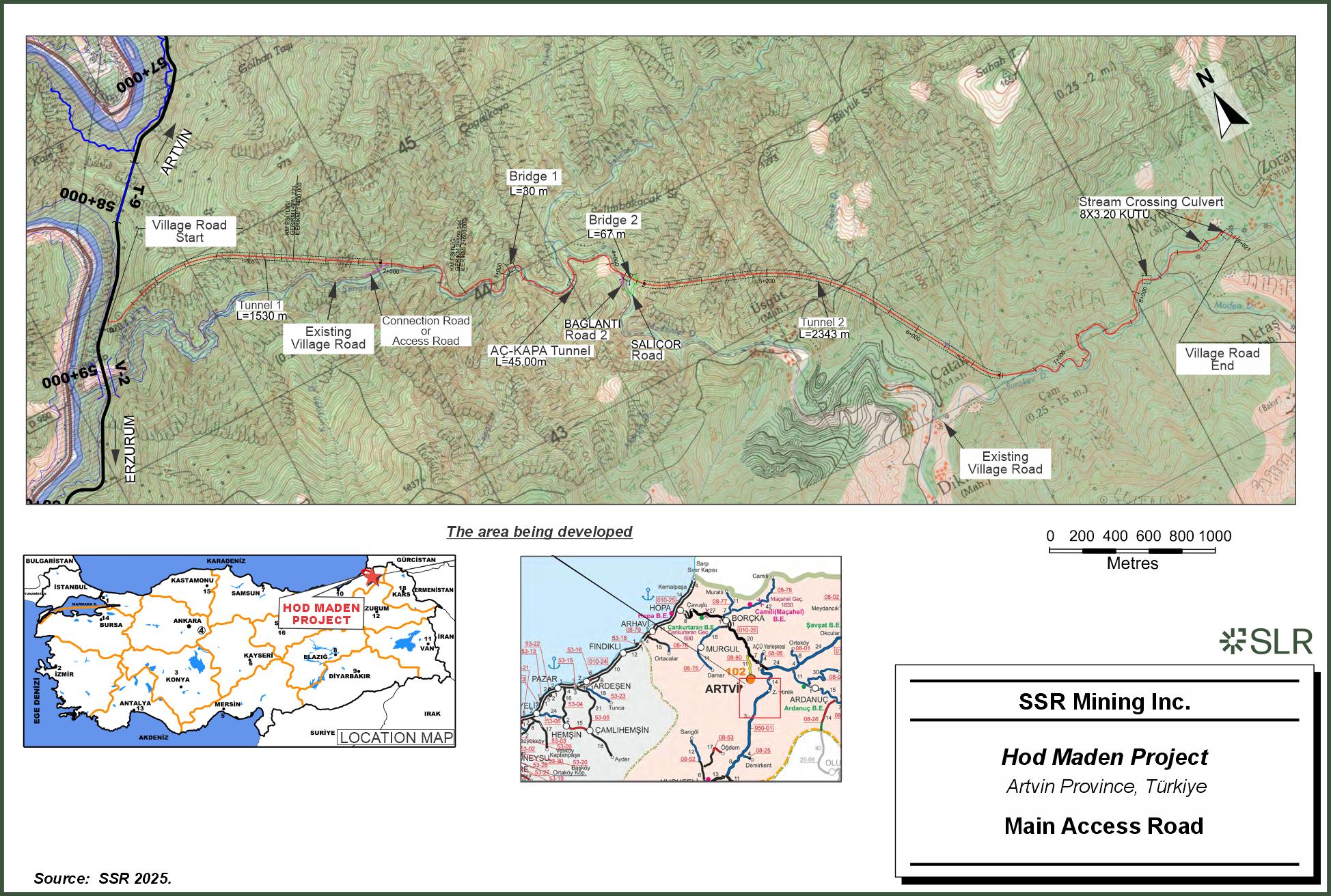

| Figure 4-1: Main (Yukarimaden) Access Road |

4-3 |

| Figure 4-2: Monthly Average On-Site Precipitation (2017–2024) |

4-6 |

| Figure 4-3: Project Area Map |

4-13 |

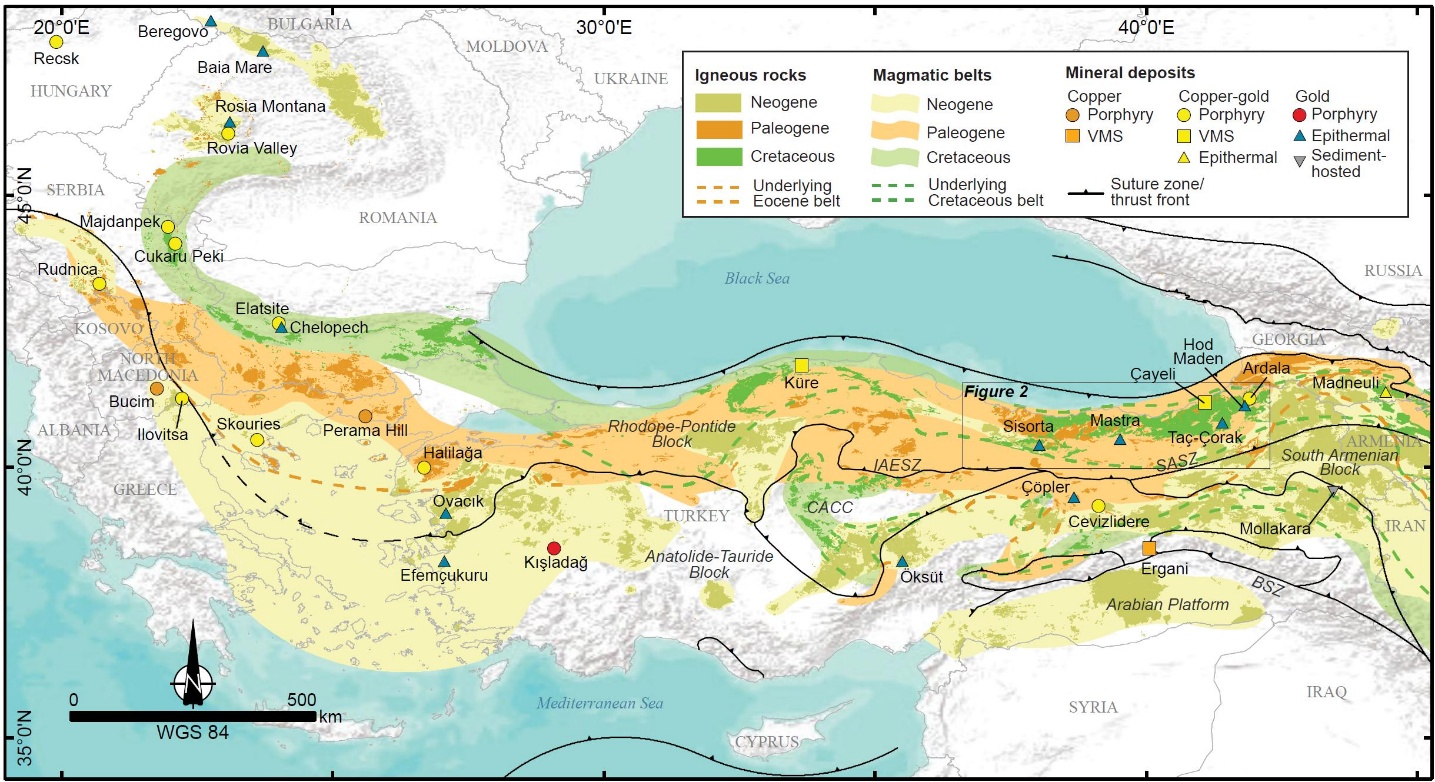

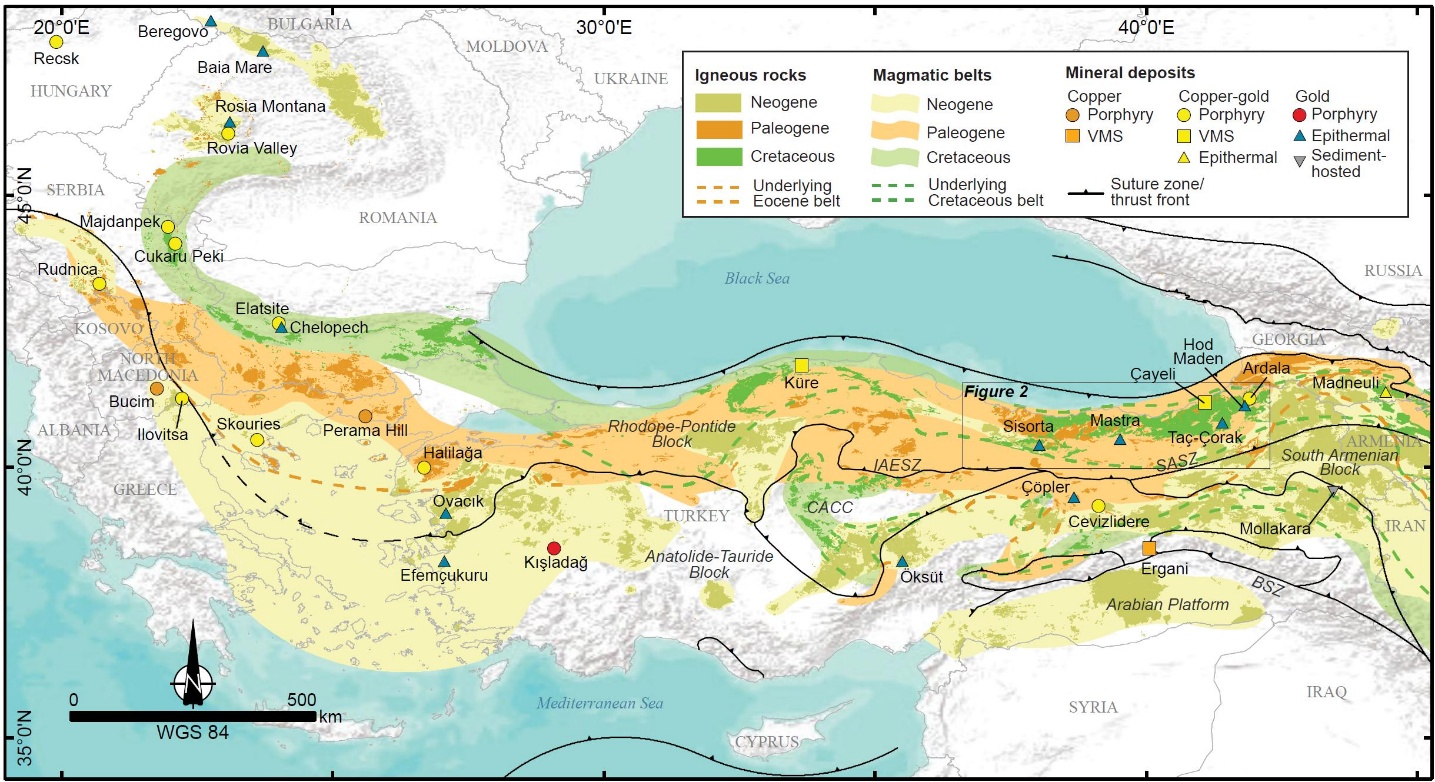

| Figure 6-1: Tectonomagmatic Map of the Western Tethyan Orogenic Belt |

6-2 |

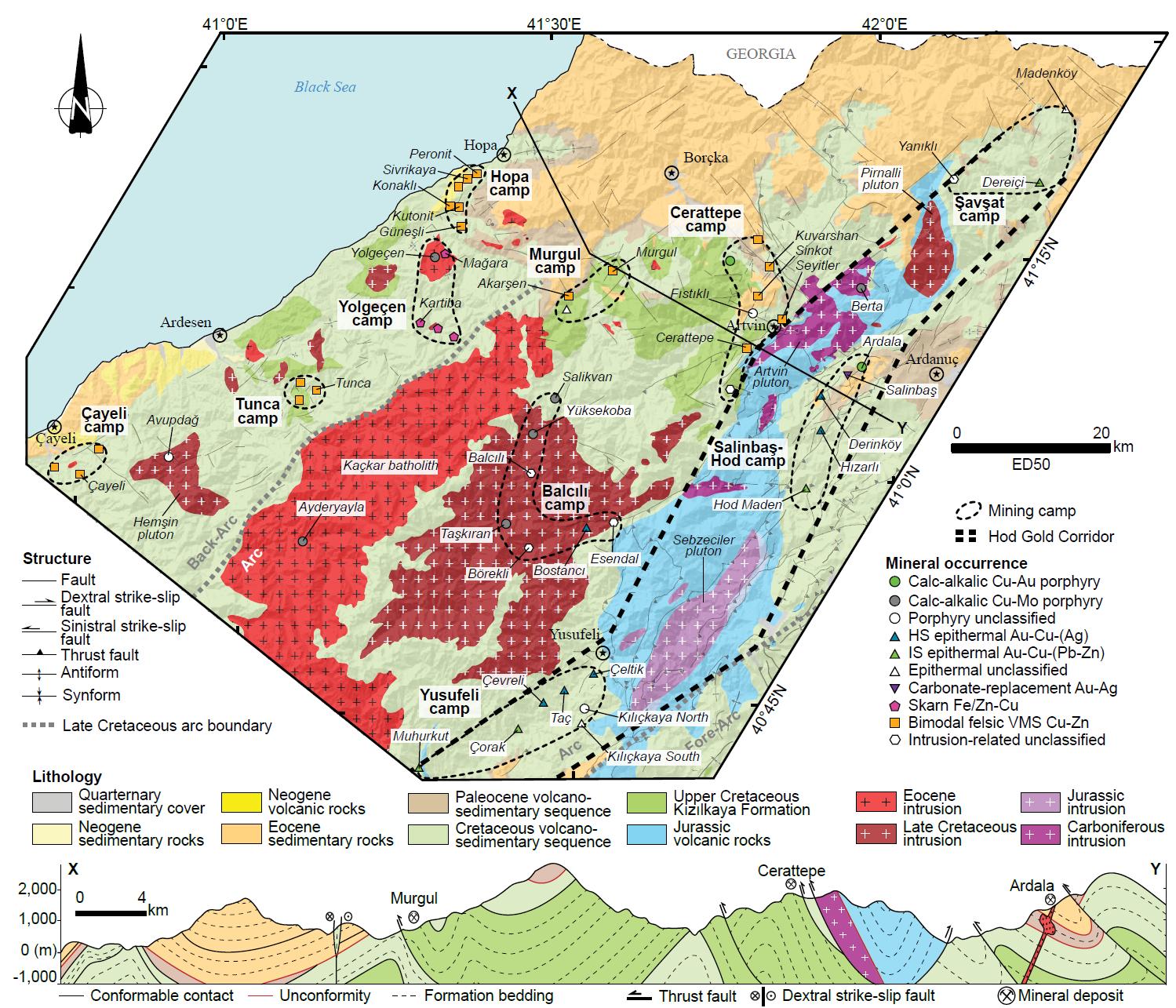

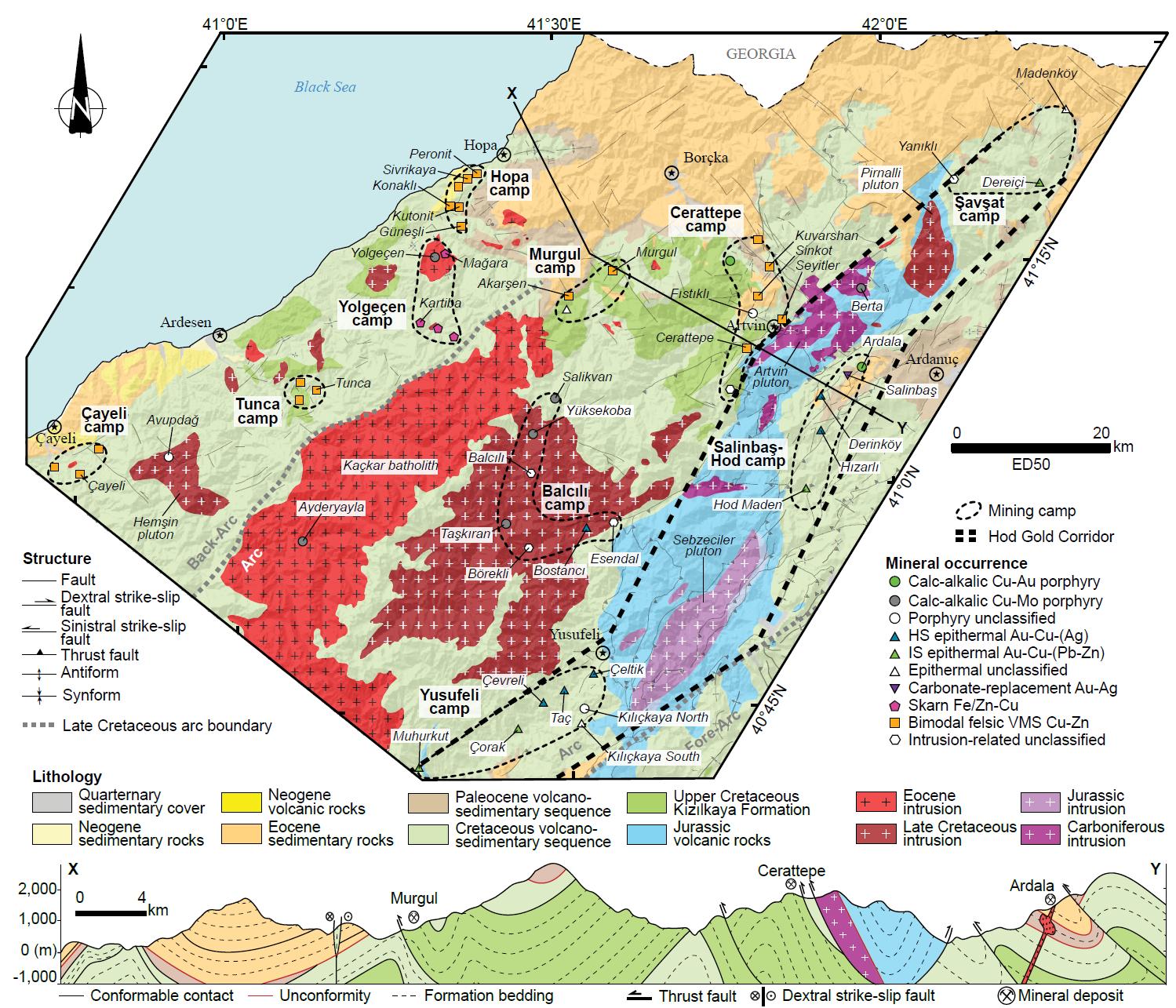

| Figure 6-2: Geological Map of the Artvin District |

6-3 |

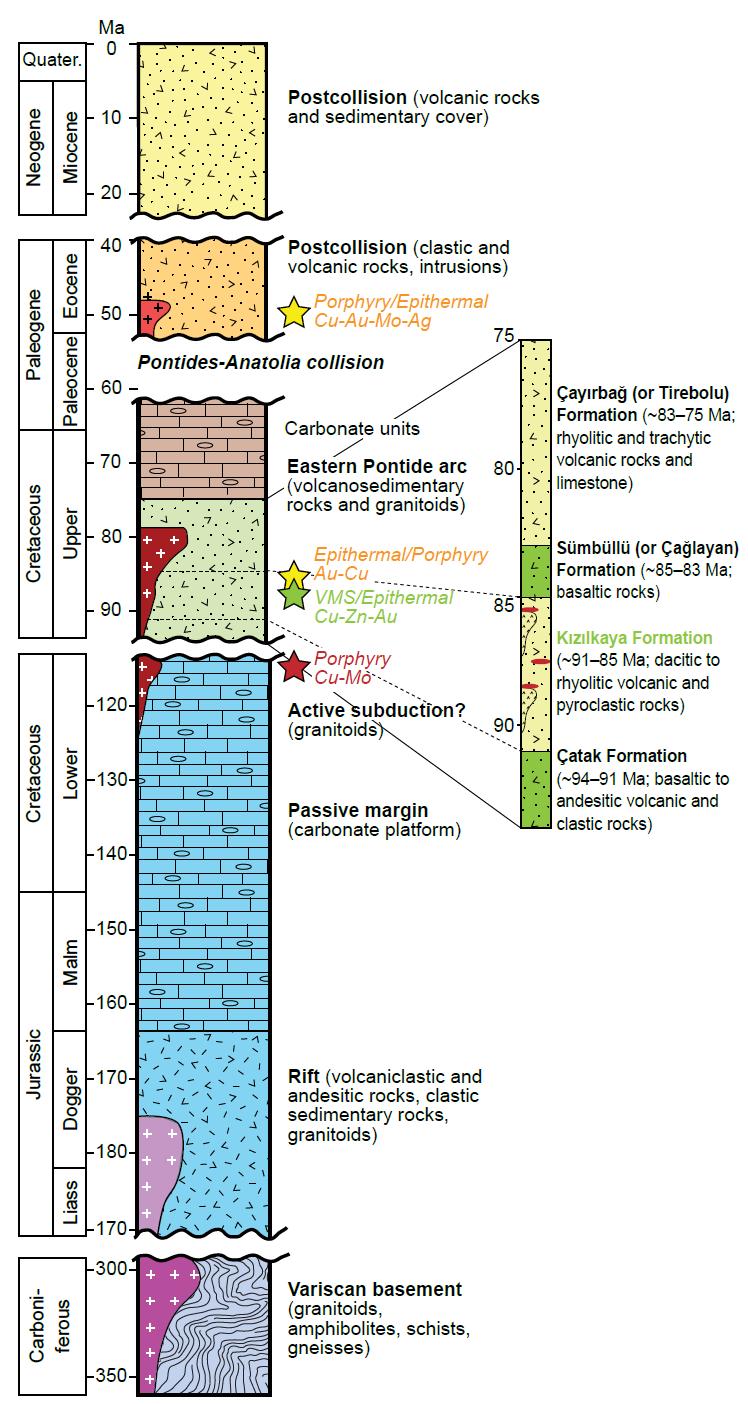

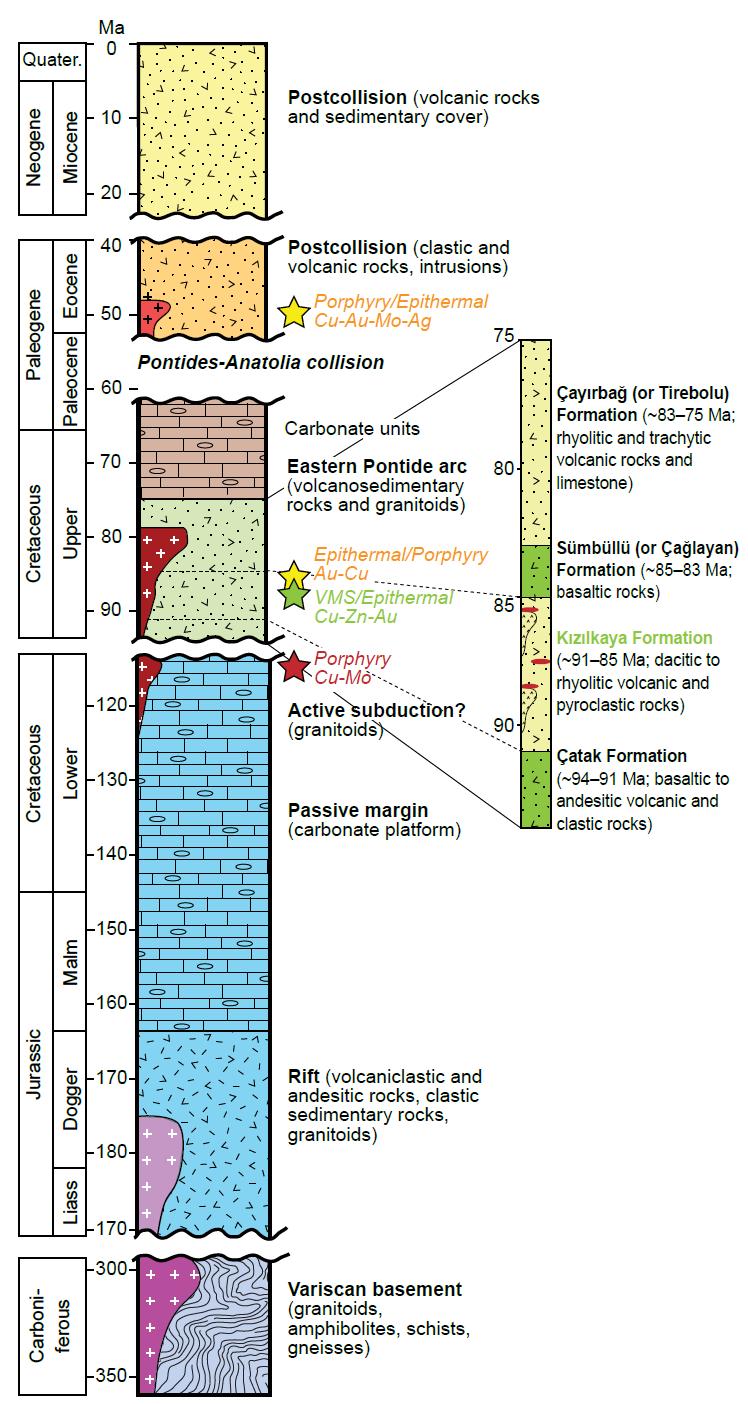

| Figure 6-3: Simplified Stratigraphy of the Artvin District |

6-4 |

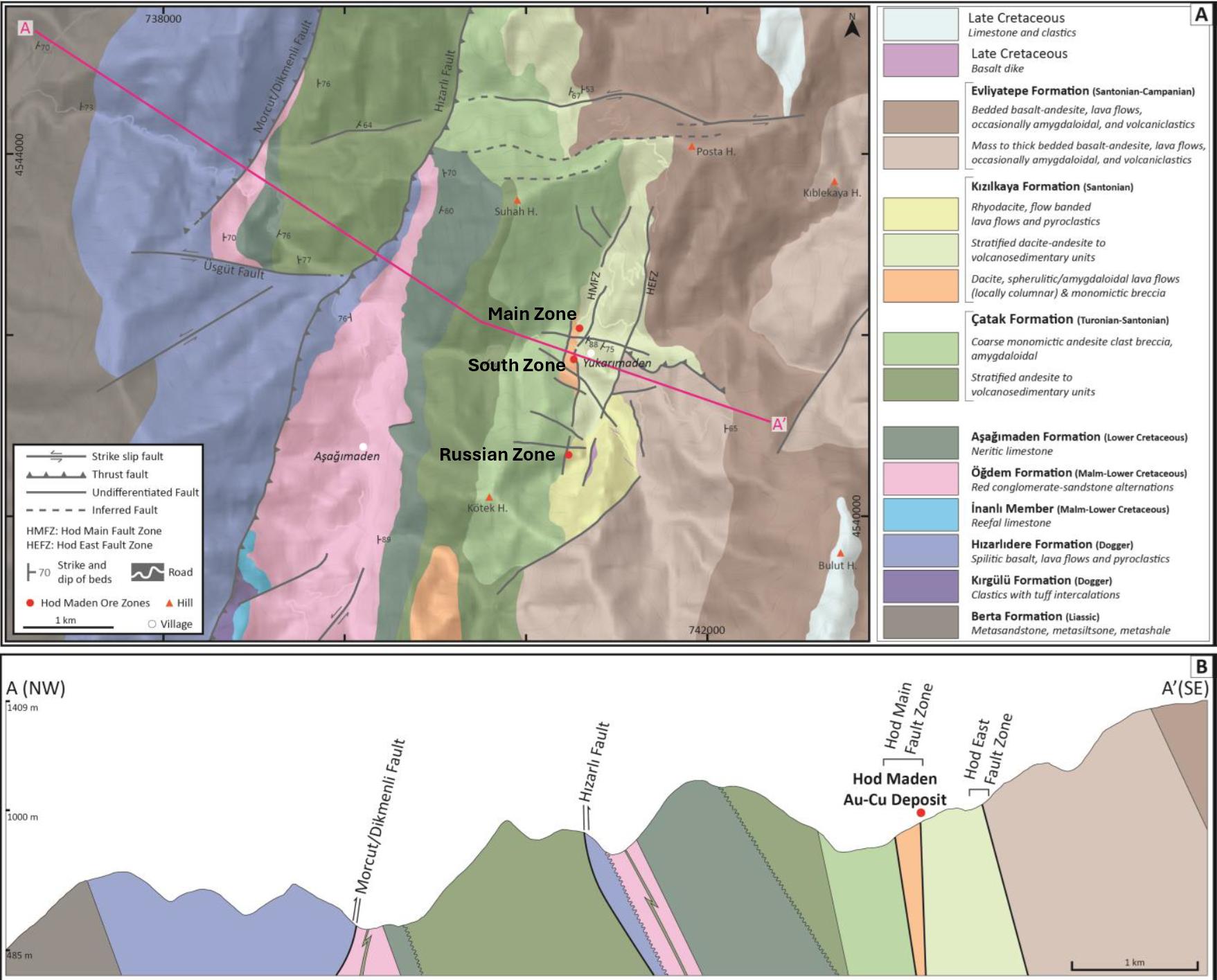

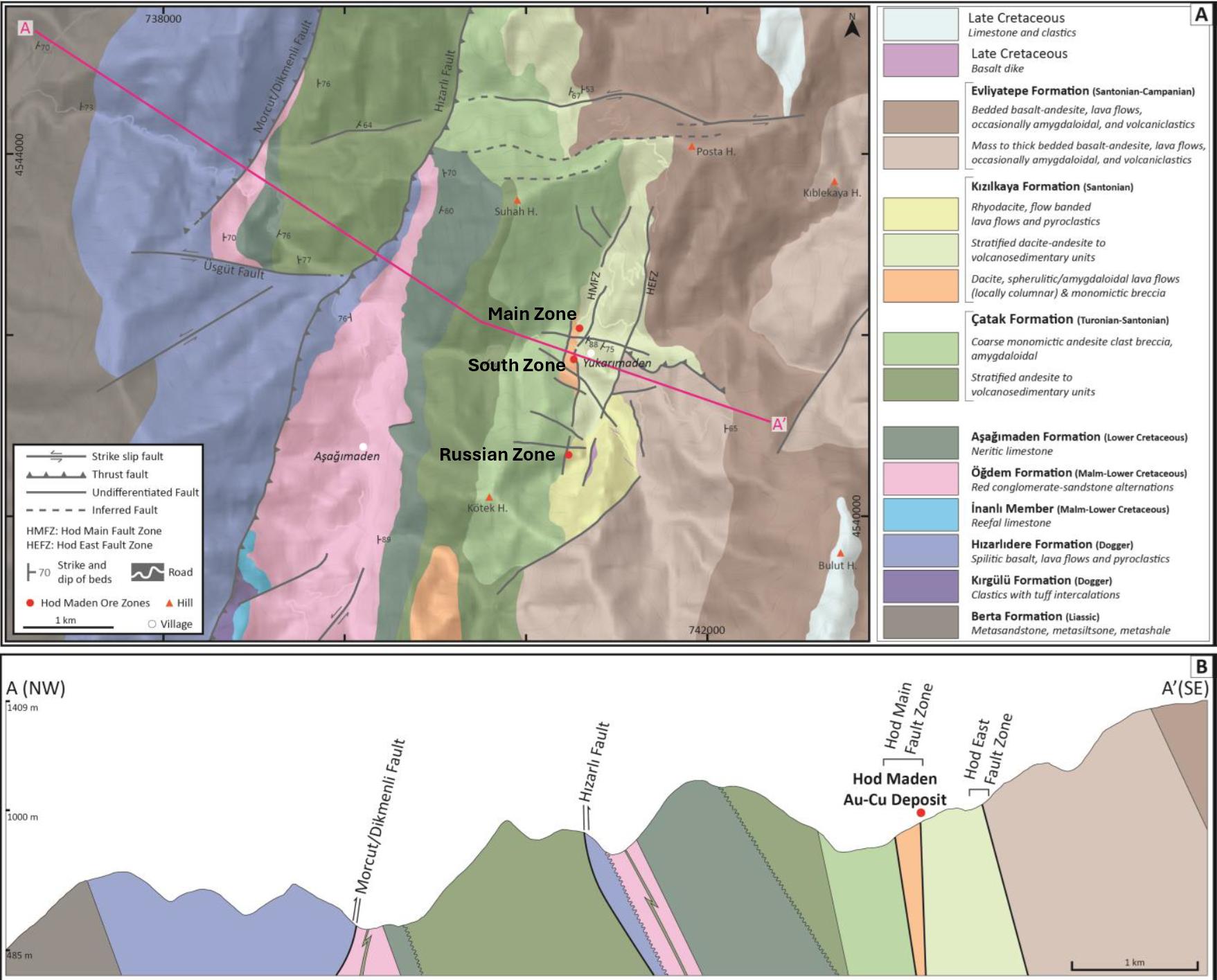

| Figure 6-4: Geological Map of the Hod Maden Region |

6-6 |

| | x |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

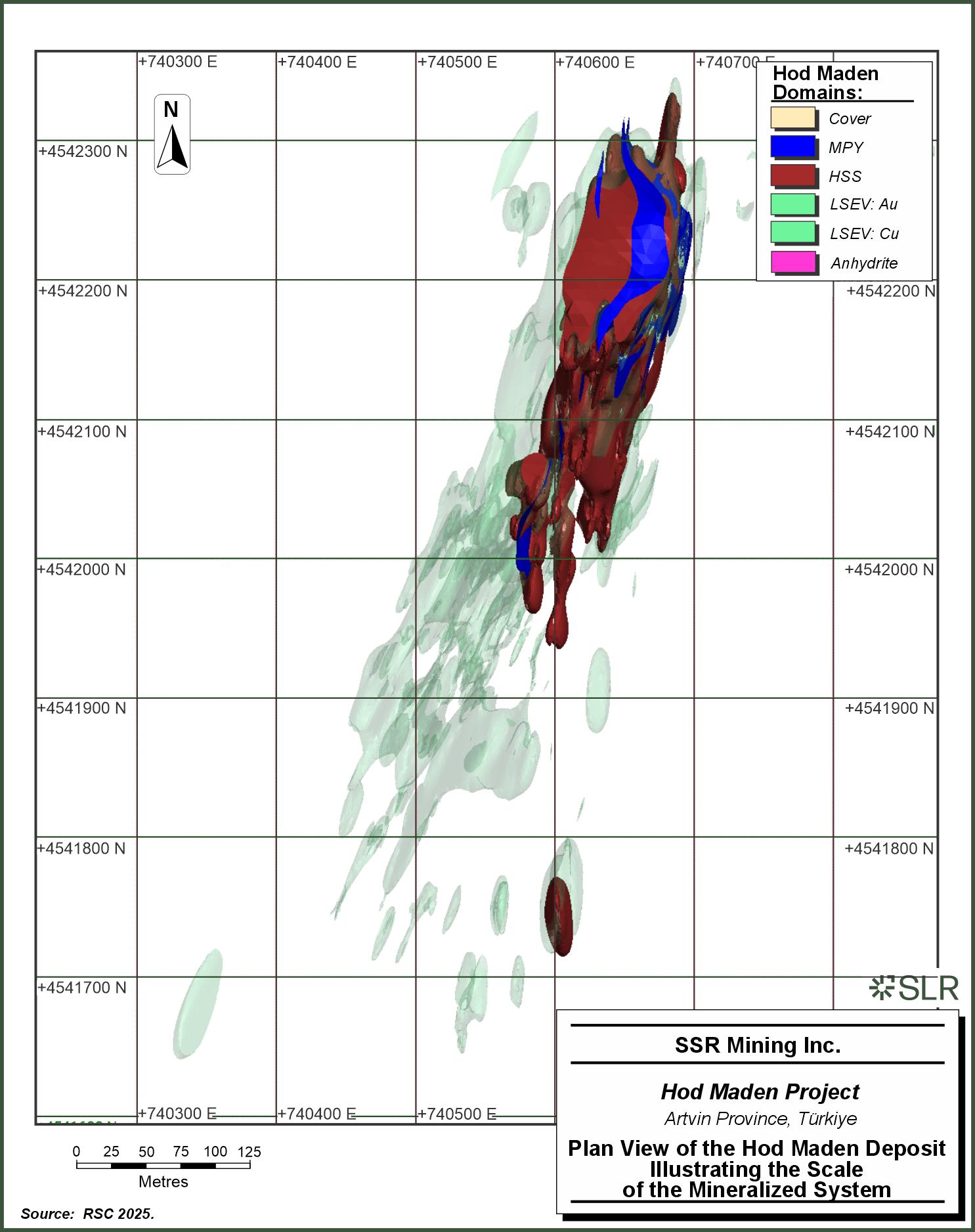

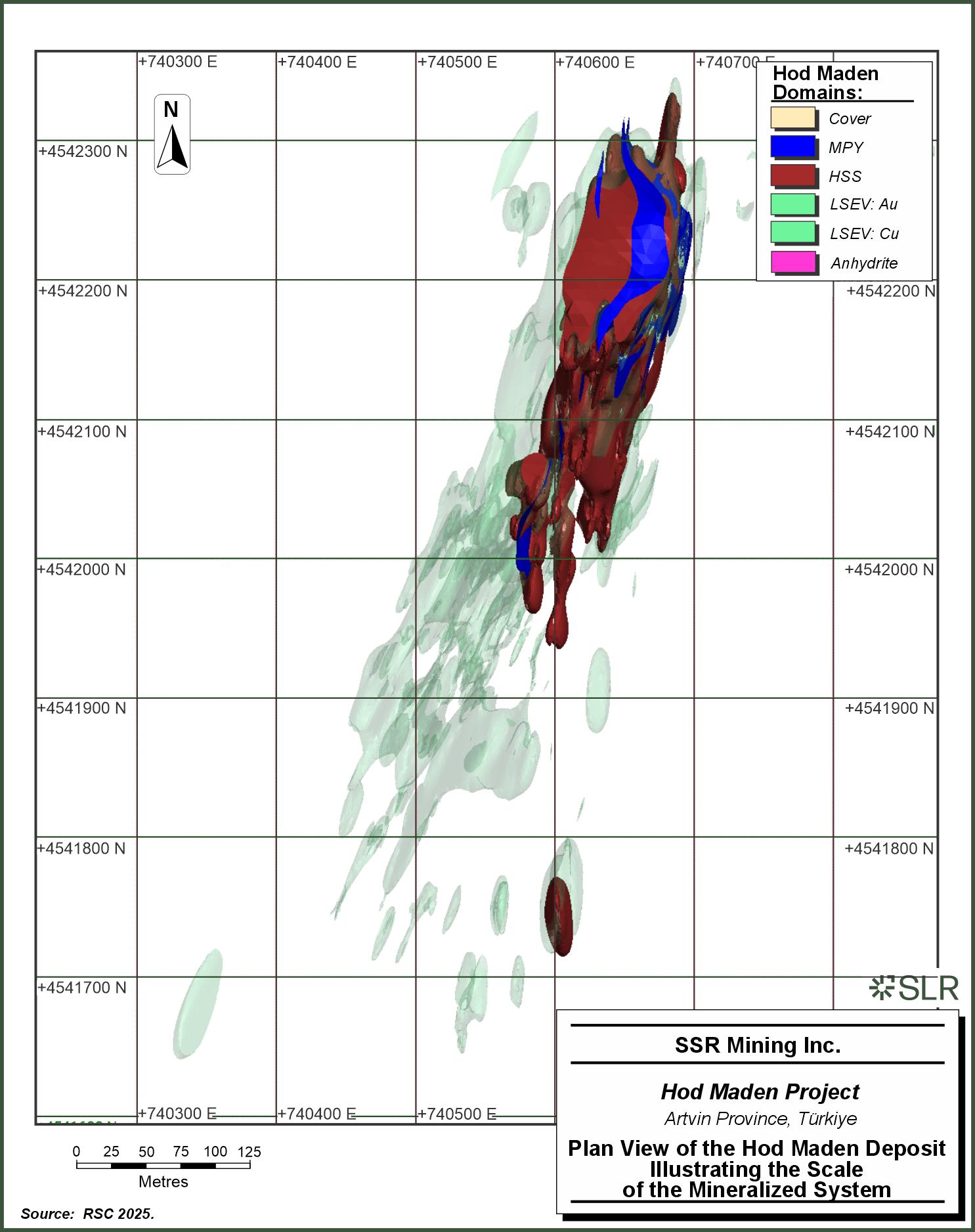

| Figure 6-5: Plan View of the Hod Maden Deposit Illustrating the Scale of the Mineralized System |

6-7 |

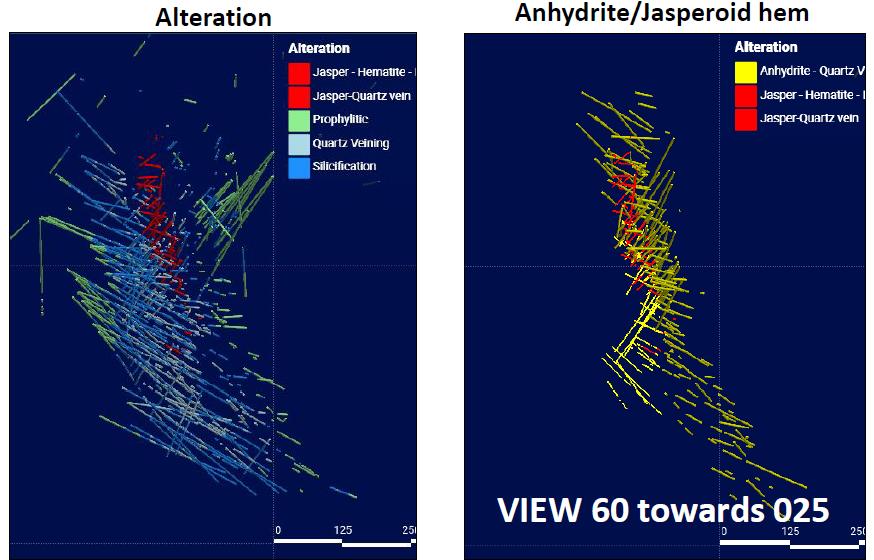

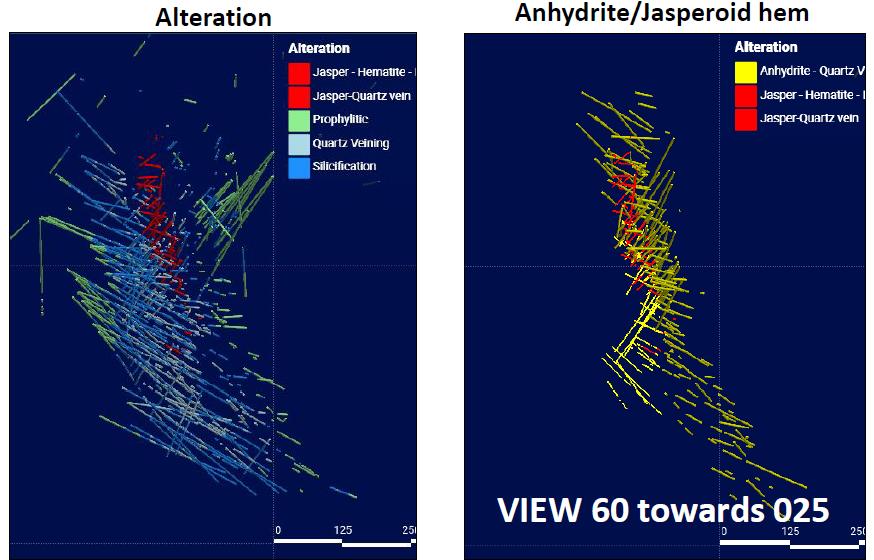

| Figure 6-6: Alteration Distribution throughout the Hod Maden Deposit |

6-9 |

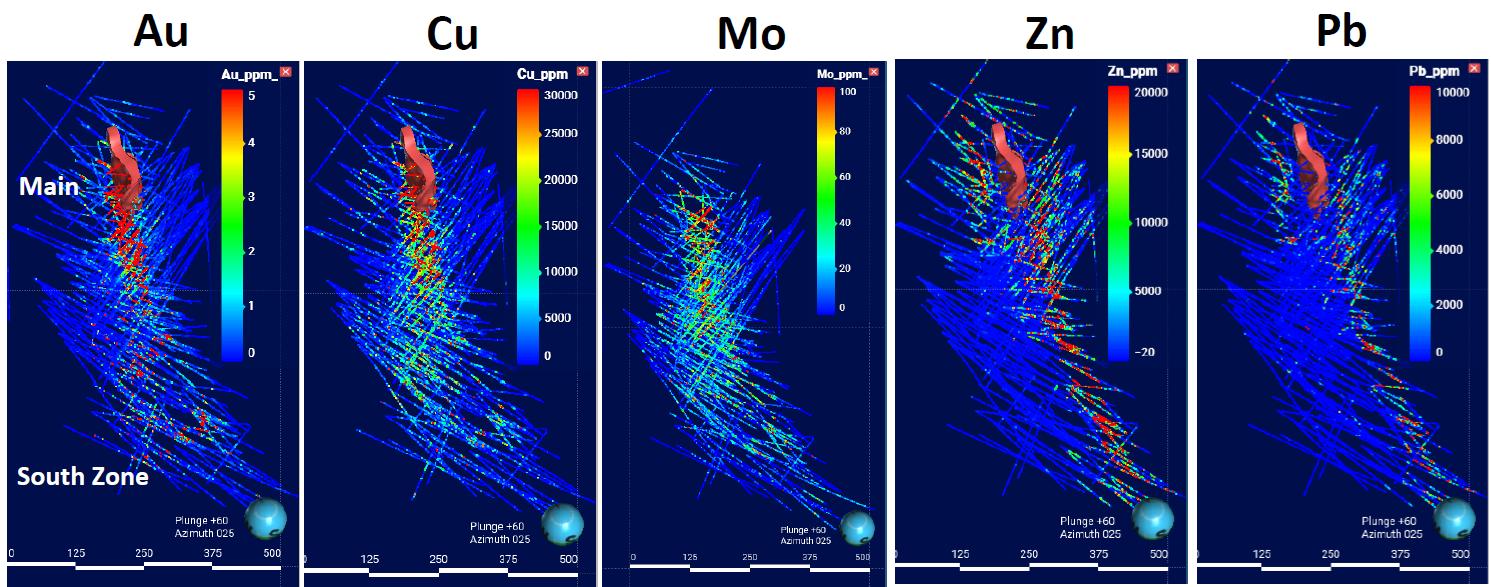

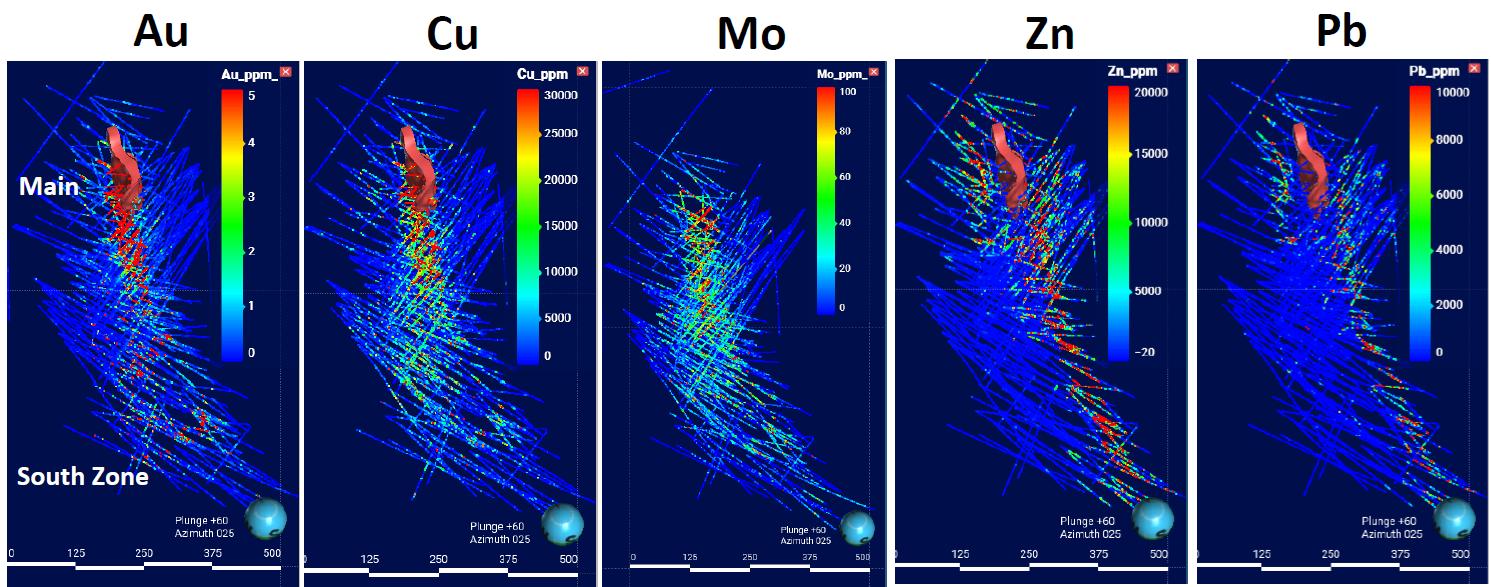

| Figure 6-7: Mapped Element Zonations for the Main Zone and South Zone |

6-10 |

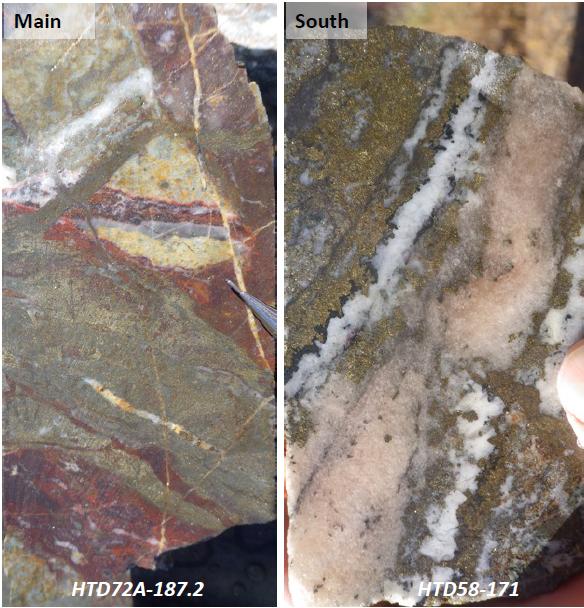

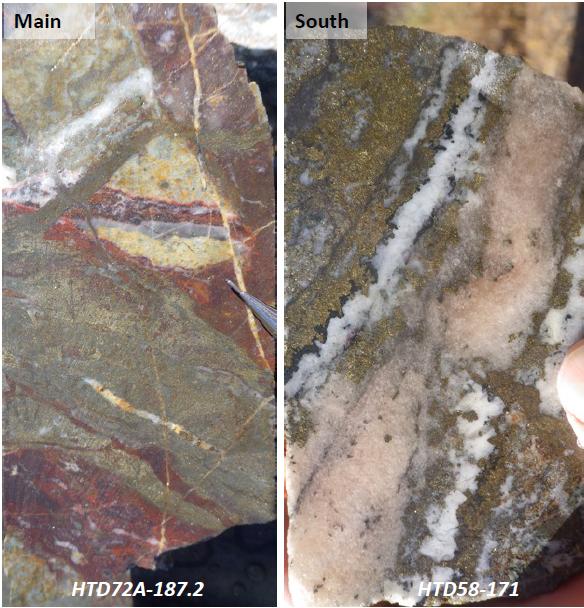

| Figure 6-8: Vein Textures in the Main Zone (left) and South Zone (right) |

6-12 |

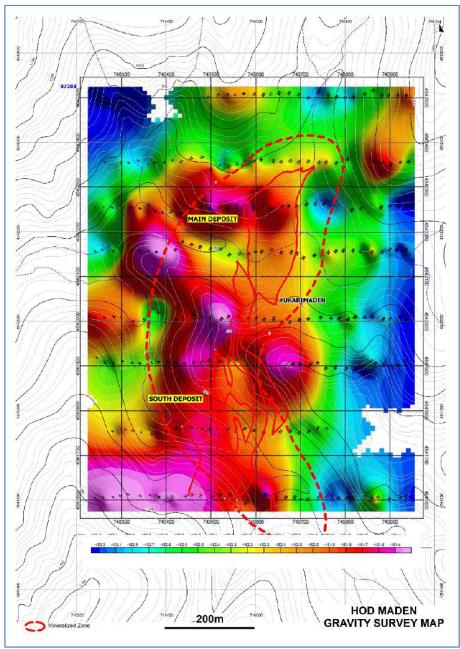

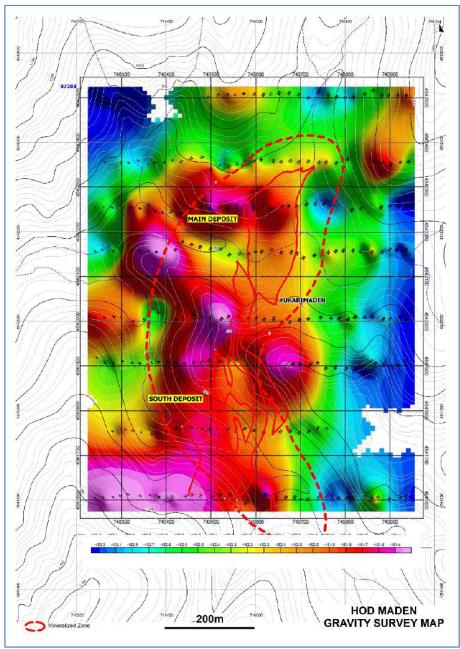

| Figure 7-1: Hod Maden Bouguer Gravity Map |

7-3 |

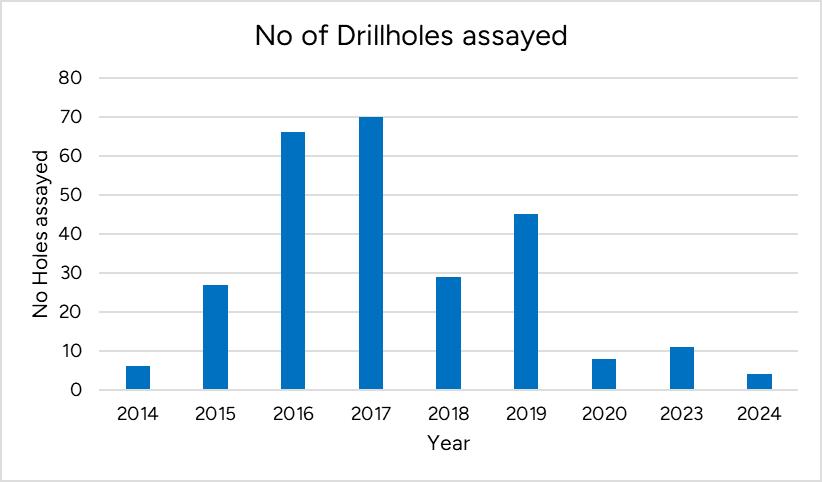

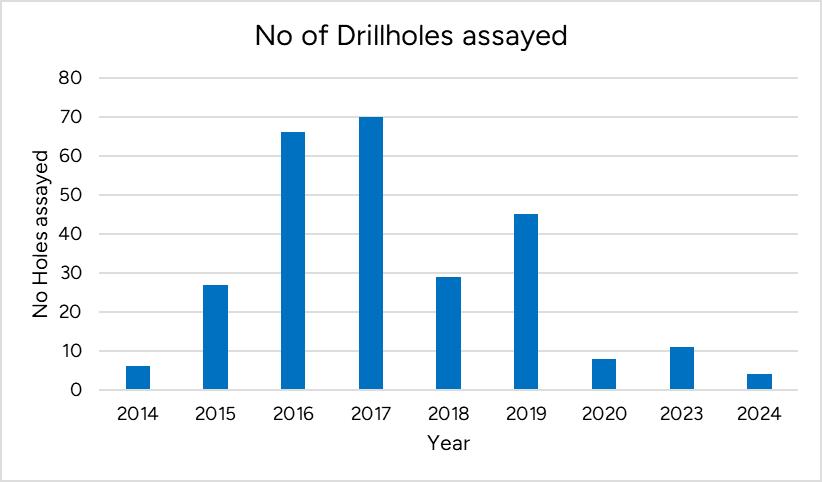

| Figure 7-2: Number of Assayed Drill Holes by Year |

7-6 |

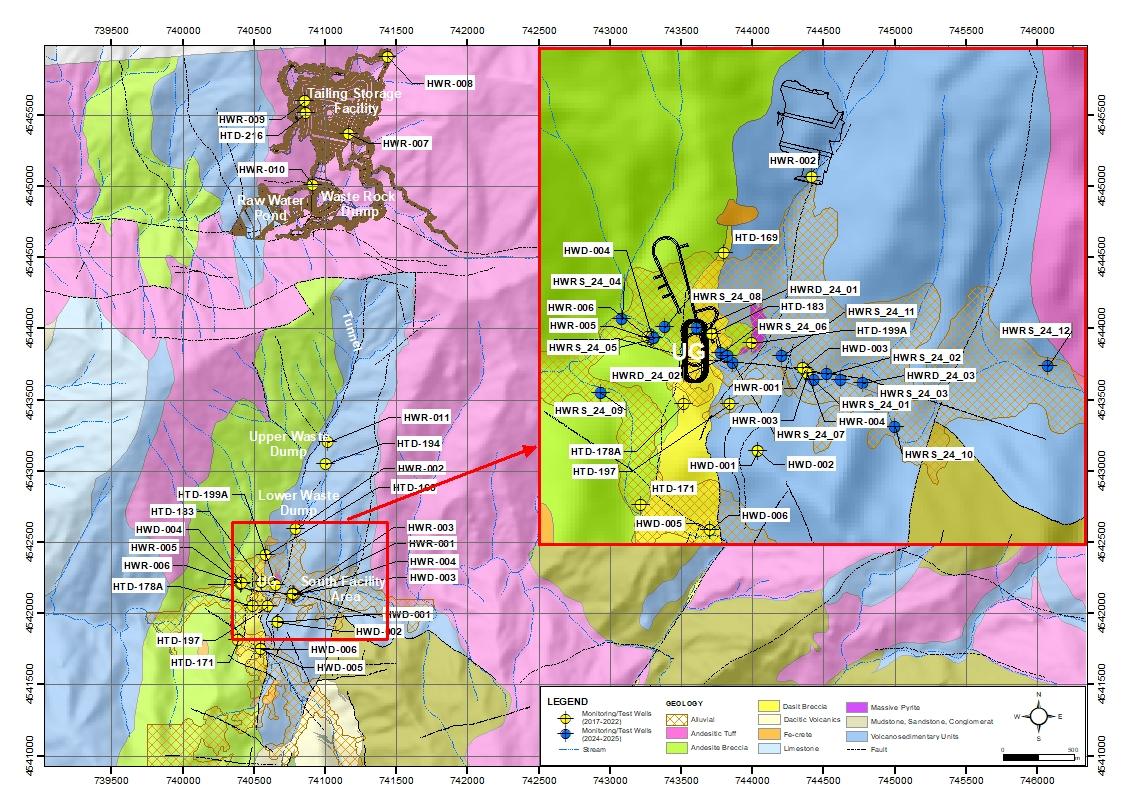

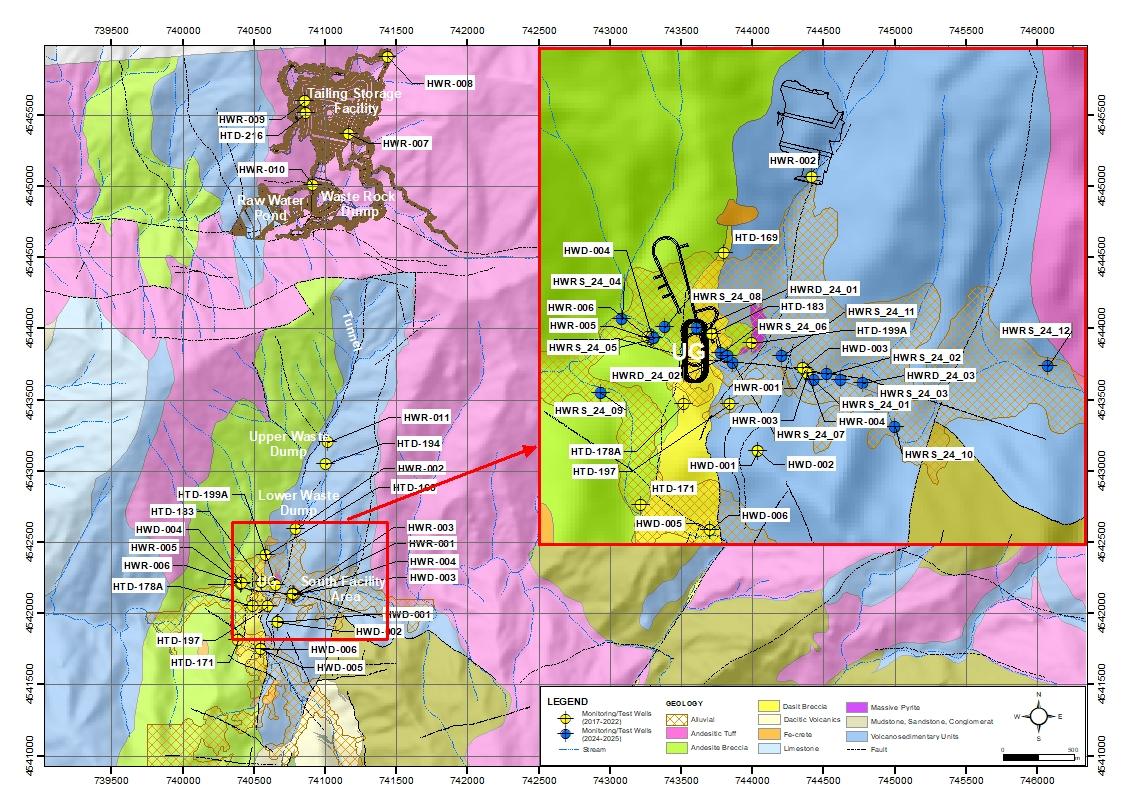

| Figure 7-3: Monitoring Well Locations |

7-9 |

| Figure 7-4: Packer Tests Measured Hydraulic Conductivity Values with Depth |

7-11 |

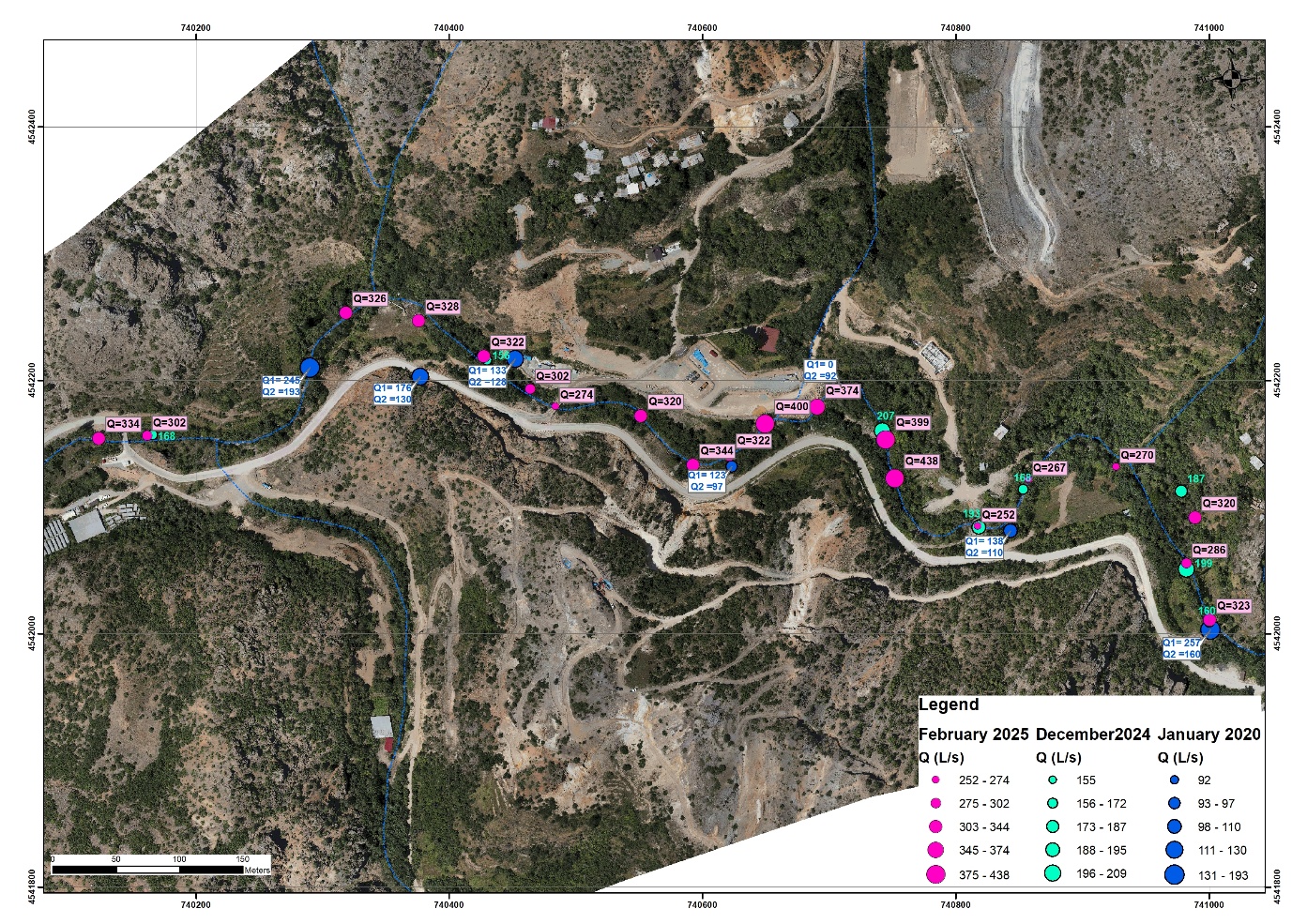

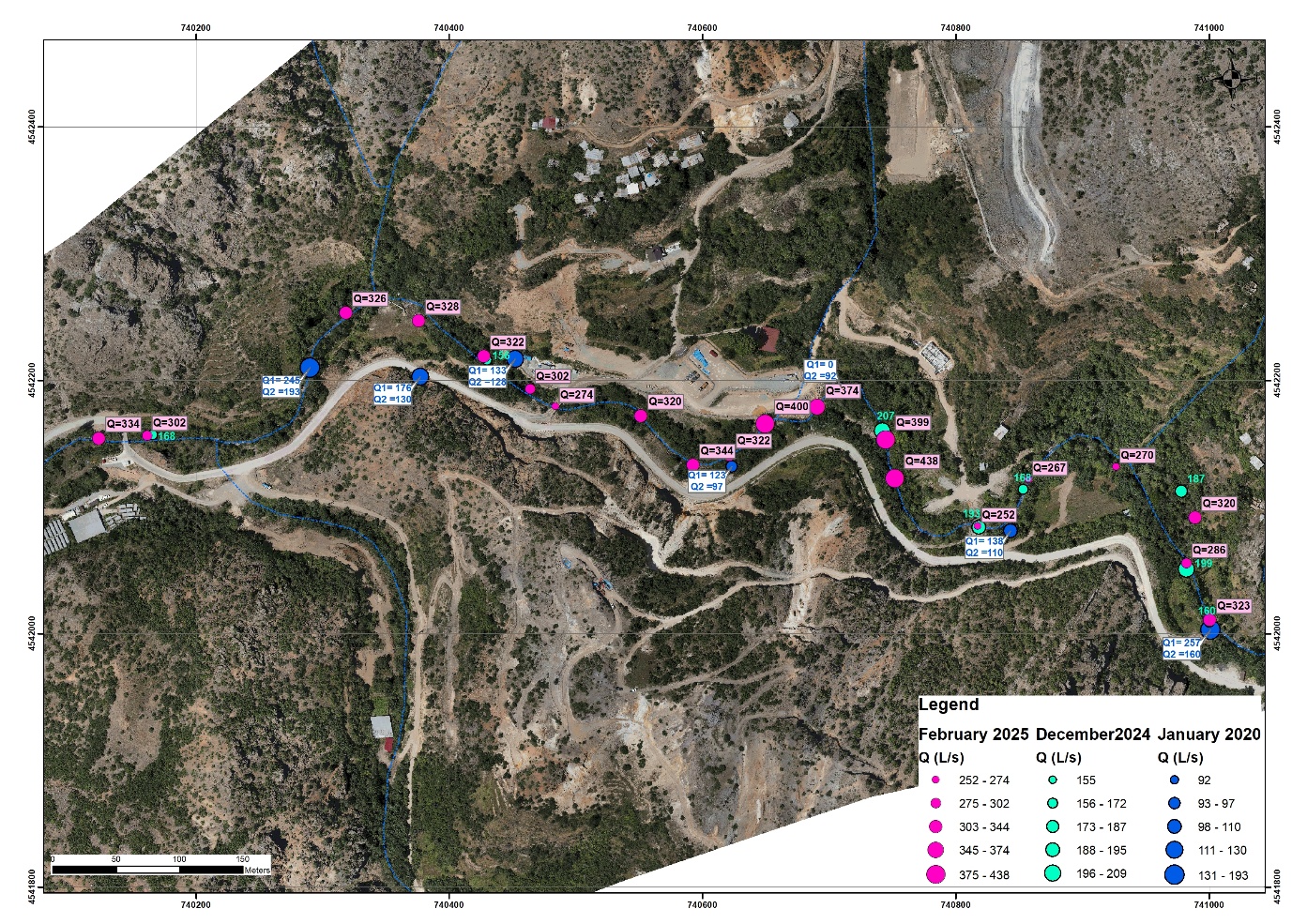

| Figure 7-5: Stream Flow Locations and Measured Flow Rates |

7-14 |

| Figure 8-1: DLS Histograms for Each Survey Method |

8-10 |

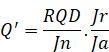

| Figure 8-2: Diamond Core Recovery at Hod Maden since December 2014 |

8-10 |

| Figure 8-3: Relative Difference Plot for First-Split Duplicates (2014–2022) |

8-11 |

| Figure 8-4: Relative Difference Plot for First-Split Duplicates (2023–2024) |

8-11 |

| Figure 8-5: Relative Difference Plot for Third-Split Duplicates (2014–2020) |

8-12 |

| Figure 8-6: Relative Difference Plot for Third-Split Duplicates (2023–2024) |

8-12 |

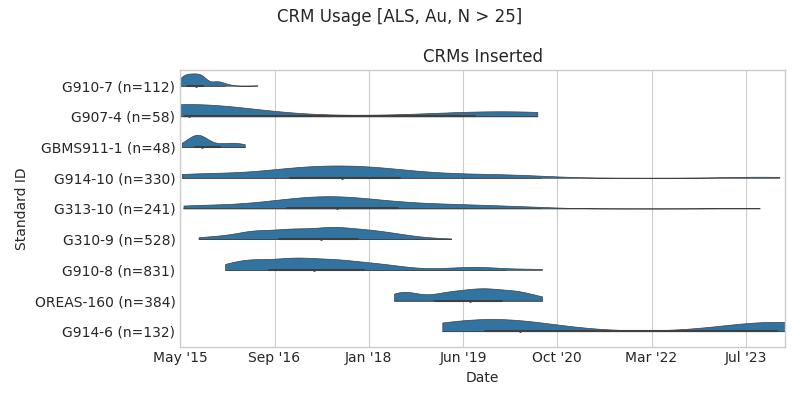

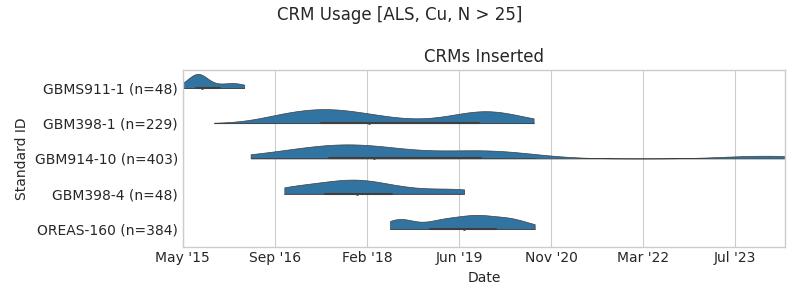

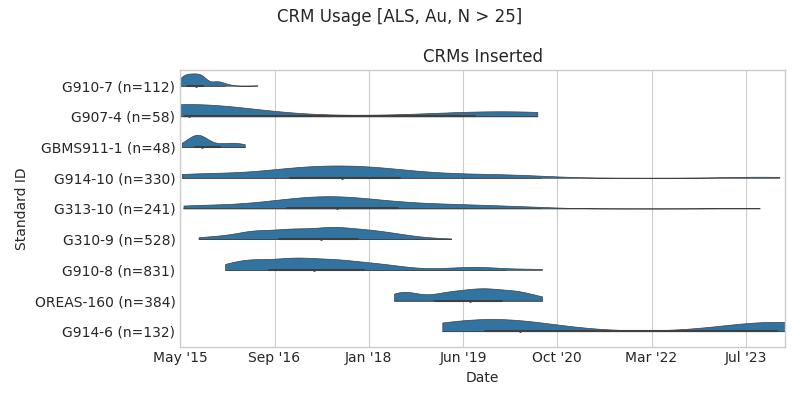

| Figure 8-7: CRMs inserted by SSR since 2015, analyzed for Au at ALS |

8-13 |

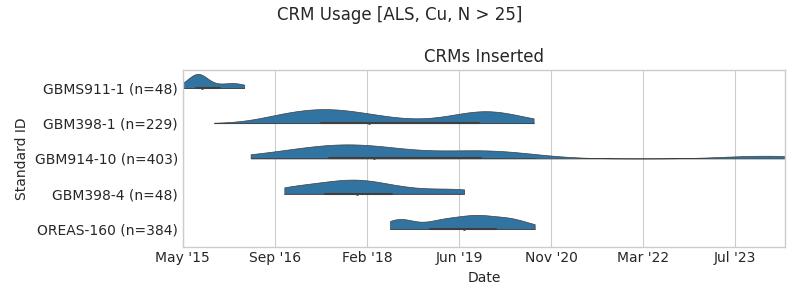

| Figure 8-8: CRMs inserted by SSR since 2015, analyzed for Cu at ALS |

8-13 |

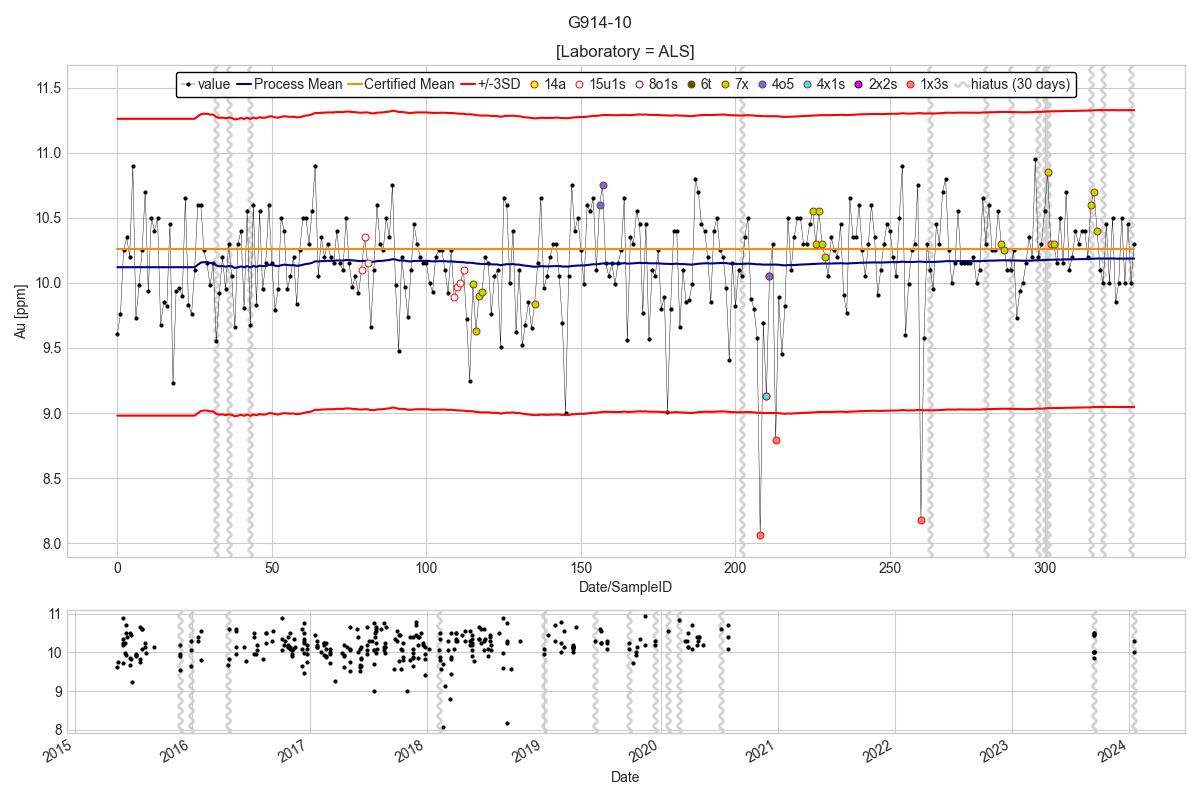

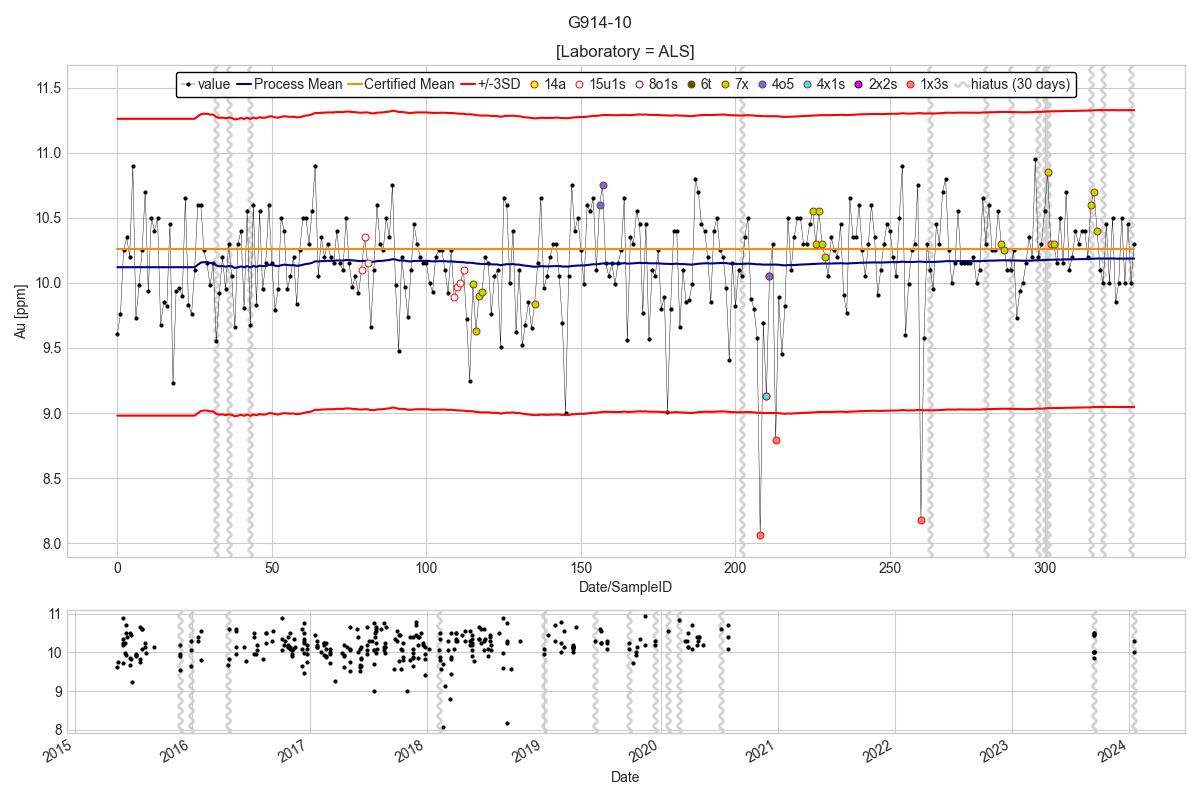

| Figure 8-9: Shewhart Control Plot for G914-10 Au by AA25 (2015–2020) |

8-14 |

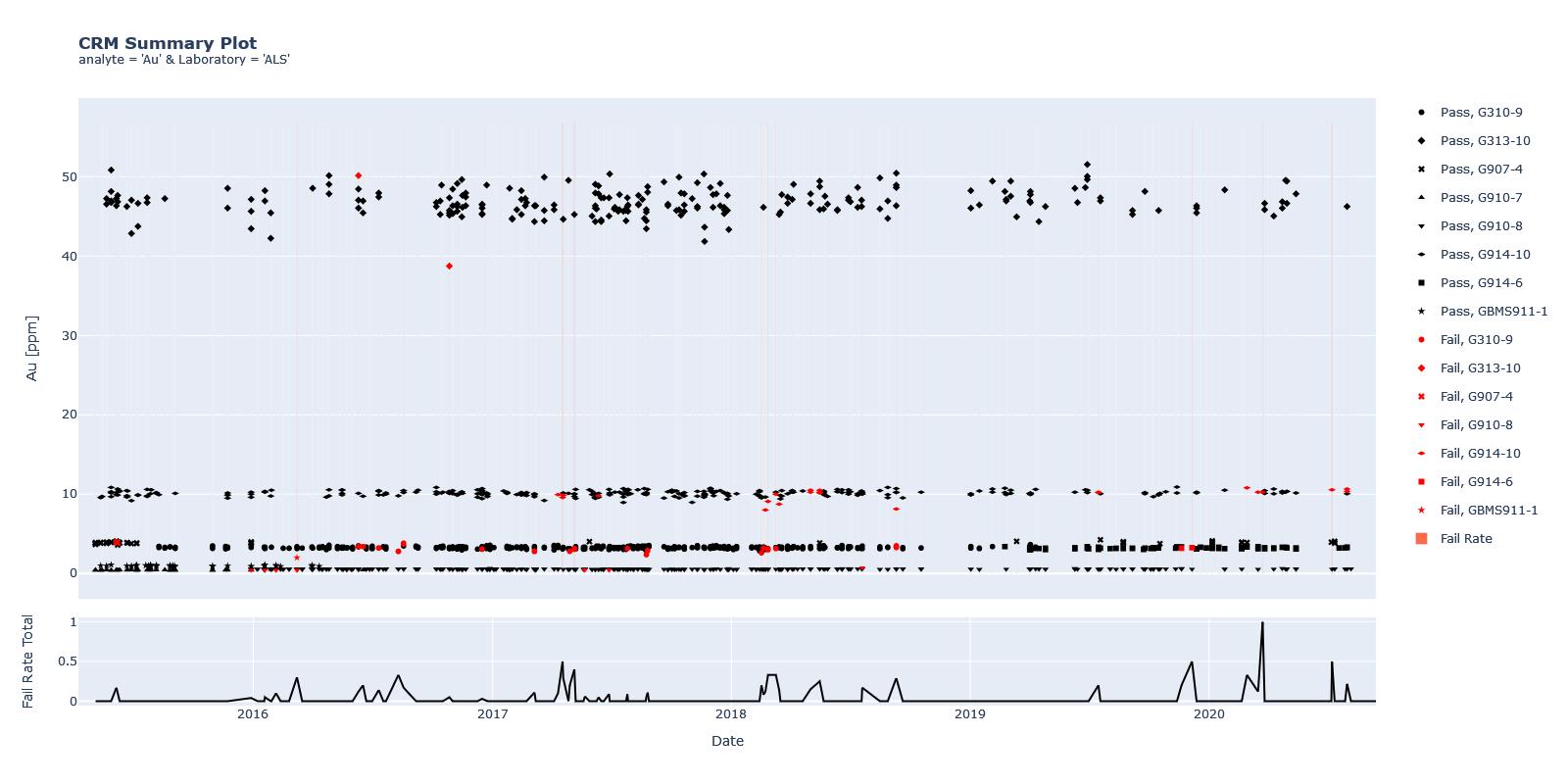

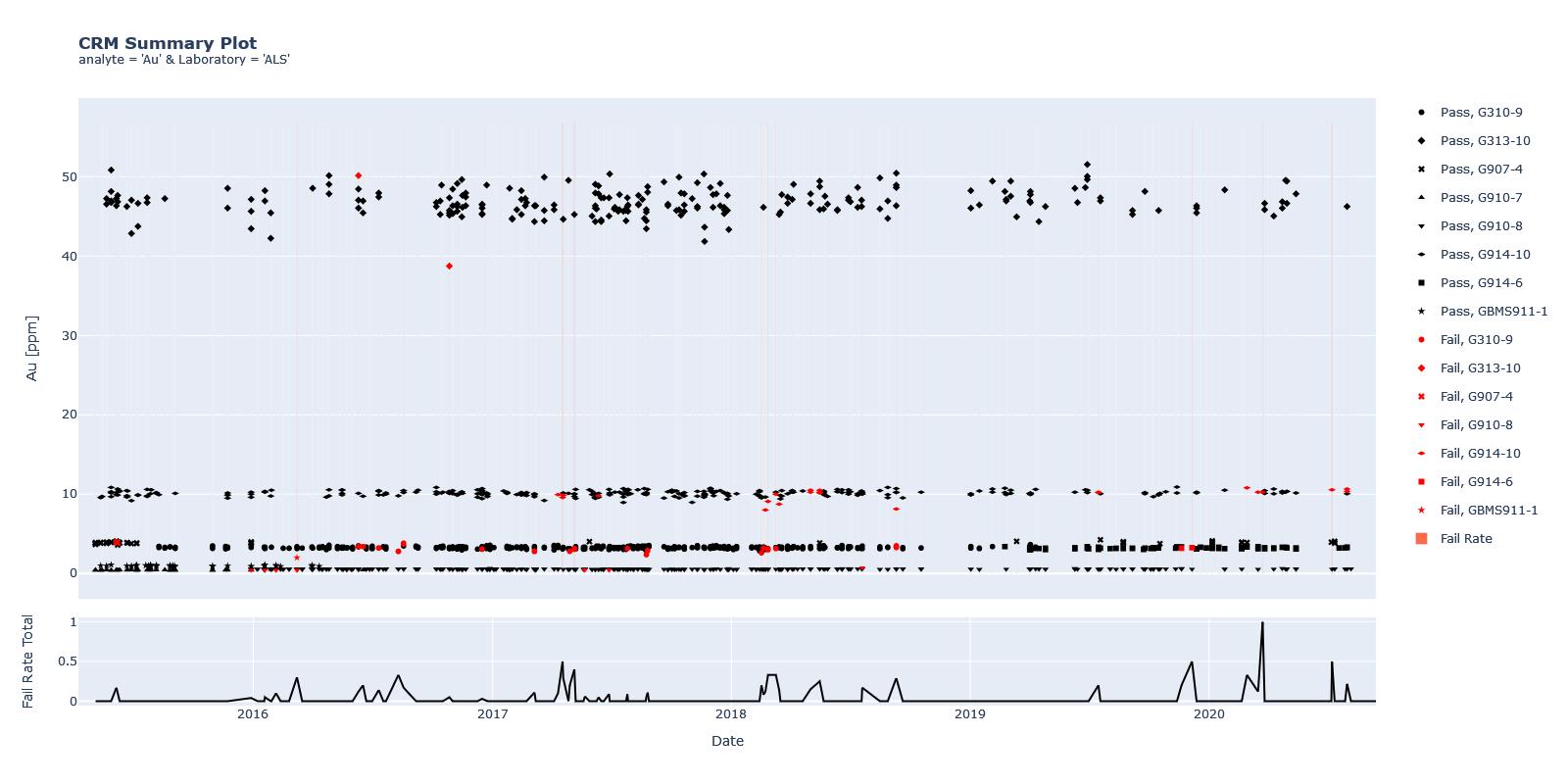

| Figure 8-10: Heat Map for Au, all CRMs analyzed at ALS (2015–2021) |

8-14 |

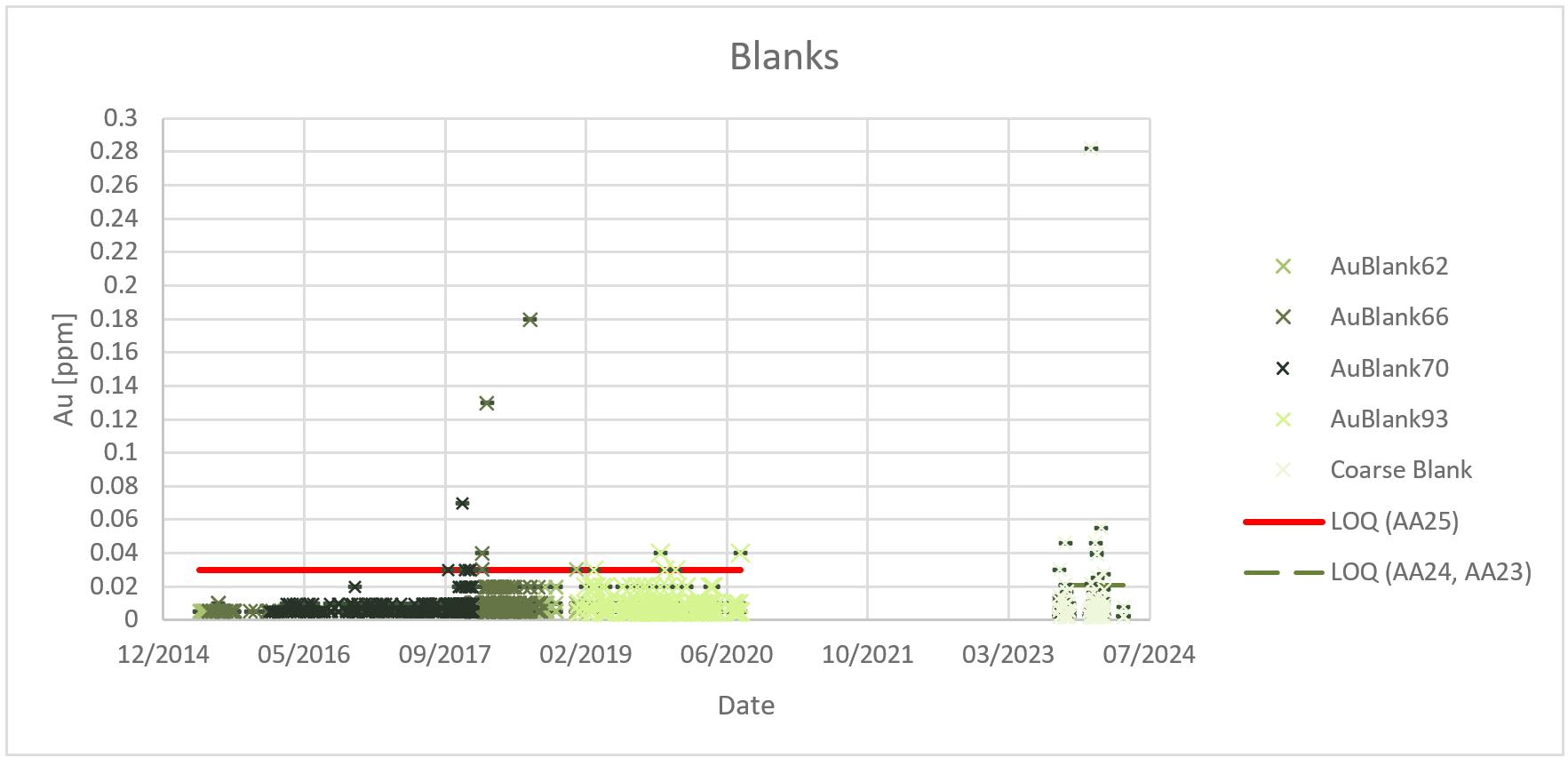

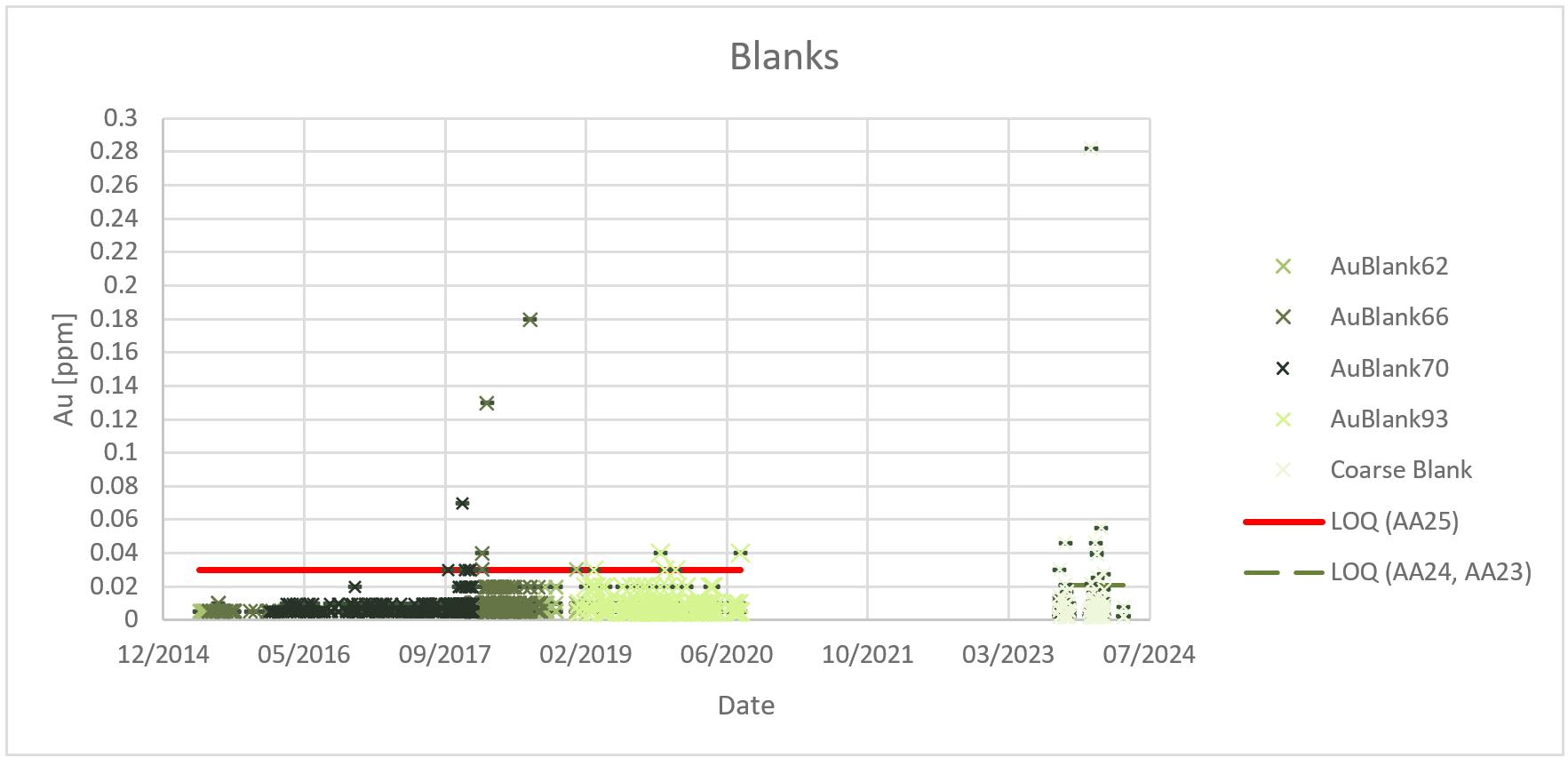

| Figure 8-11: Hod Maden Blank Analyses for Au by Analysis Date (ALS), 2014–2024 |

8-15 |

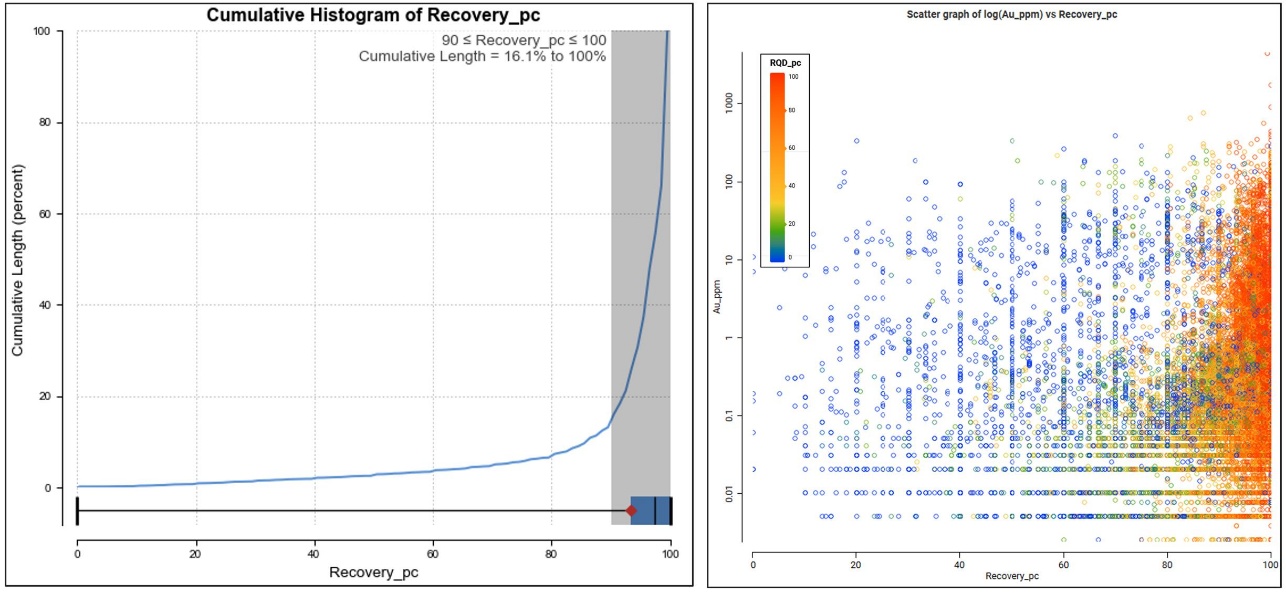

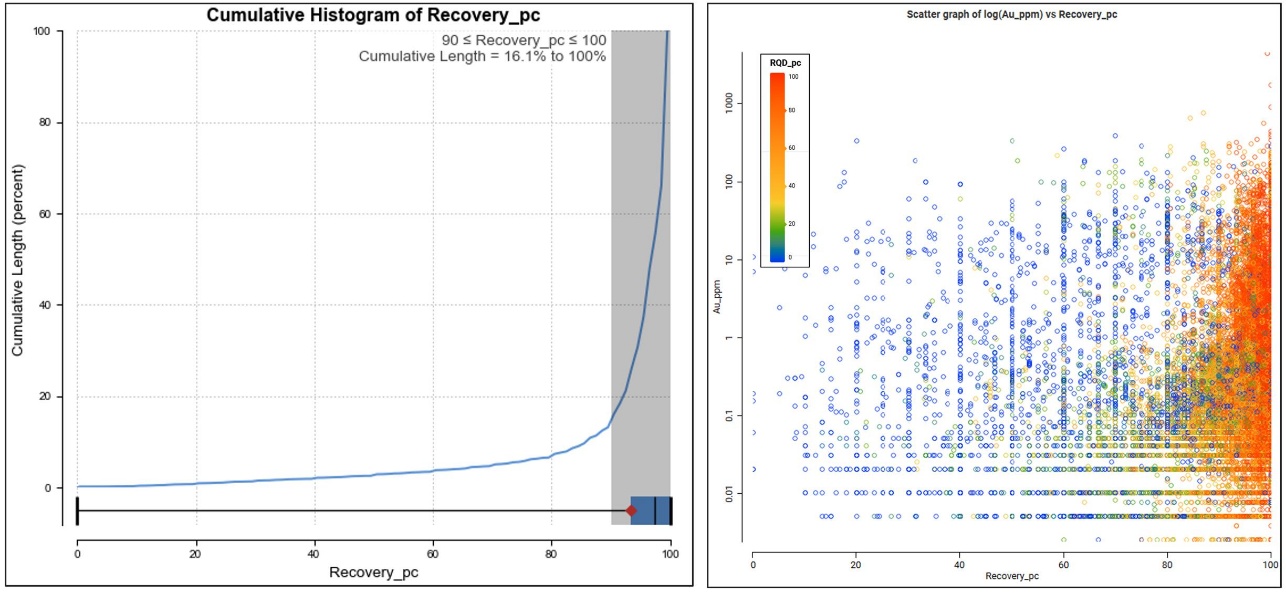

| Figure 8-12: Recovery Statistics for All Holes since 2014 |

8-19 |

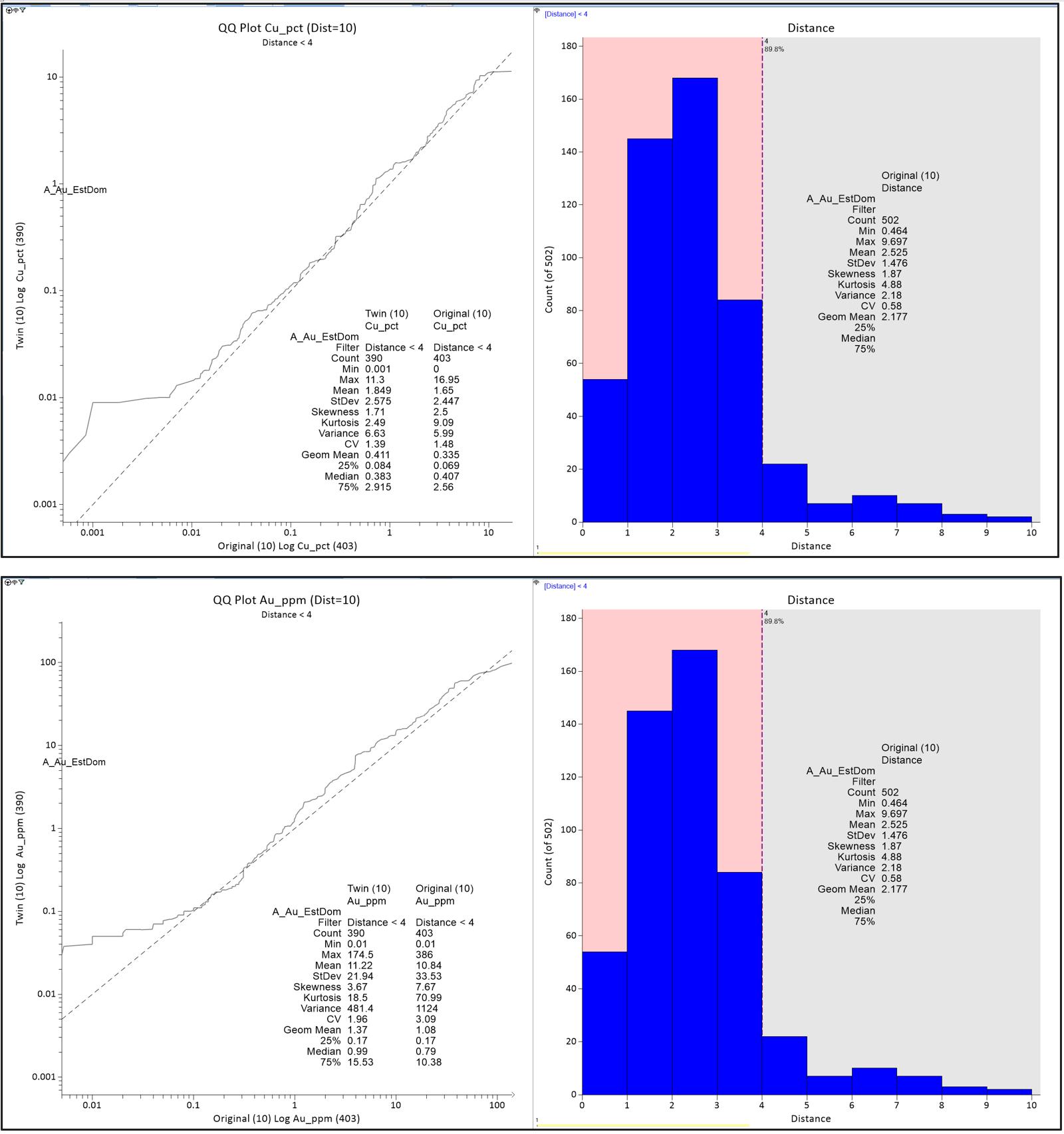

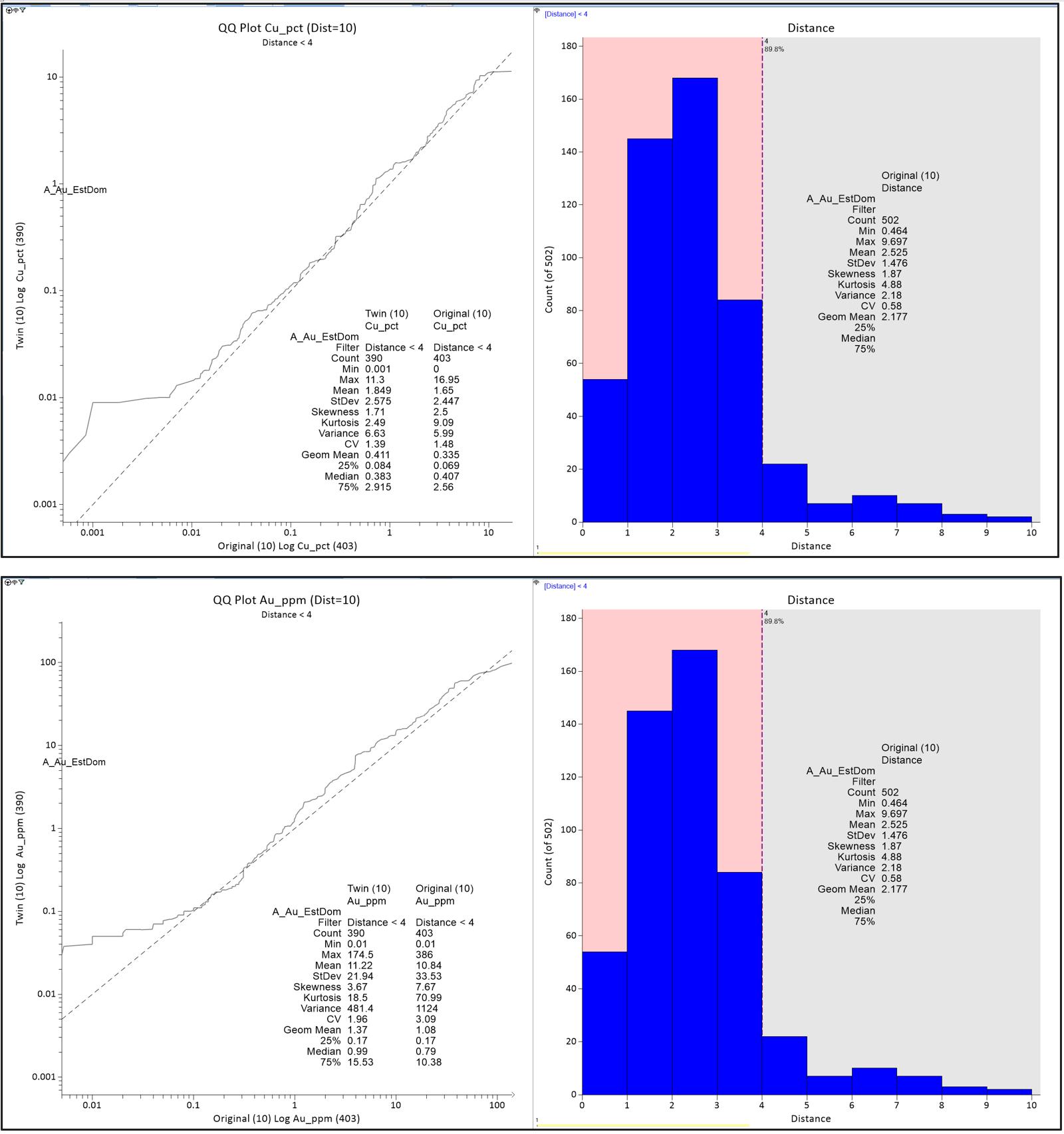

| Figure 8-13: Comparison of Grades from Six Twin Holes at Hod Maden |

8-20 |

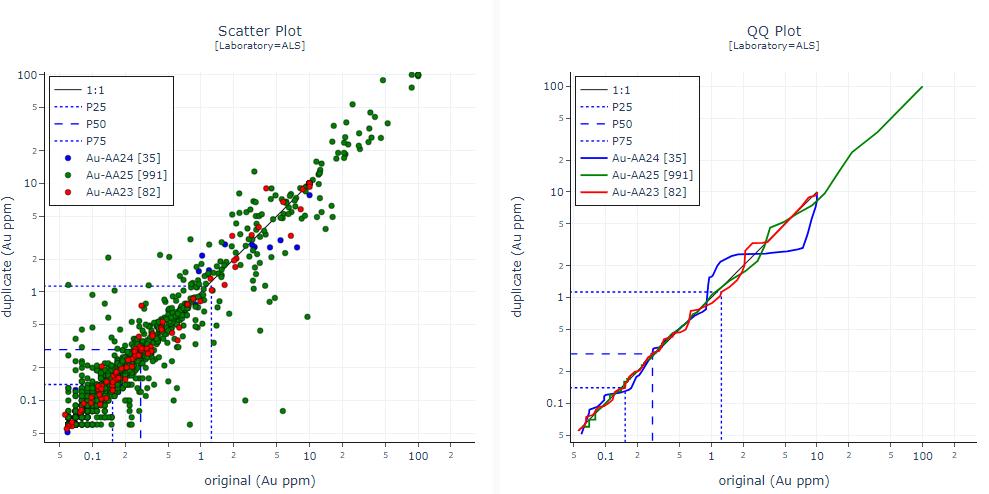

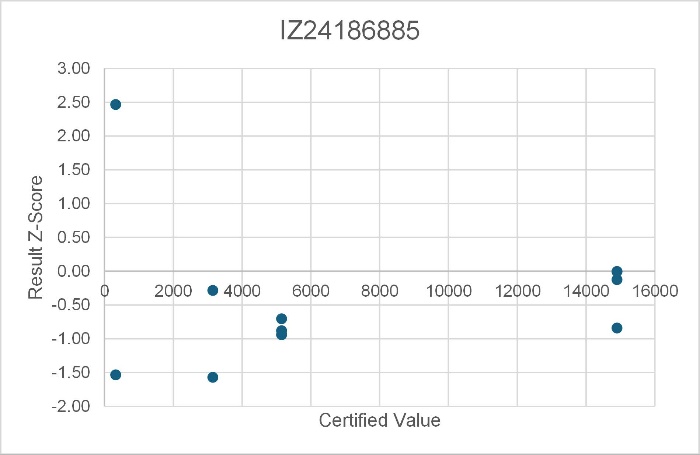

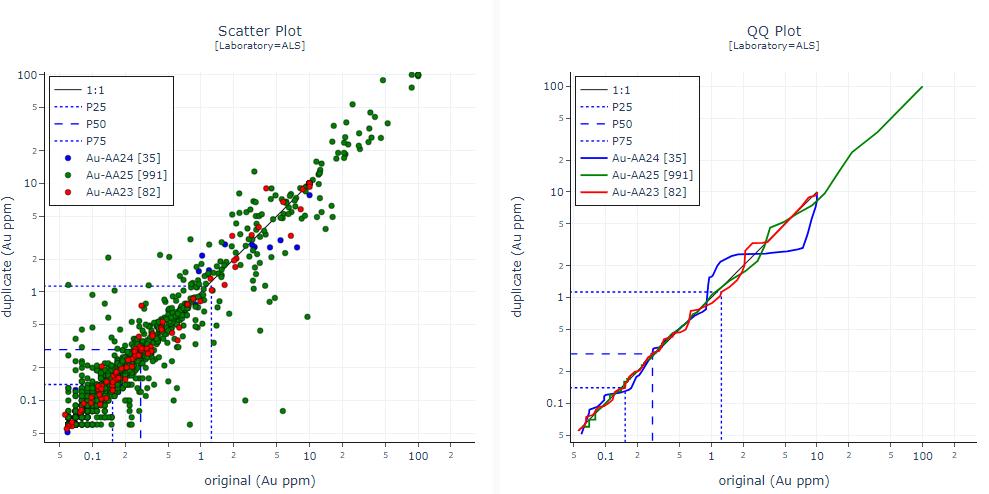

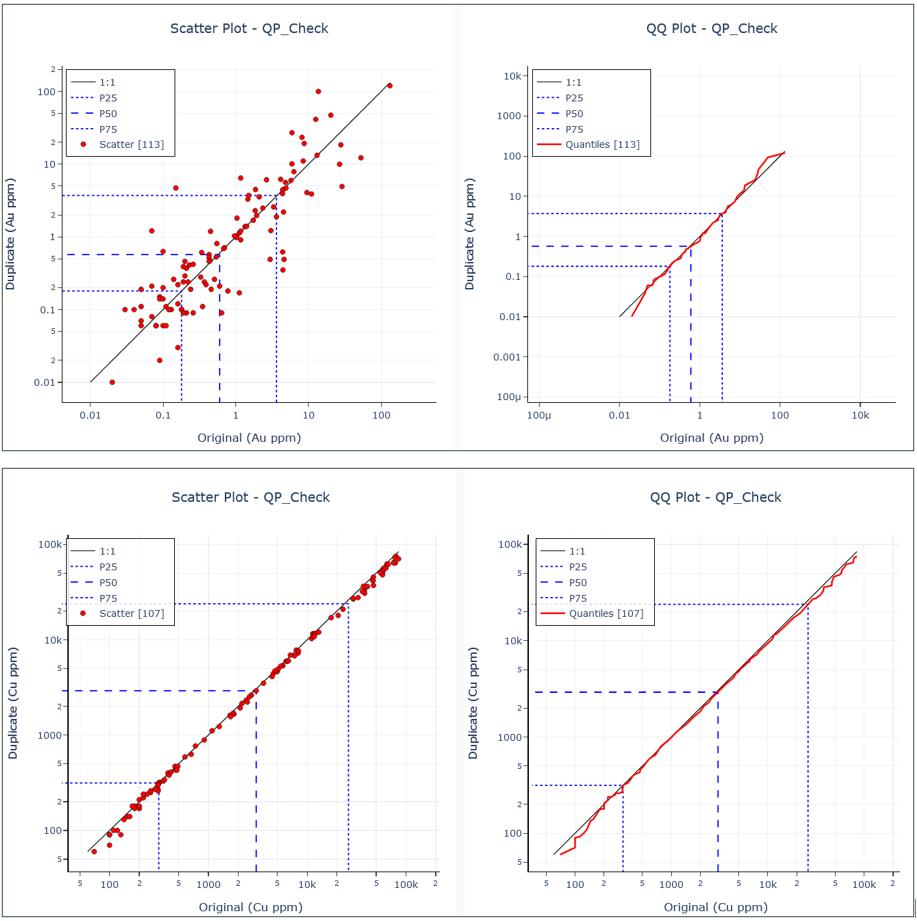

| Figure 8-14: Scatter and QQ Plot for Au in First-Split Duplicates (2014–2024). |

8-21 |

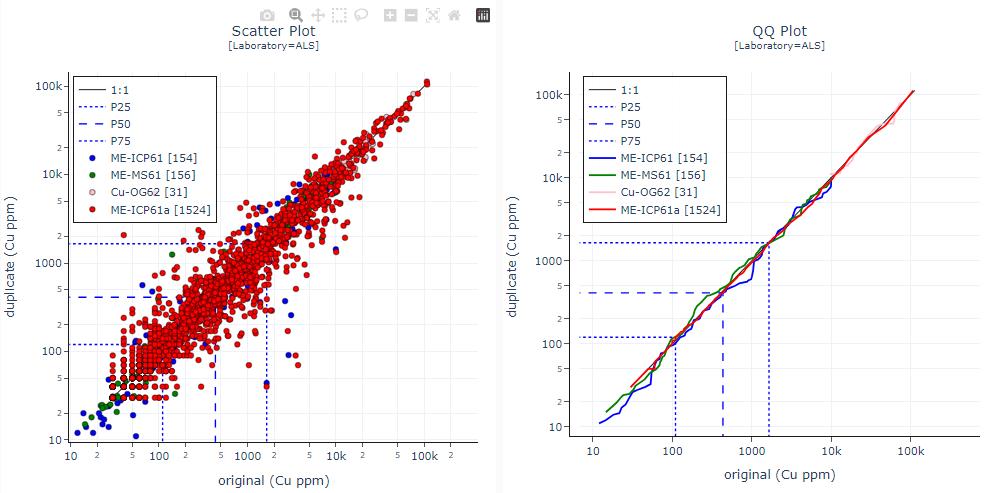

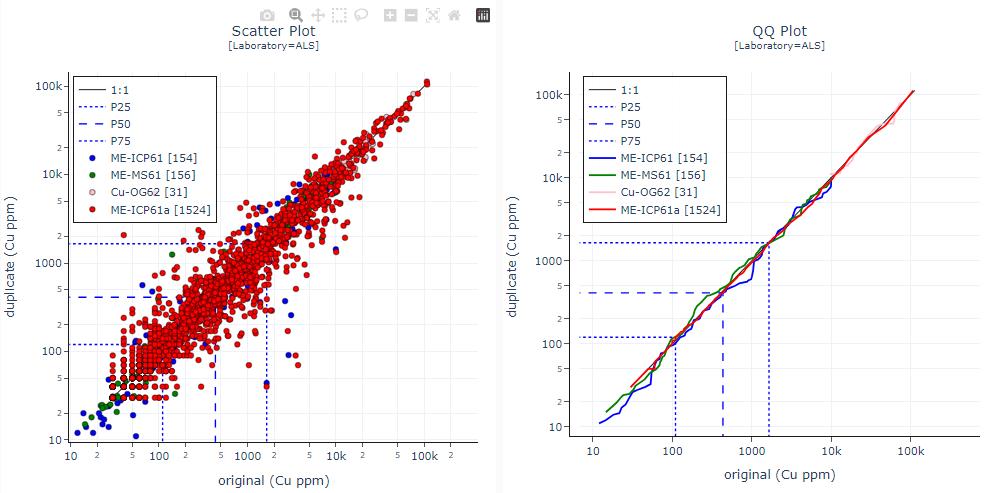

| Figure 8-15: Scatter and QQ Plot for Cu in First-Split Duplicates (2014–2024). |

8-21 |

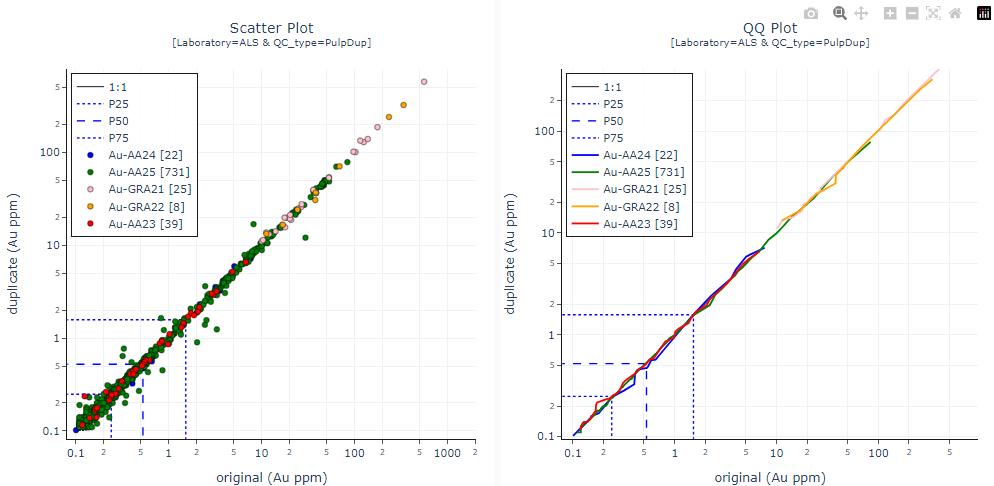

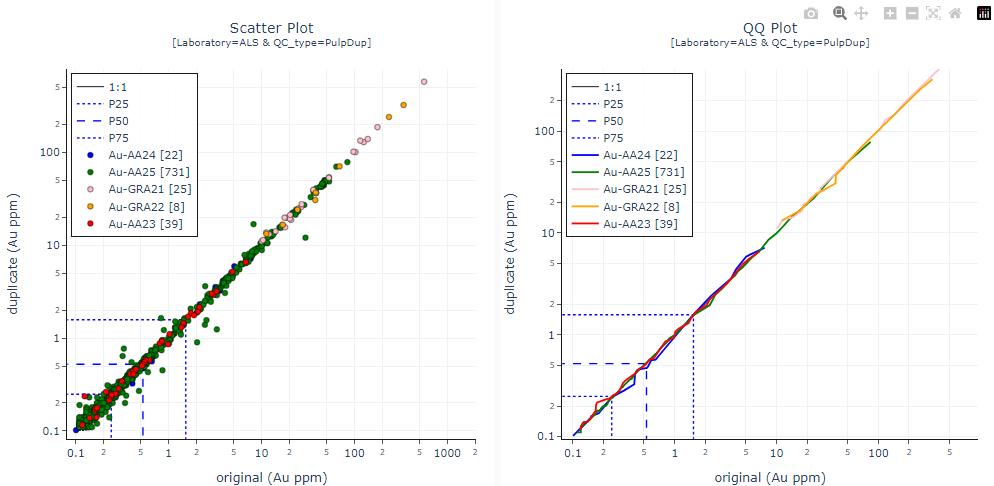

| Figure 8-16: Scatter and QQ Plot for Au in Third-Split Duplicates (2014–2024). |

8-23 |

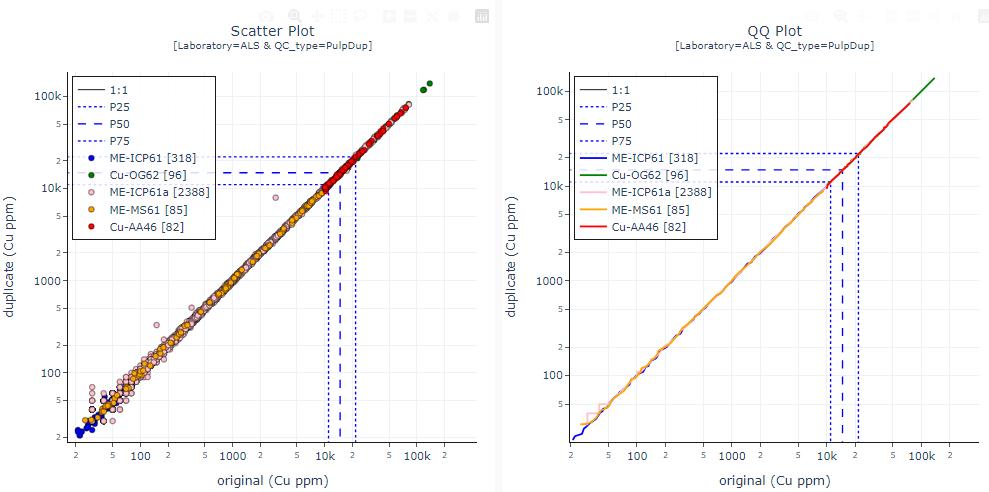

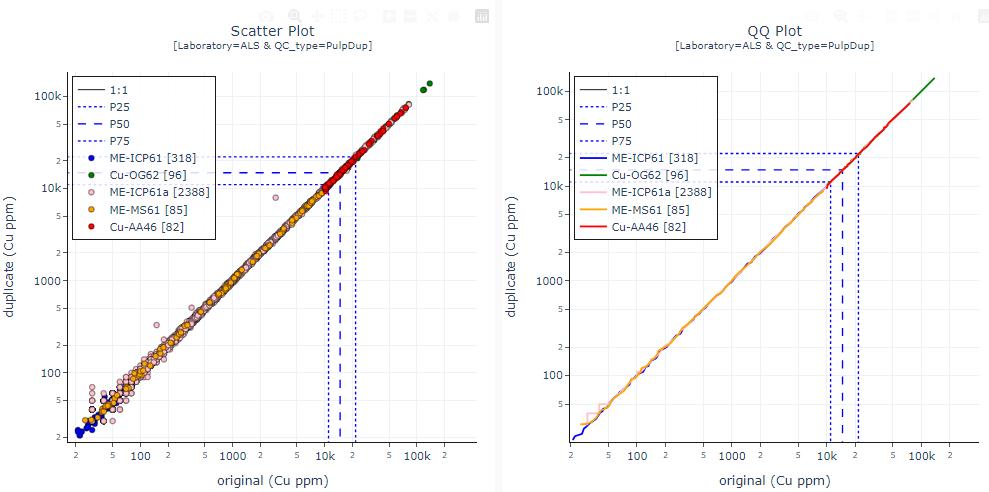

| Figure 8-17: Scatter and QQ Plot for Cu in Third-Split Duplicates (2014–2024). |

8-23 |

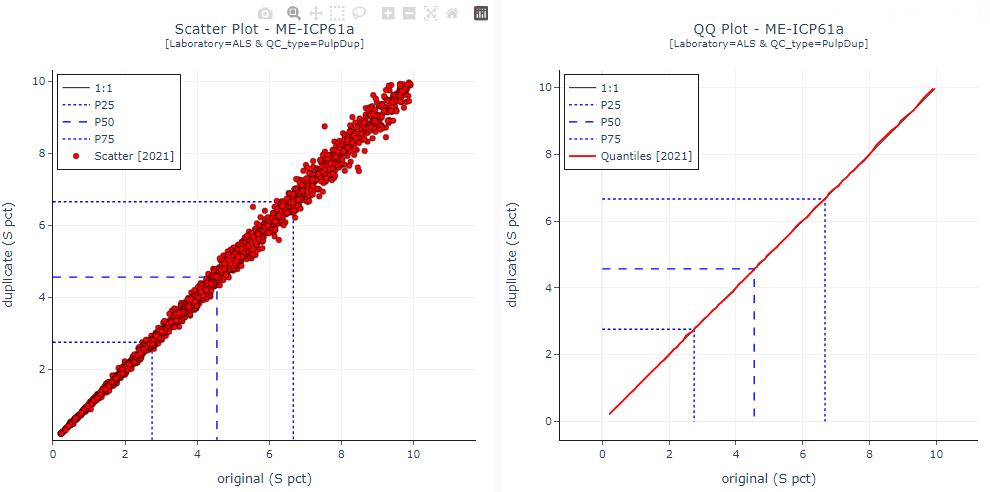

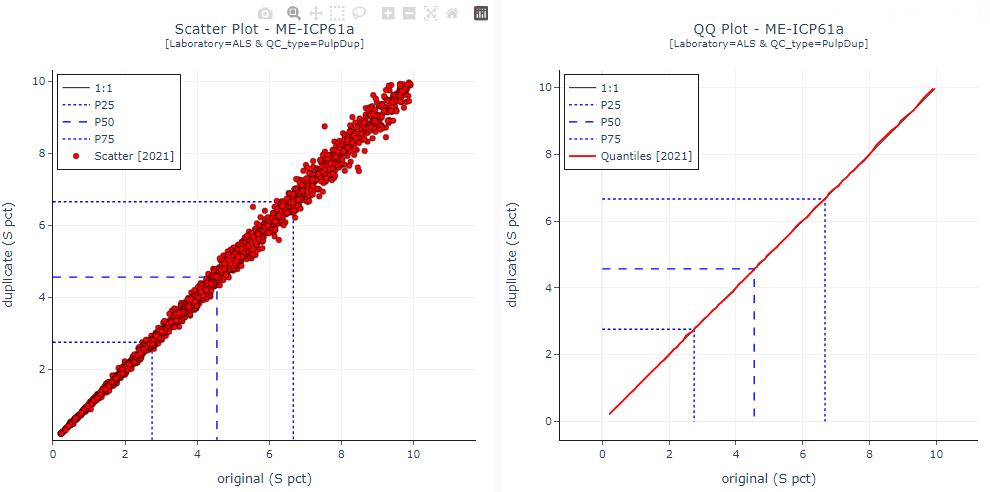

| Figure 8-18: Scatter and QQ Plot for S in Third-Split Duplicates (2014–2024) |

8-25 |

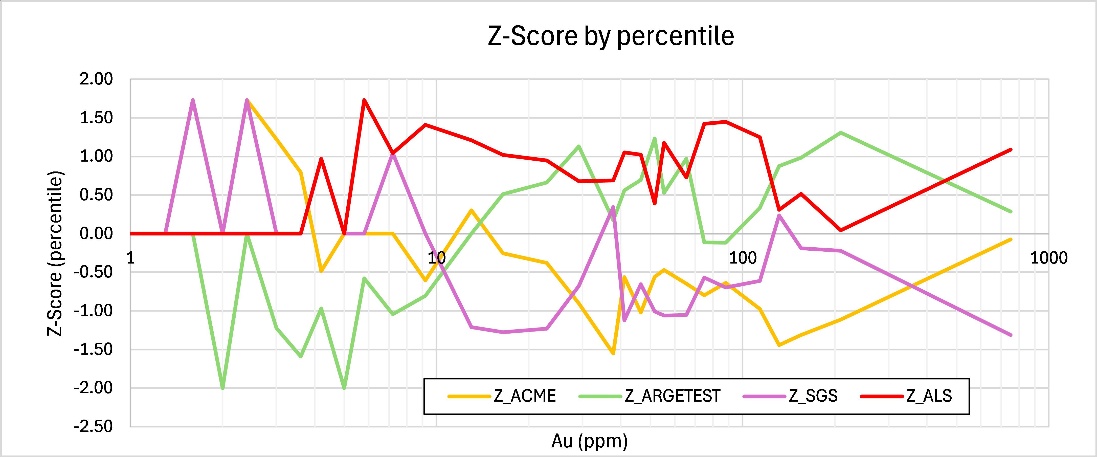

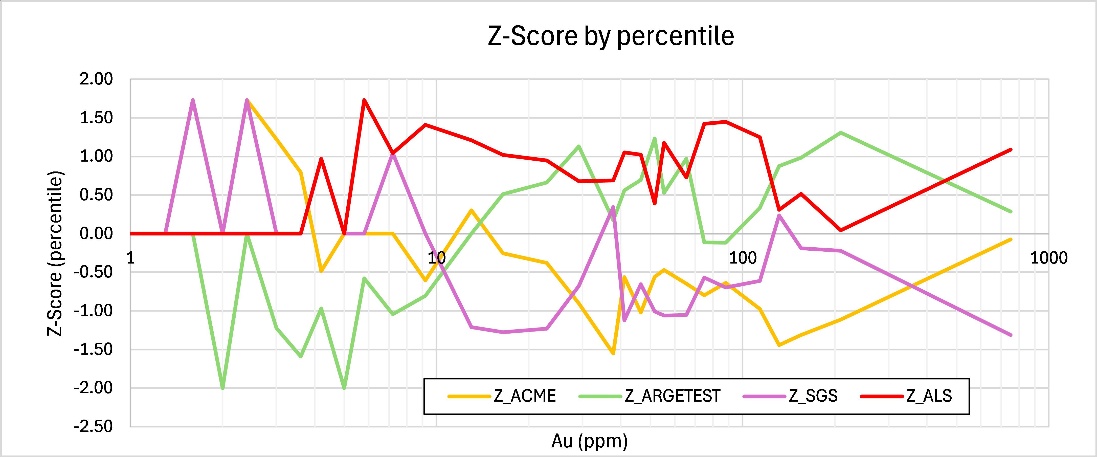

| Figure 8-19: Percentile Comparison of Umpire Analyses for Hod Maden, Au |

8-26 |

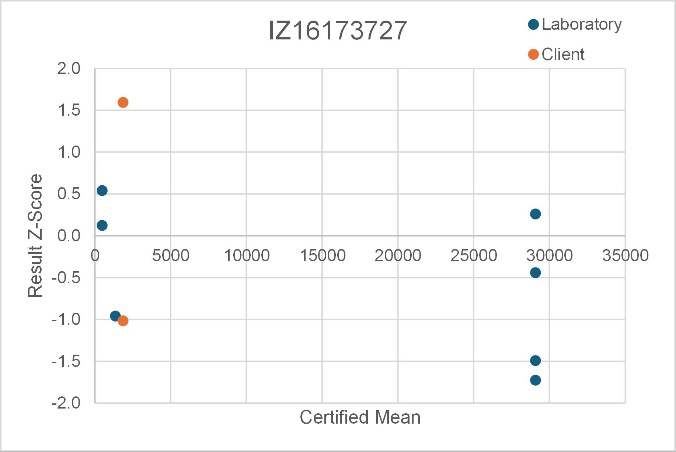

| Figure 9-1: Results for CRMs in batches IZ16173727 (Original) and IZ24186885 (Check) |

9-3 |

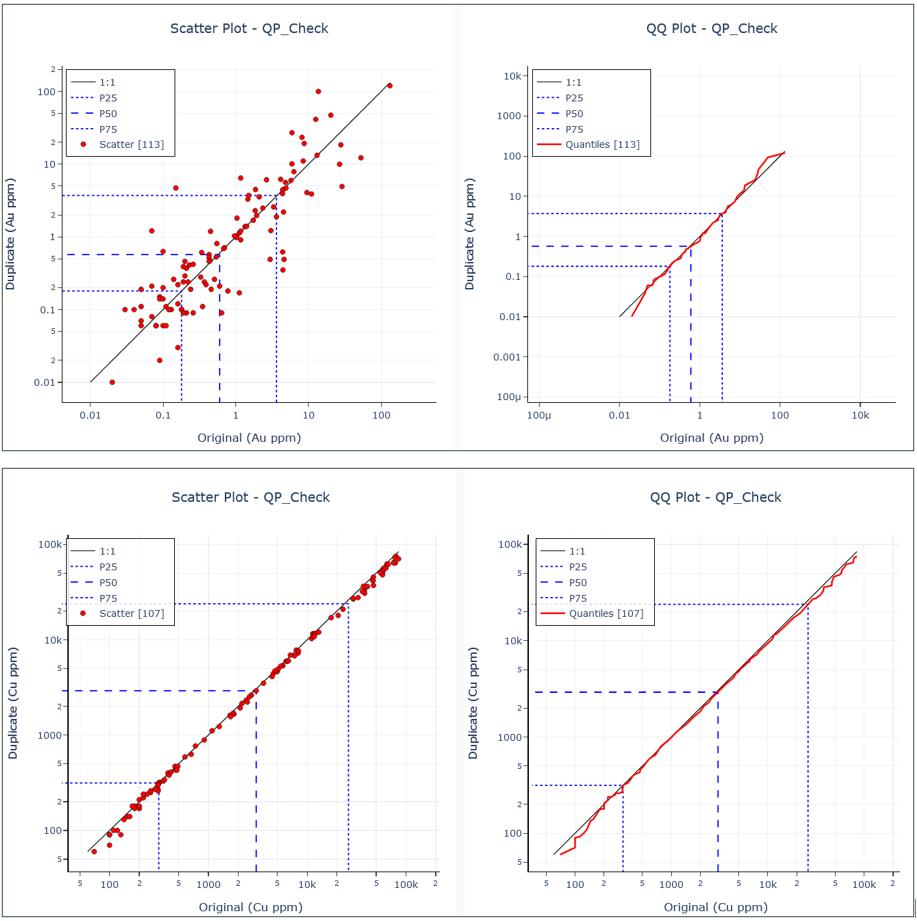

| Figure 9-2: Scatter and QQ plots for the Check Samples |

9-4 |

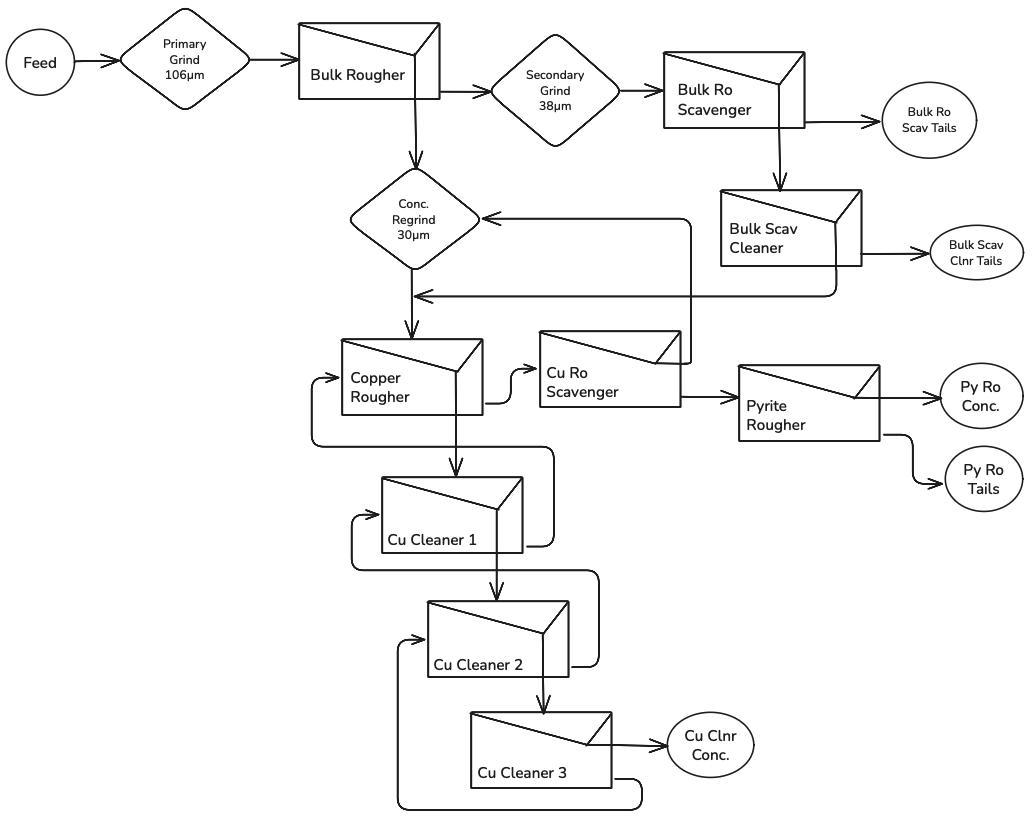

| Figure 10-1: Locked Cycle Flotation Test Flowsheet |

10-3 |

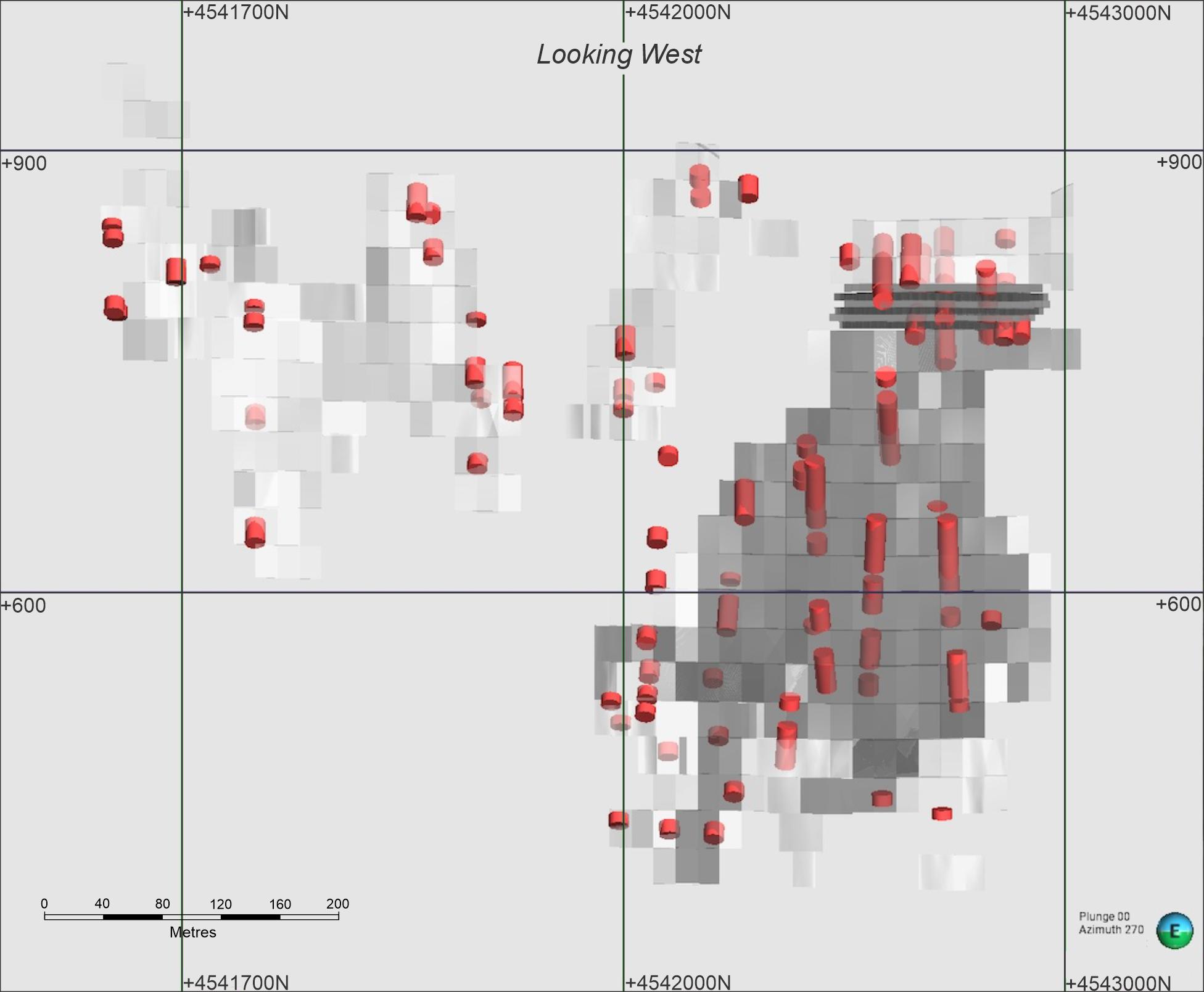

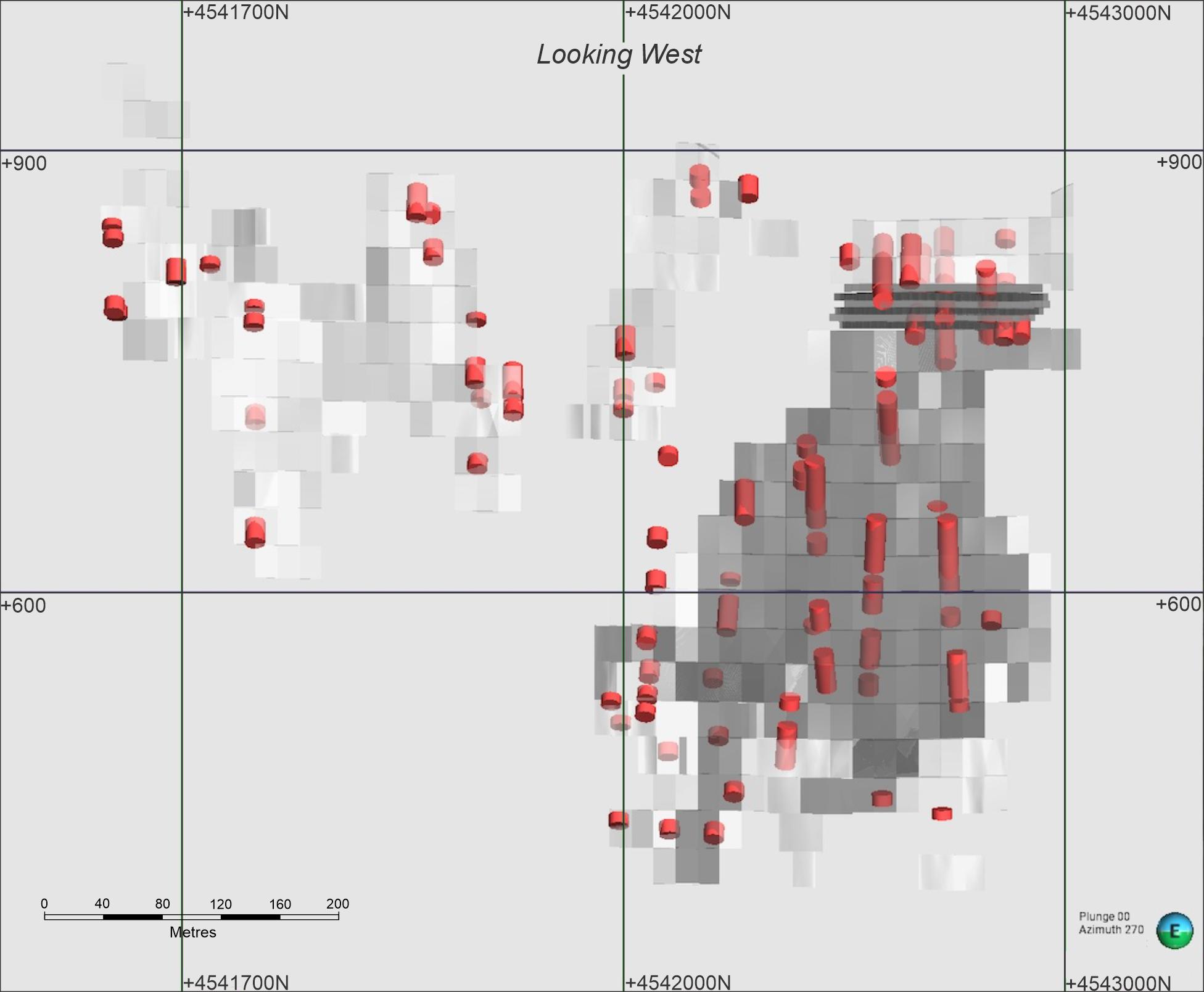

| Figure 10-2: Cross Section of Mining Shapes vs Intervals Tested (Looking West) |

10-9 |

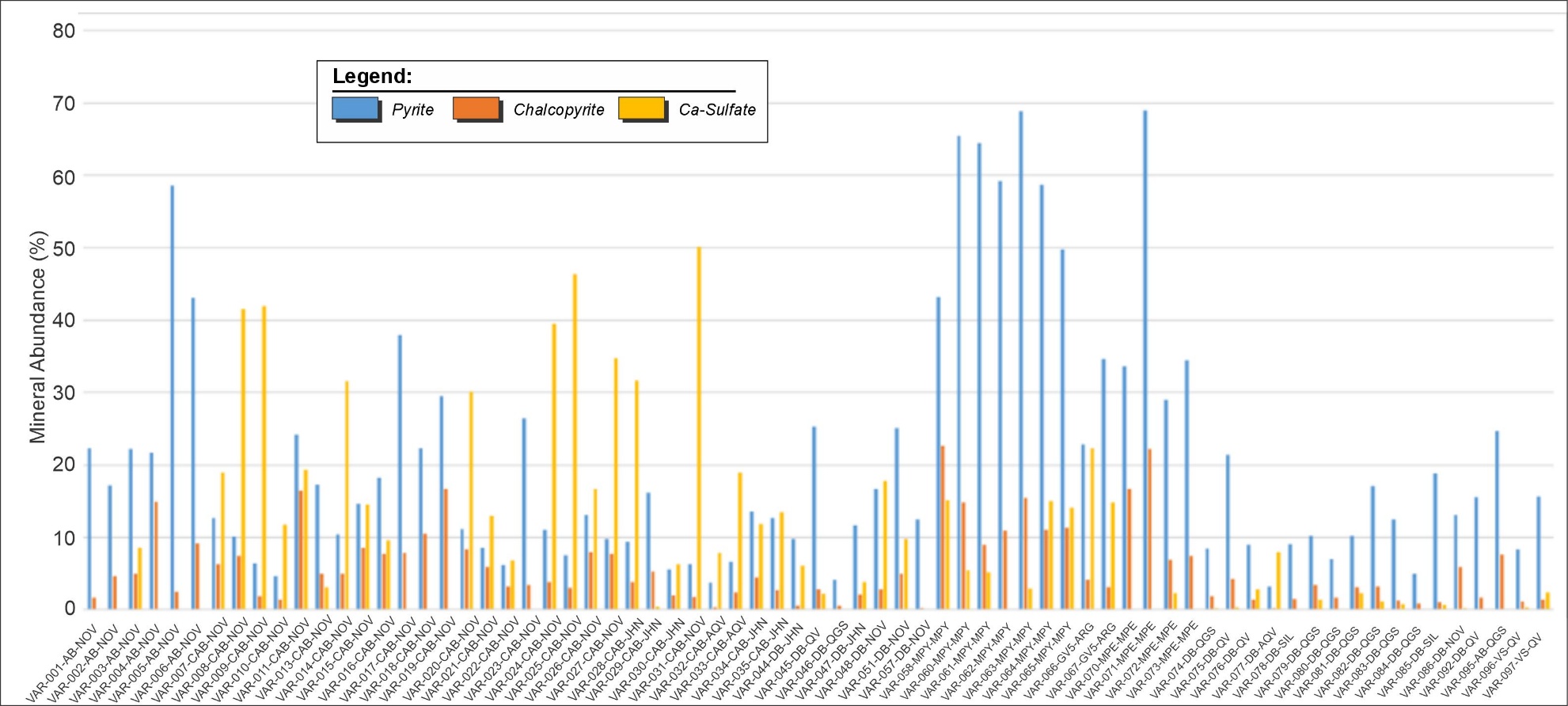

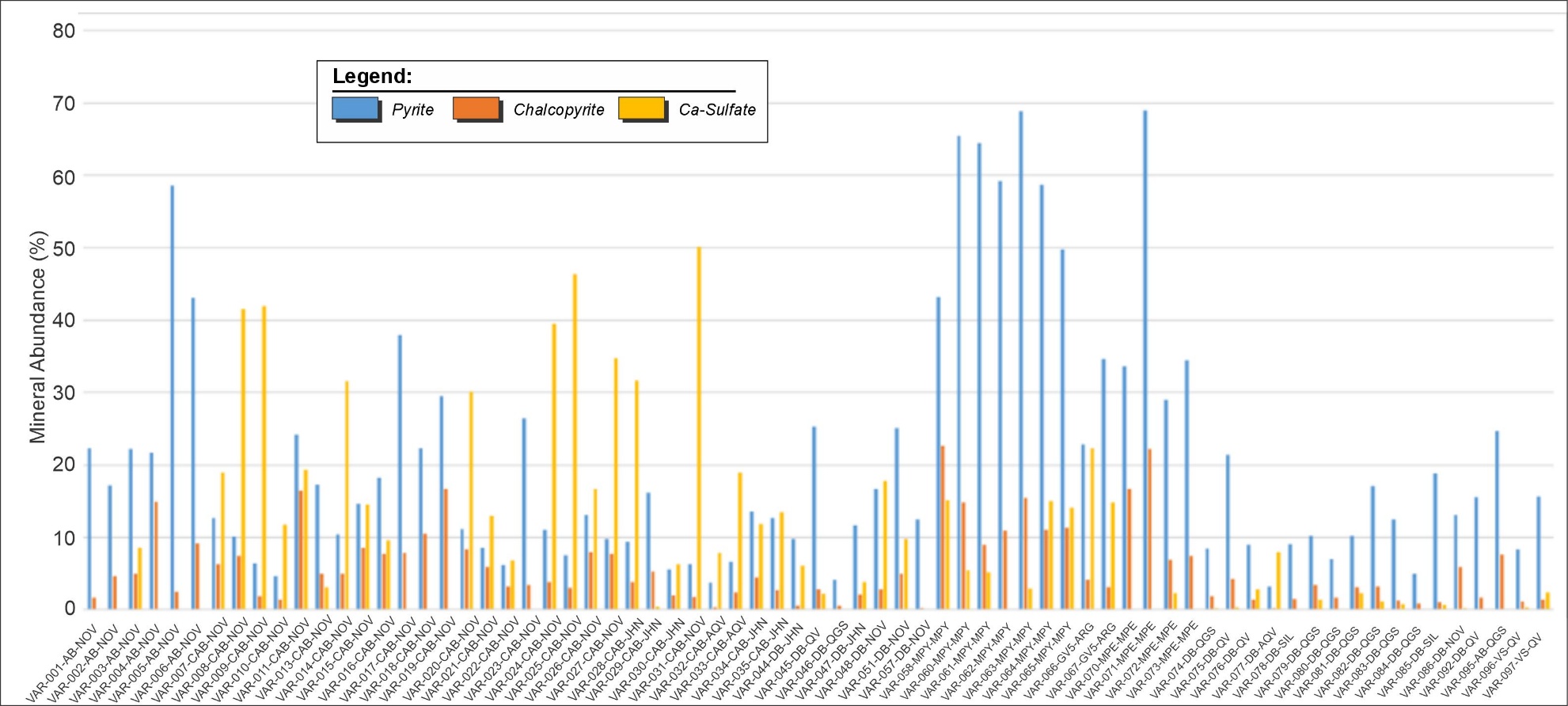

| Figure 10-3: Distribution of Pyrite, Chalcopyrite and Ca-Sulfate in the Variability Samples |

10-11 |

| | xi |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

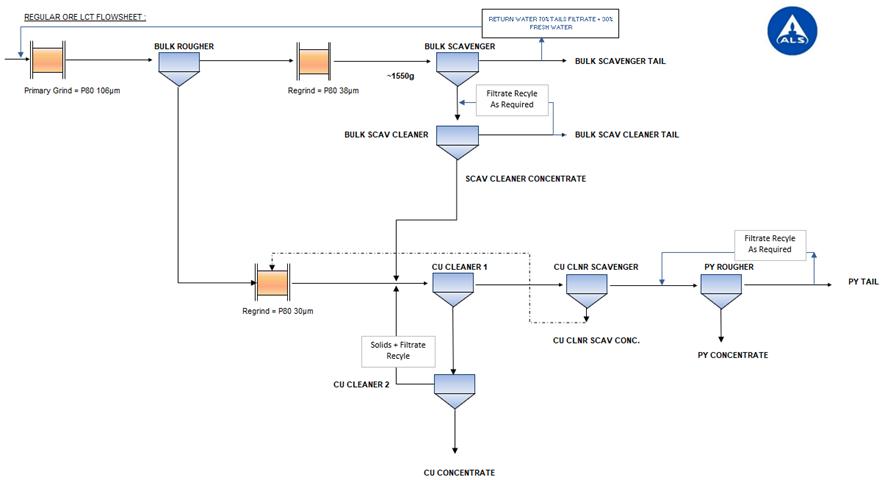

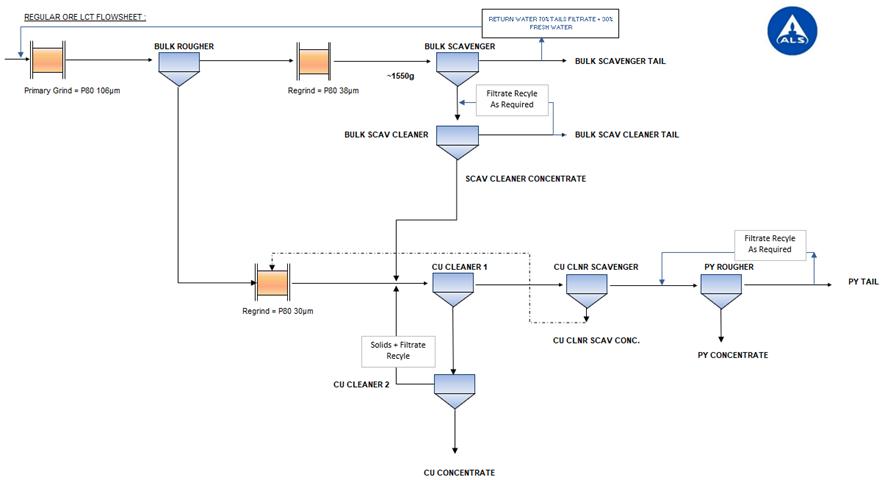

| Figure 10-4: LCT Flowsheet |

10-17 |

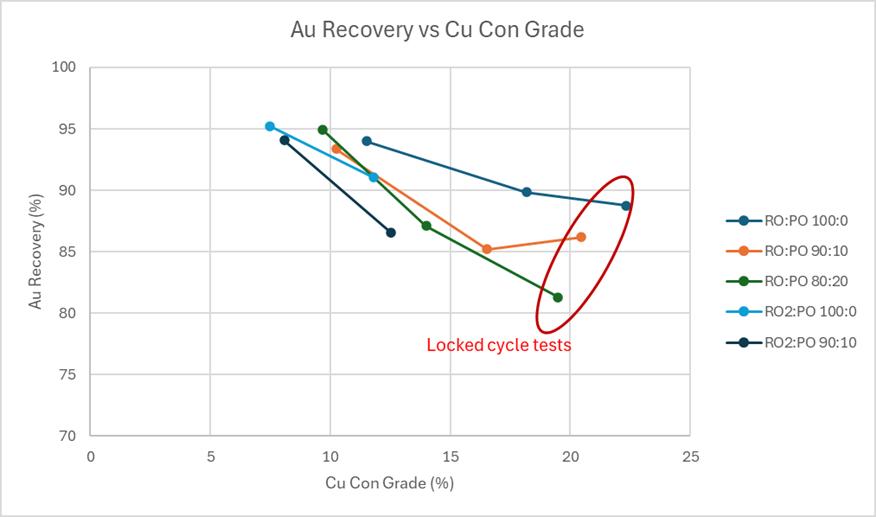

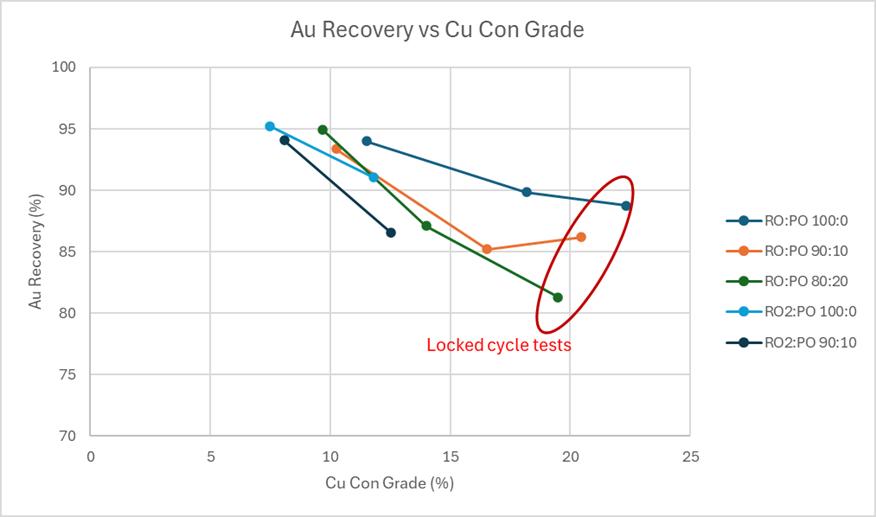

| Figure 10-5: Relationship between Copper Concentrate Grade and Gold Recovery |

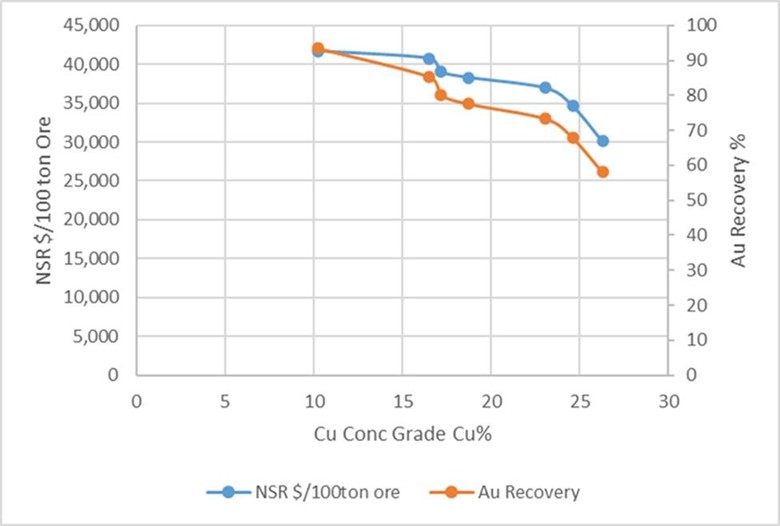

10-19 |

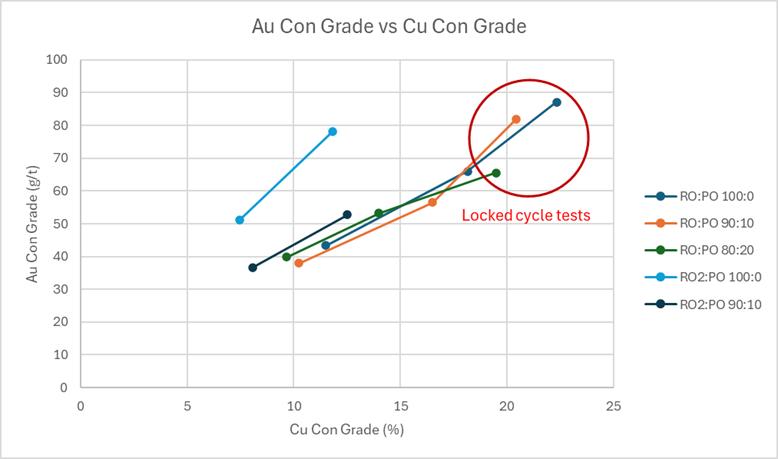

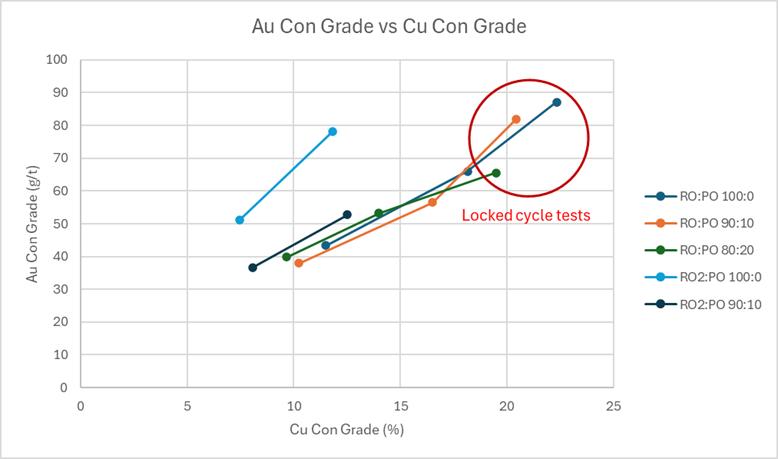

| Figure 10-6: Relationship between Copper Concentrate Grade and Gold Concentrate Grade |

10-20 |

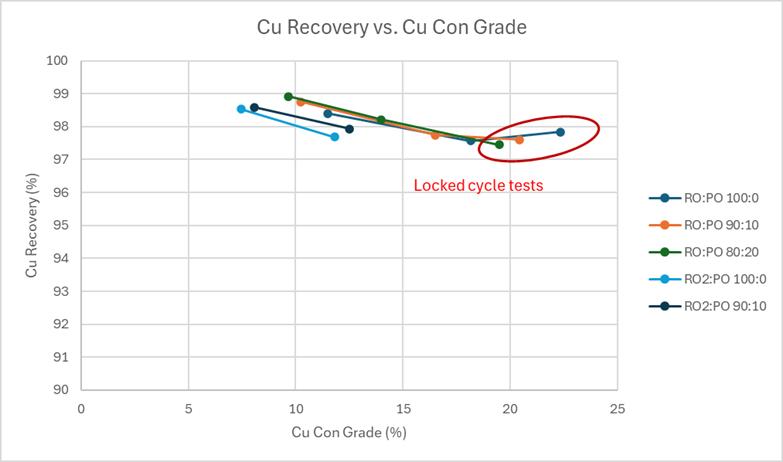

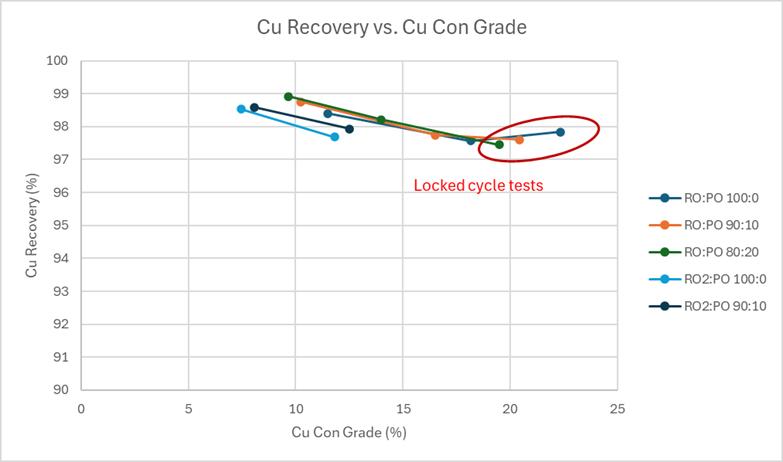

| Figure 10-7: Relationship between Copper Concentrate Grade and Copper Recovery |

10-20 |

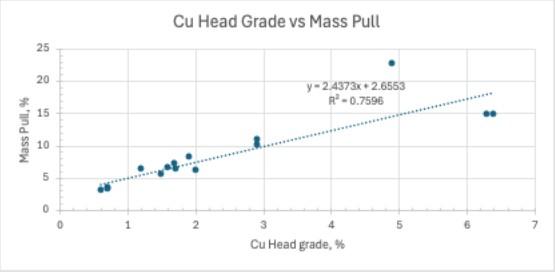

| Figure 10-8: Mass Pull Based on Copper Head Grade |

10-23 |

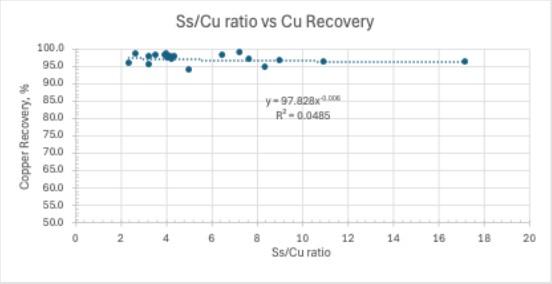

| Figure 10-9: Cu Recovery as a Function of S/Cu Ratio |

10-24 |

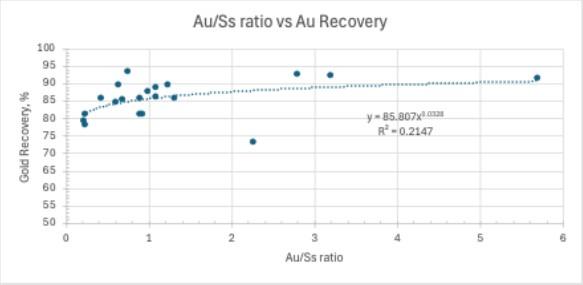

| Figure 10-10: Au Recovery as a Function of Au/Ss Ratio |

10-24 |

| Figure 10-11: NSR Analysis and Gold Recovery Based on Concentrate Copper Grade |

10-25 |

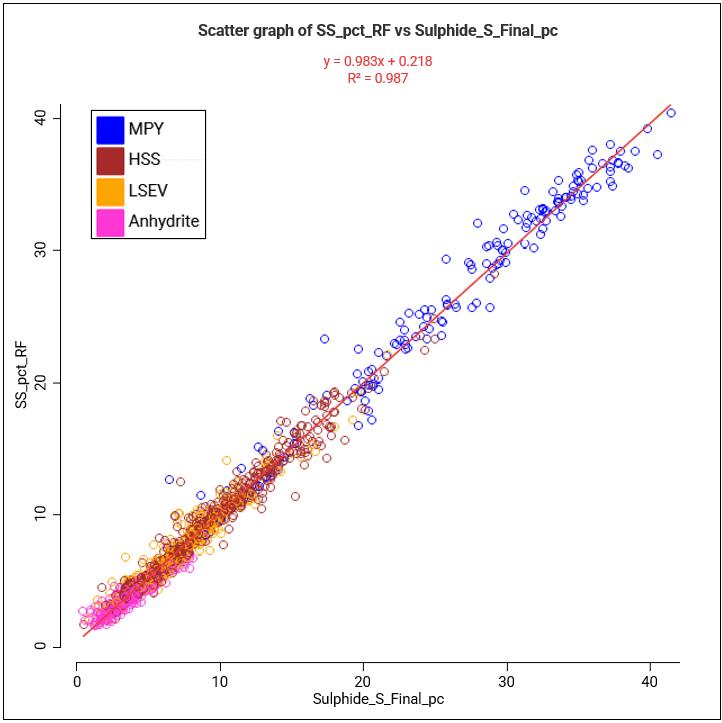

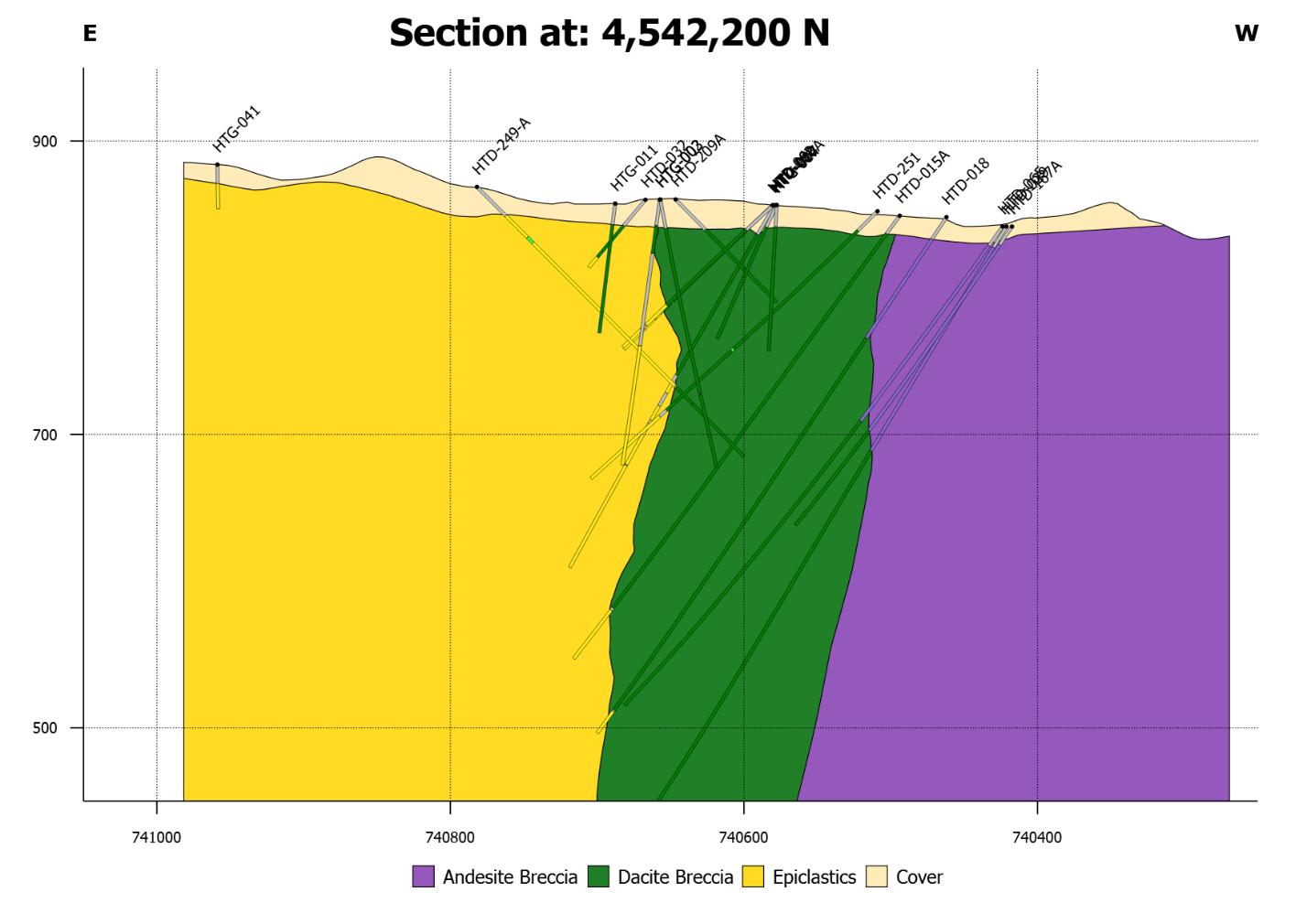

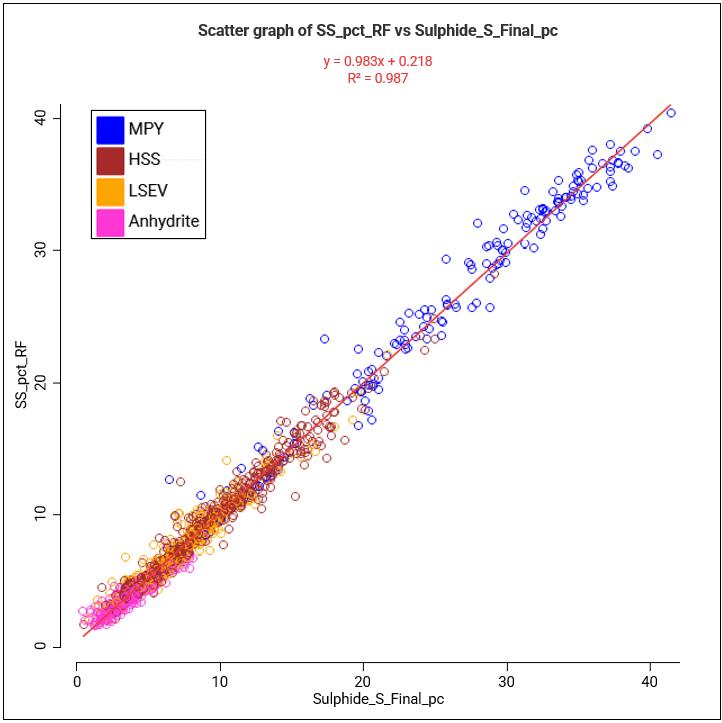

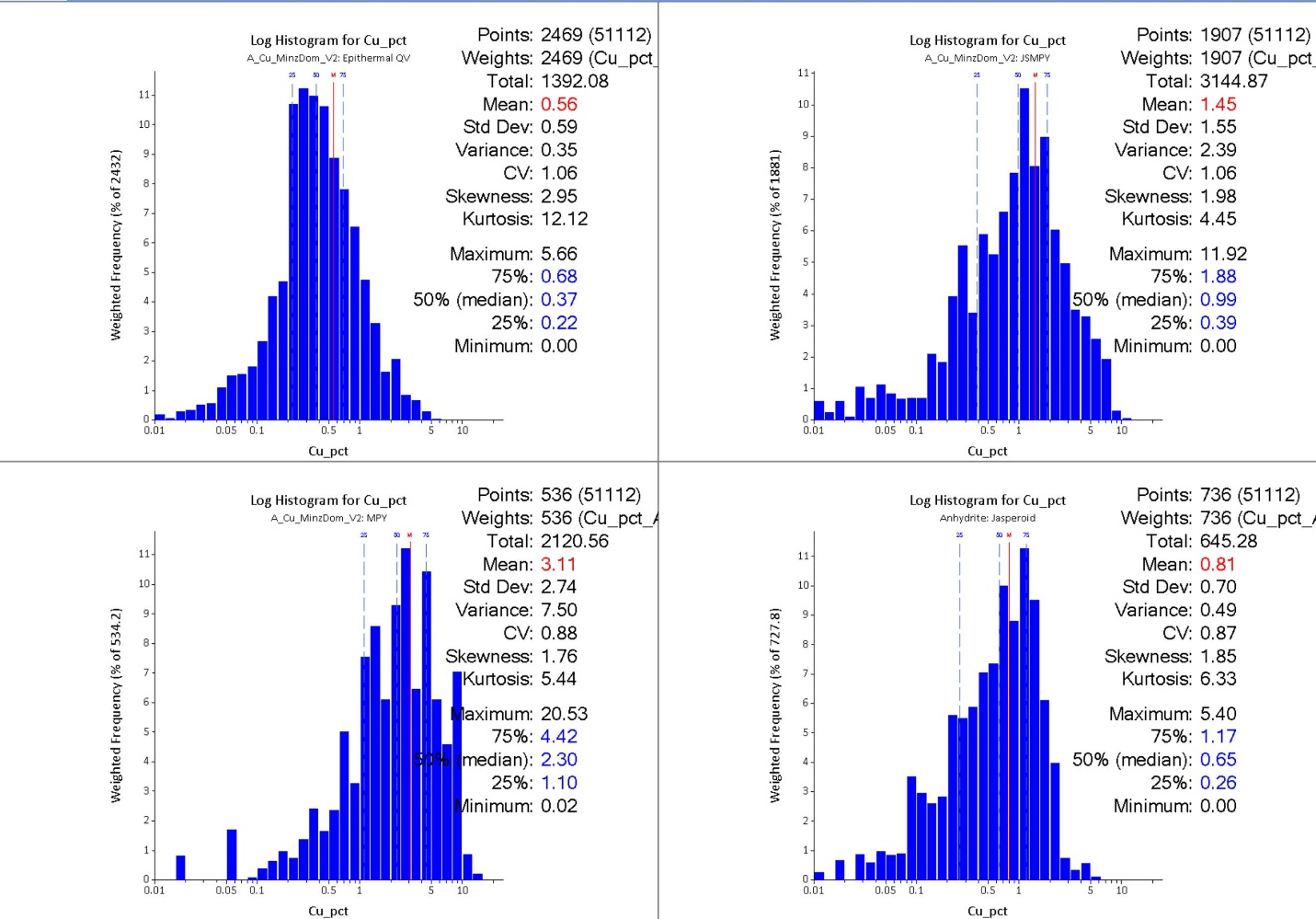

| Figure 11-1: Random Forest Regression of Sulfide S (SS) |

11-4 |

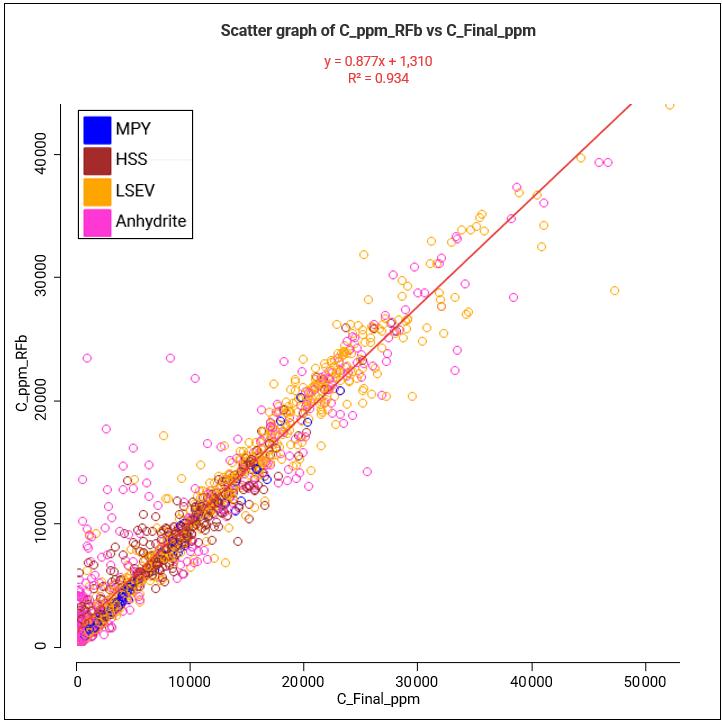

| Figure 11-2: Random Forest Regression of Carbon |

11-4 |

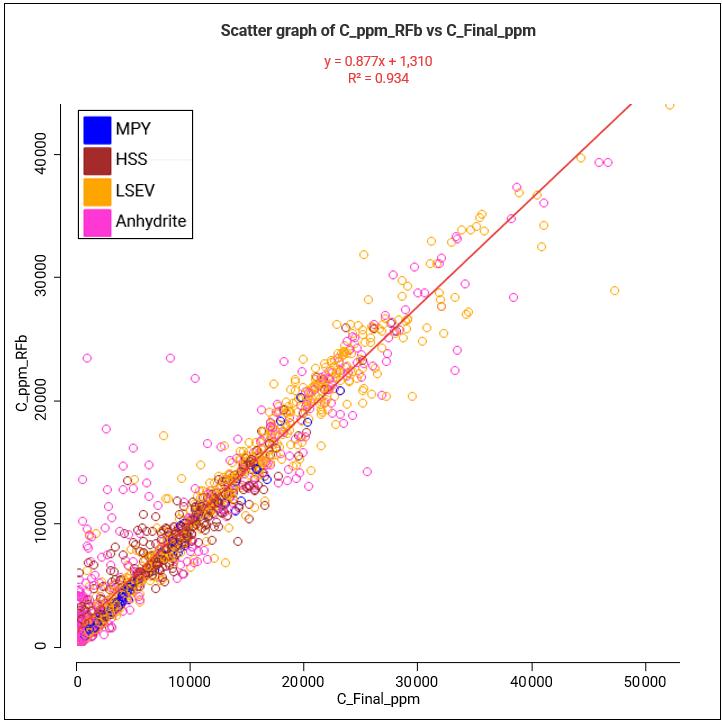

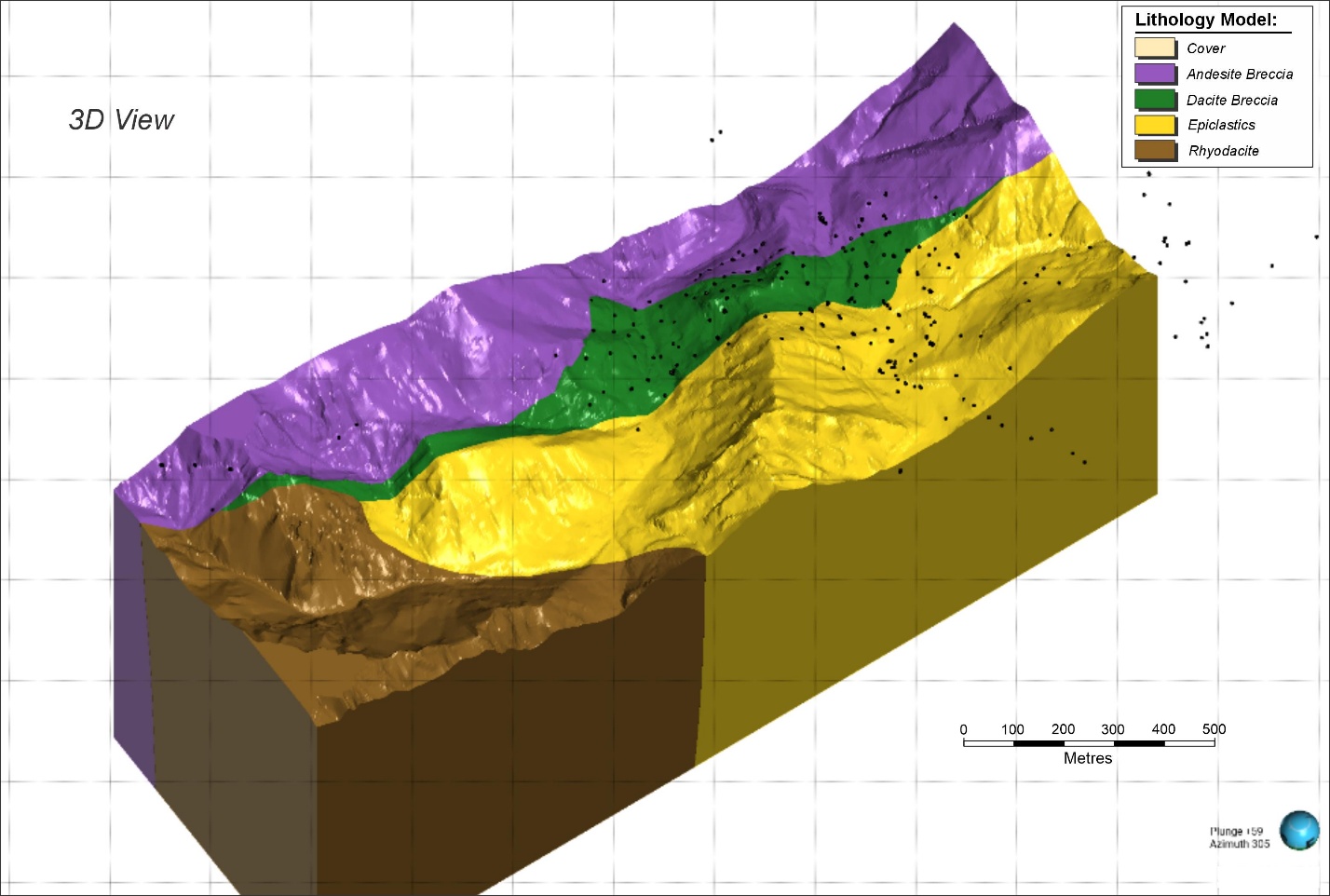

| Figure 11-3: Perspective View of the Primary Lithology Model |

11-7 |

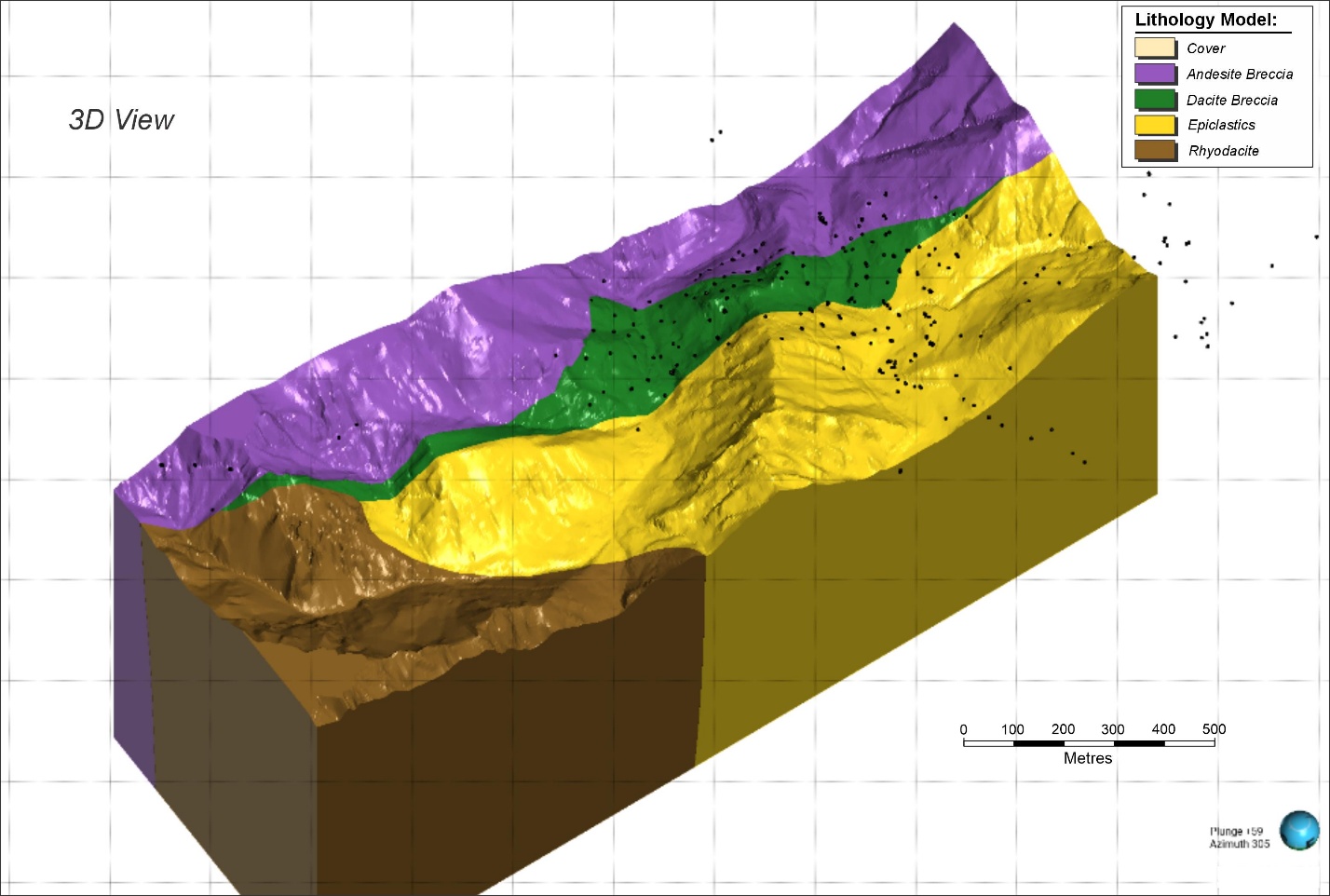

| Figure 11-4: Cross-section of the Solid Geology Model |

11-8 |

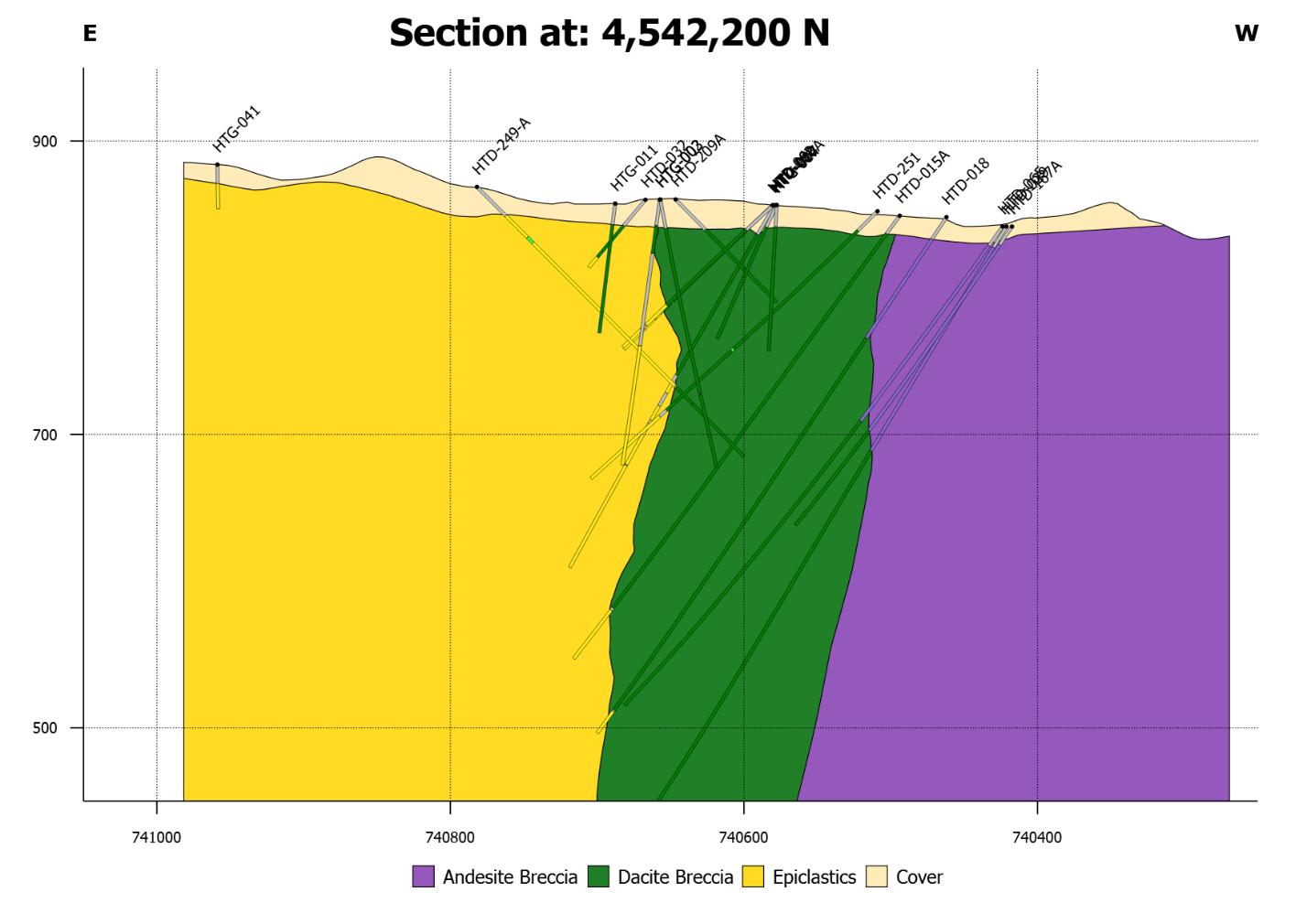

| Figure 11-5: Ratio of Co and Al Correlates with Massive Pyrite and Jasperoid |

11-10 |

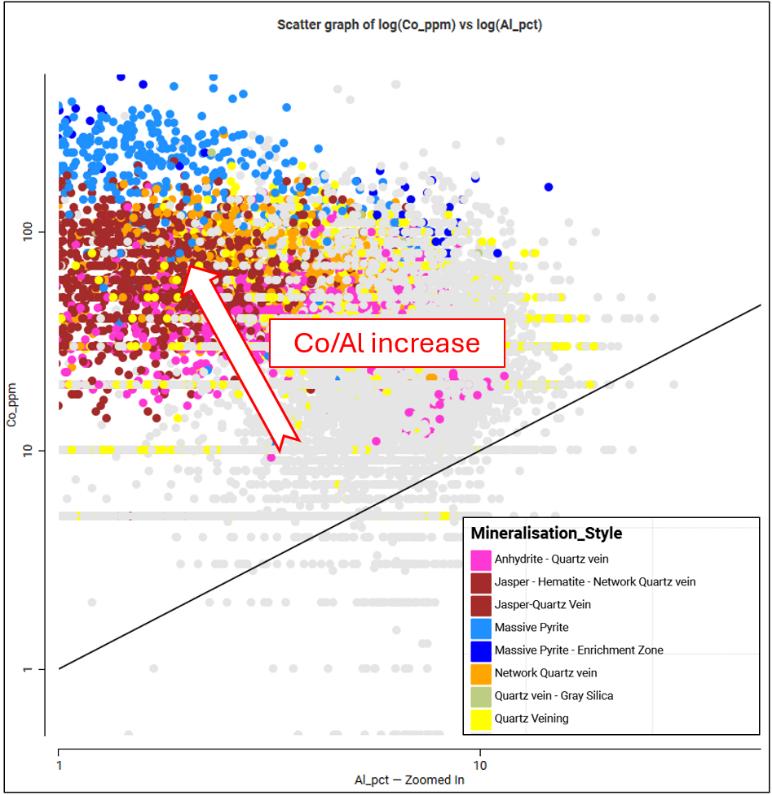

| Figure 11-6: Logged Mineralization Style (left). Geochemical Proxy (right) |

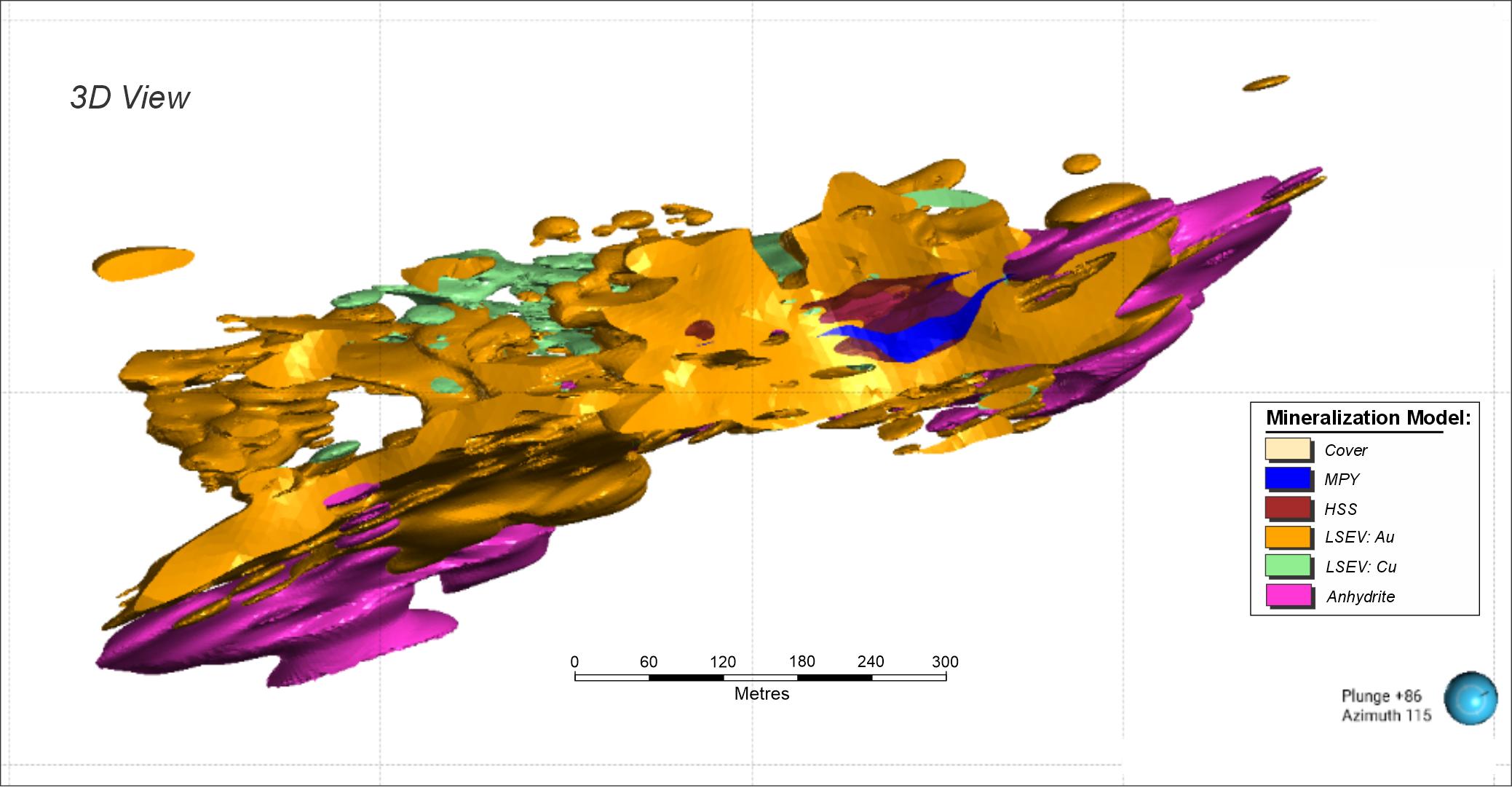

11-11 |

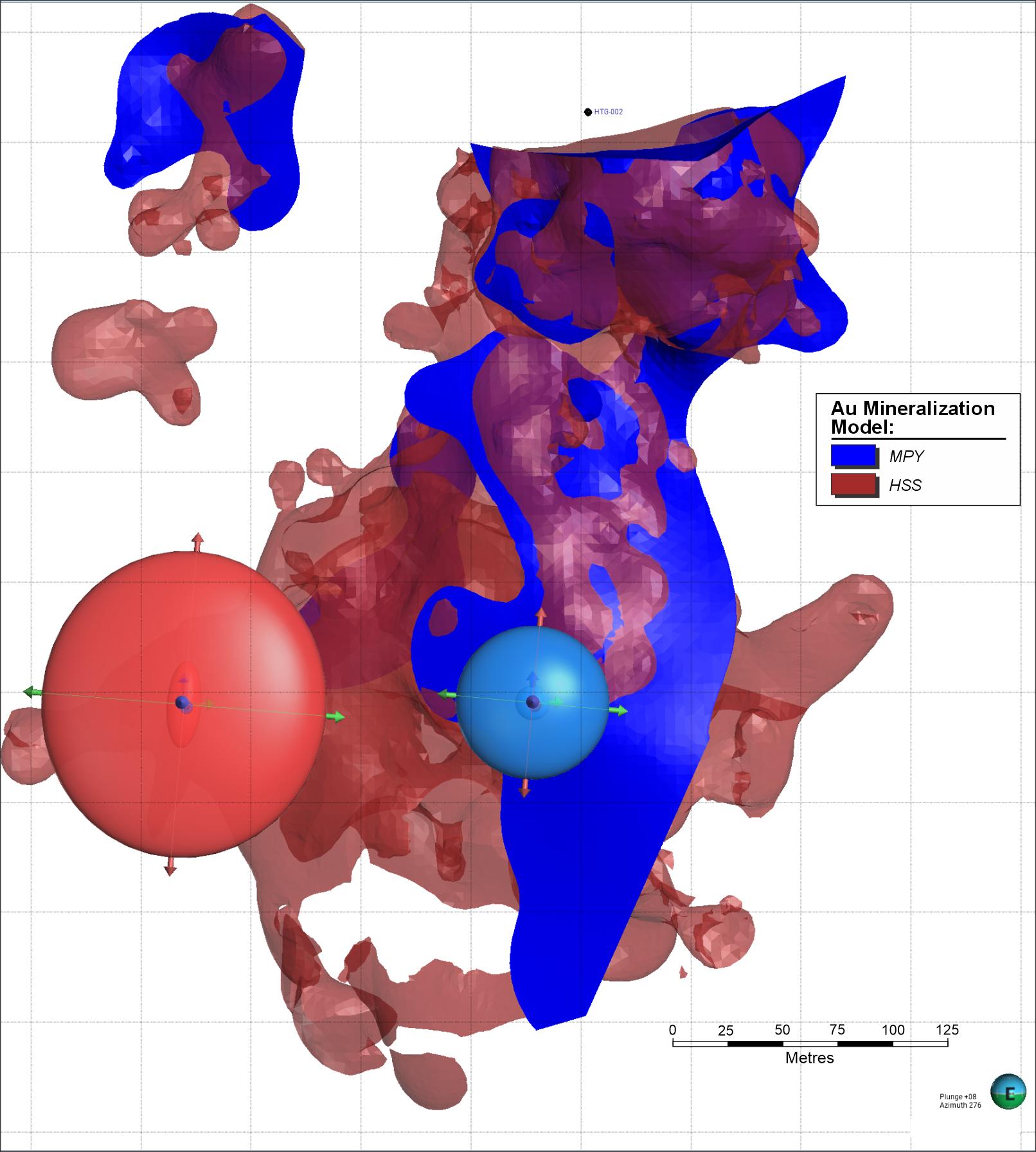

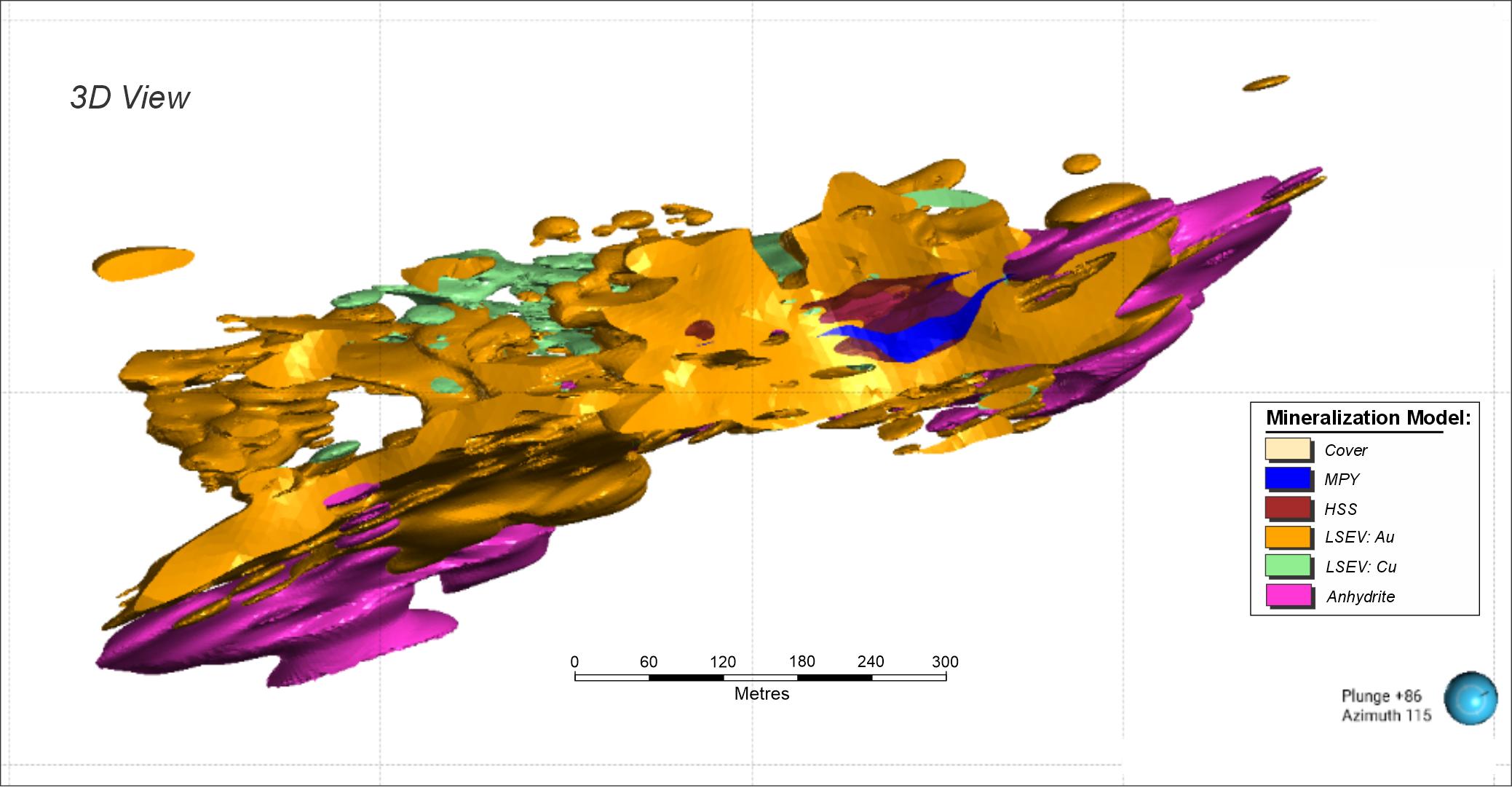

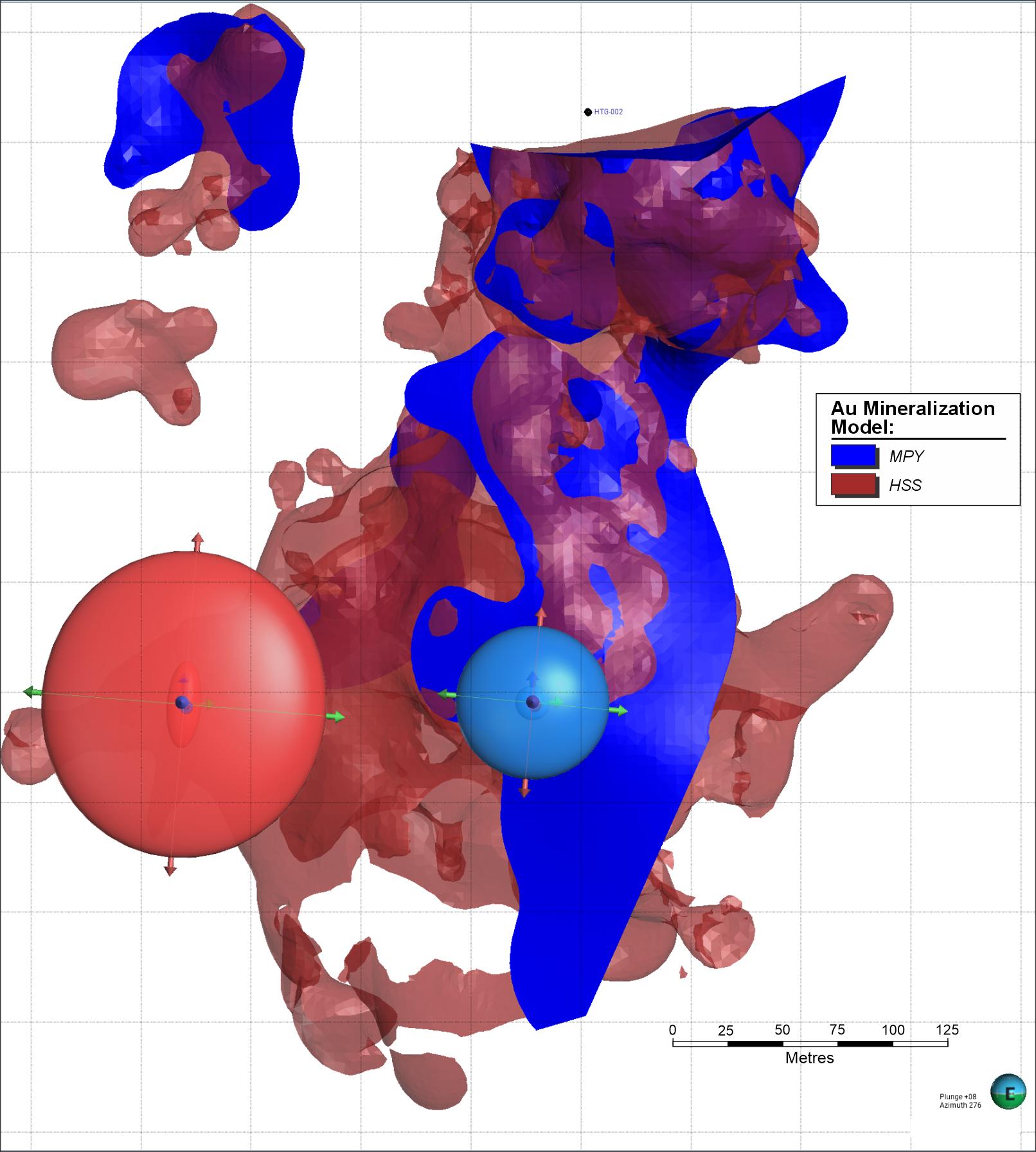

| Figure 11-7: Perspective View of the Mineralization Model for Hod Maden |

11-11 |

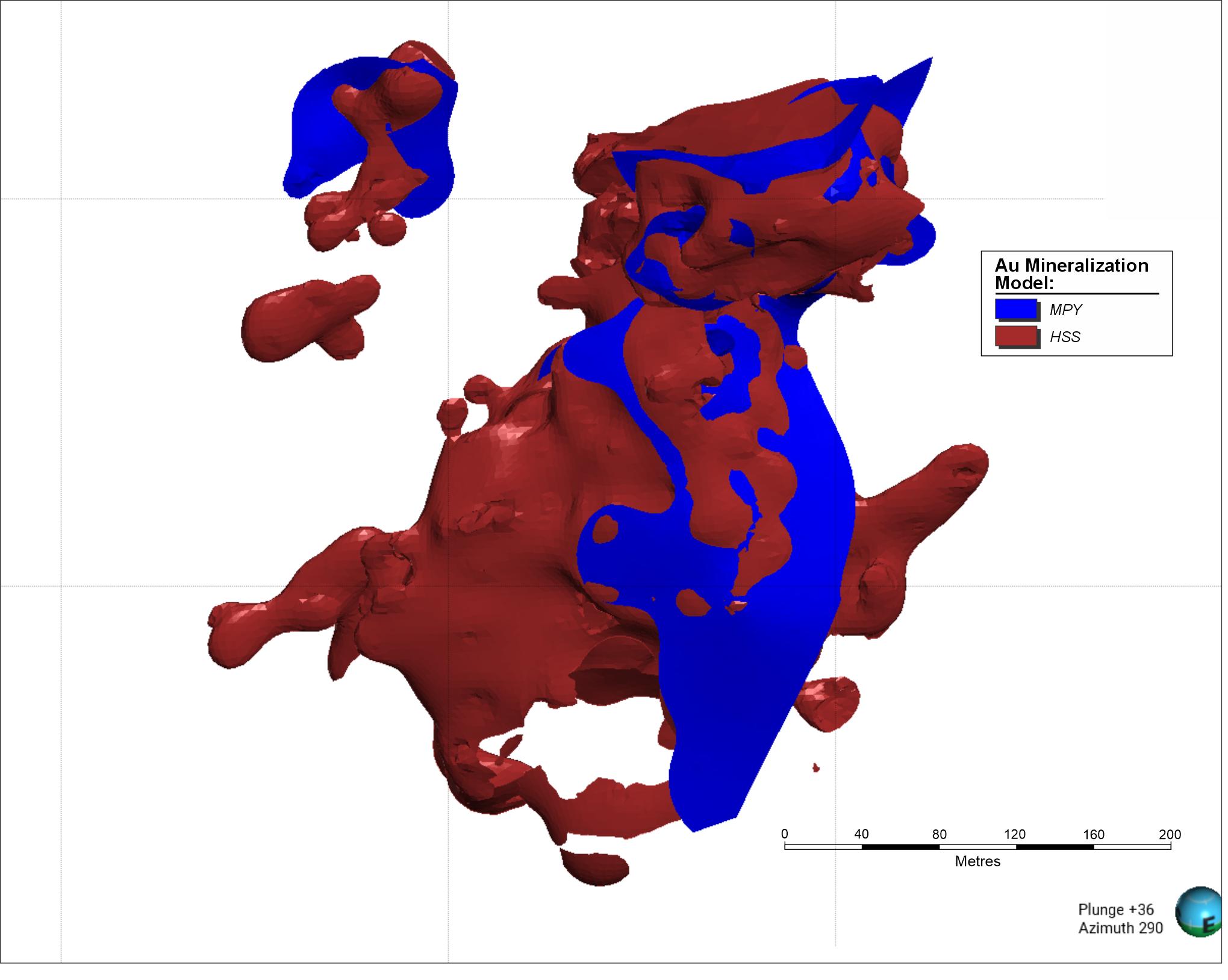

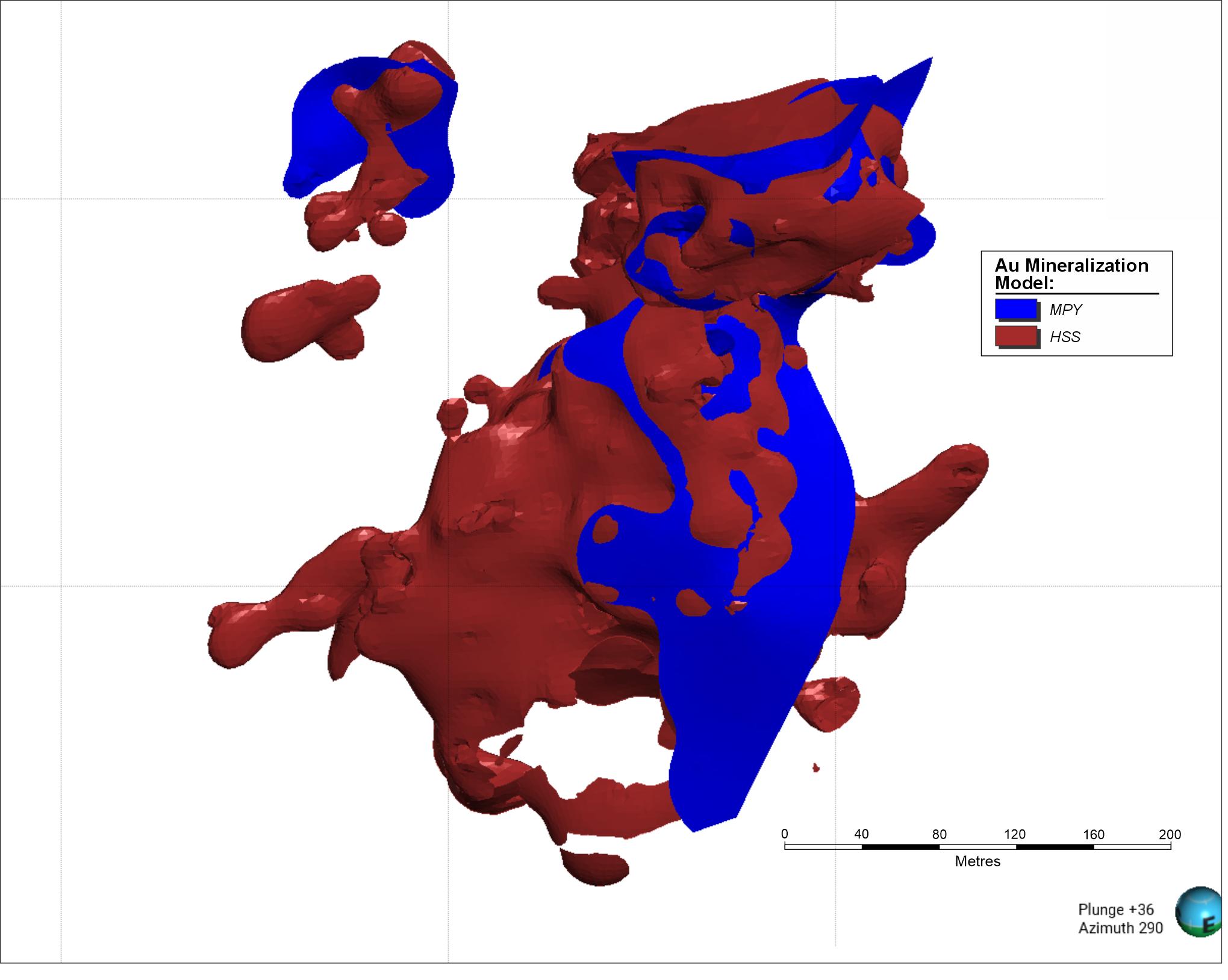

| Figure 11-8: Perspective View of the Mineralization Model Illustrating the Relationship of the MPY and HSS Domains |

11-12 |

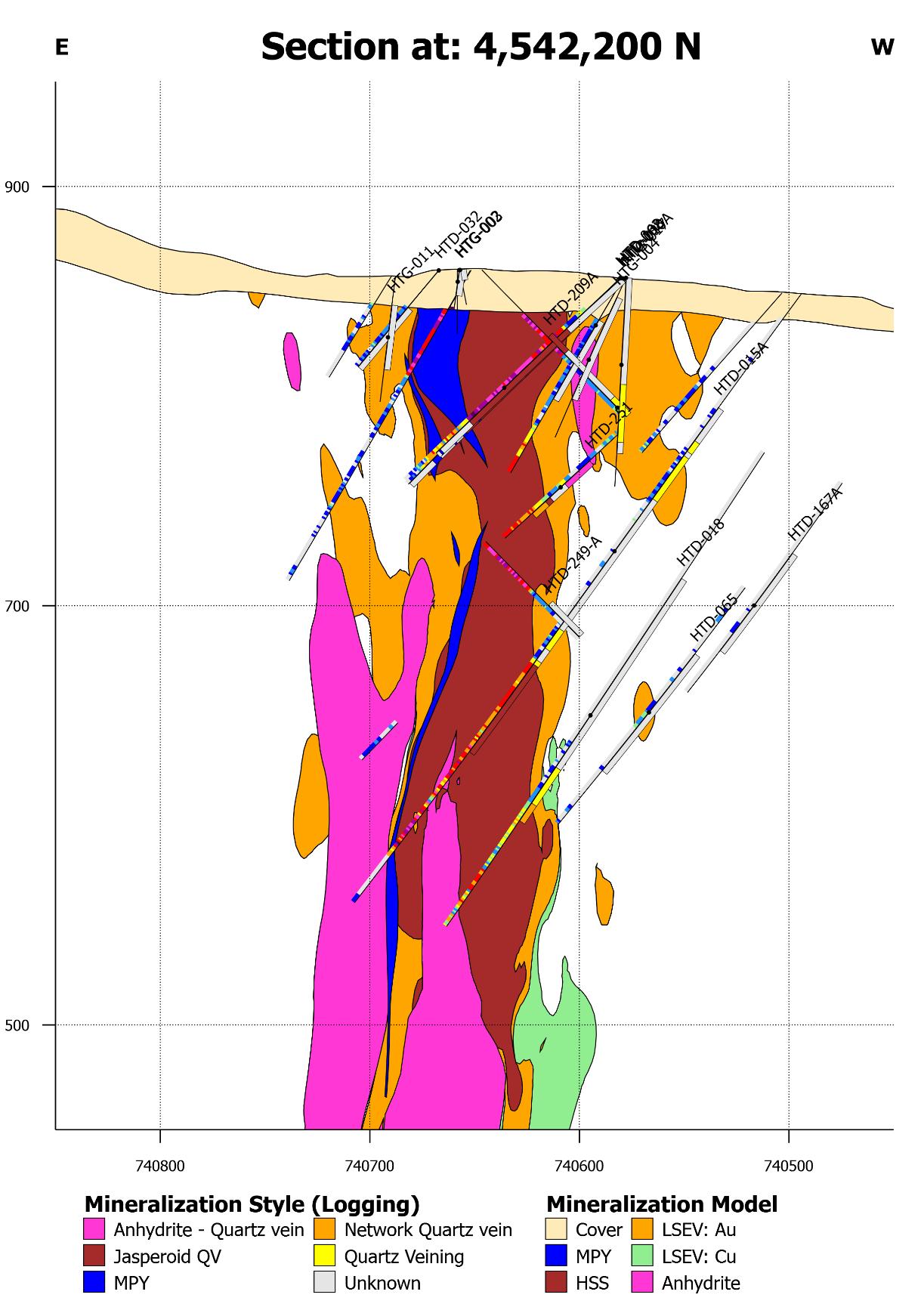

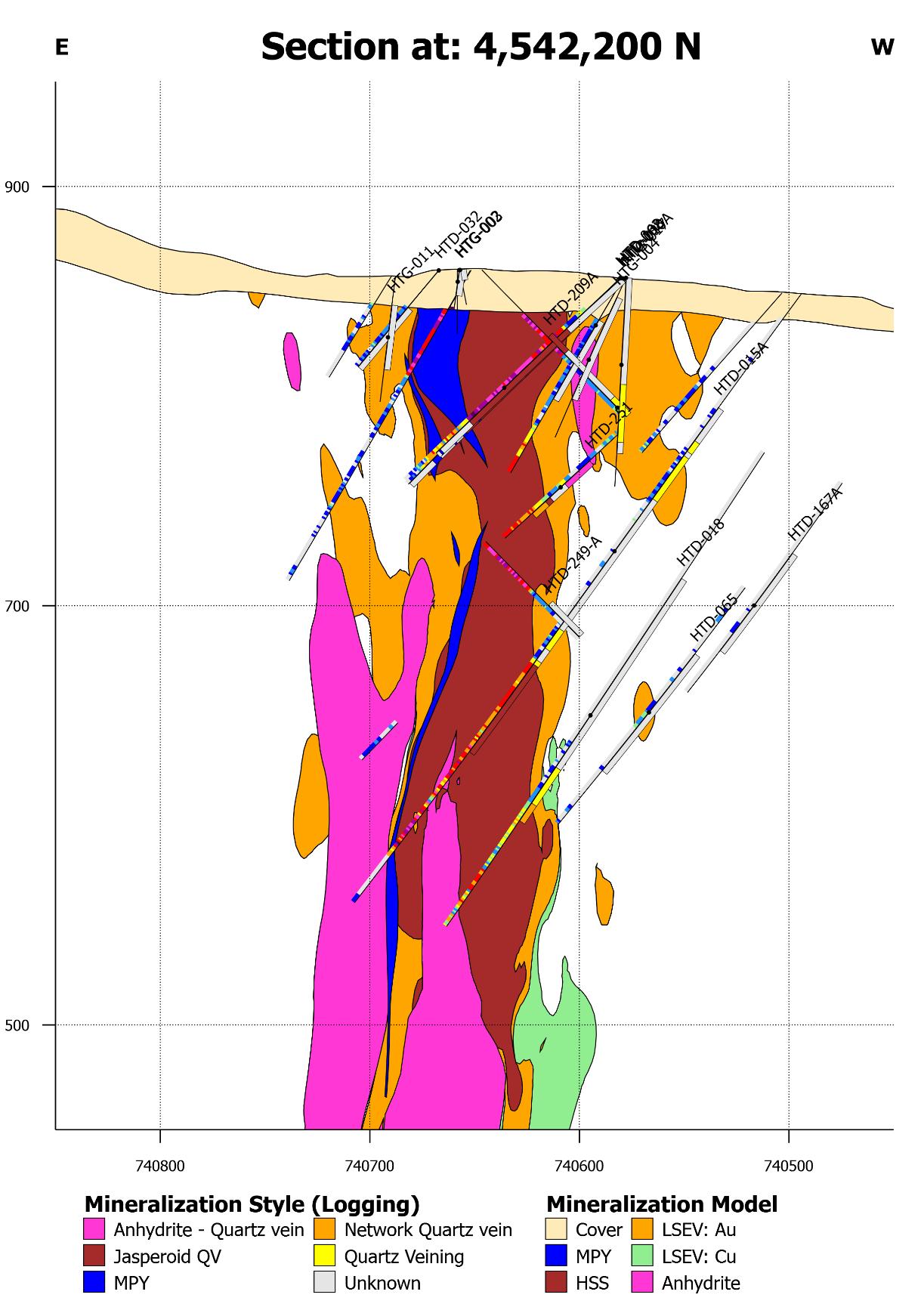

| Figure 11-9: Cross-section of the Mineralization Model |

11-13 |

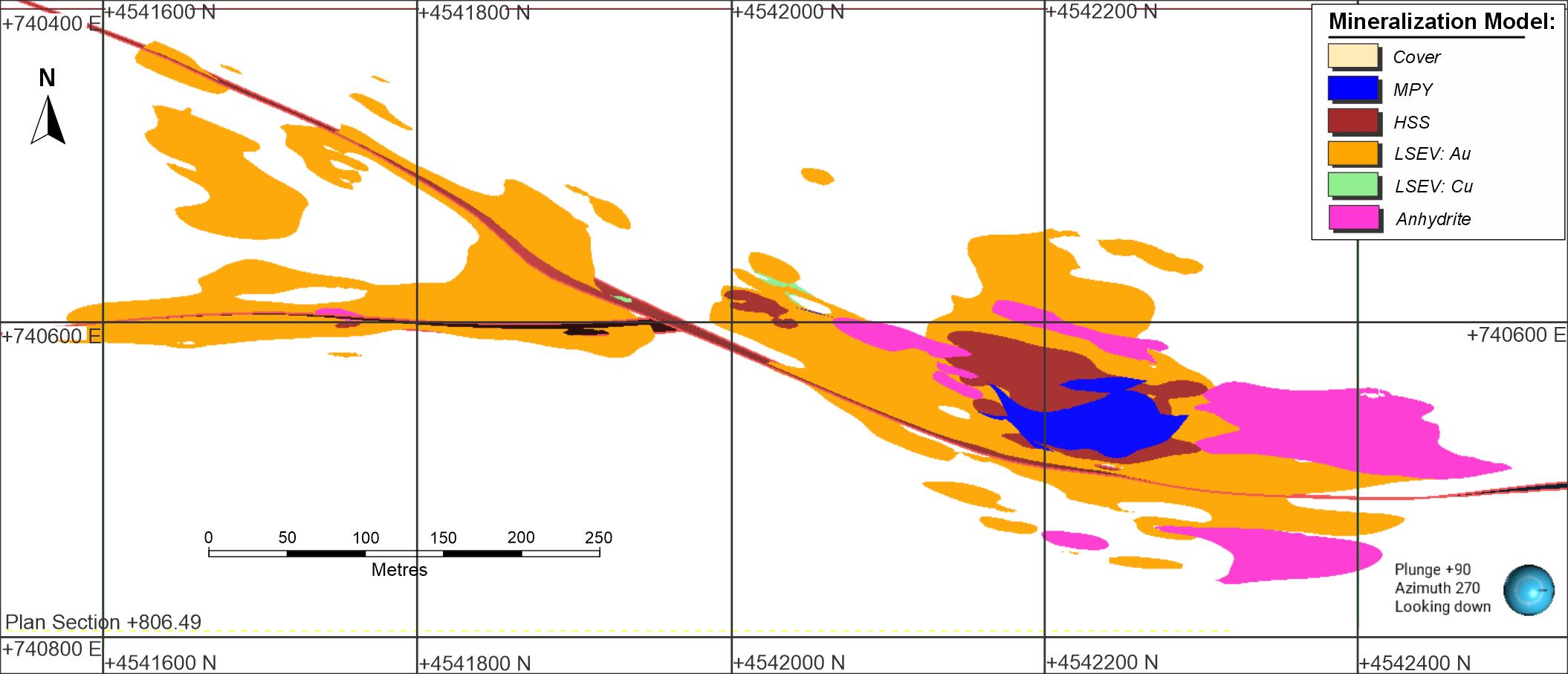

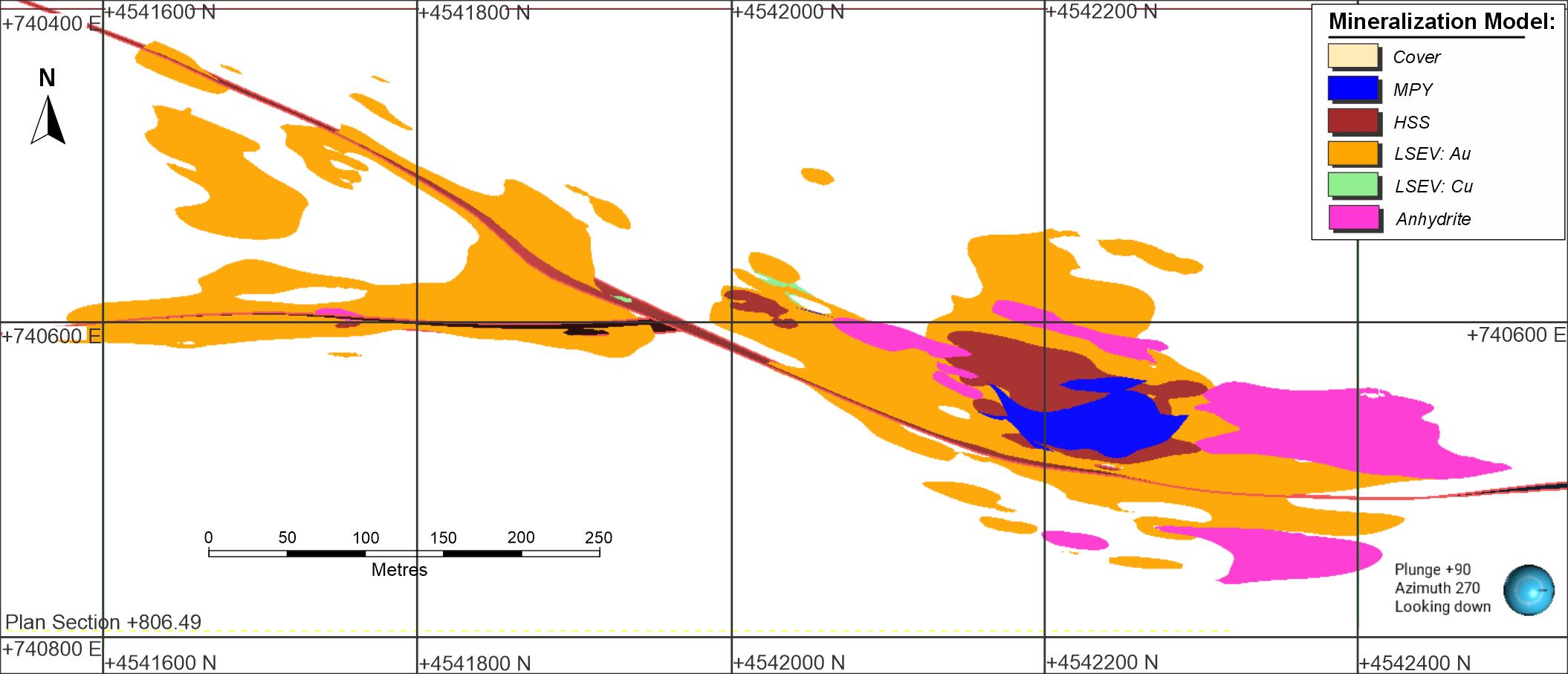

| Figure 11-10: Plan View of the Mineralization Model, illustrating Controlling Trends |

11-14 |

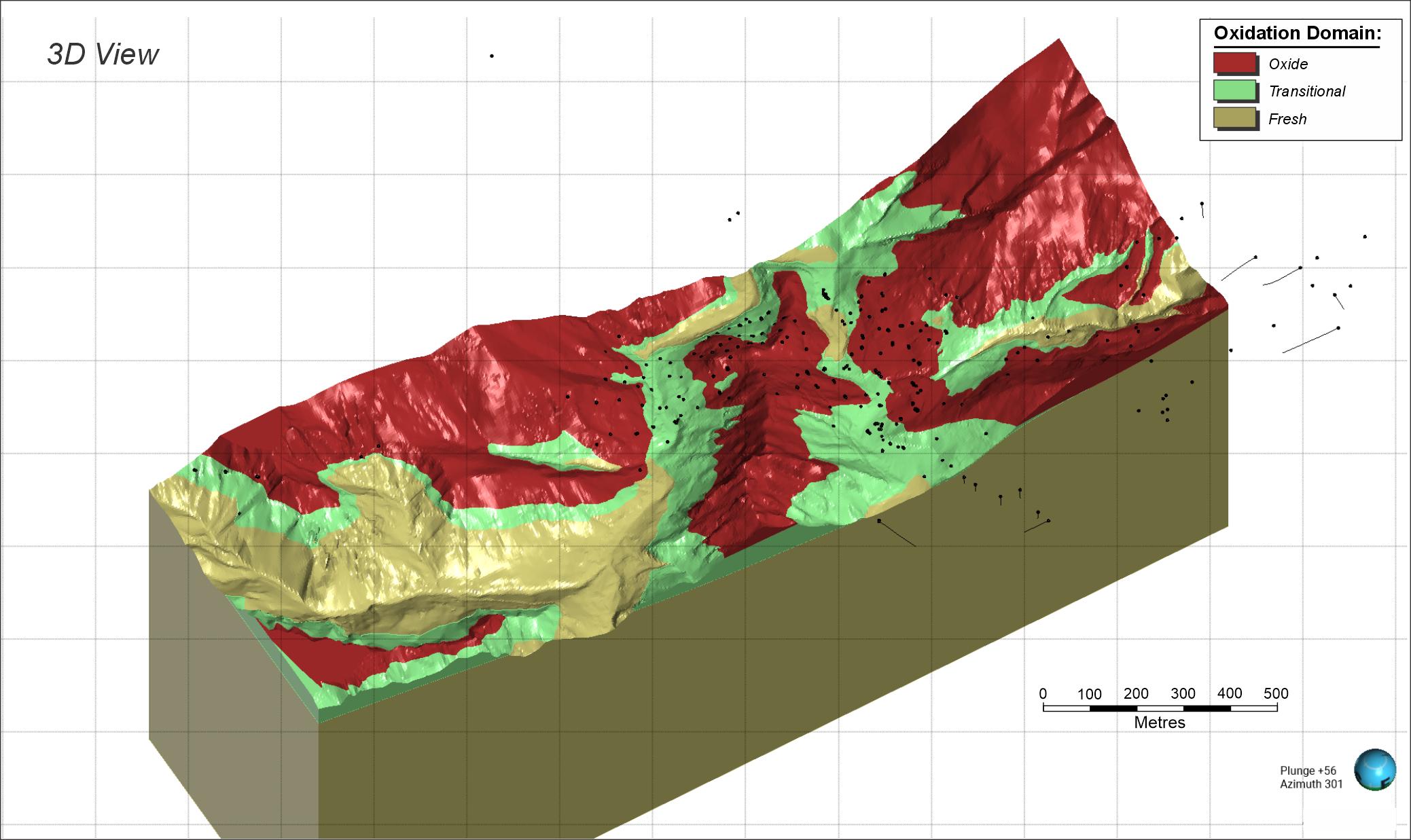

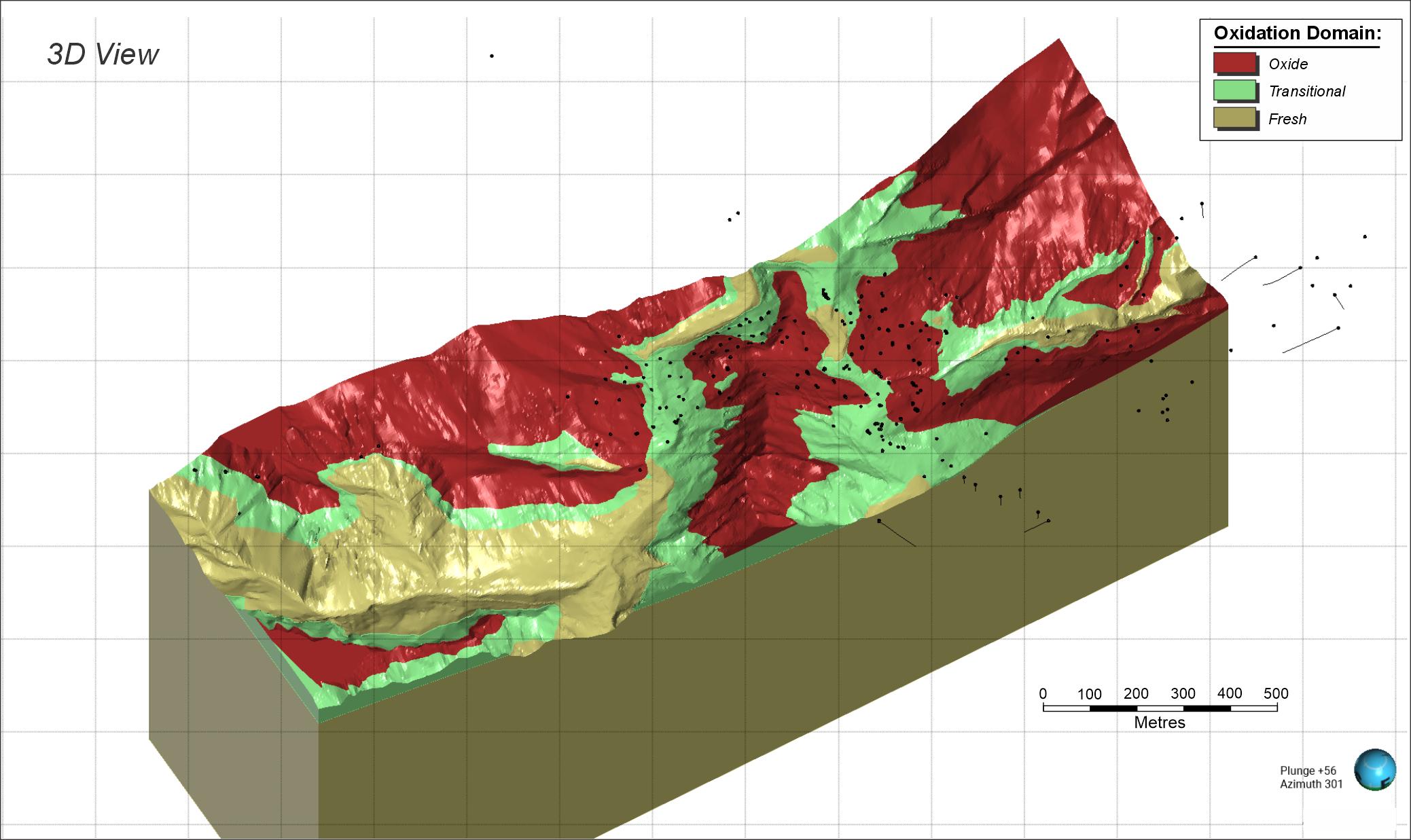

| Figure 11-11: Perspective View of the Oxidation Model |

11-15 |

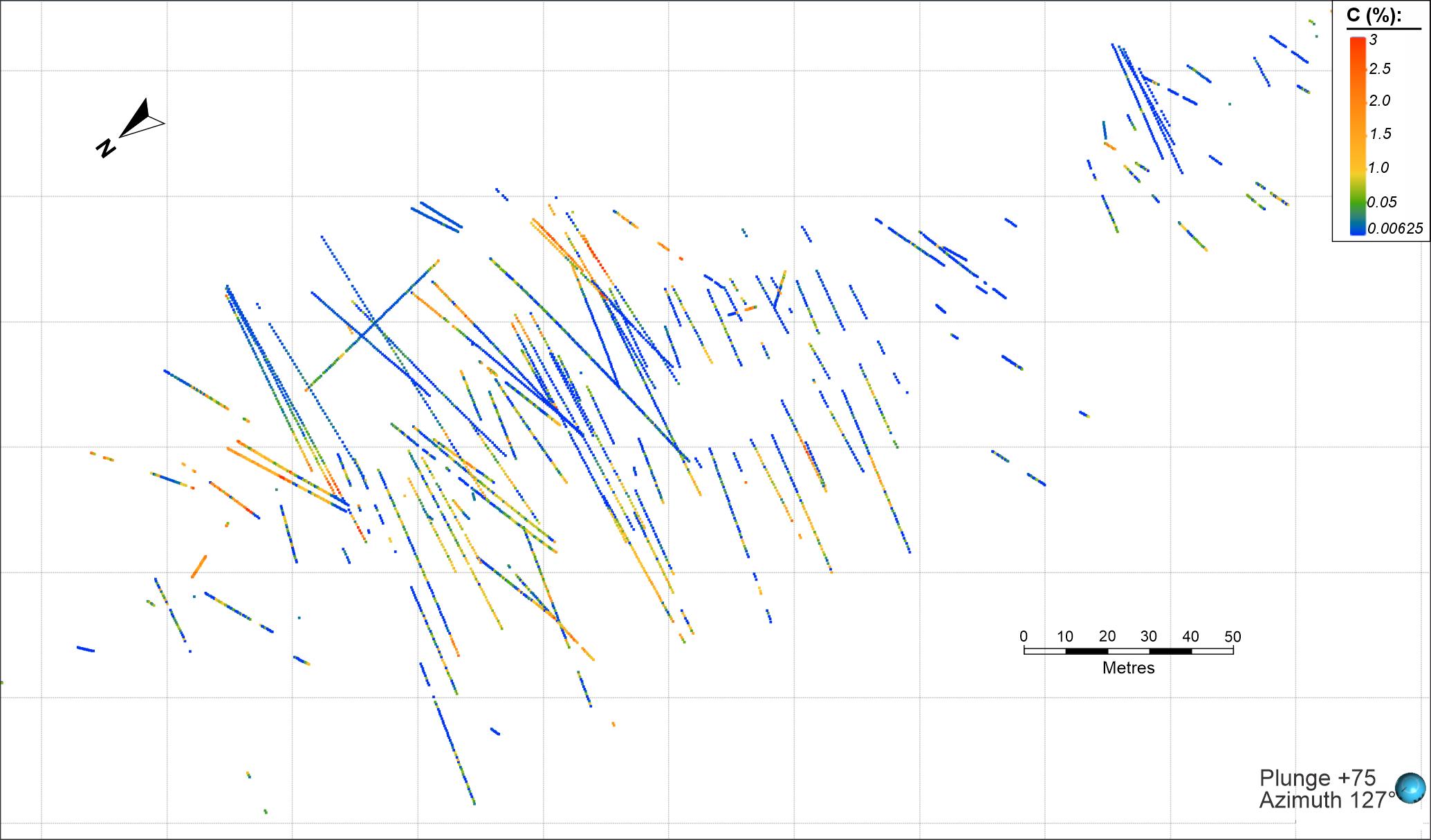

| Figure 11-12: Declustered Composite Statistics for Au in the Mineralized Domains |

11-16 |

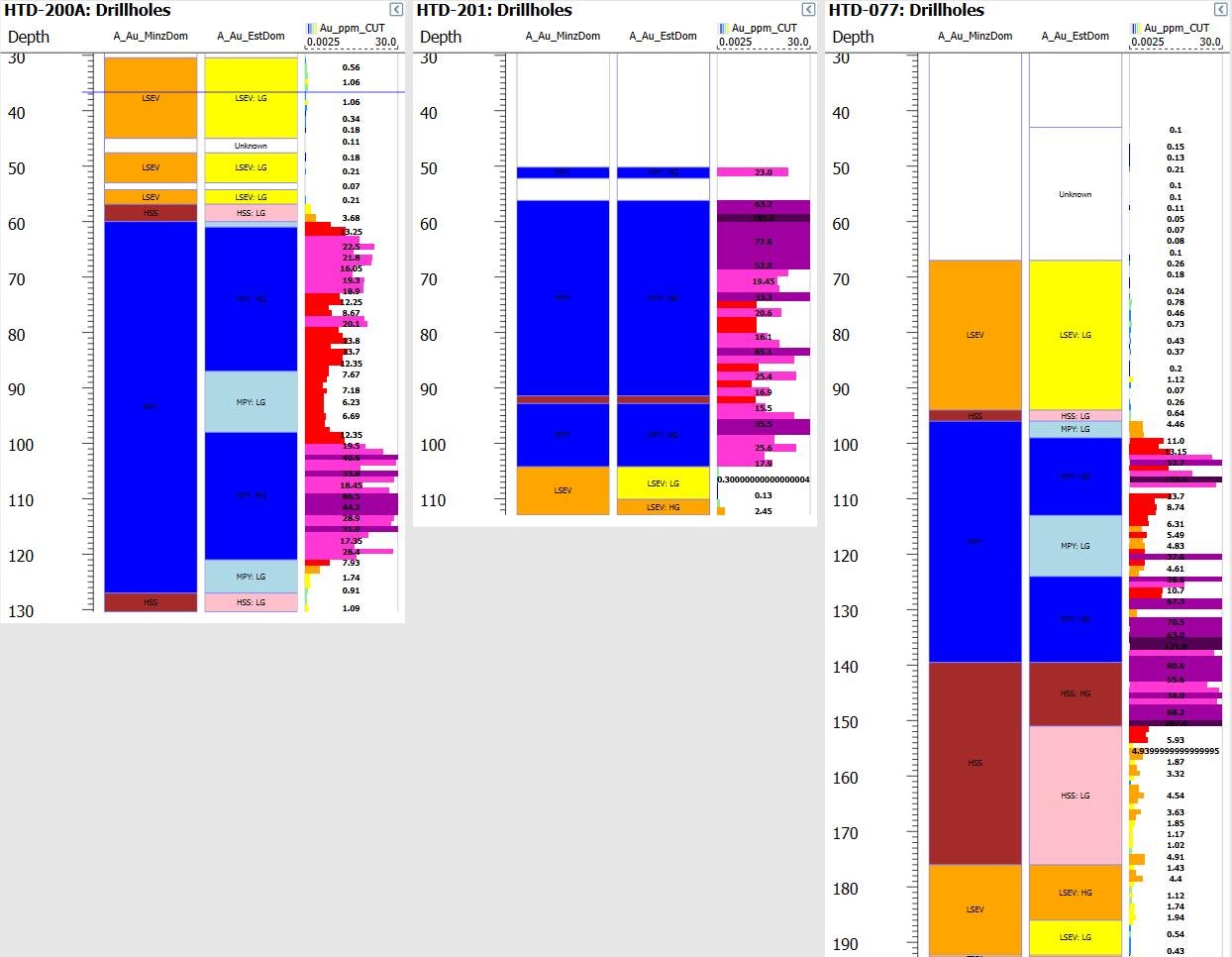

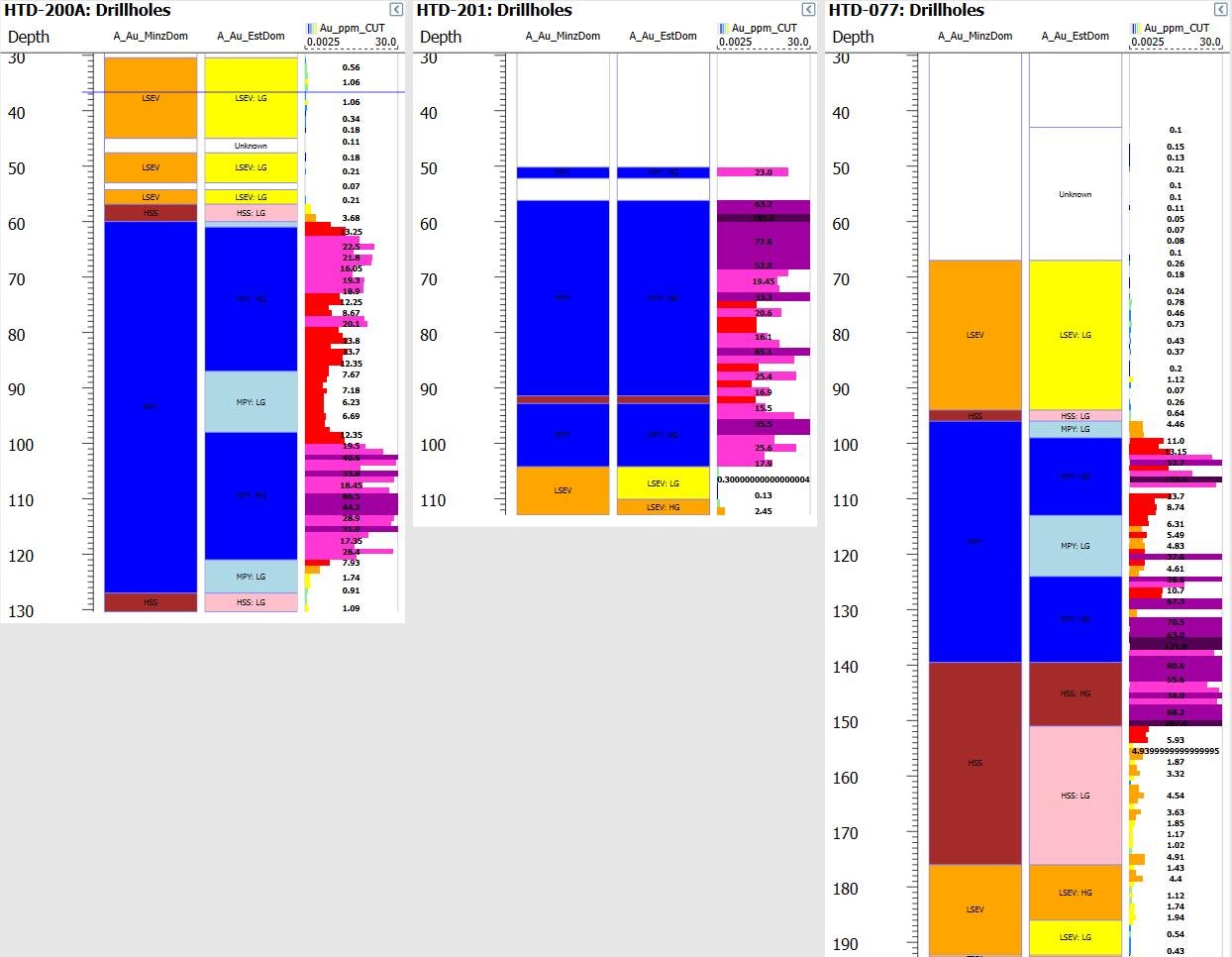

| Figure 11-13: Drill Hole Correlation Supporting the Modeling of a High-Grade Sub-Domain |

11-17 |

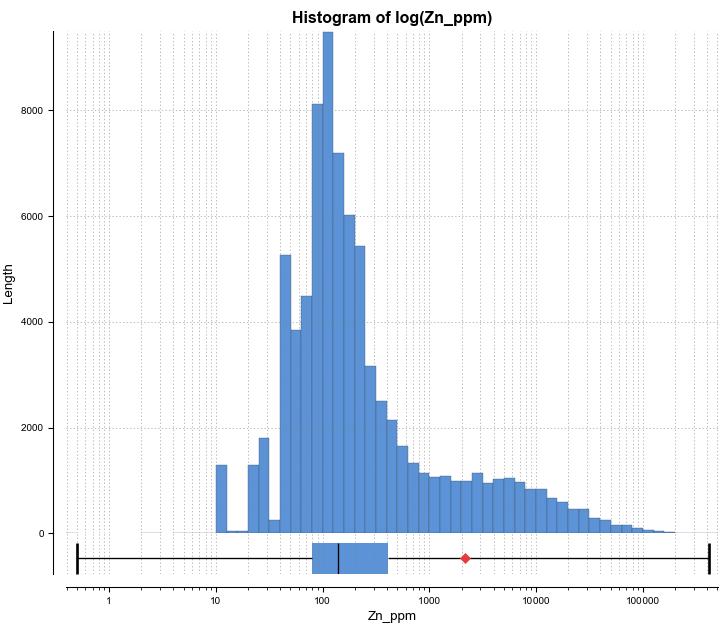

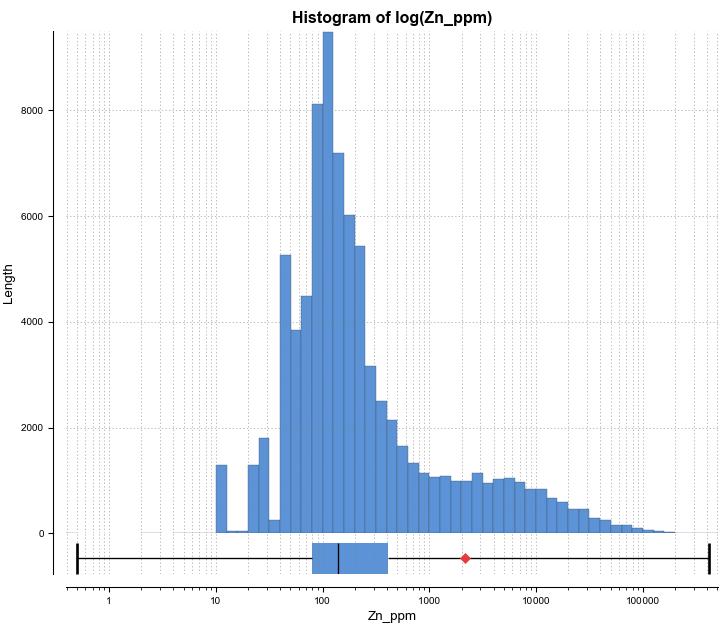

| Figure 11-14: Histogram for Zn |

11-19 |

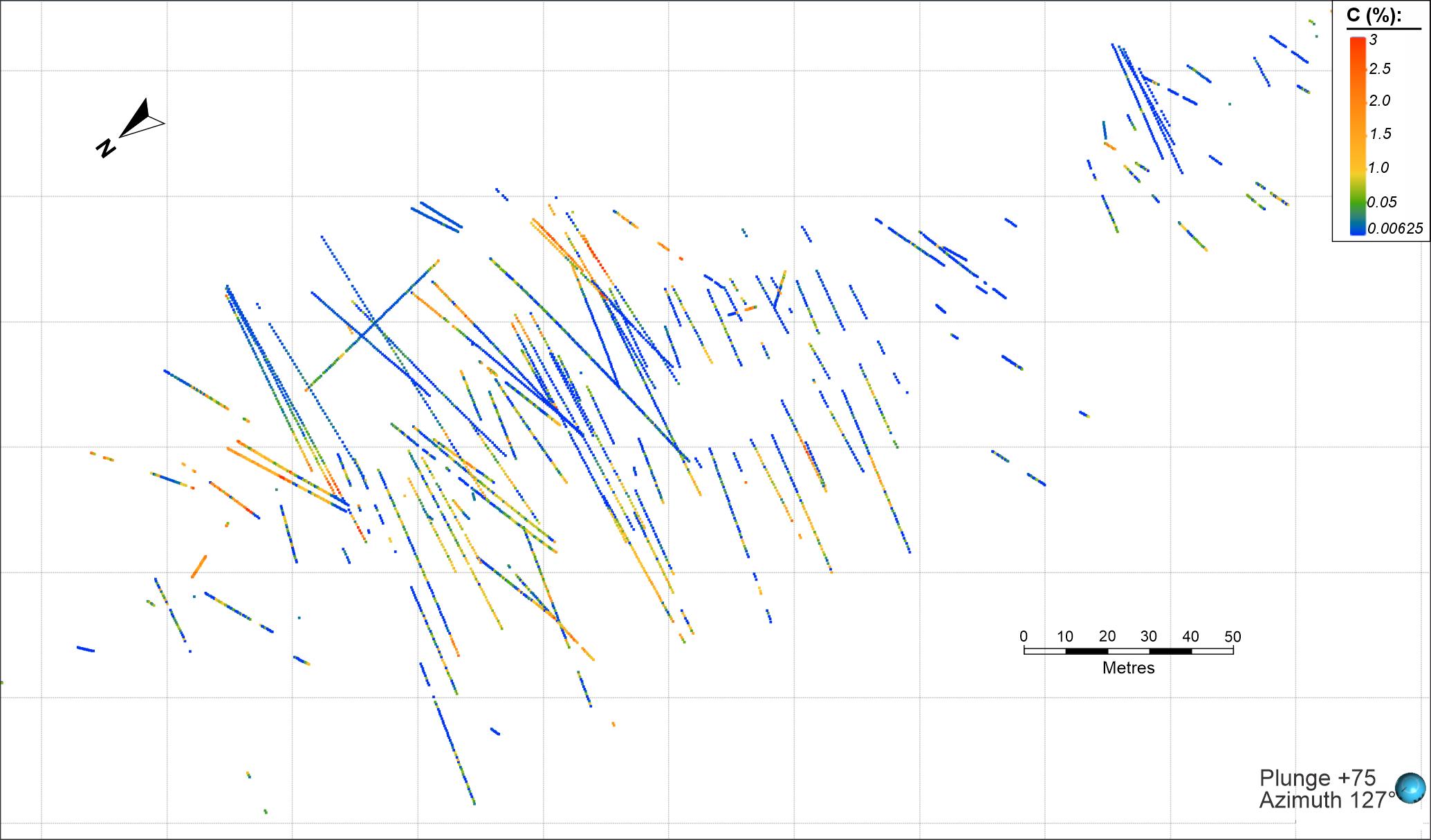

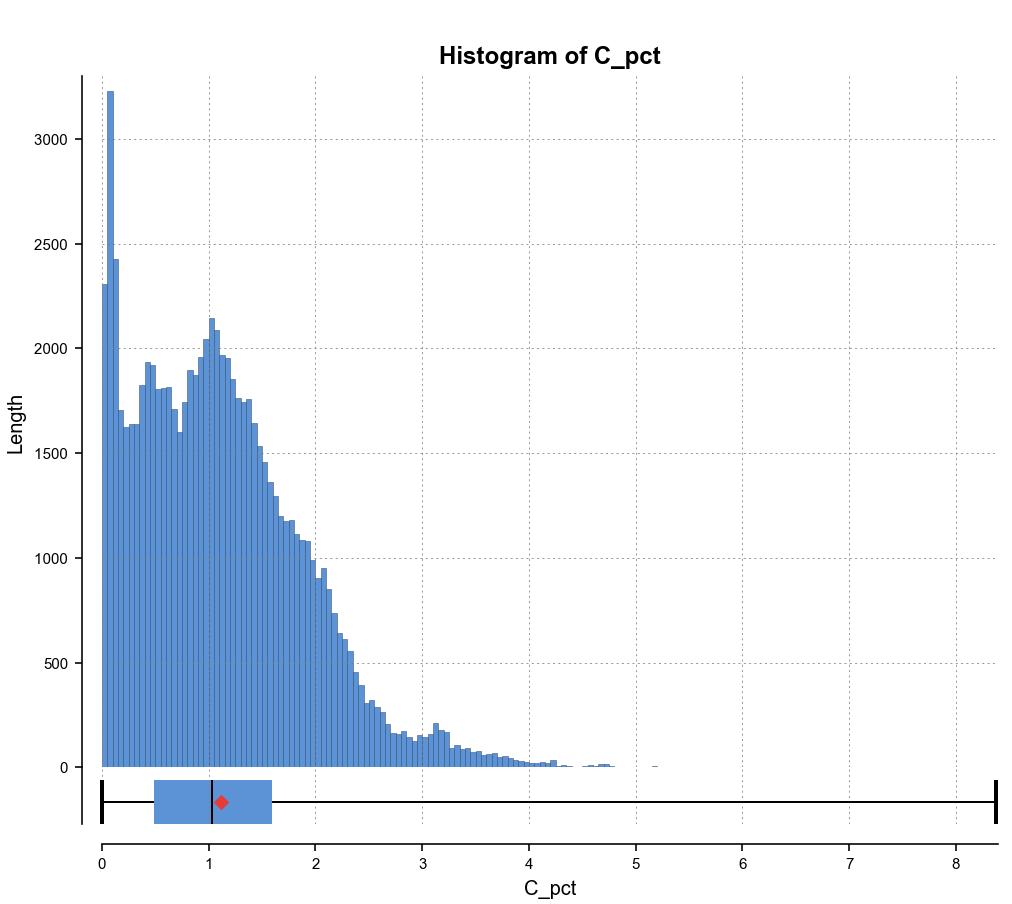

| Figure 11-15: Multimodality for C in MPY and HSS Domains |

11-20 |

| Figure 11-16: Multimodality for C, all data |

11-21 |

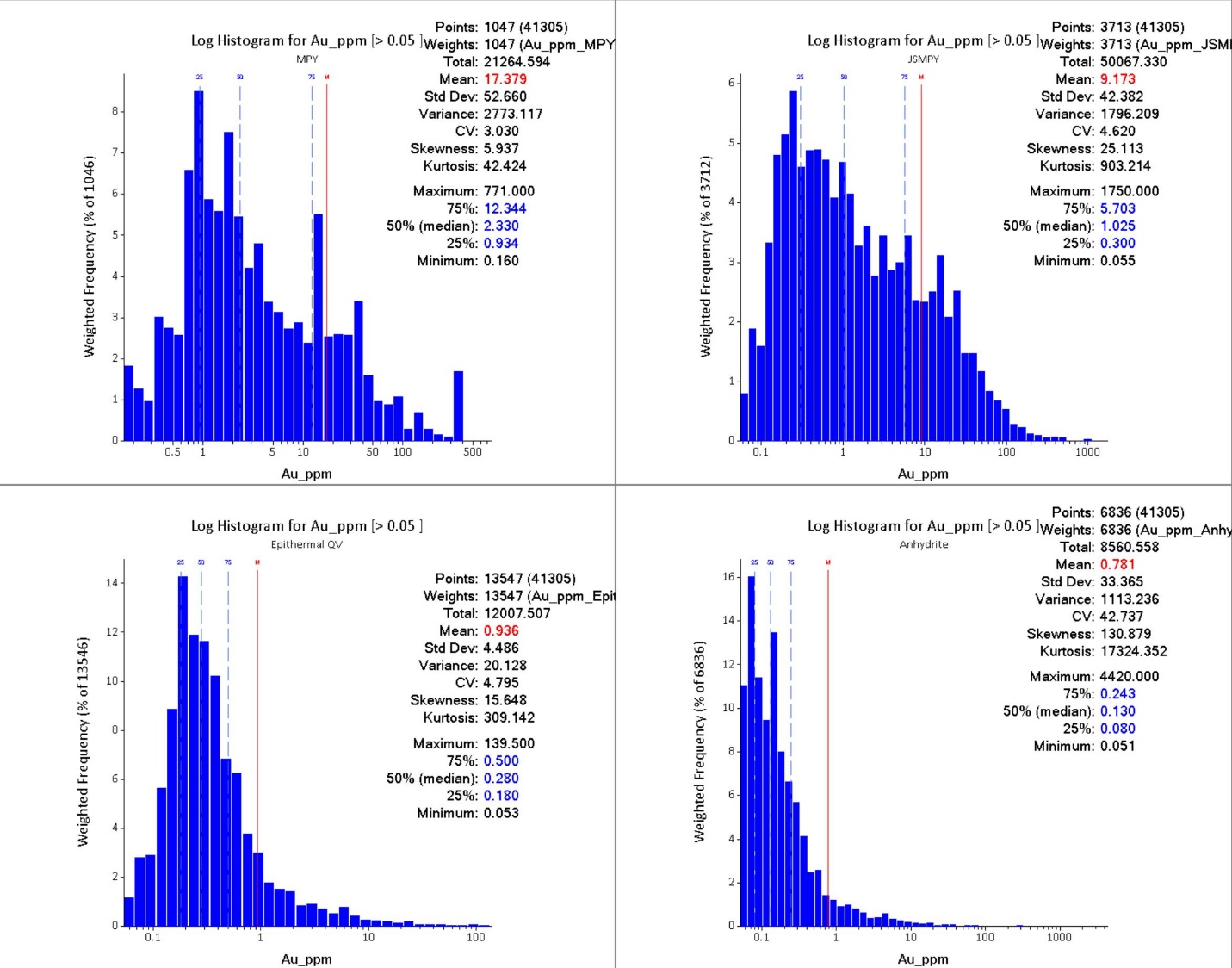

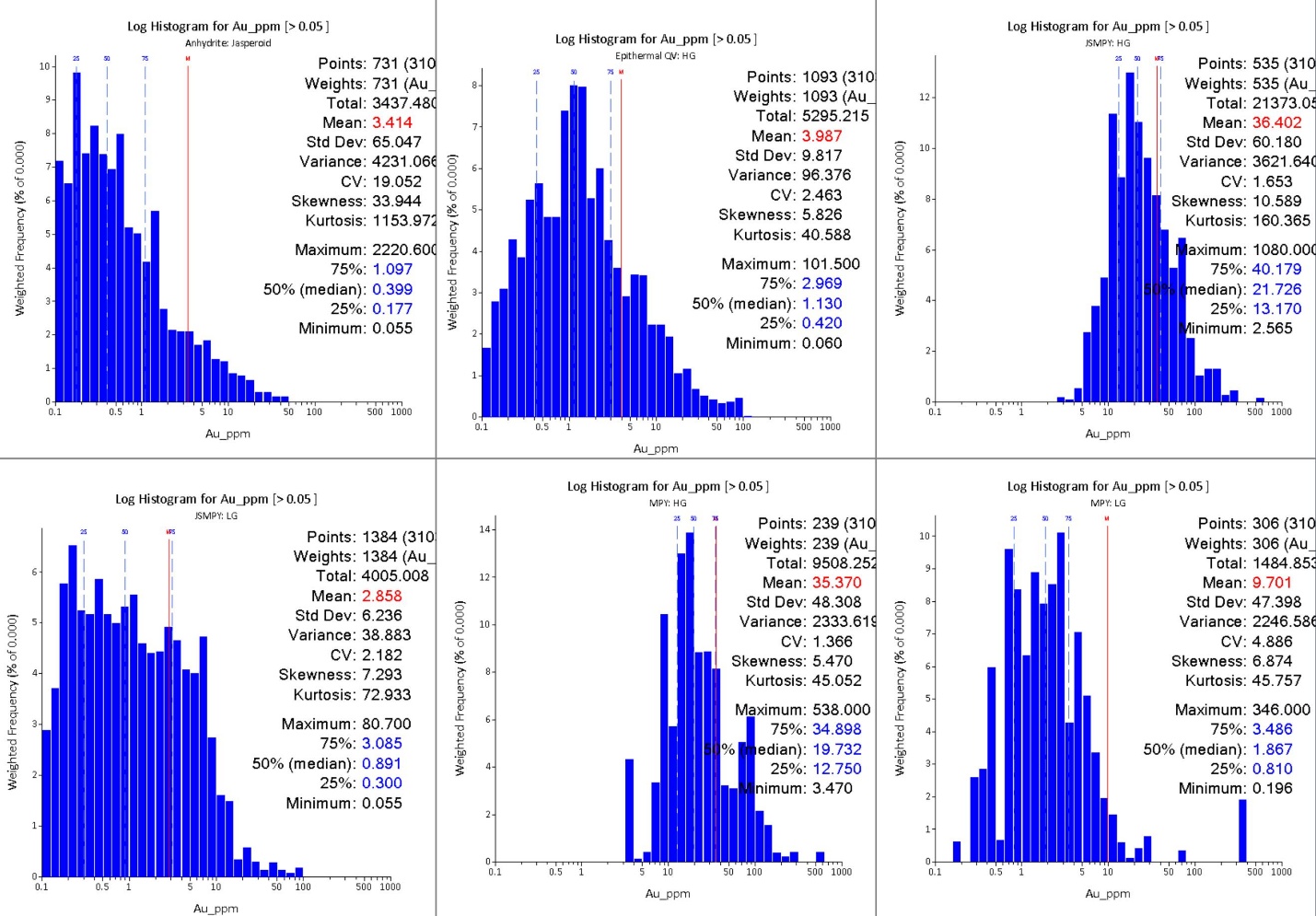

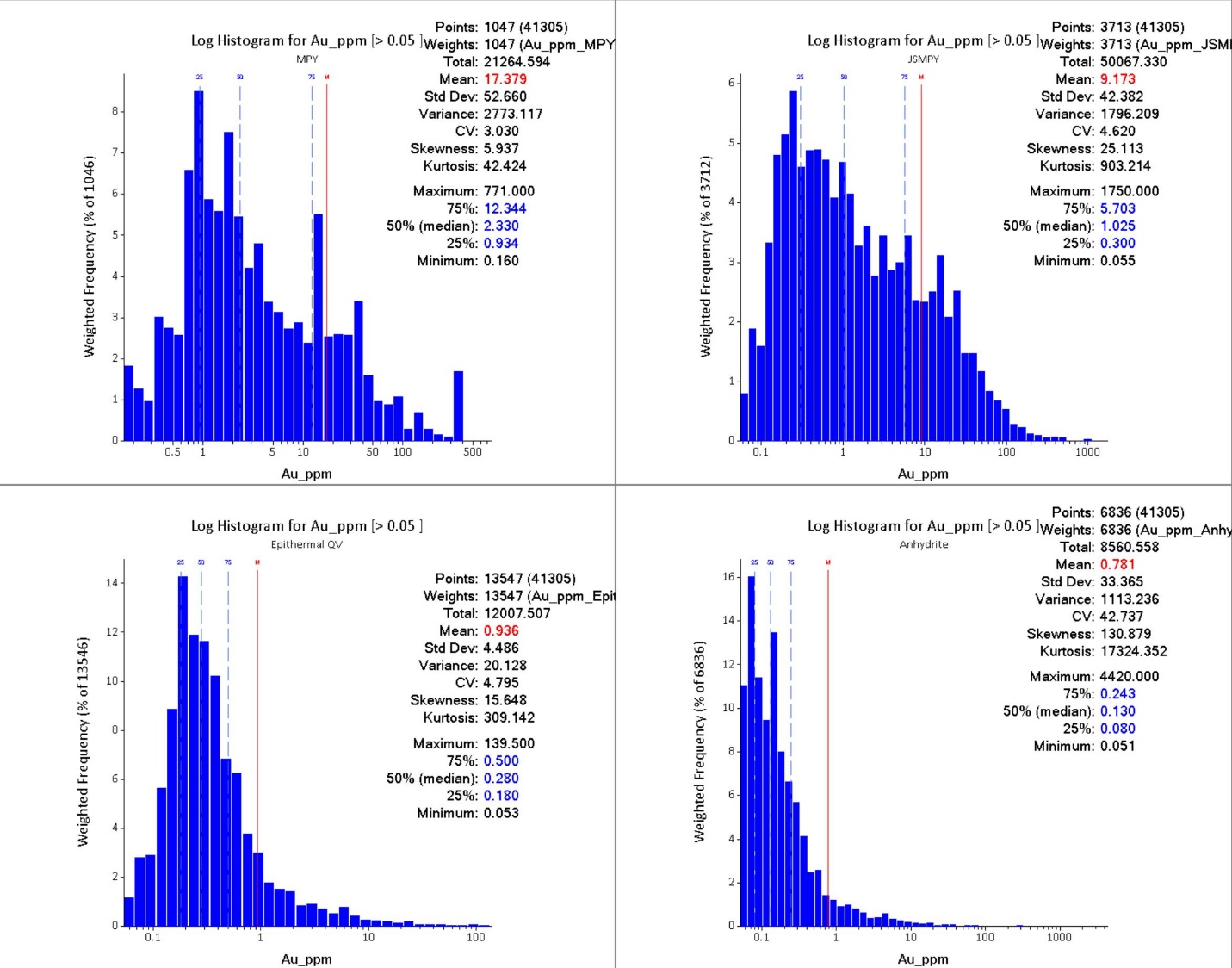

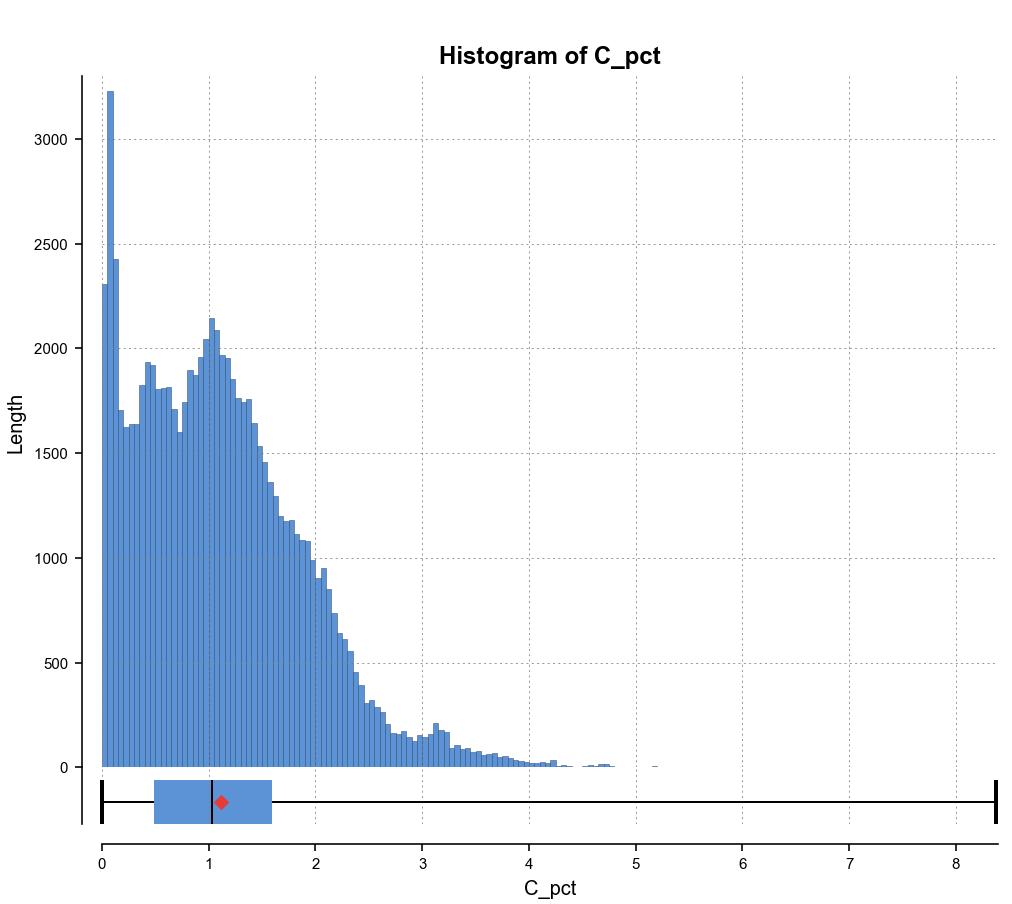

| Figure 11-17: Log-histograms for Au in Key Estimation Domains |

11-23 |

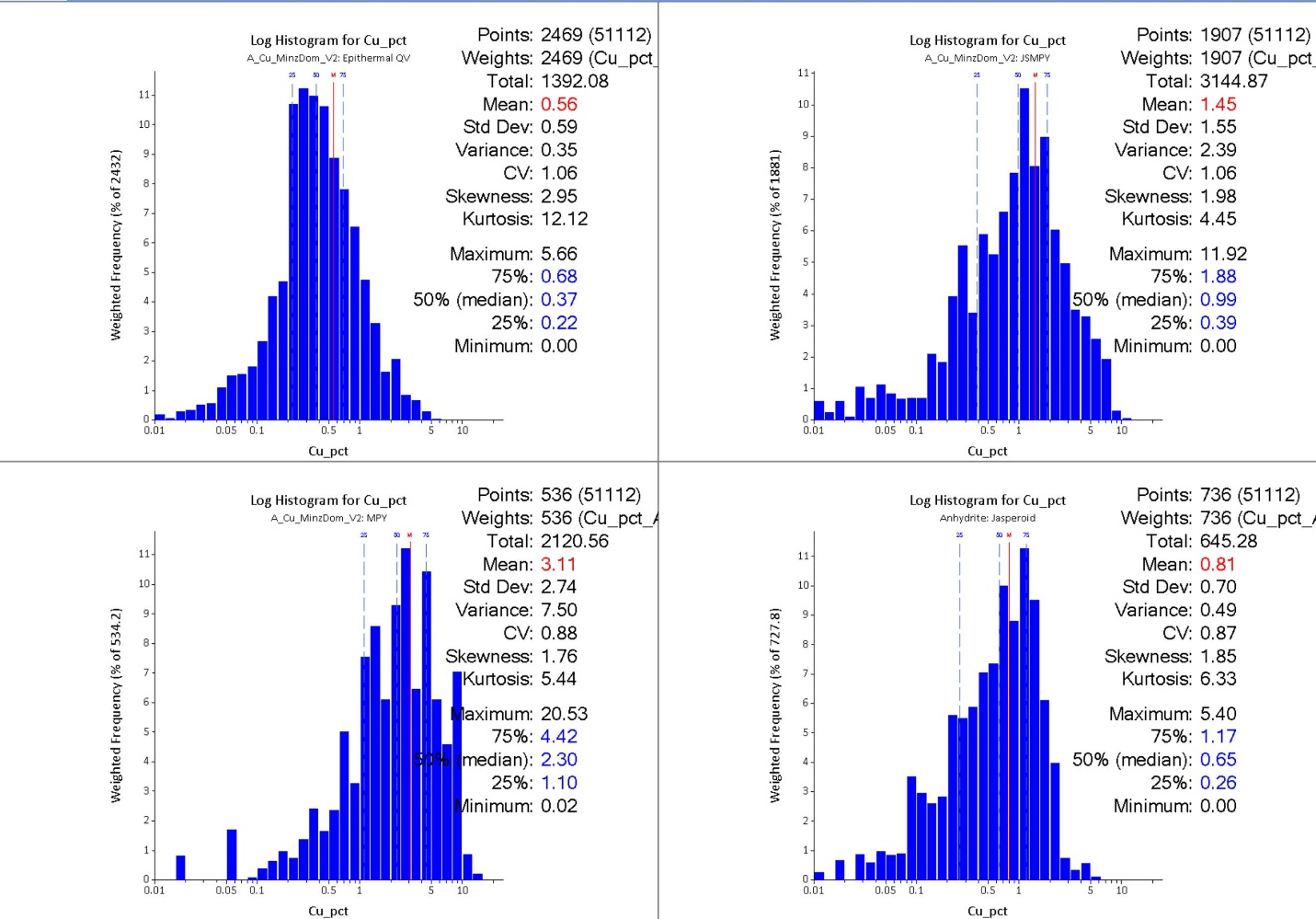

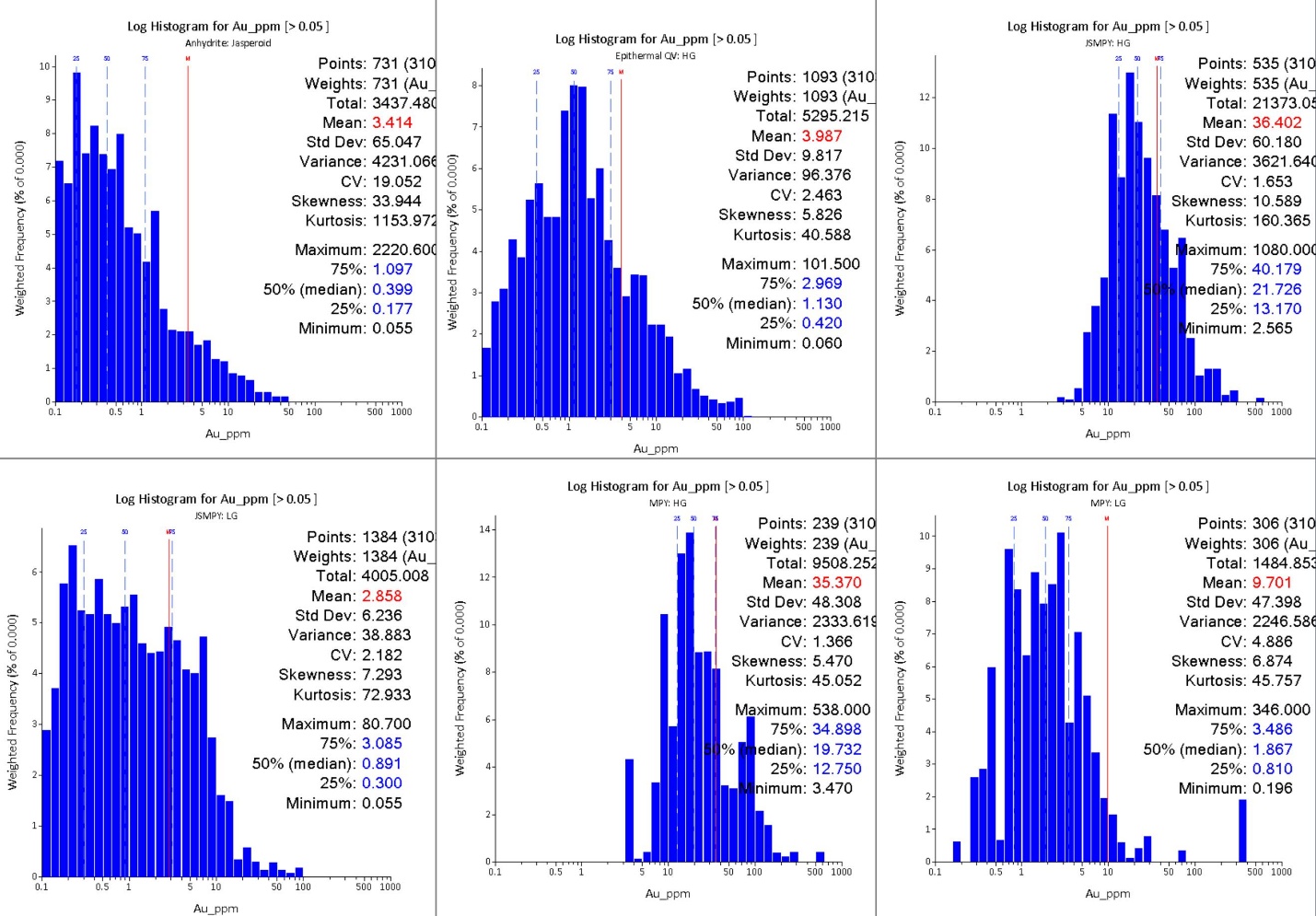

| Figure 11-18: Log-histograms for Cu in the Key Estimation Domains |

11-24 |

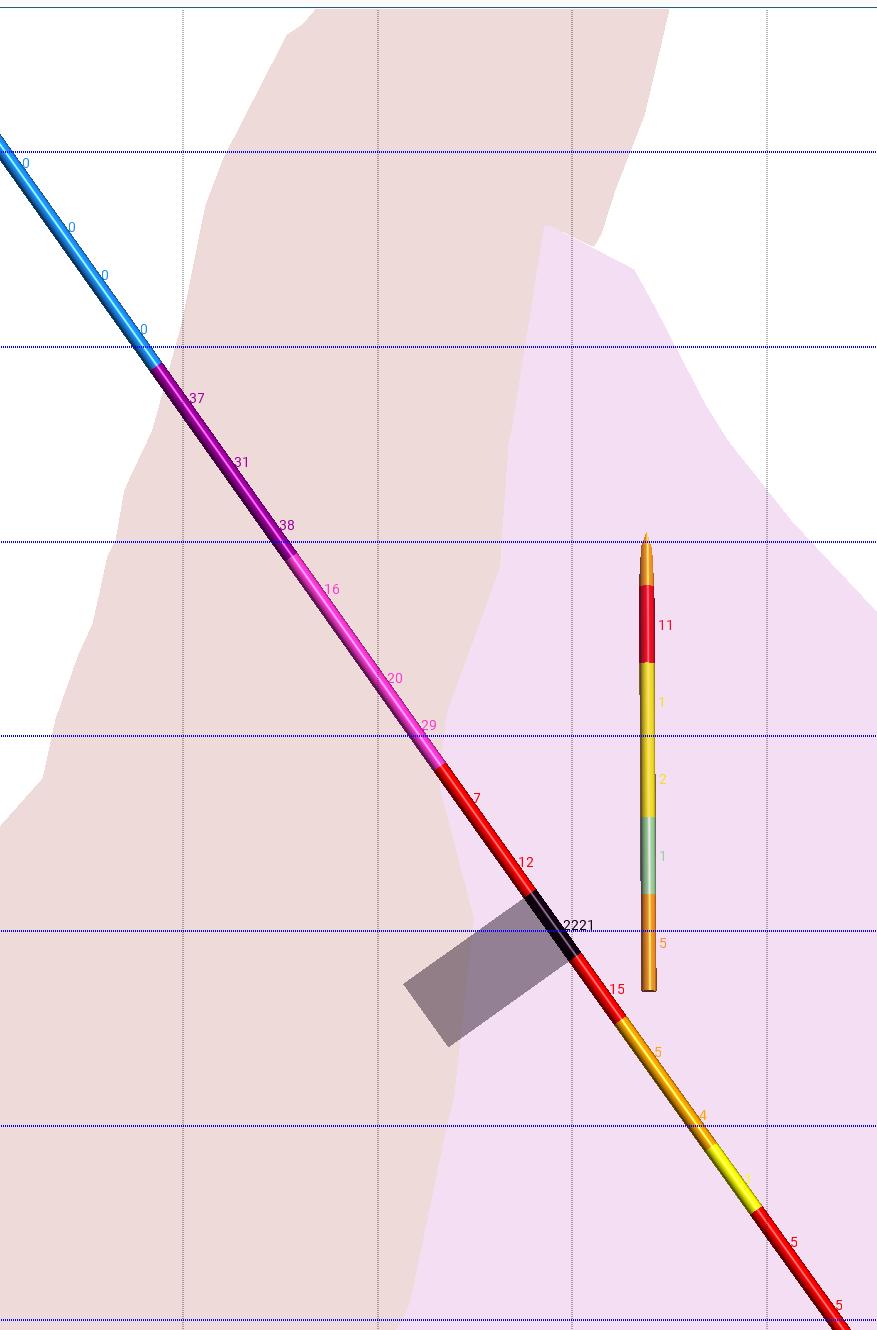

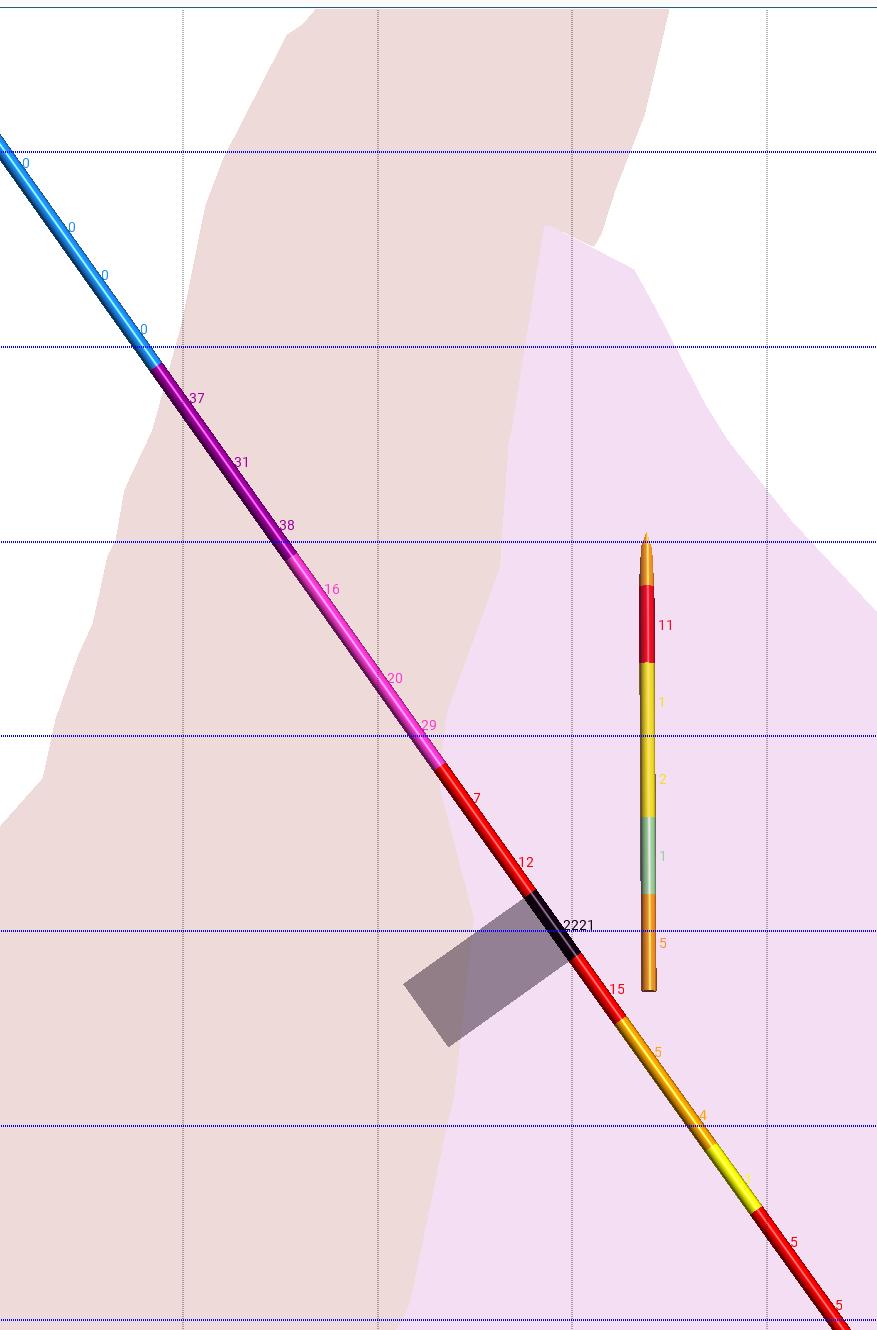

| Figure 11-19: HTD-085 - Highest Grade (grams per tonne) Au Composite Occurring in the Anhydrite:HSS Sub-Domain |

11-26 |

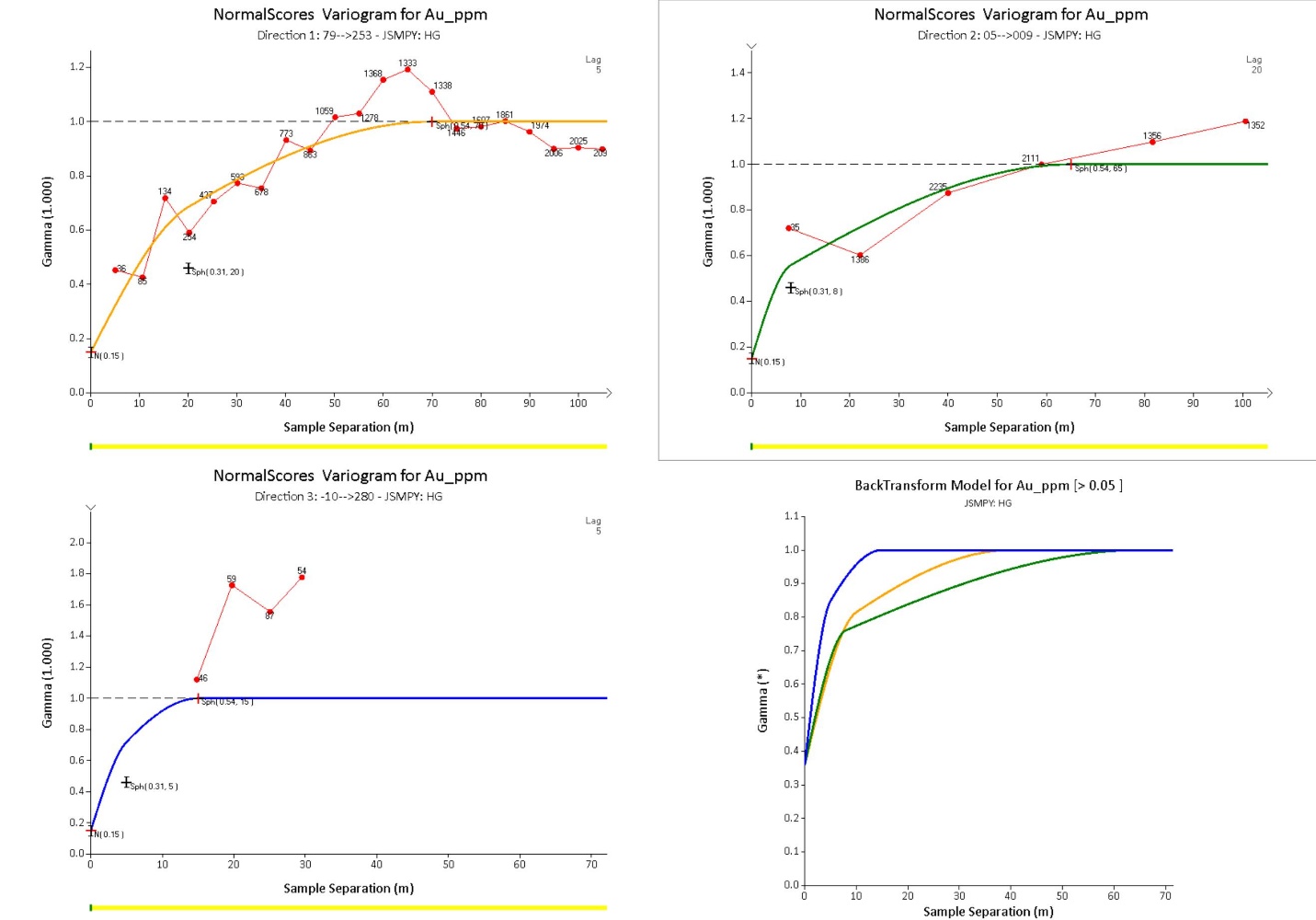

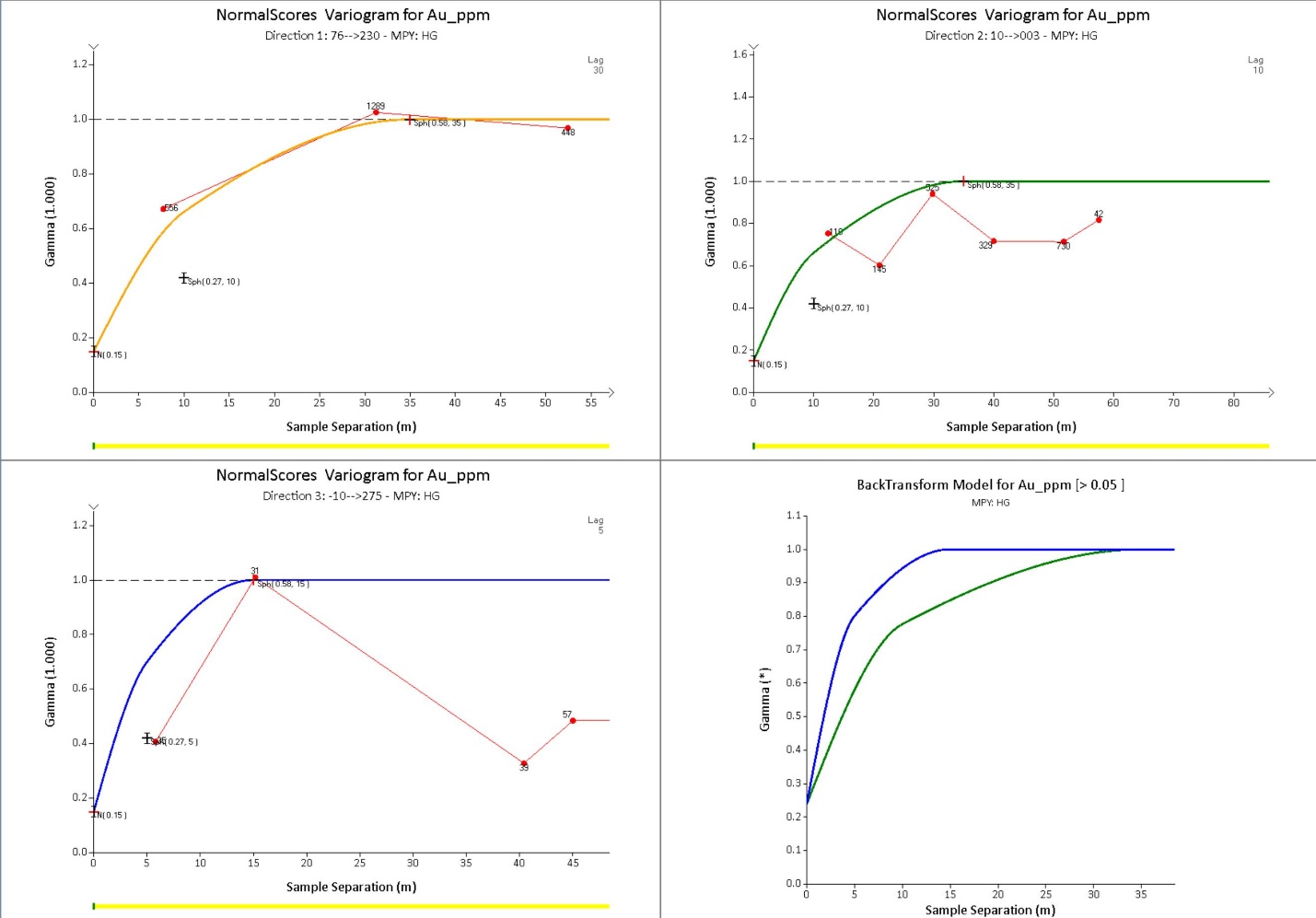

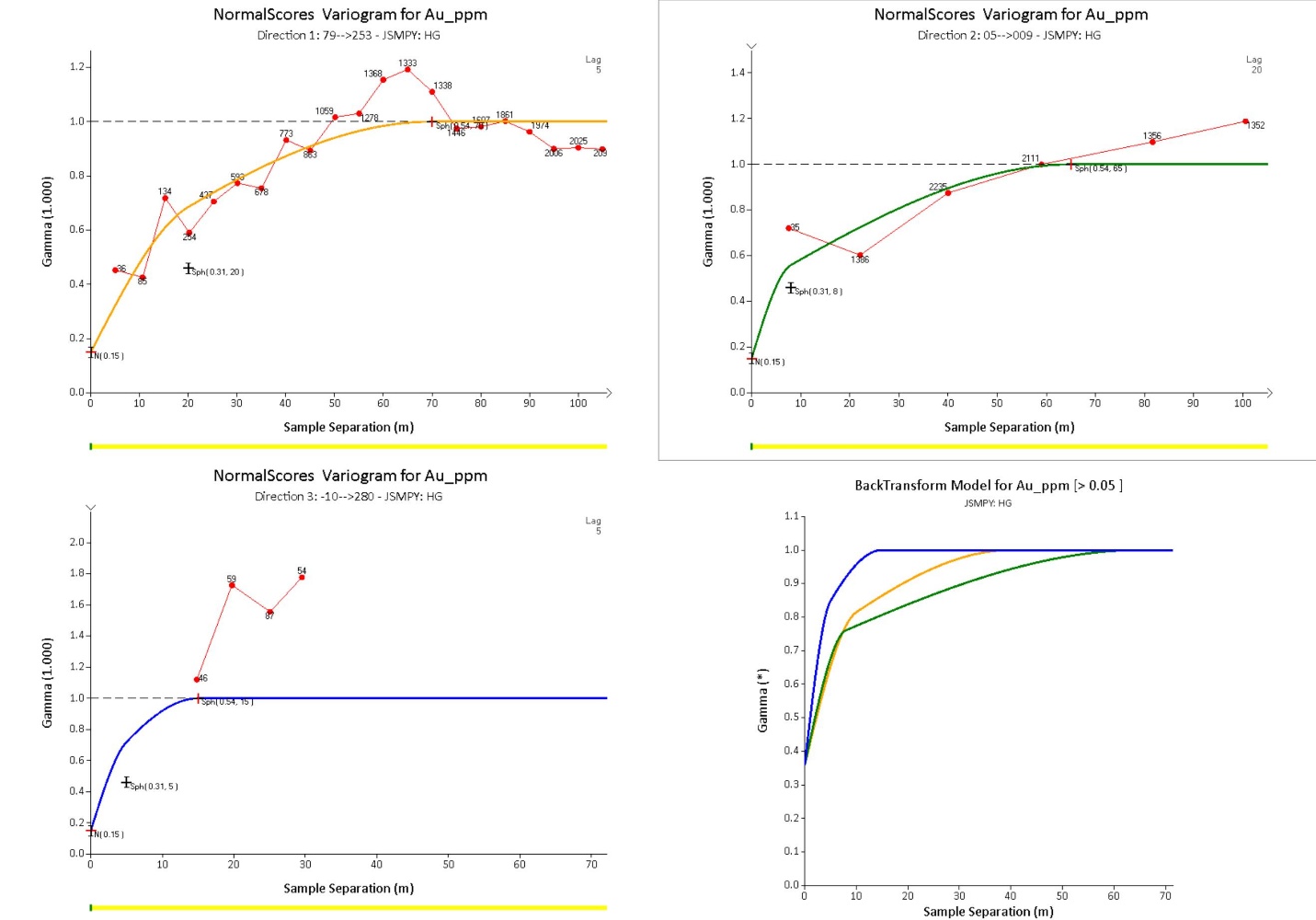

| Figure 11-20: Experimental and Modeled Variograms for Au in the HSS:HG Domain |

11-27 |

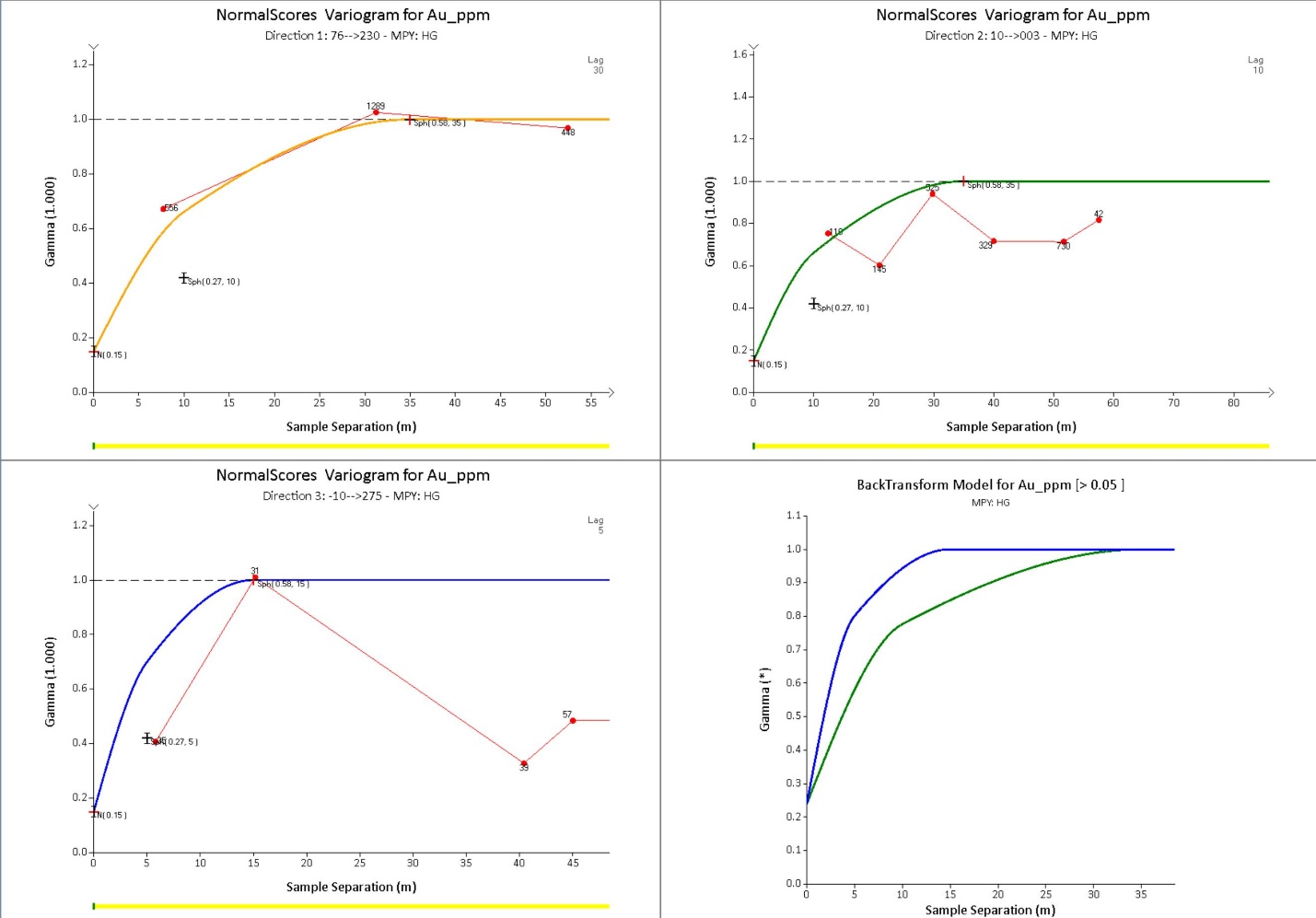

| Figure 11-21: Experimental and Modeled Variograms for Au in the MPY:HG Domain |

11-28 |

| Figure 11-22: Variogram Models for the High-Grade MPY and HSS Domains |

11-29 |

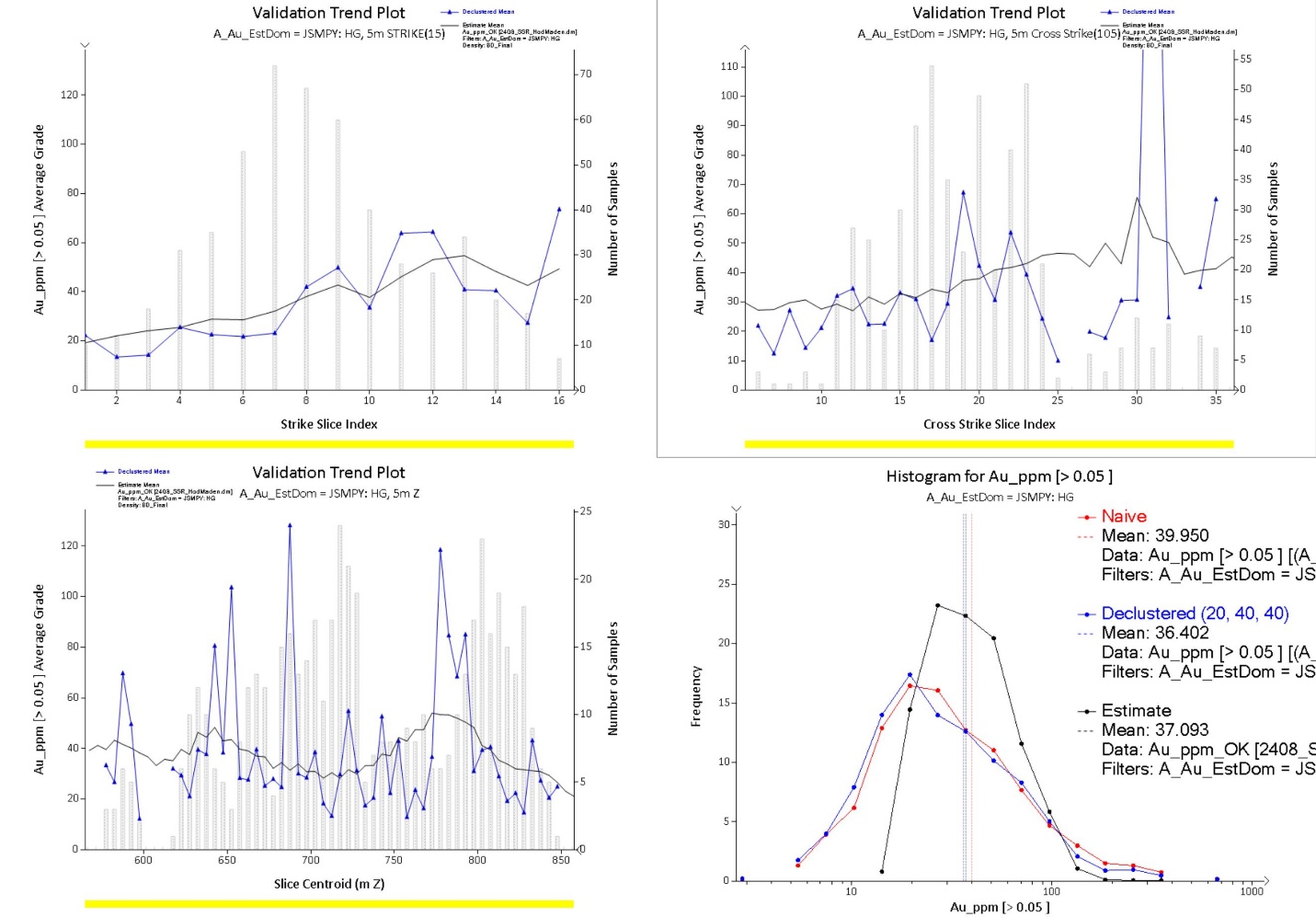

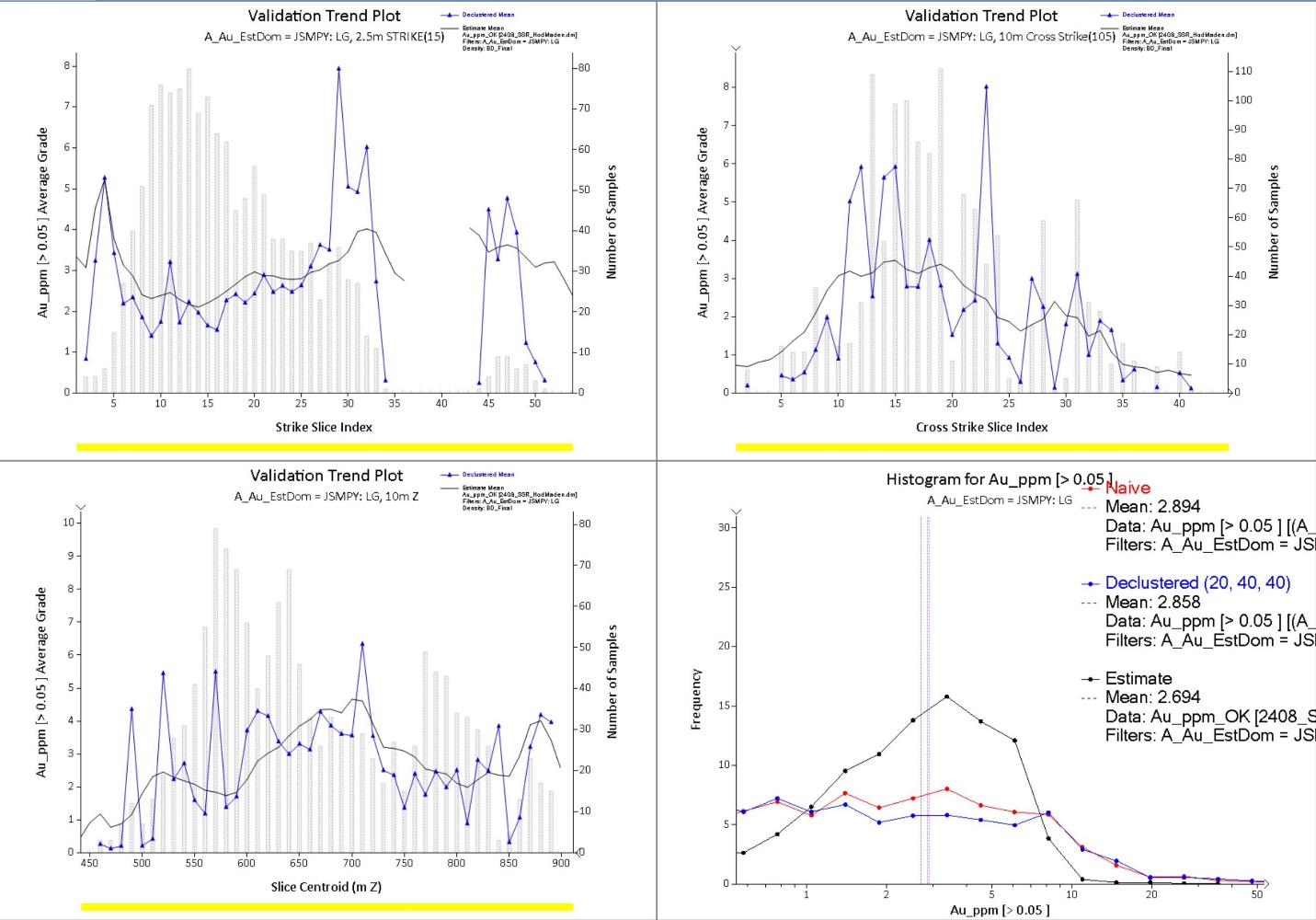

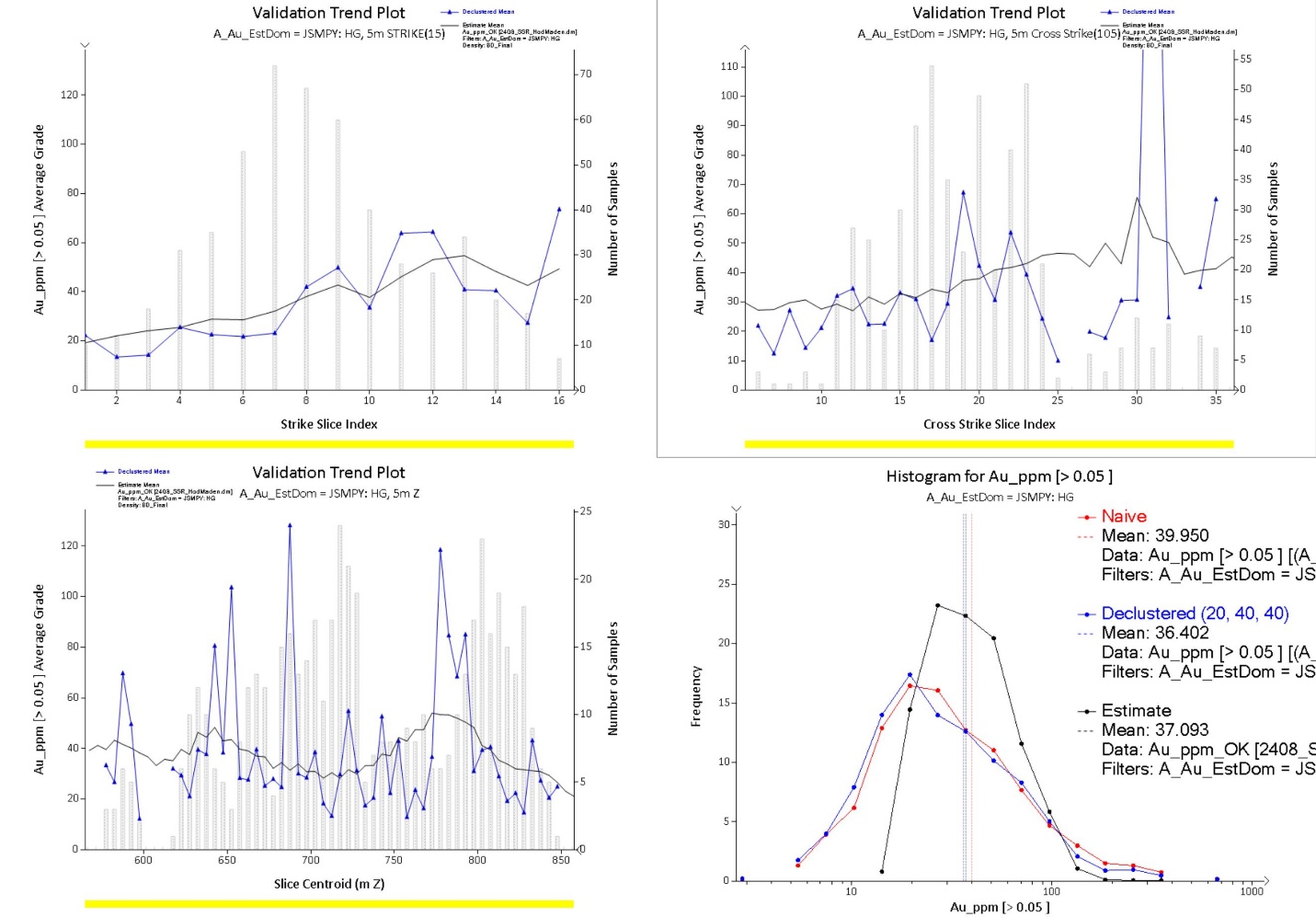

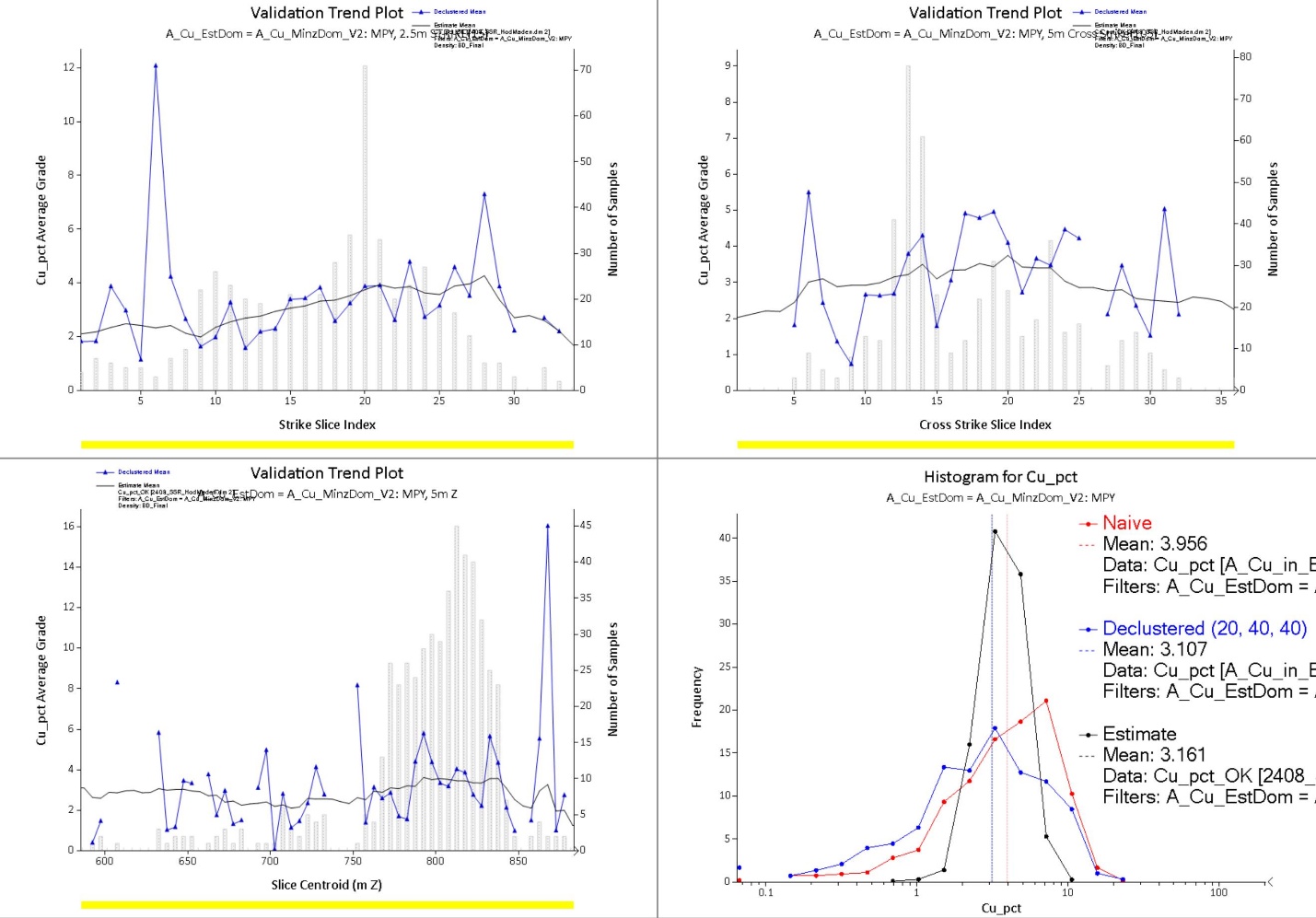

| Figure 11-23: Swath Plots and Log-Histogram for Au, Comparing Input Data and Block Grades in the HSS:HG Domain |

11-34 |

| | xii |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

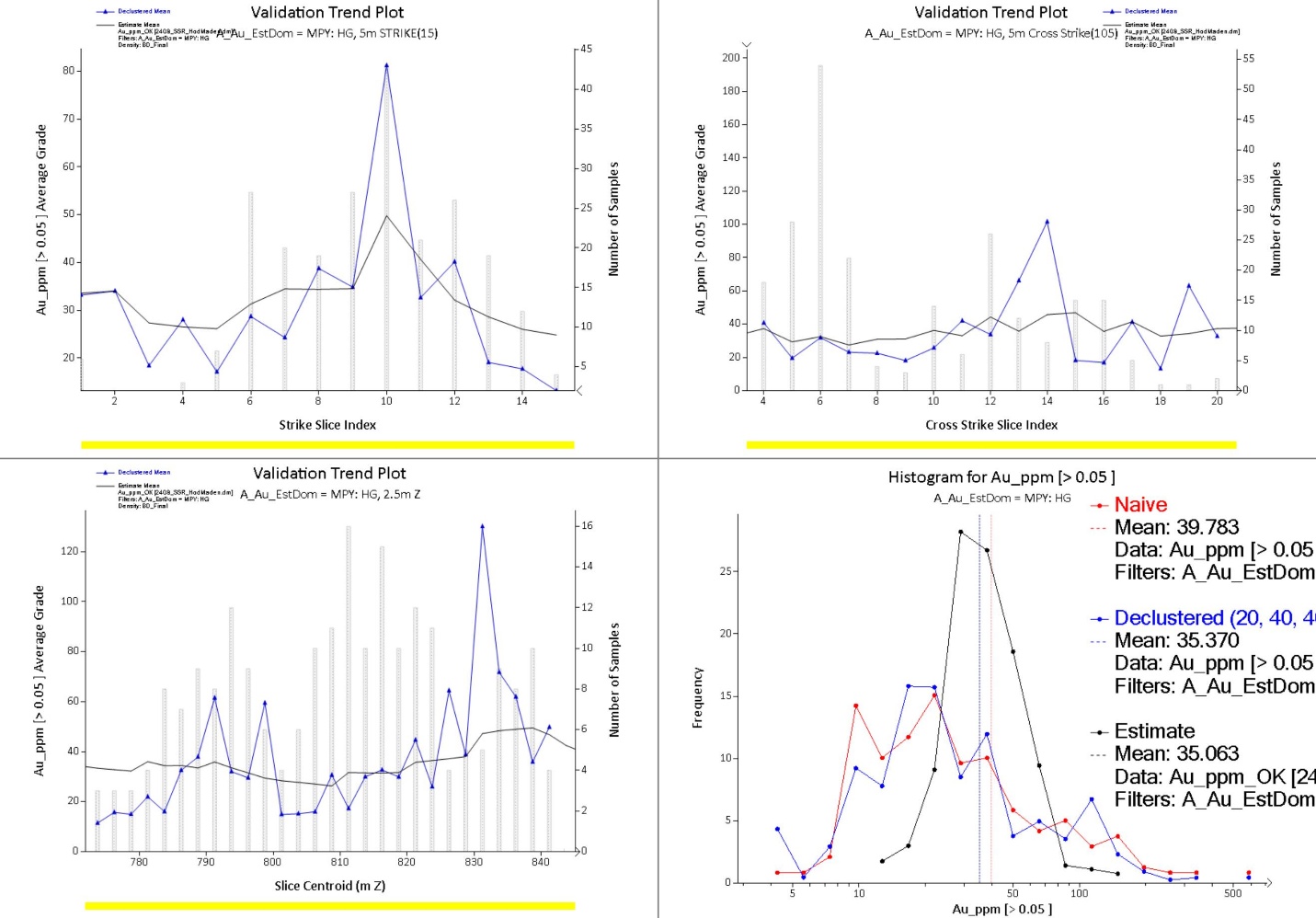

| Figure 11-24: Swath Plots and Log-Histogram for Au, Comparing Input Data and Block Grades in the MPY:HG Domain |

11-35 |

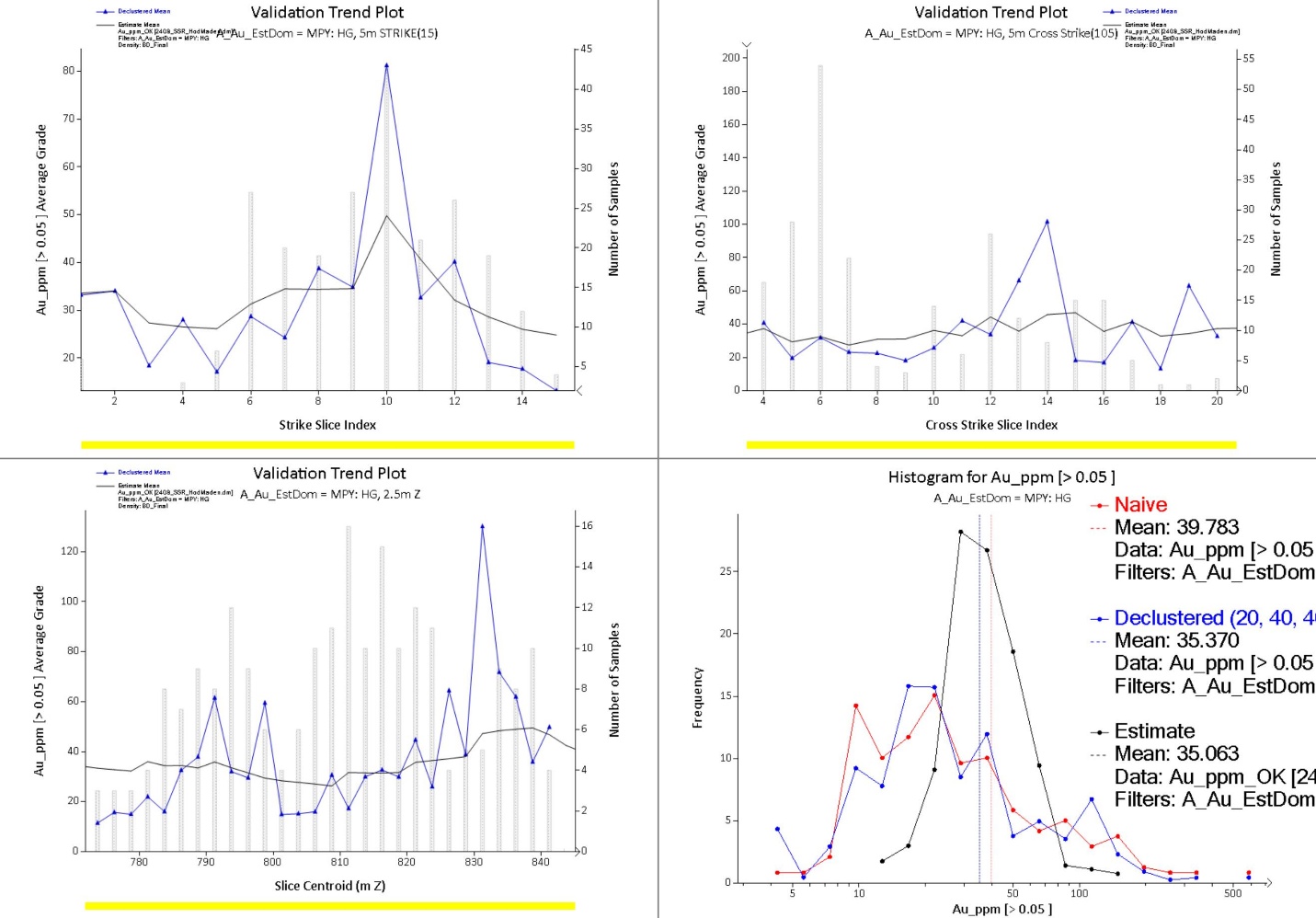

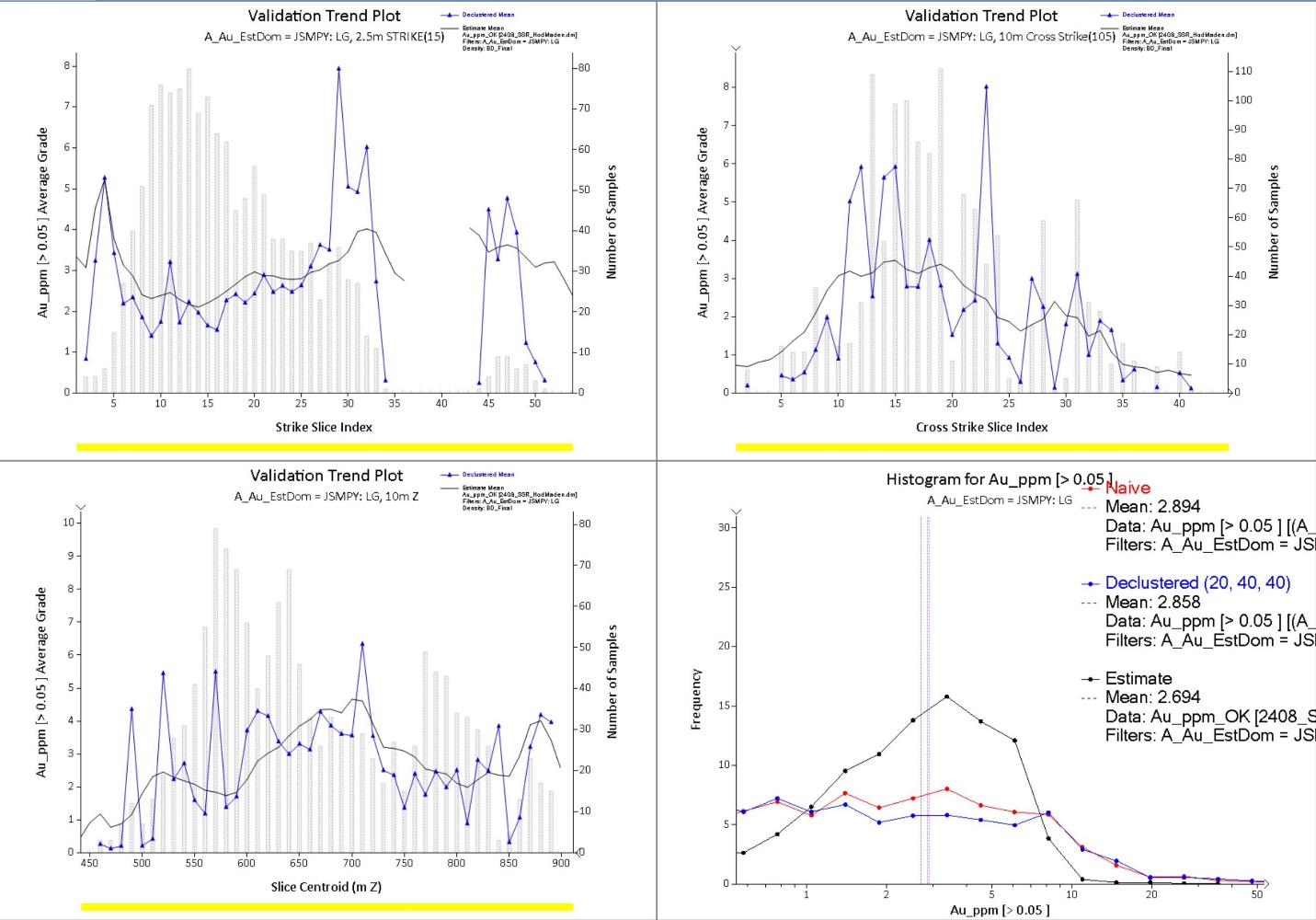

| Figure 11-25: Swath Plots and Log-Histogram for Au, Comparing Input Data and Block Grades in the HSS:LG Domain |

11-36 |

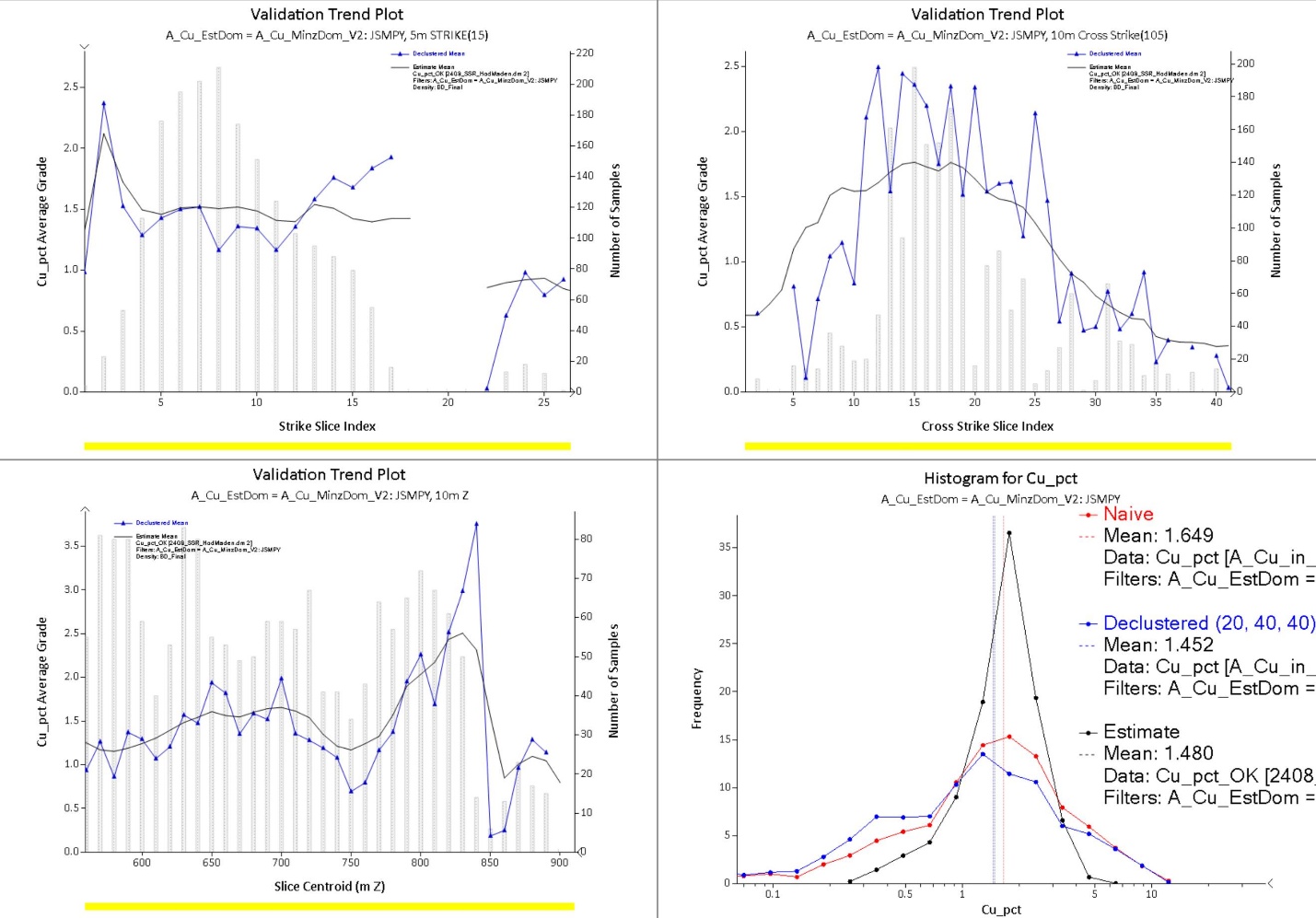

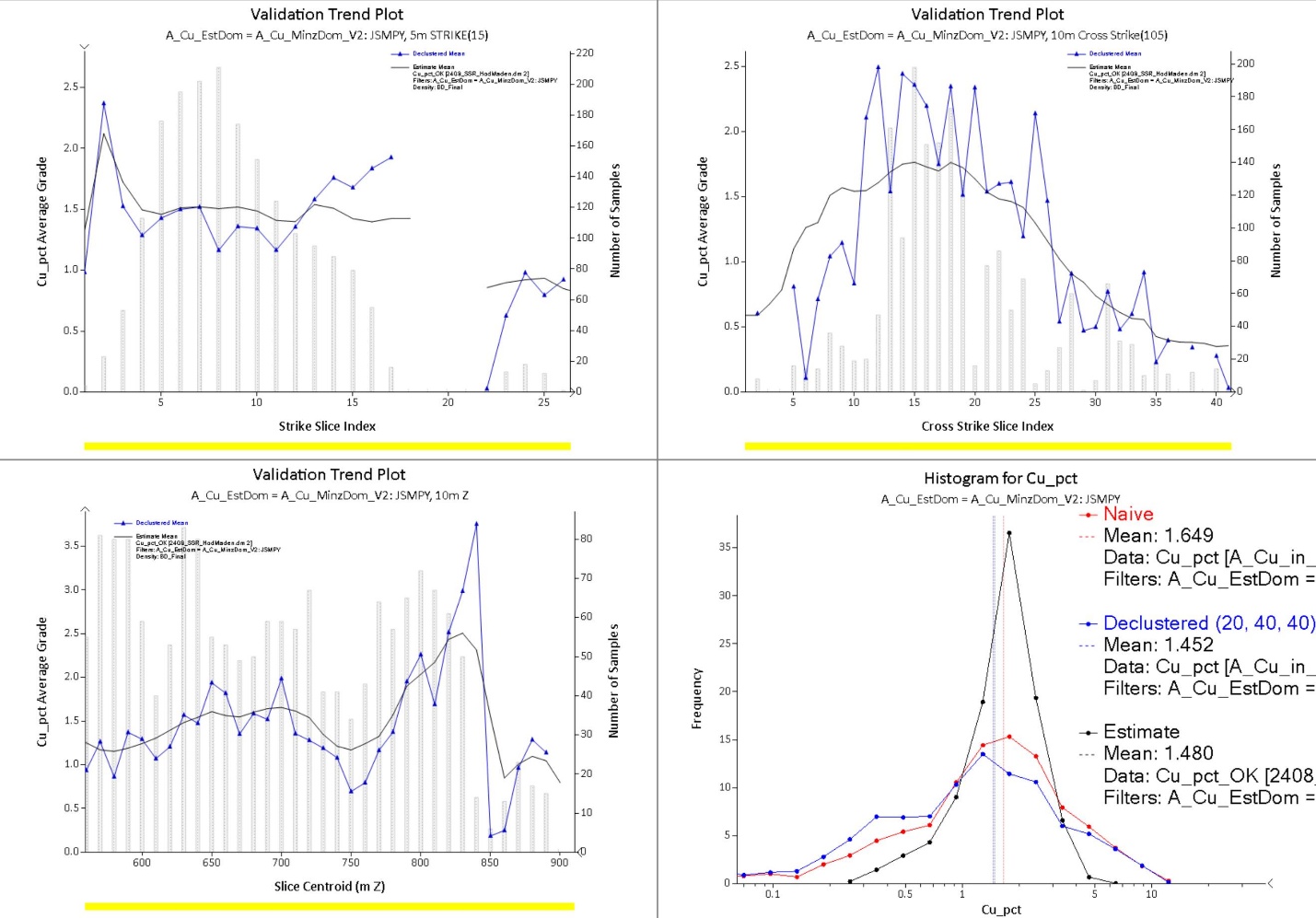

| Figure 11-26: Swath Plots and Log-Histogram for Cu Comparing Input Data and Block Grades in the HSS Domain |

11-37 |

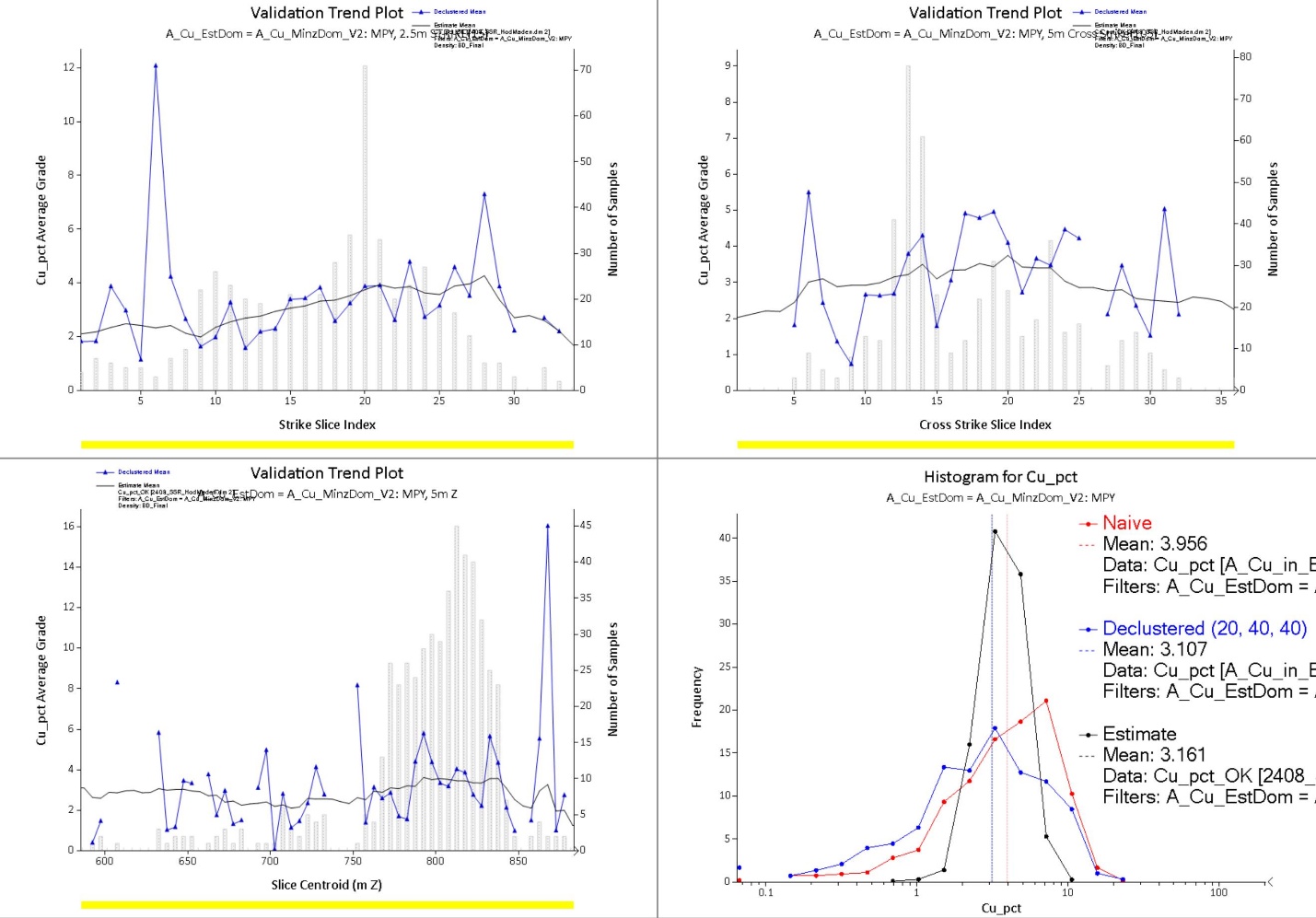

| Figure 11-27: Swath Plots and Log-Histogram for Cu, Comparing Input Data and Block Grades in the MPY Domain |

11-38 |

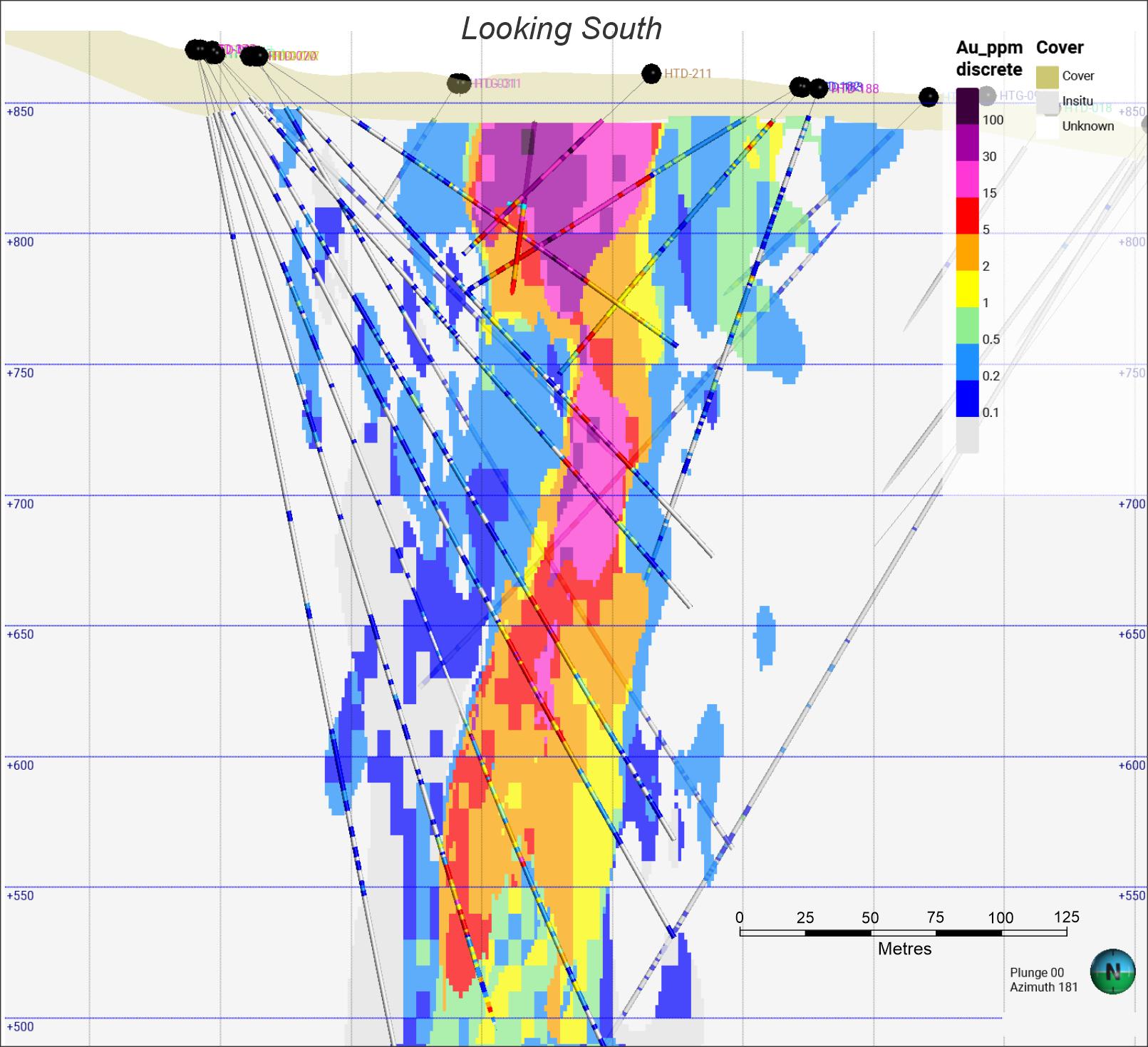

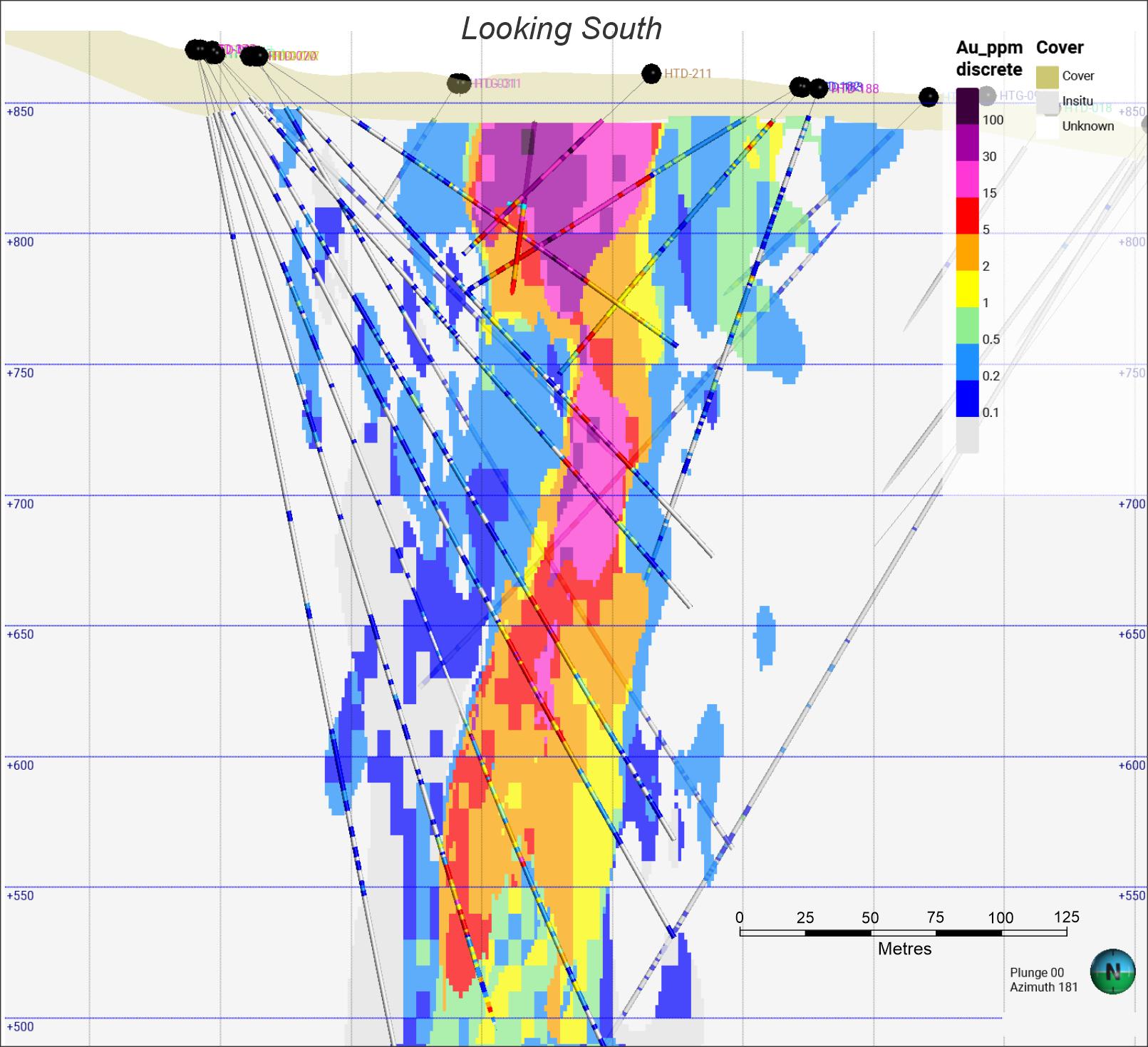

| Figure 11-28: Visual Validation of the Au Estimate at 4542215 N, Looking South |

11-39 |

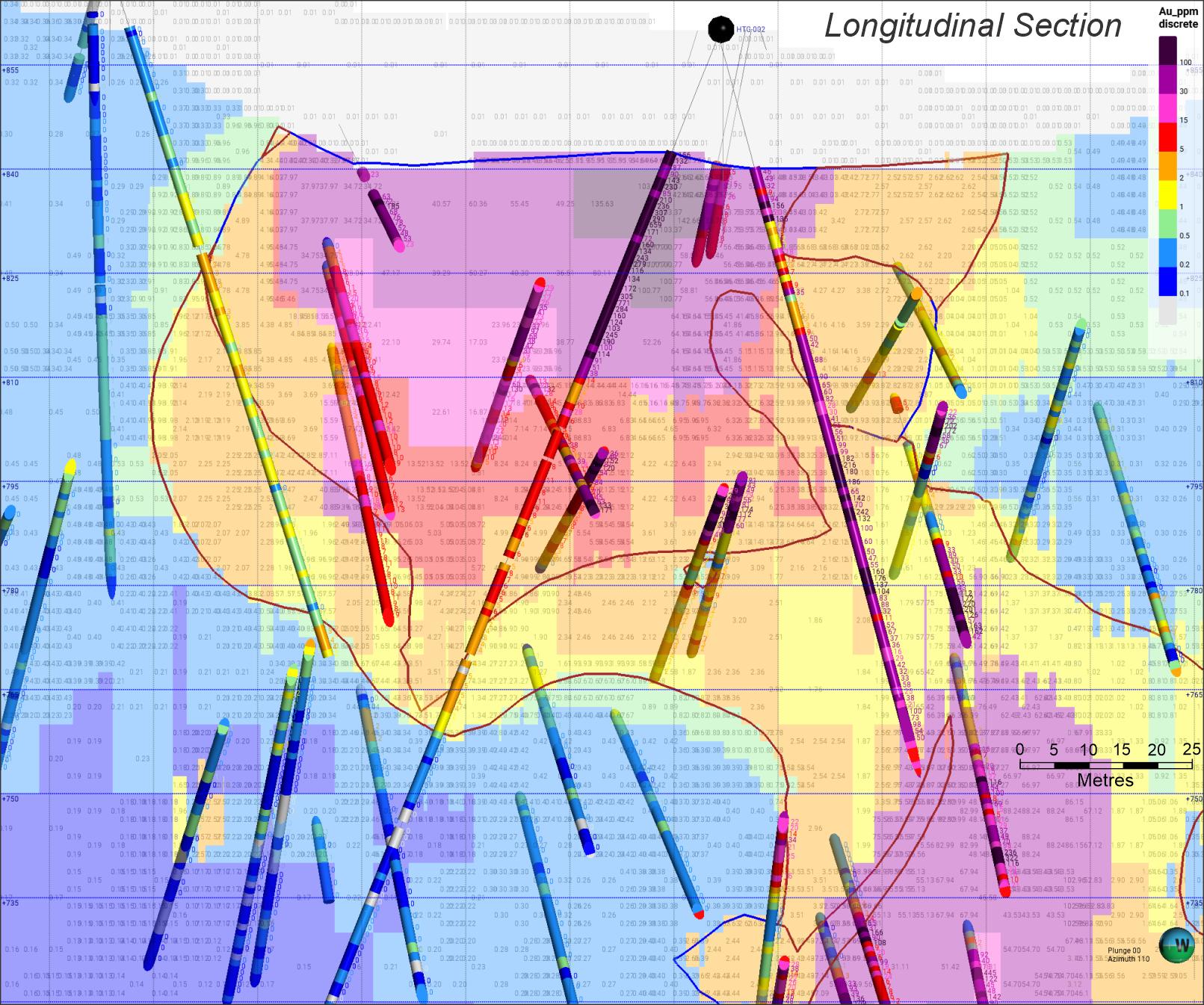

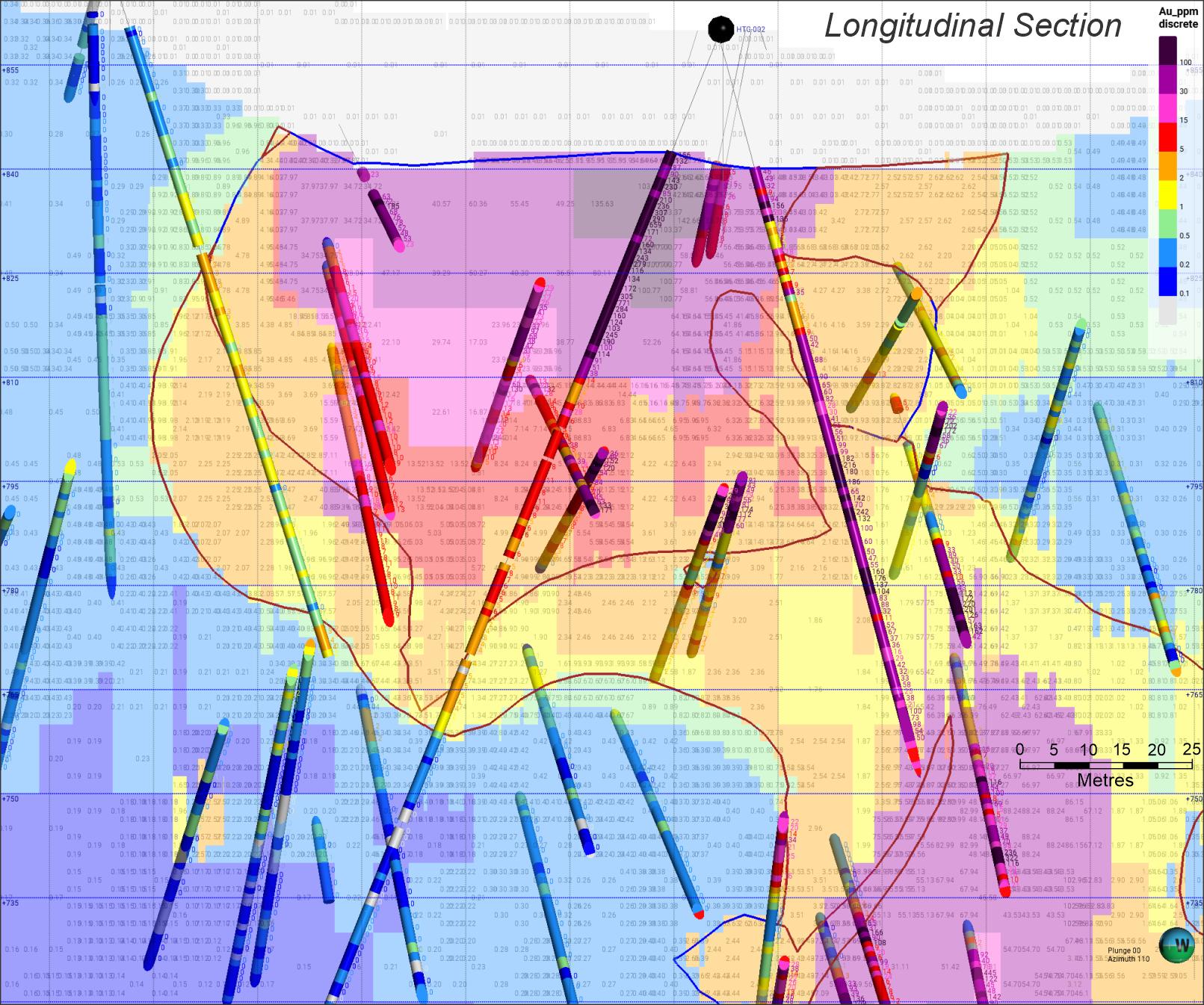

| Figure 11-29: Visual Validation of the Au Estimate, Long Section Parallel to HTG-002 |

11-40 |

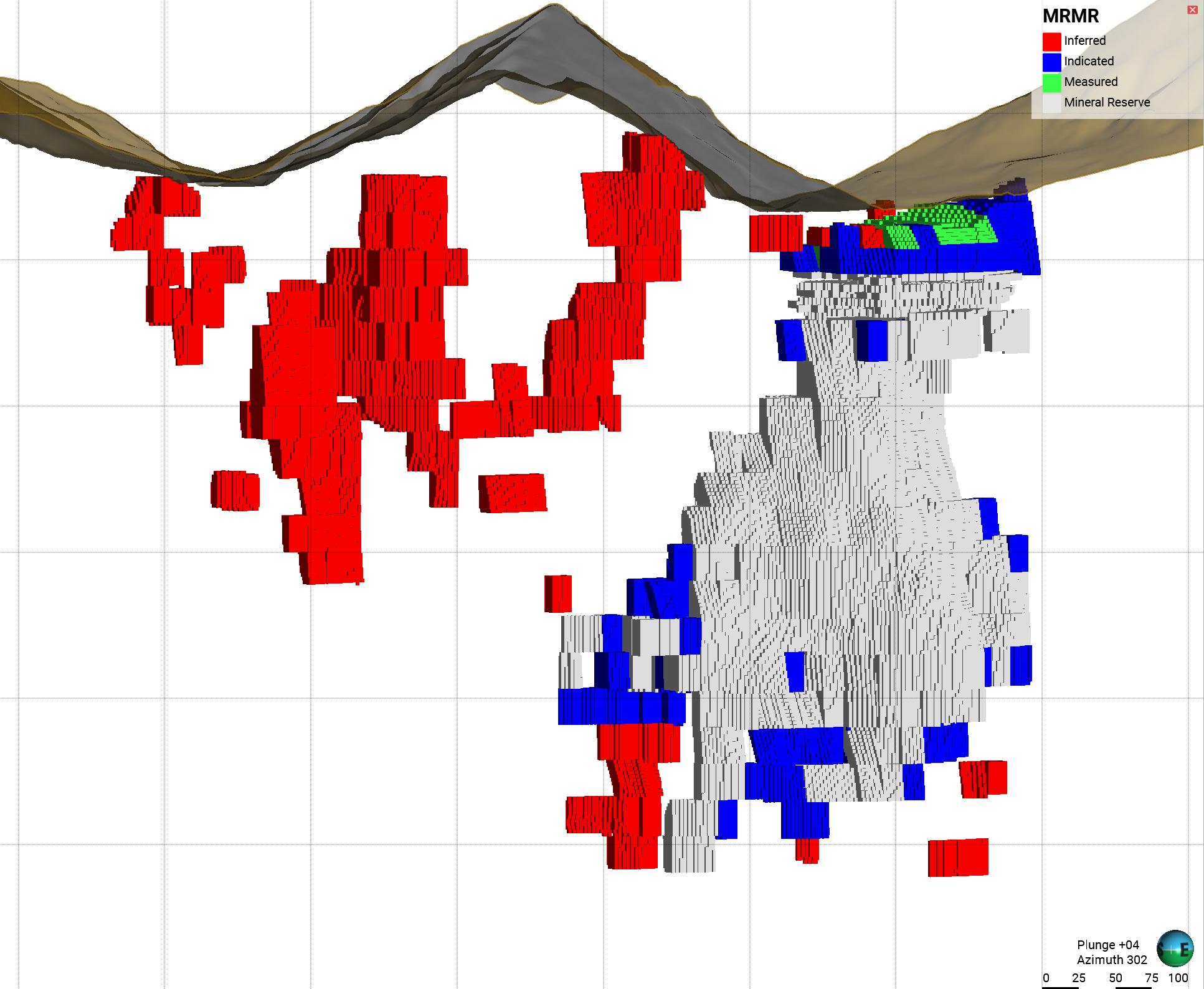

| Figure 11-30: Cross-Section showing Exclusive Mineral Resource vs Mineral Reserve MSO Shapes |

11-44 |

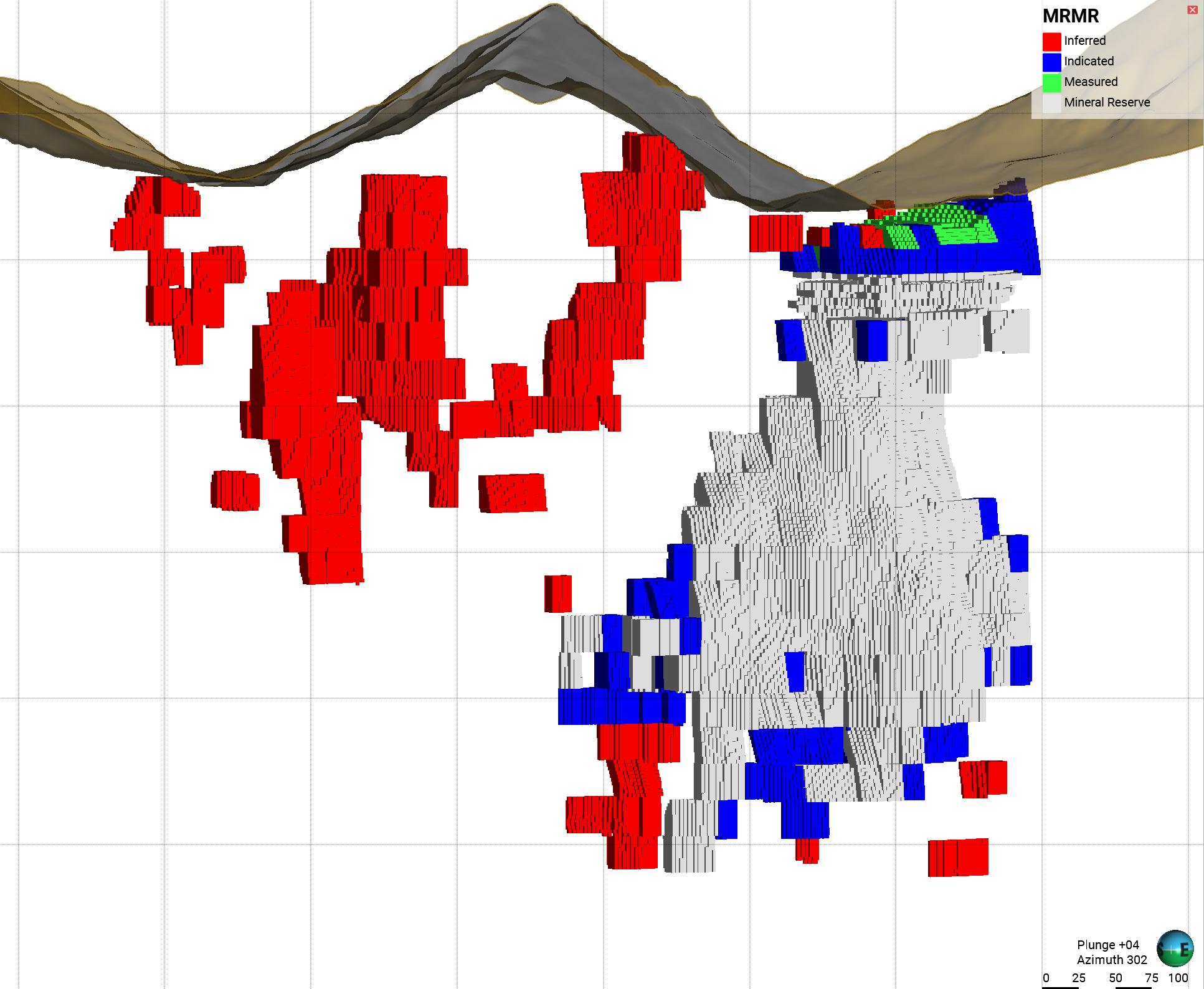

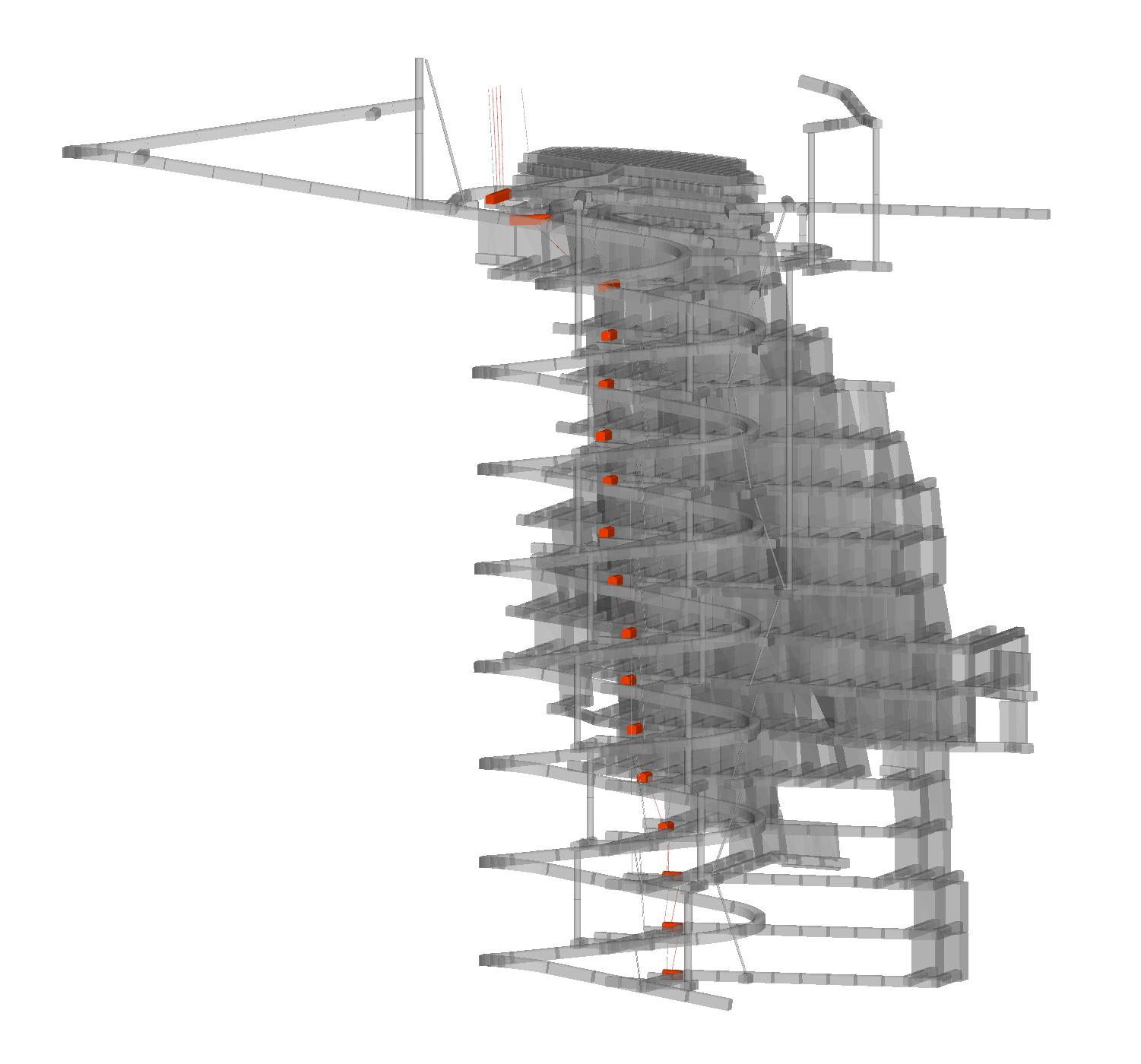

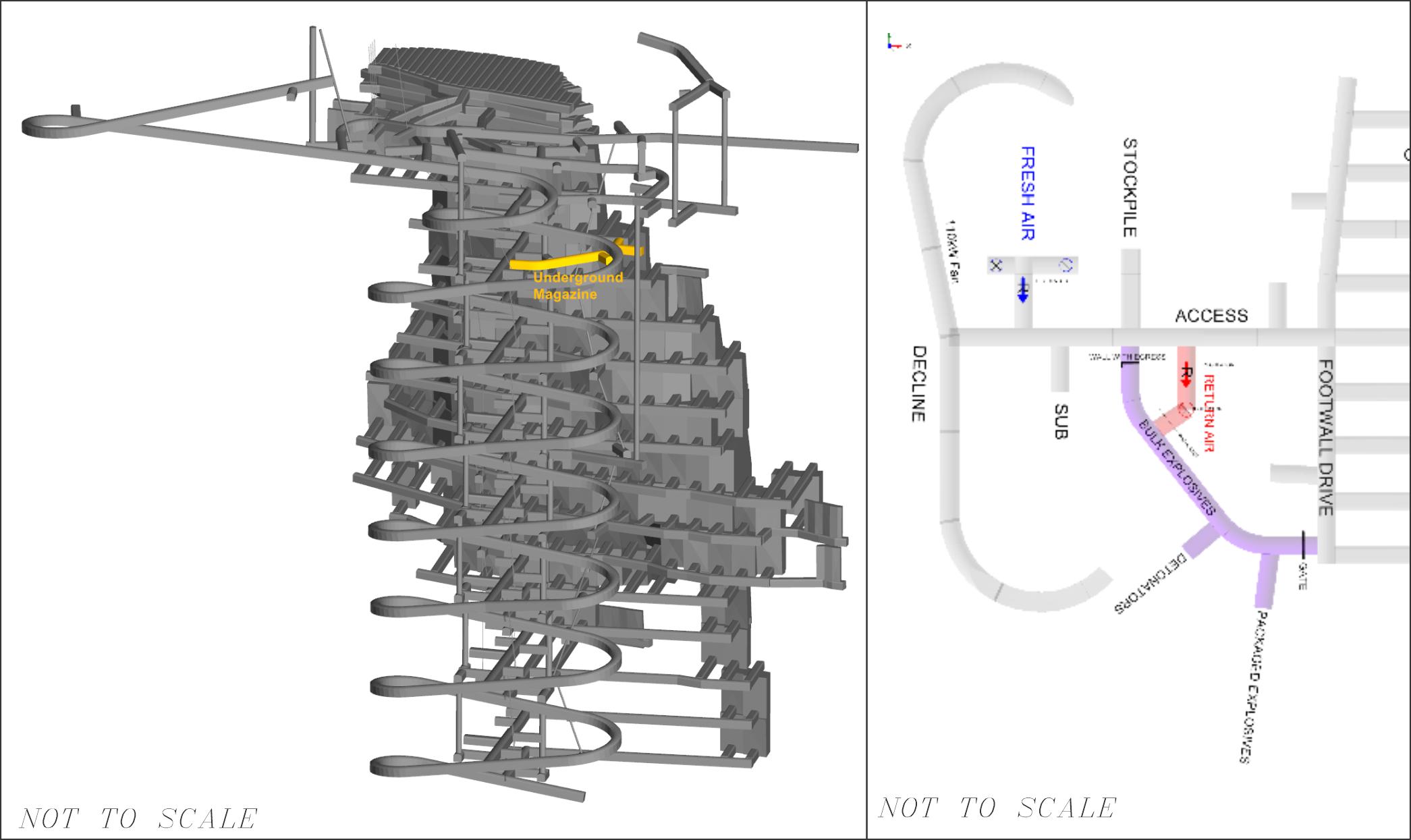

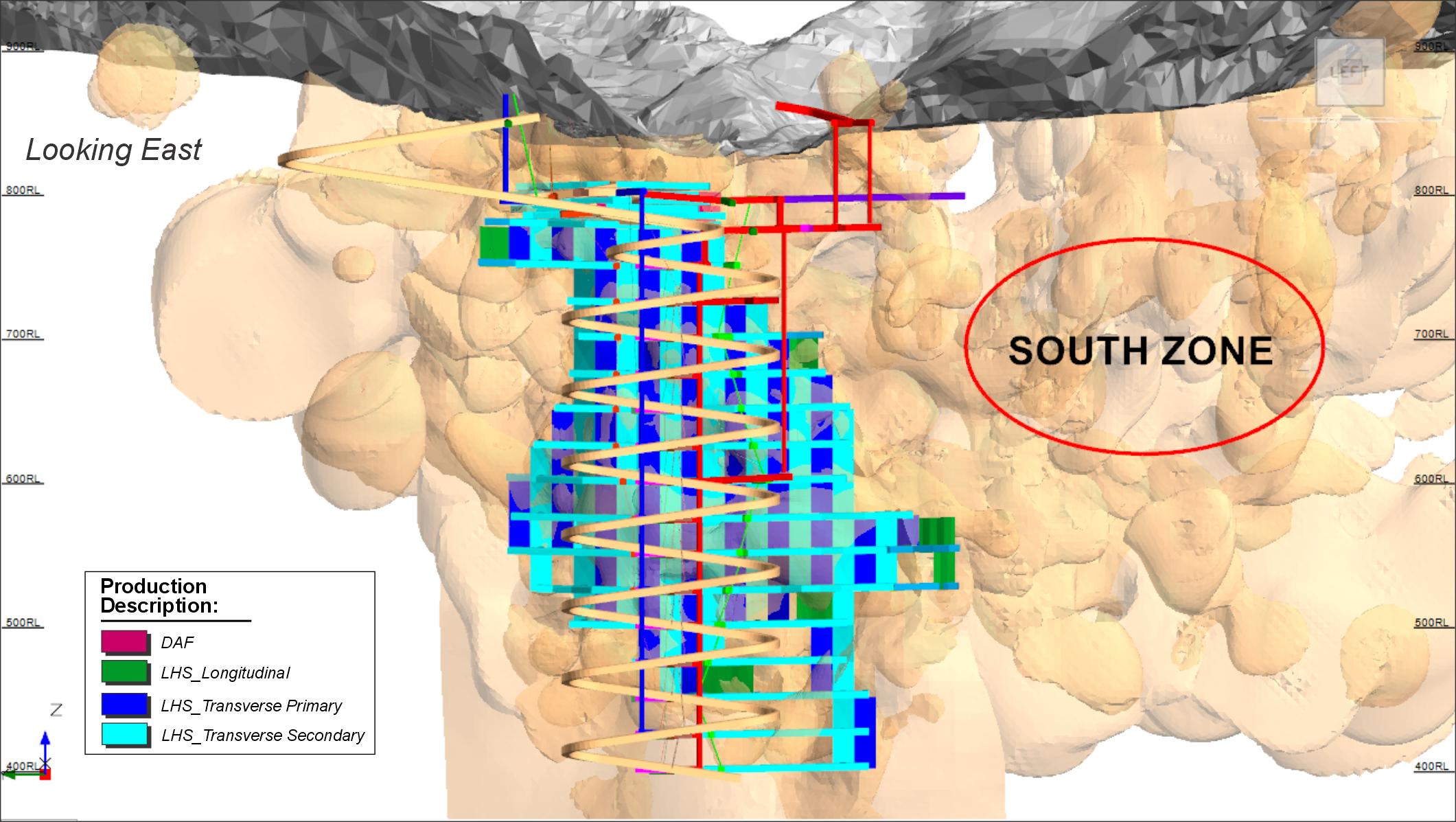

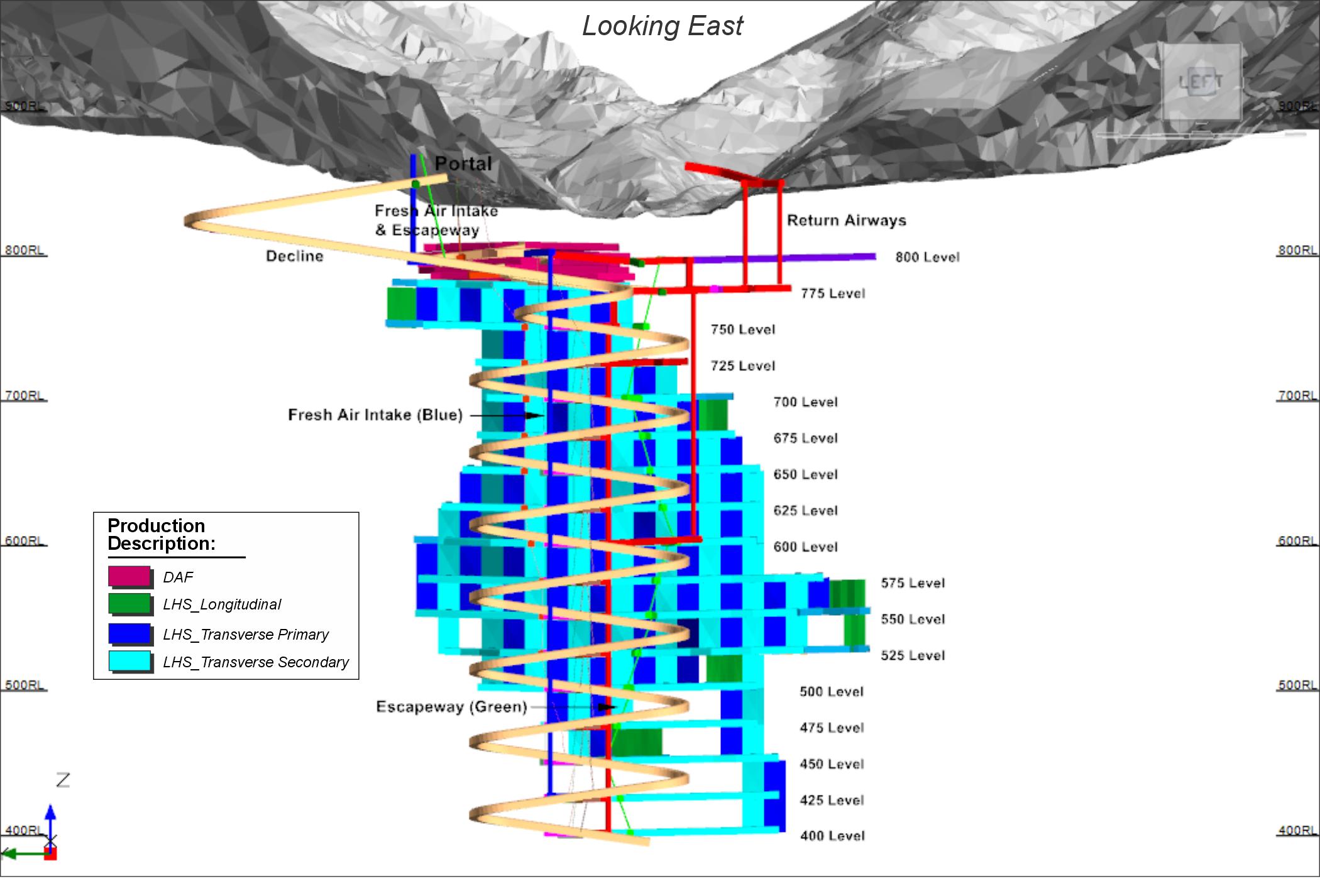

| Figure 12-1: Hod Maden Underground Mine Design and Mineralization Outlines - Longitudinal View Looking East |

12-3 |

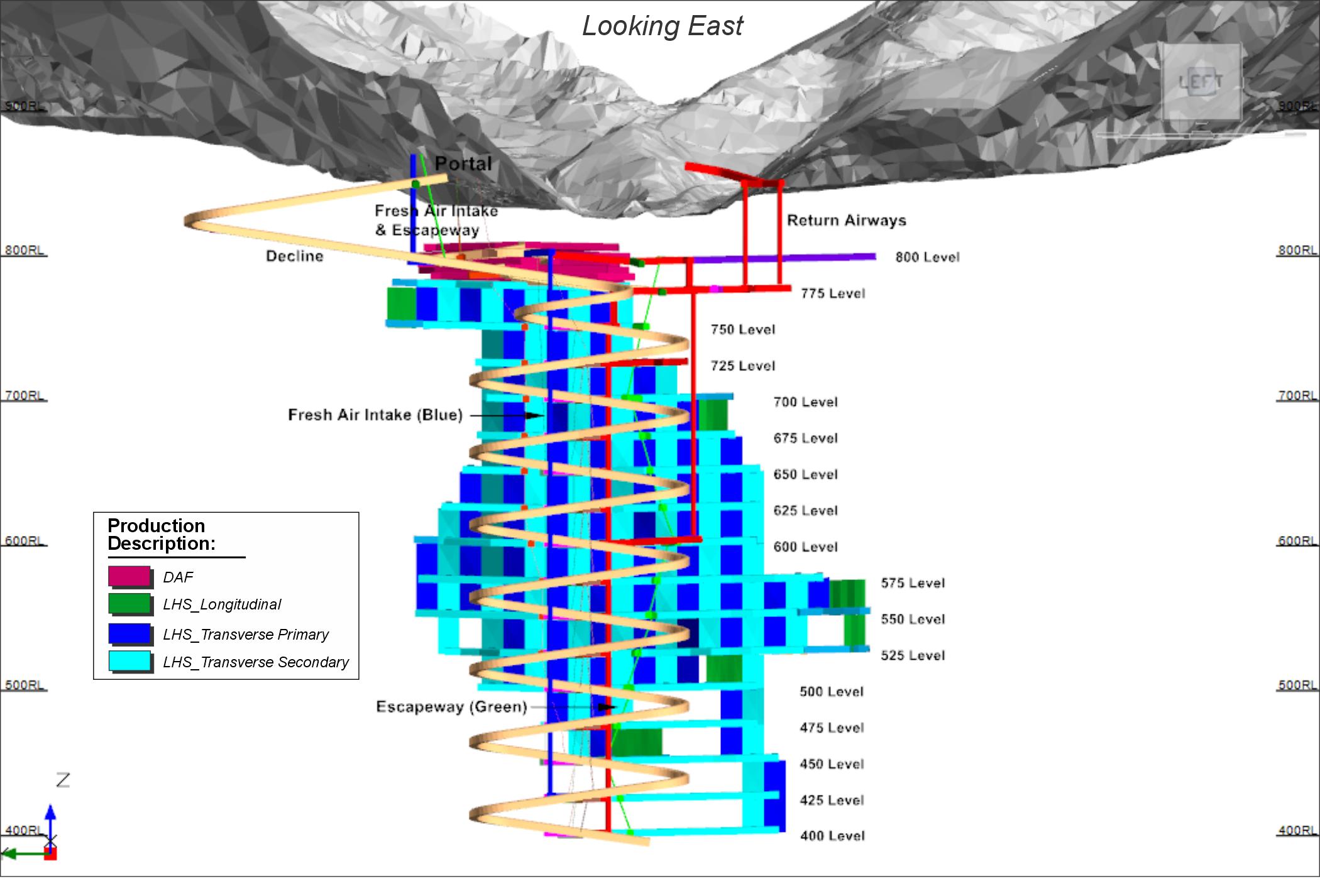

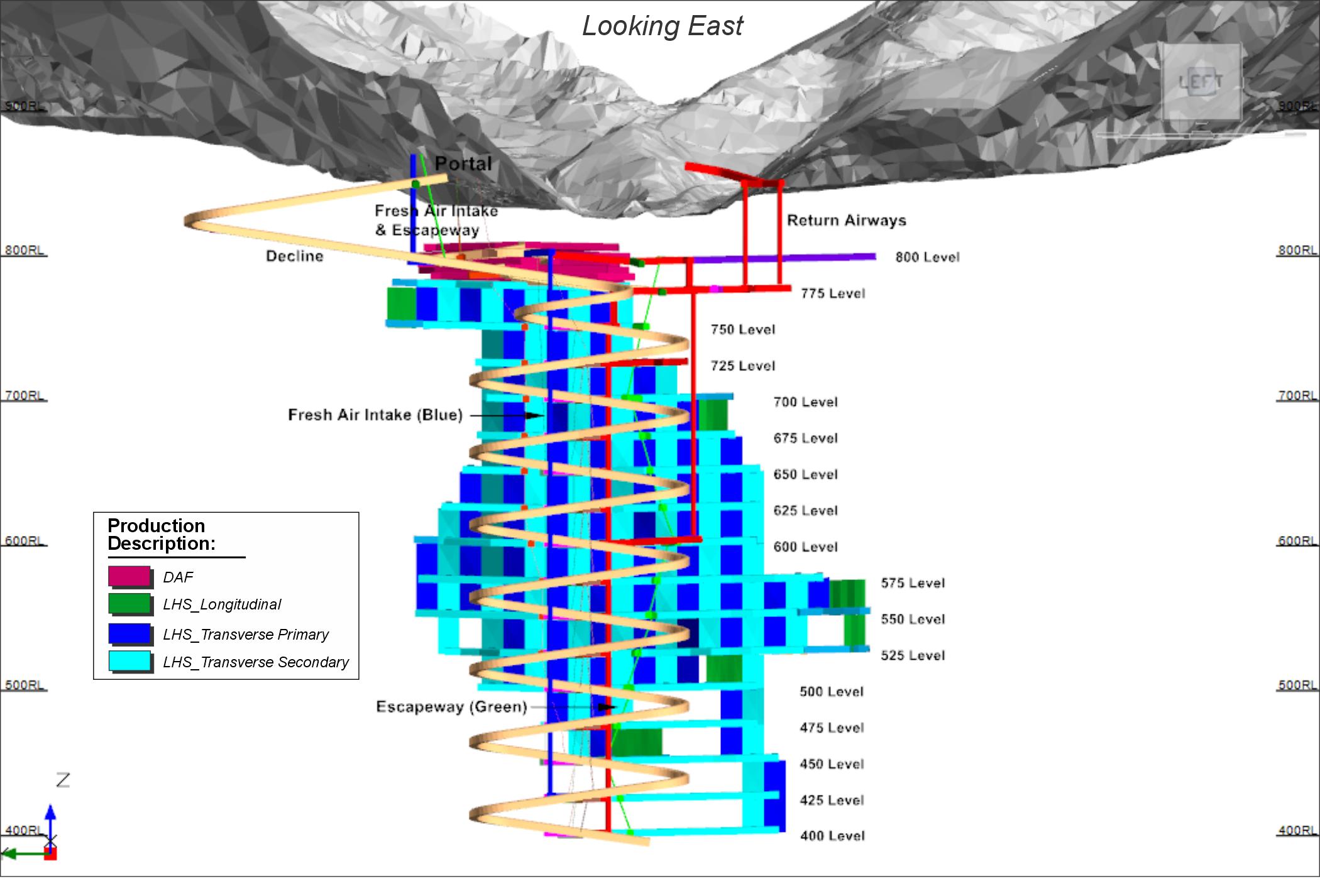

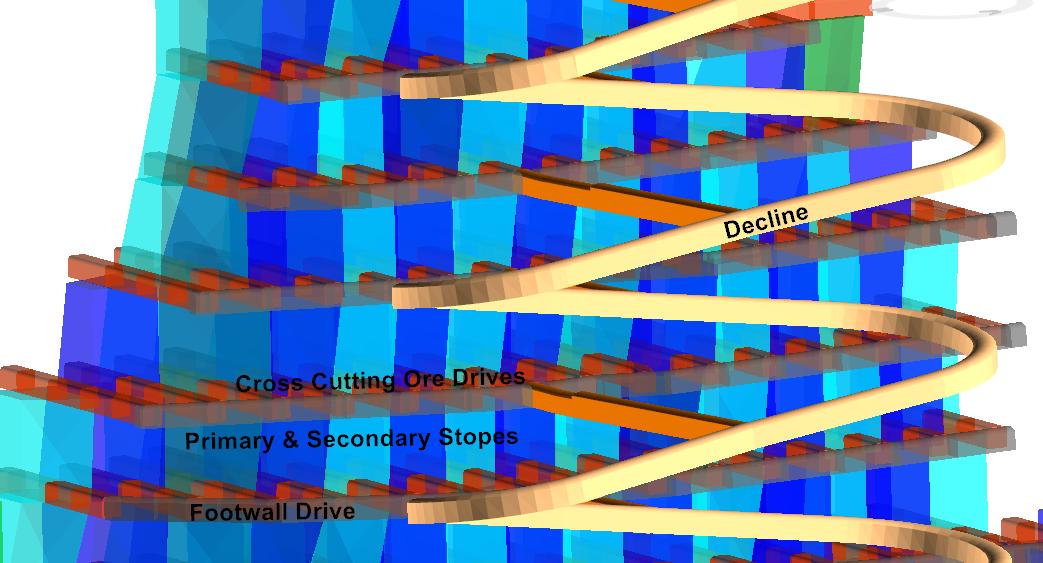

| Figure 13-1: Hod Maden Underground Mine Design - Longitudinal View Looking East |

13-2 |

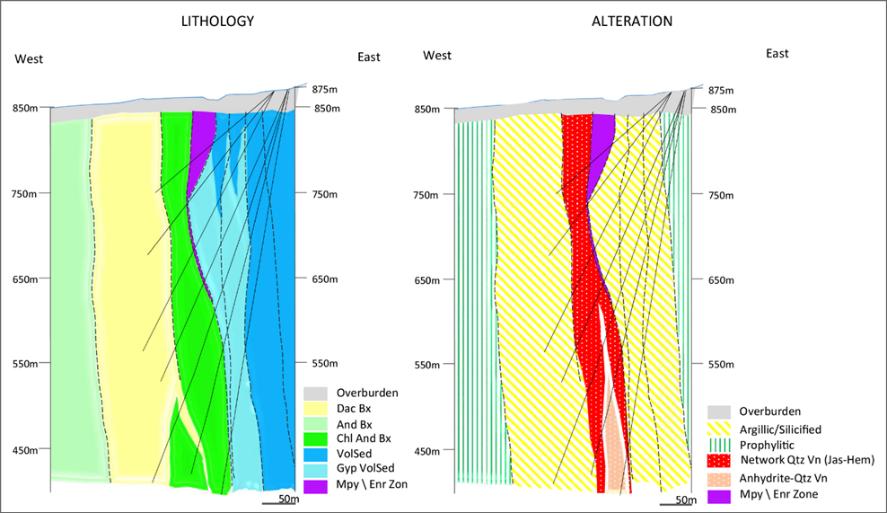

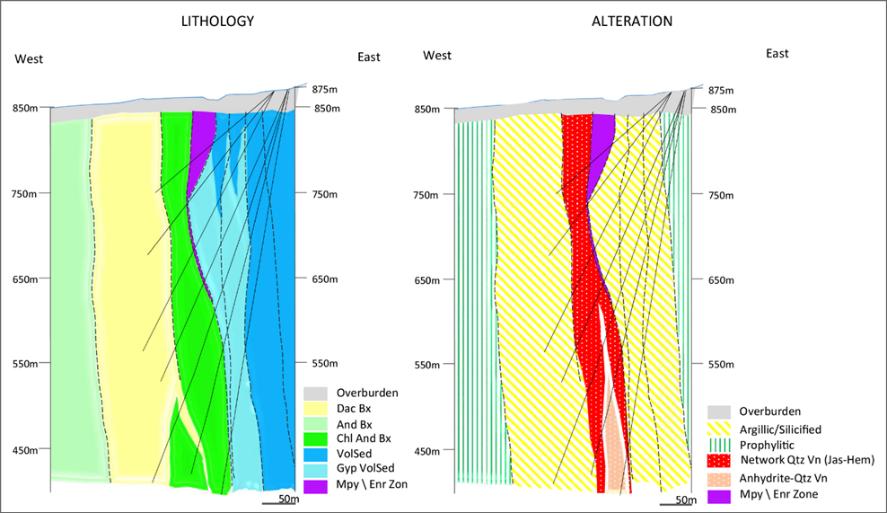

| Figure 13-2: Simplified Geological Sections, Showing the Main Lithologies and Alteration Types |

13-3 |

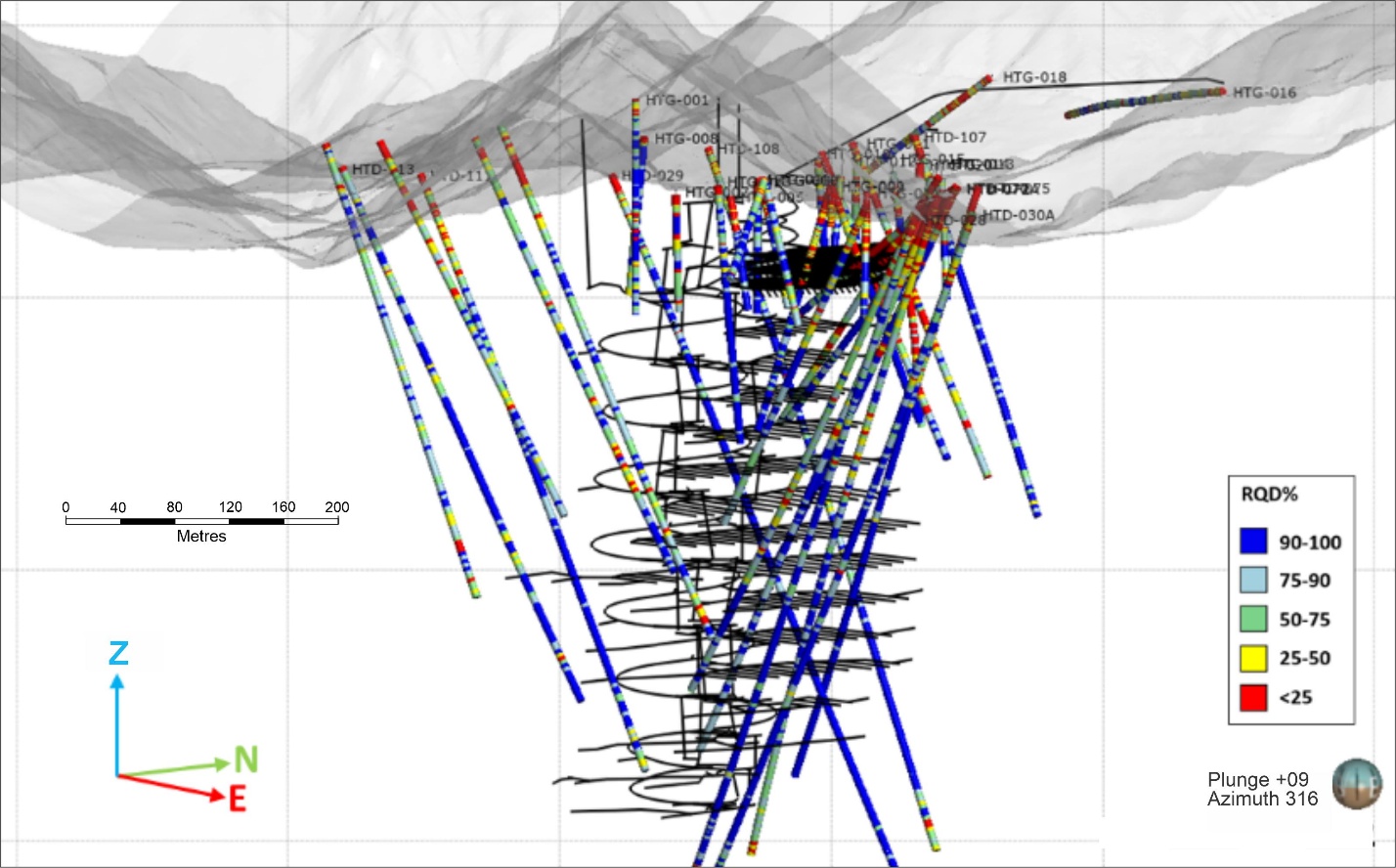

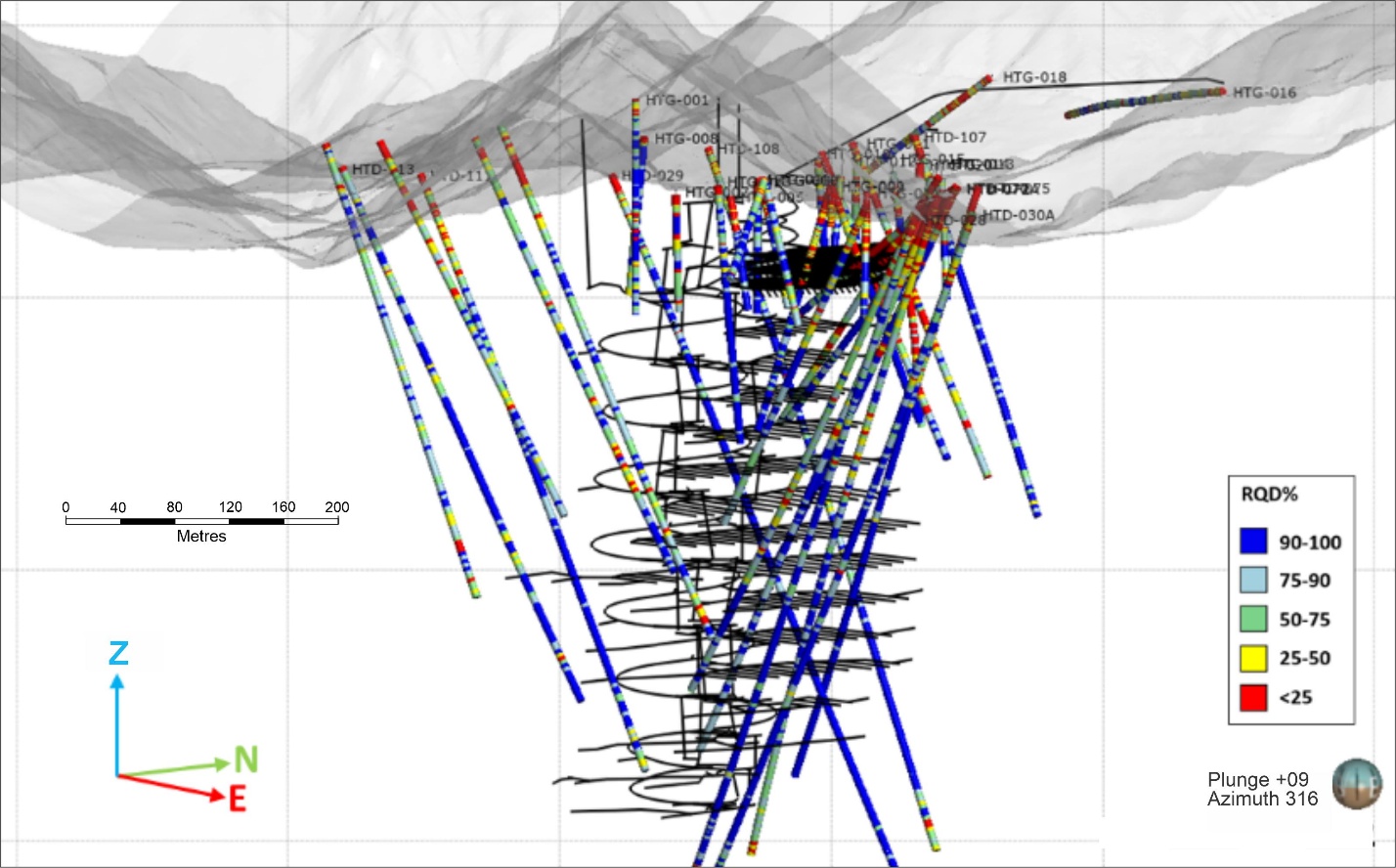

| Figure 13-3: Perspective View Showing all Drill Holes used for the Geotechnical Assessment |

13-4 |

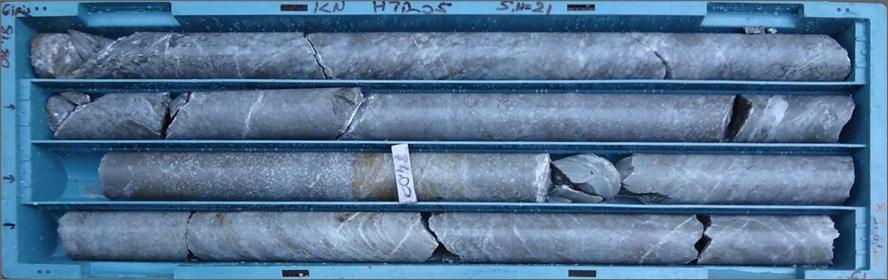

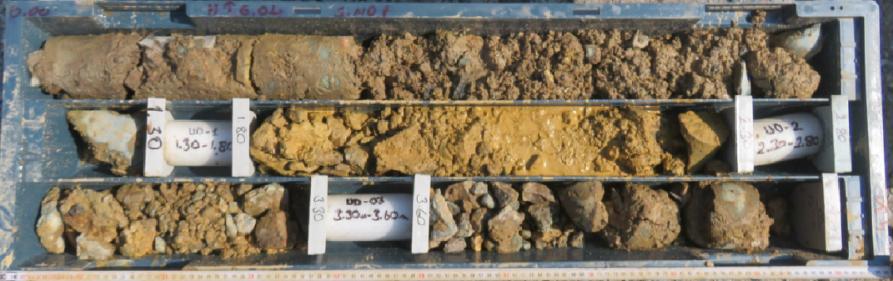

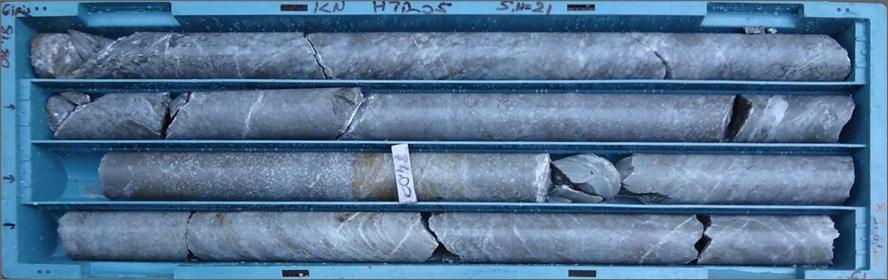

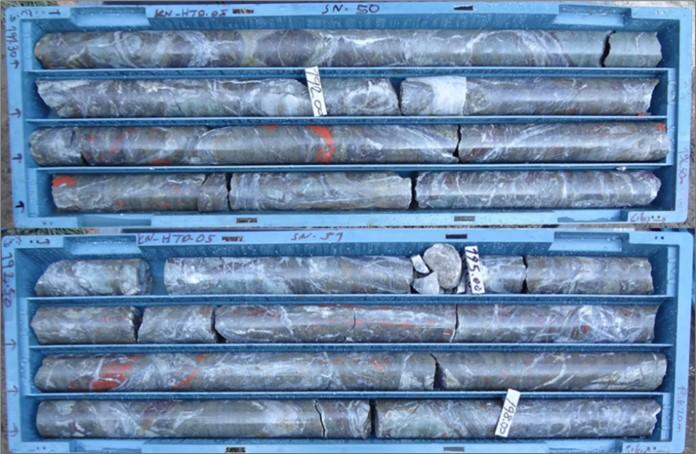

| Figure 13-4: Example of Volcanic-Sedimentary Rock |

13-5 |

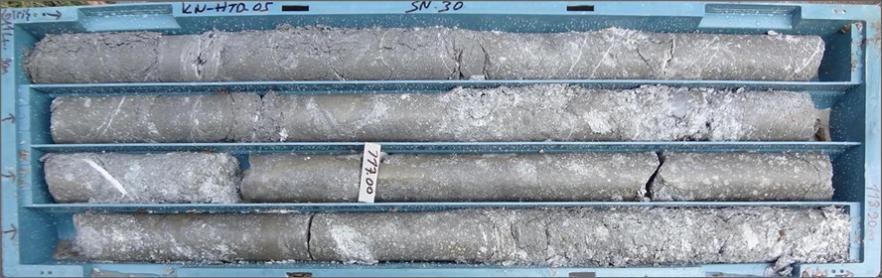

| Figure 13-5: Example of Volcanic-Sedimentary Rock Affected by Argillic Alteration |

13-5 |

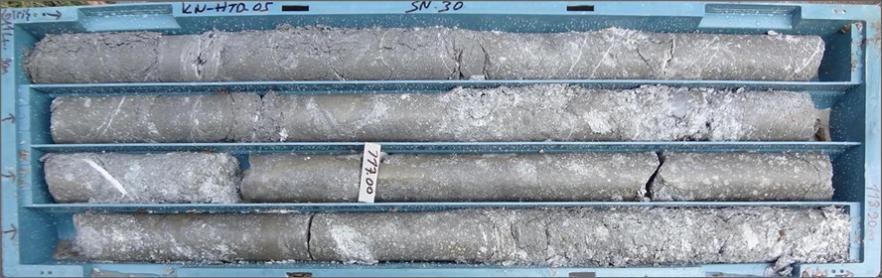

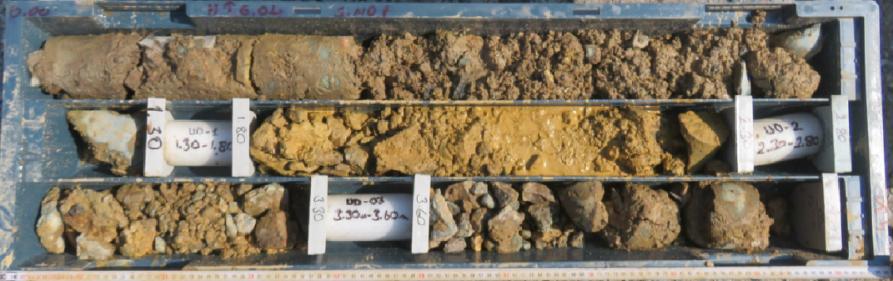

| Figure 13-6: Example of Overburden Materials - Gravel with Clay |

13-6 |

| Figure 13-7: Example of Overburden Materials - Sandstones with Cobbles |

13-6 |

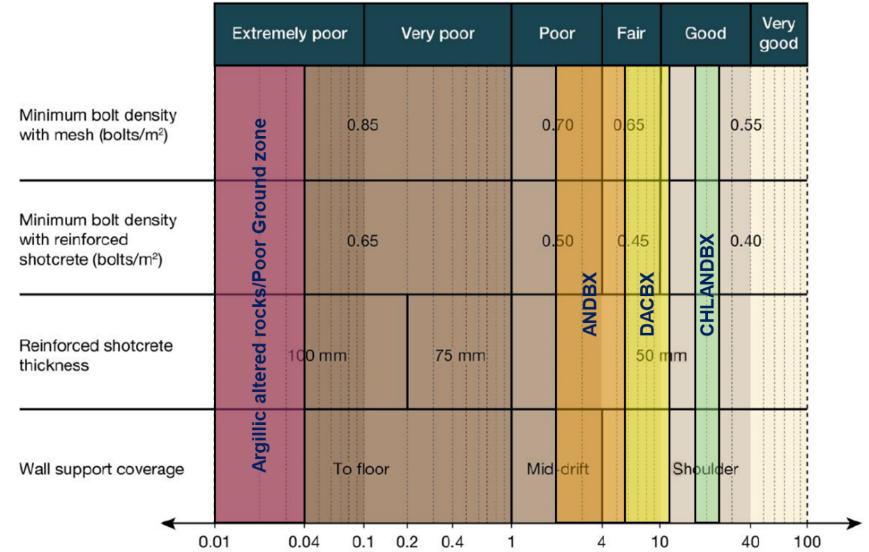

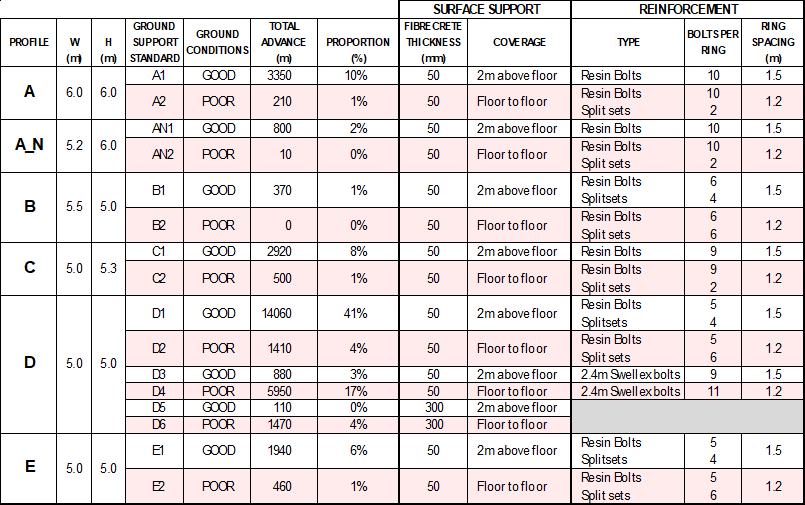

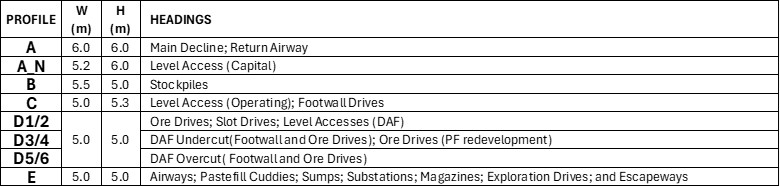

| Figure 13-8: Empirical Chart for Ground Support Selection |

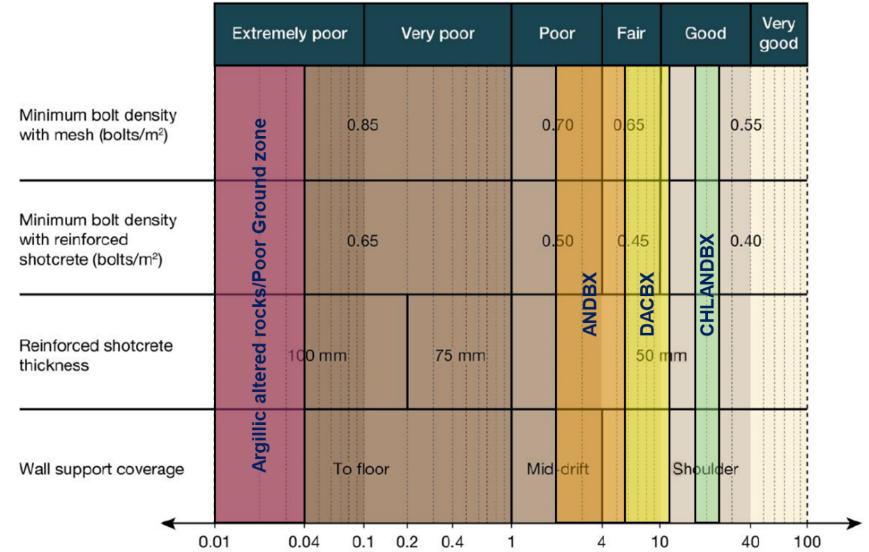

13-7 |

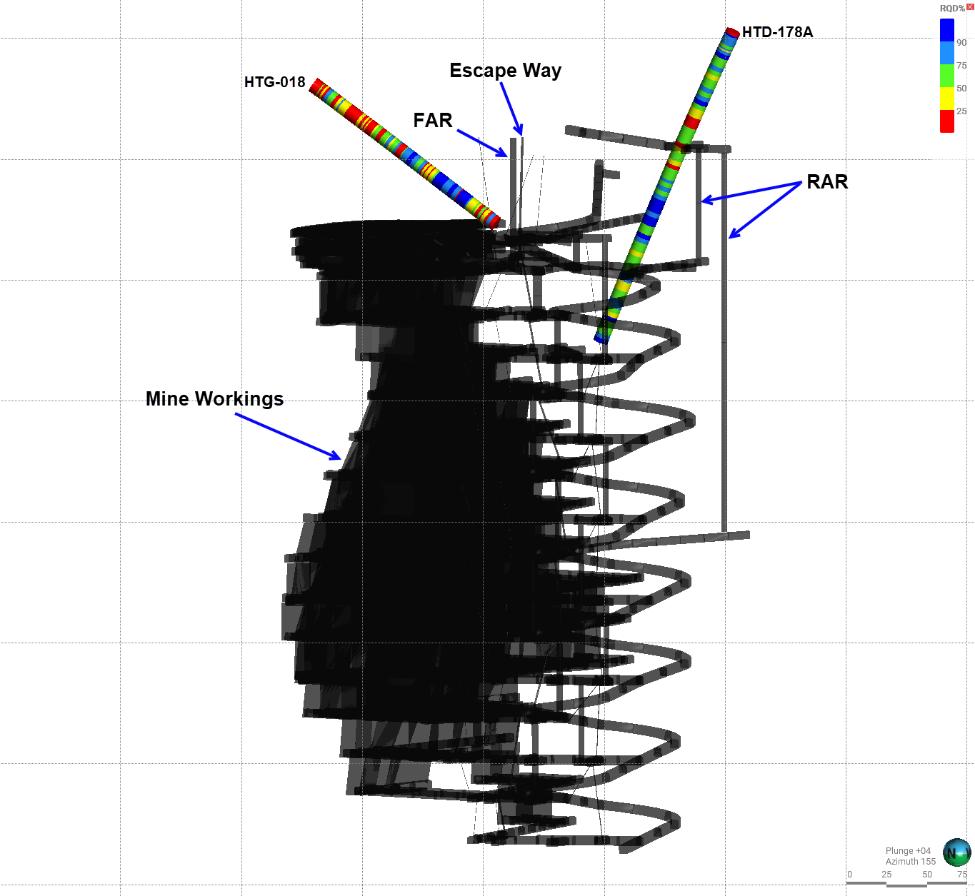

| Figure 13-9: Drill Holes Used for Shaft Stability Assessment - View Looking Northeast |

13-10 |

| Figure 13-10: Typical Hanging Wall Ground Conditions in the VGYP (HDT-005) |

13-12 |

| Figure 13-11: Typical Ore Zone Ground Conditions in the BXCA (HDT-005) |

13-13 |

| Figure 13-12: Typical Footwall Ground Conditions in the BXDA (HDT-005) |

13-13 |

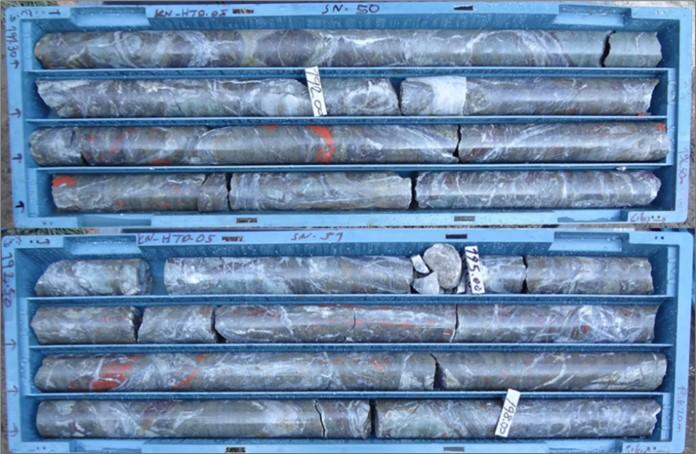

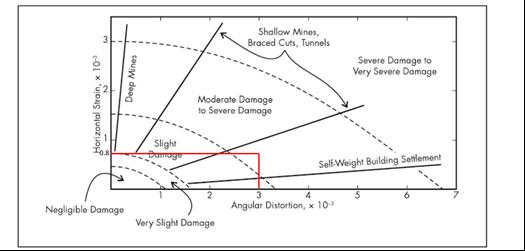

| Figure 13-13: Relationship of Damage to Angular Distortion and Horizontal Strain |

13-14 |

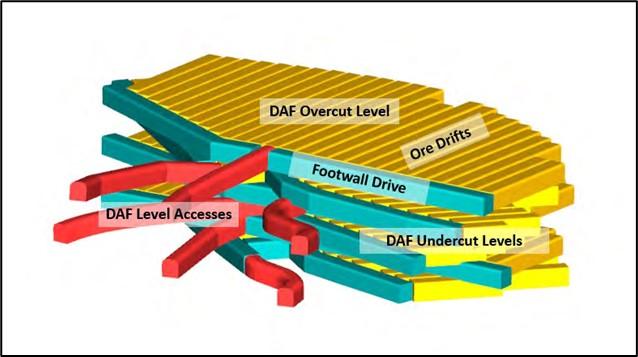

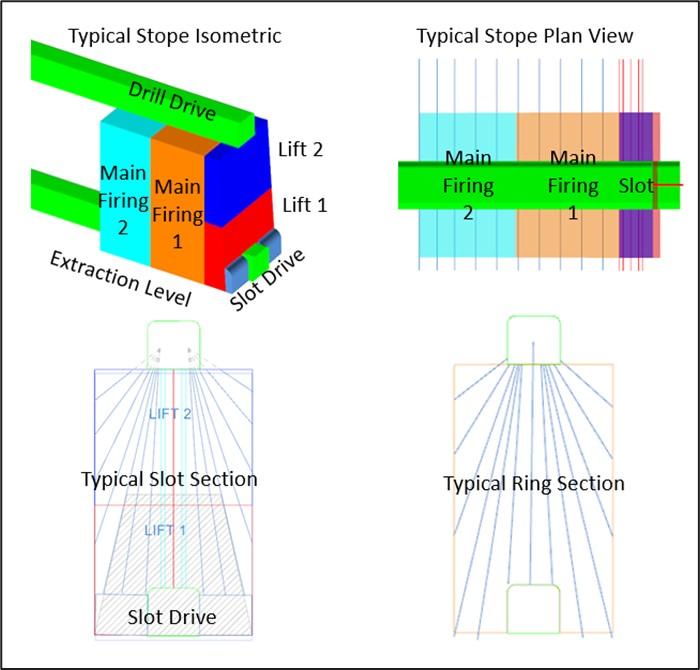

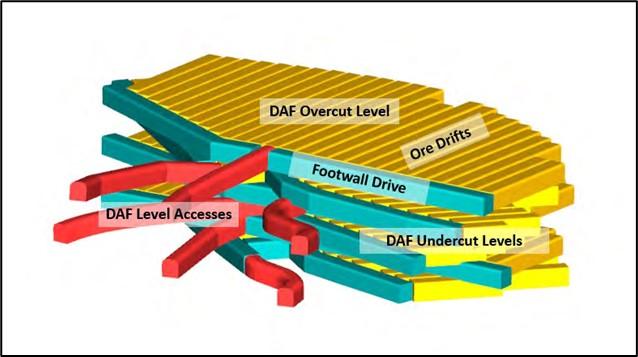

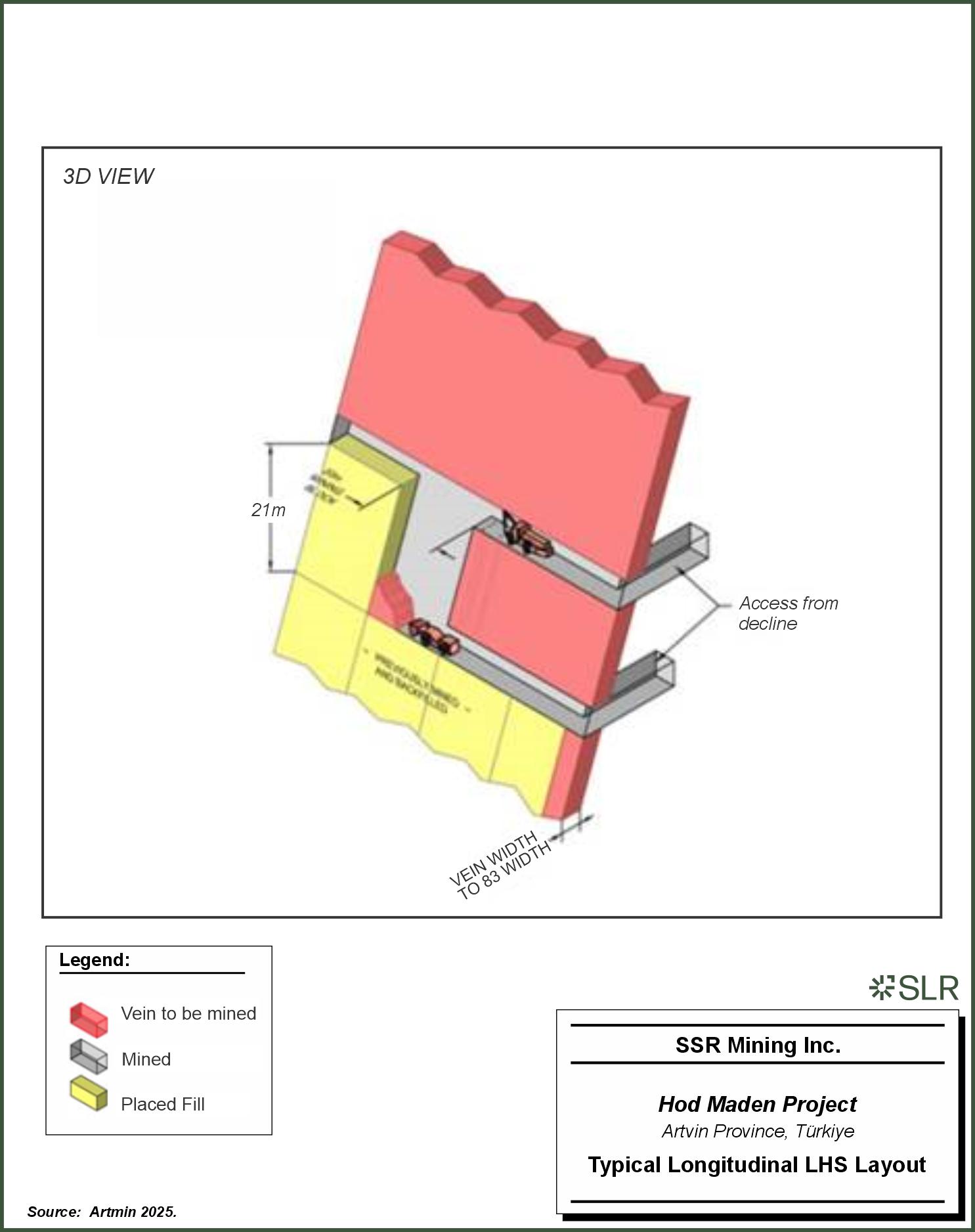

| Figure 13-14: Schematic of Modified Drift and Fill Layout - Perspective View |

13-16 |

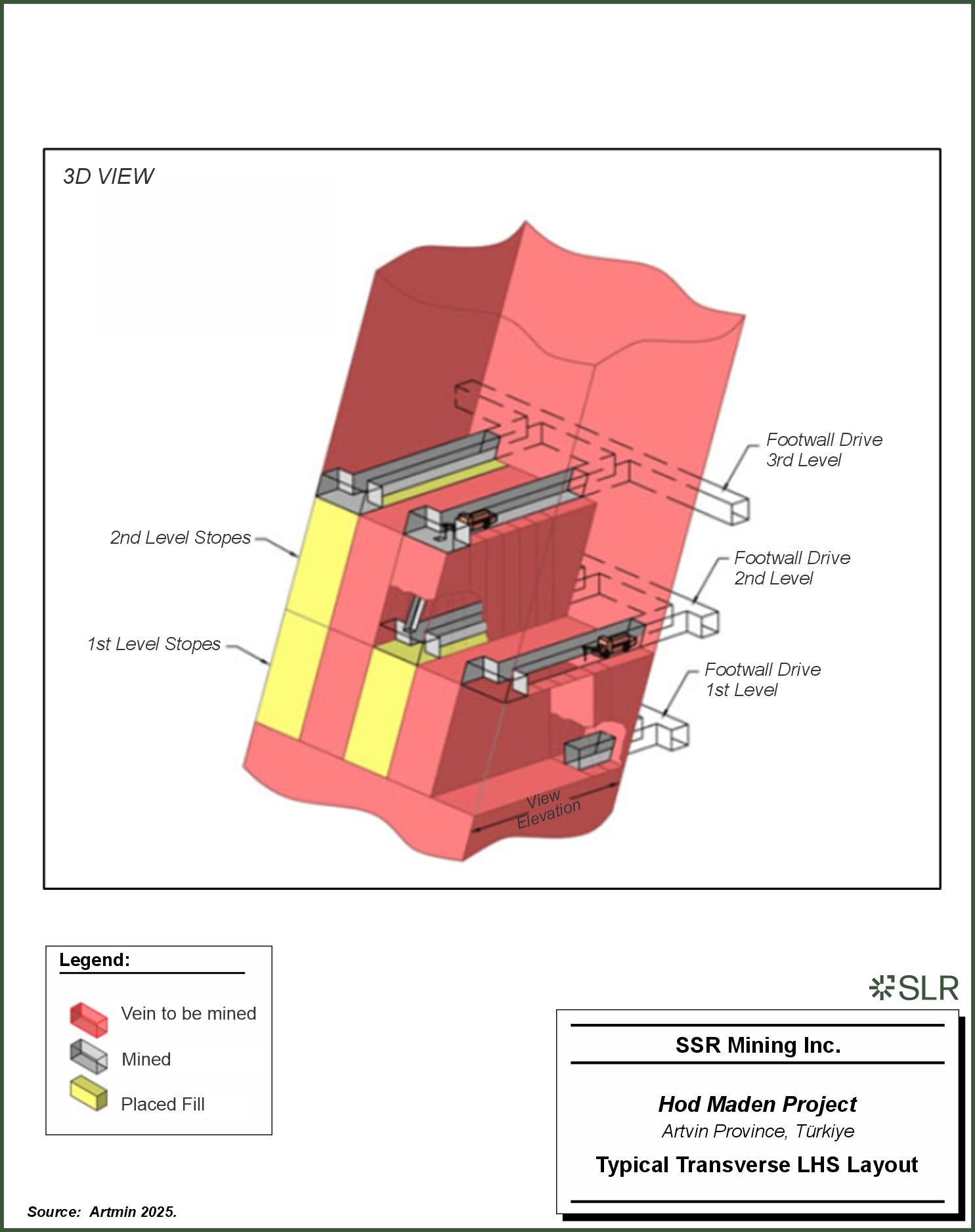

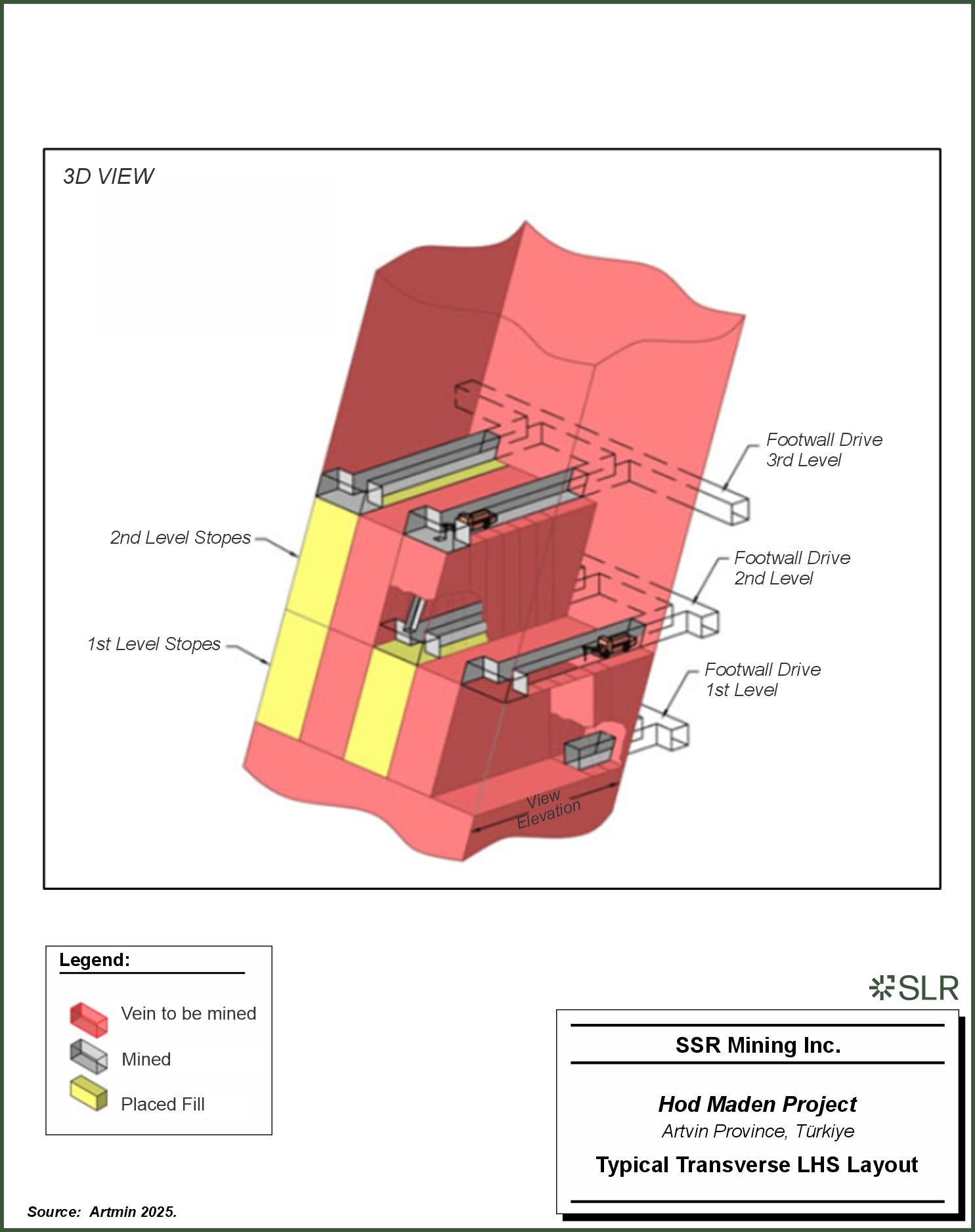

| Figure 13-15: Typical Transverse LHS Layout |

13-18 |

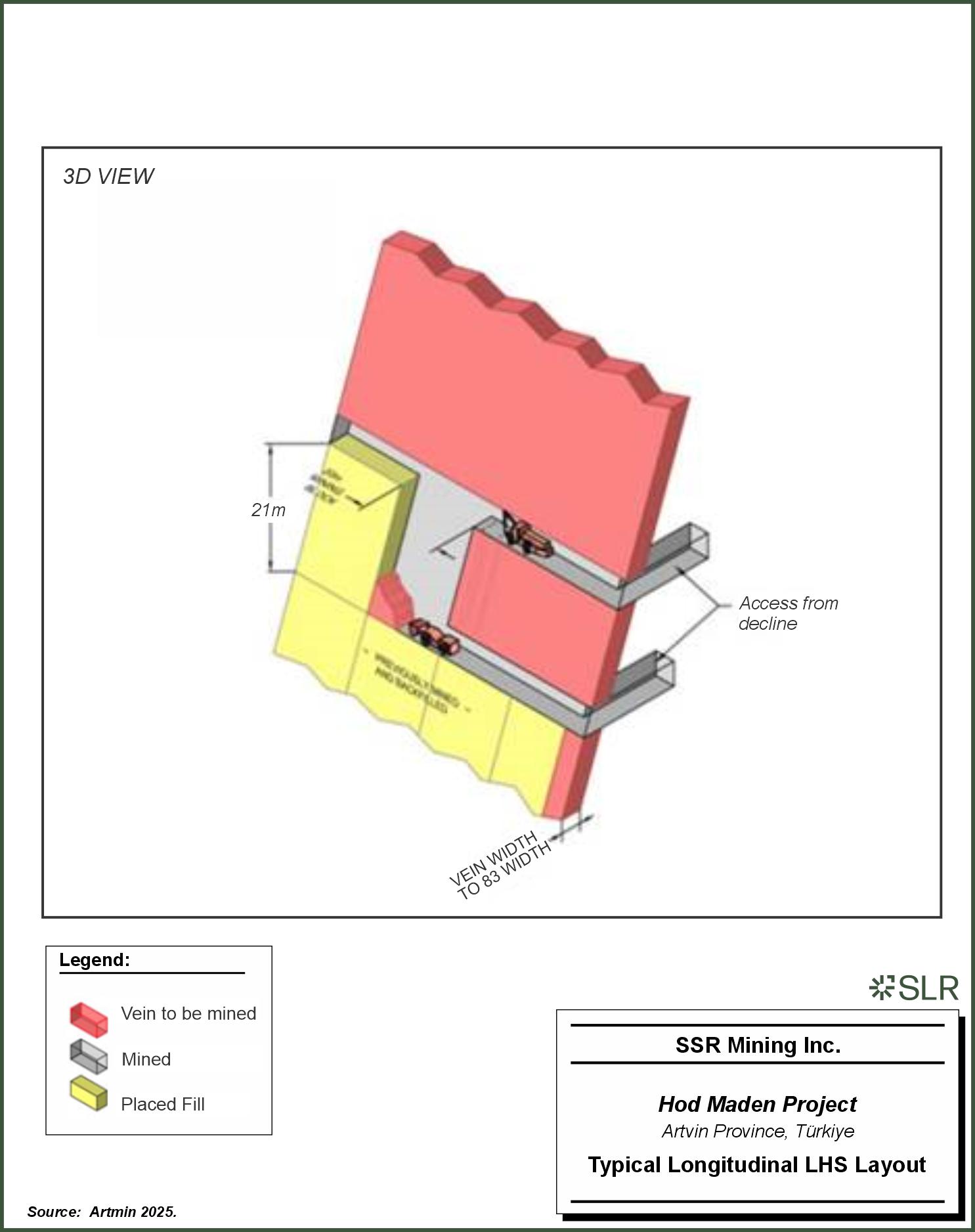

| Figure 13-16: Typical Longitudinal LHS Layout |

13-19 |

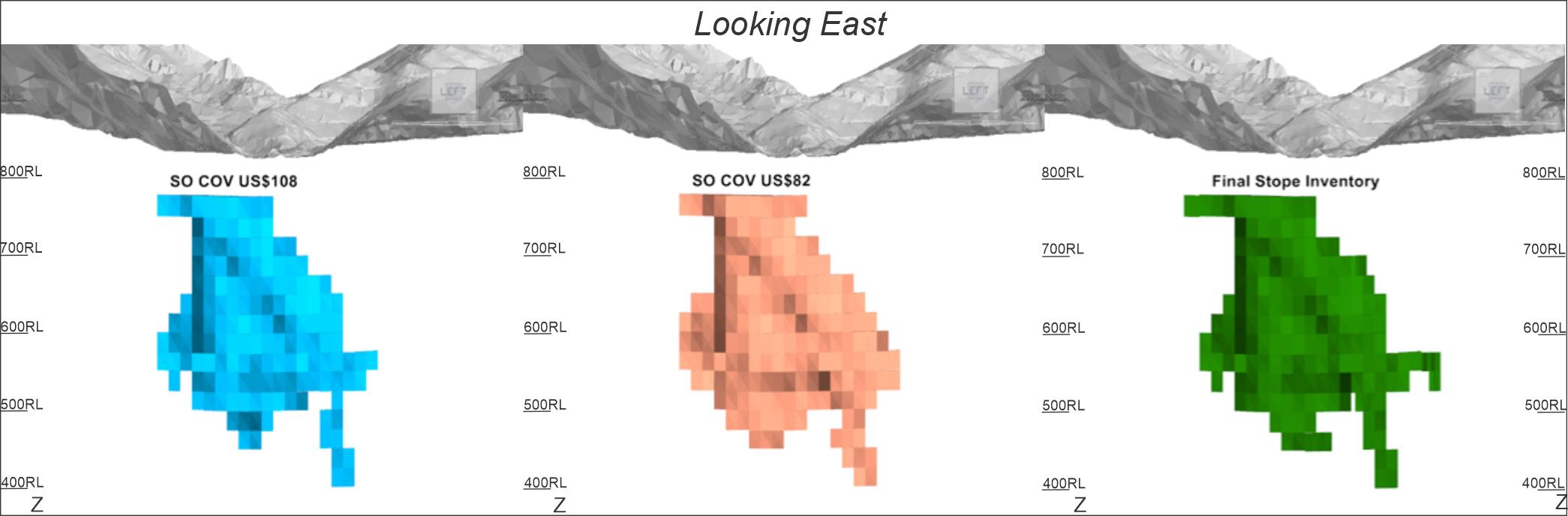

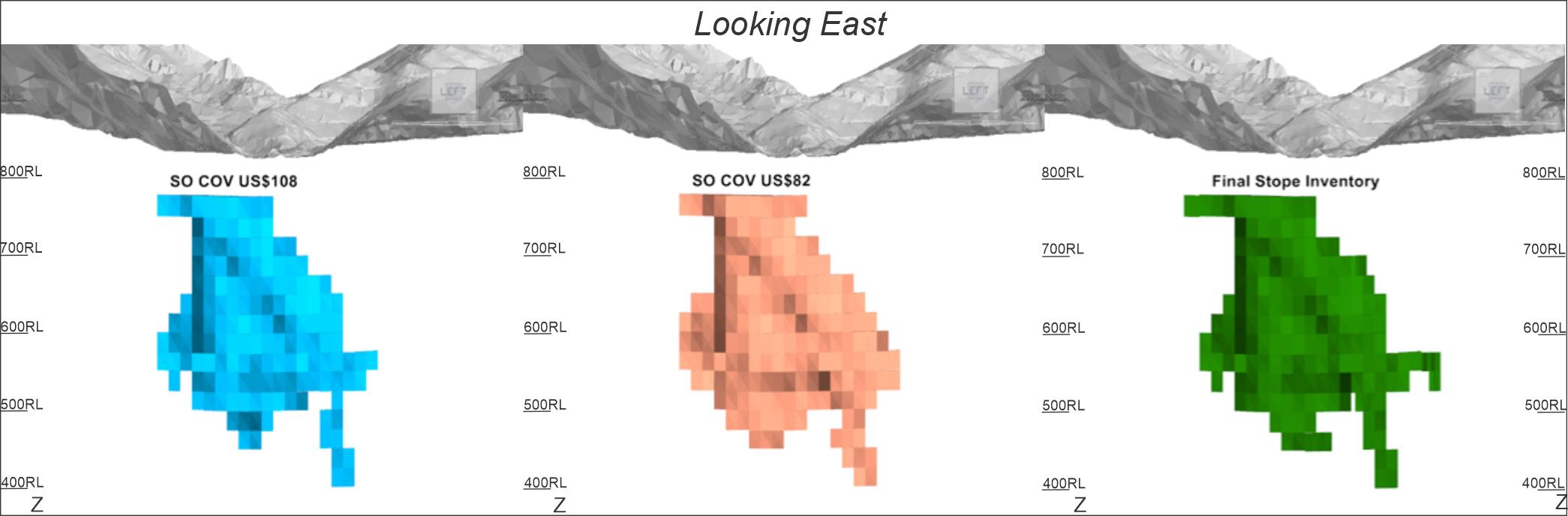

| Figure 13-17: Hod Maden SO and Final Stoping Inventories - Longitudinal Sections Looking East |

13-21 |

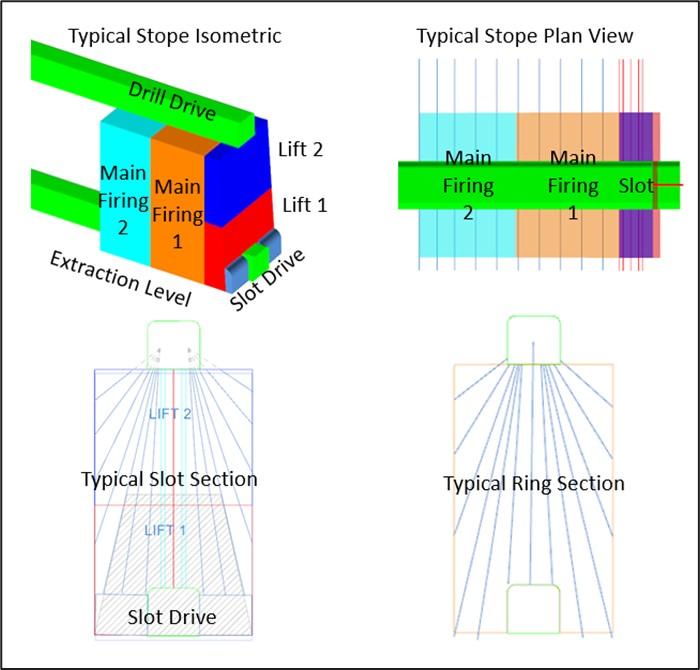

| Figure 13-18: Hod Maden Typical Transverse LH Stope Drill and Blast Design |

13-22 |

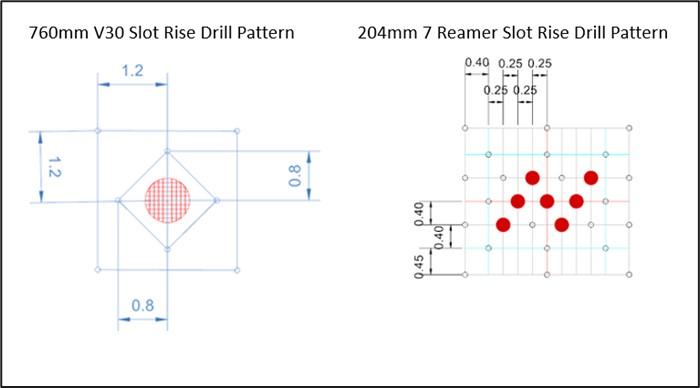

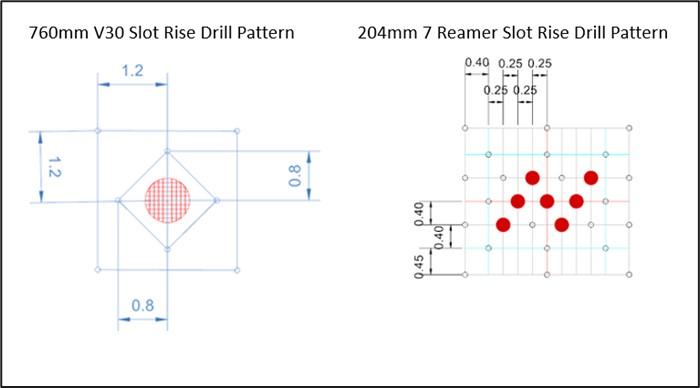

| Figure 13-19: Typical Hod Maden Slot Raise Drill Patterns |

13-23 |

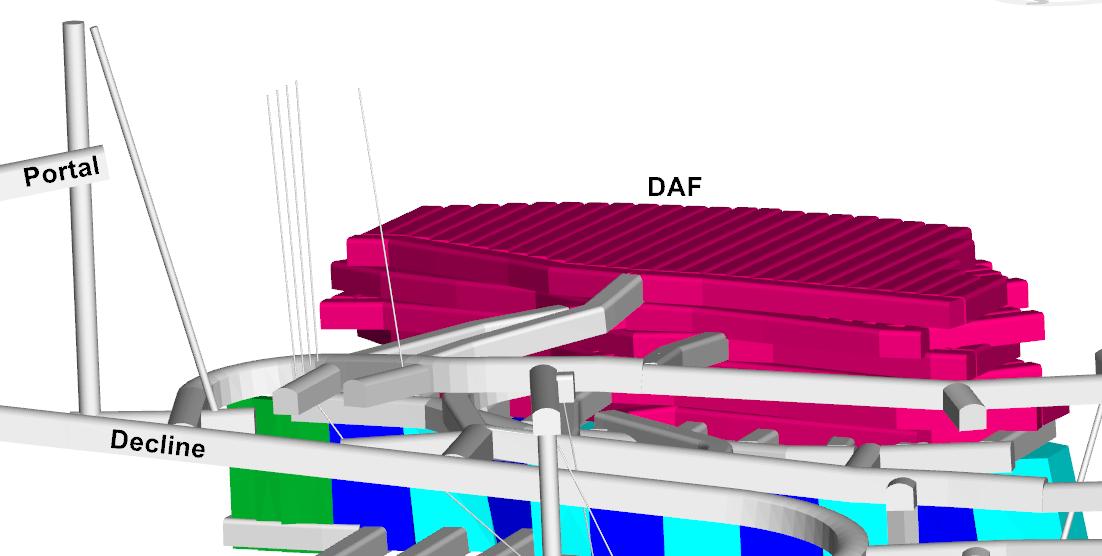

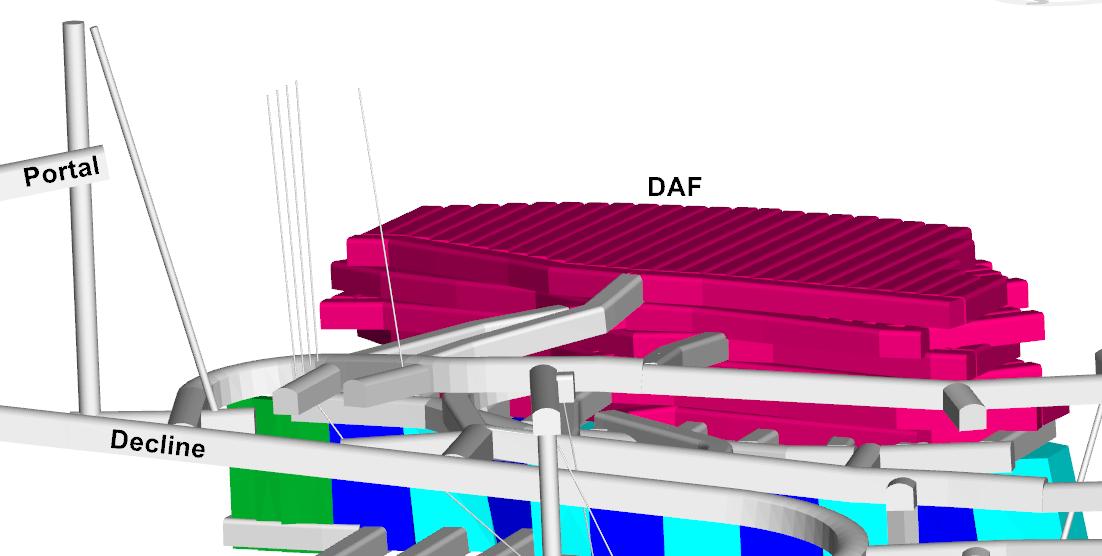

| Figure 13-20: 3D View Depicting Access to the Five DAF Levels |

13-24 |

| | xiii |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| Figure 13-21: Hod Maden Underground Mine Design - Looking East |

13-25 |

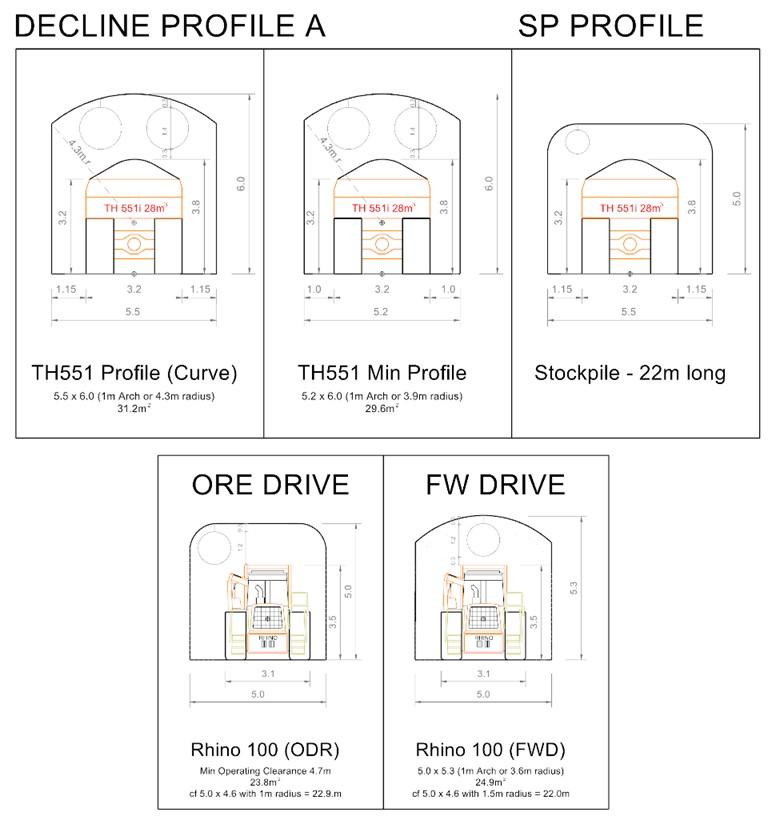

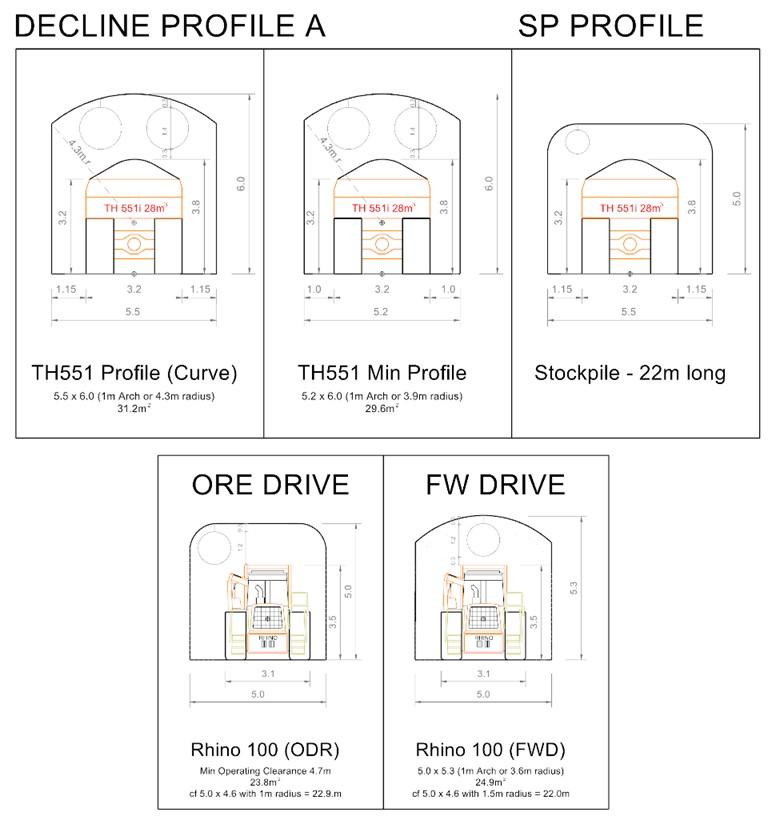

| Figure 13-22: Hod Maden Typical Decline and Level Drive Profiles |

13-26 |

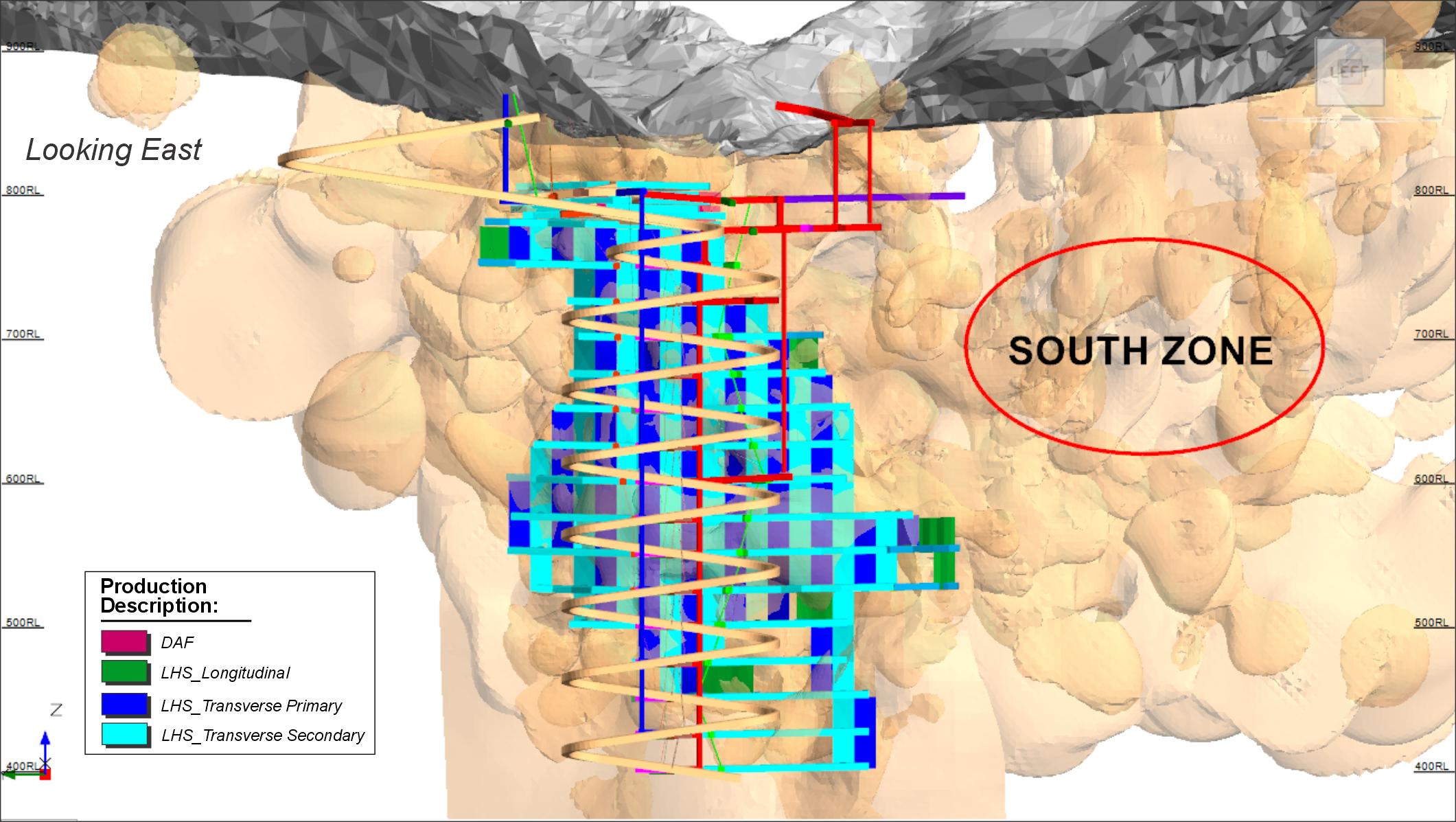

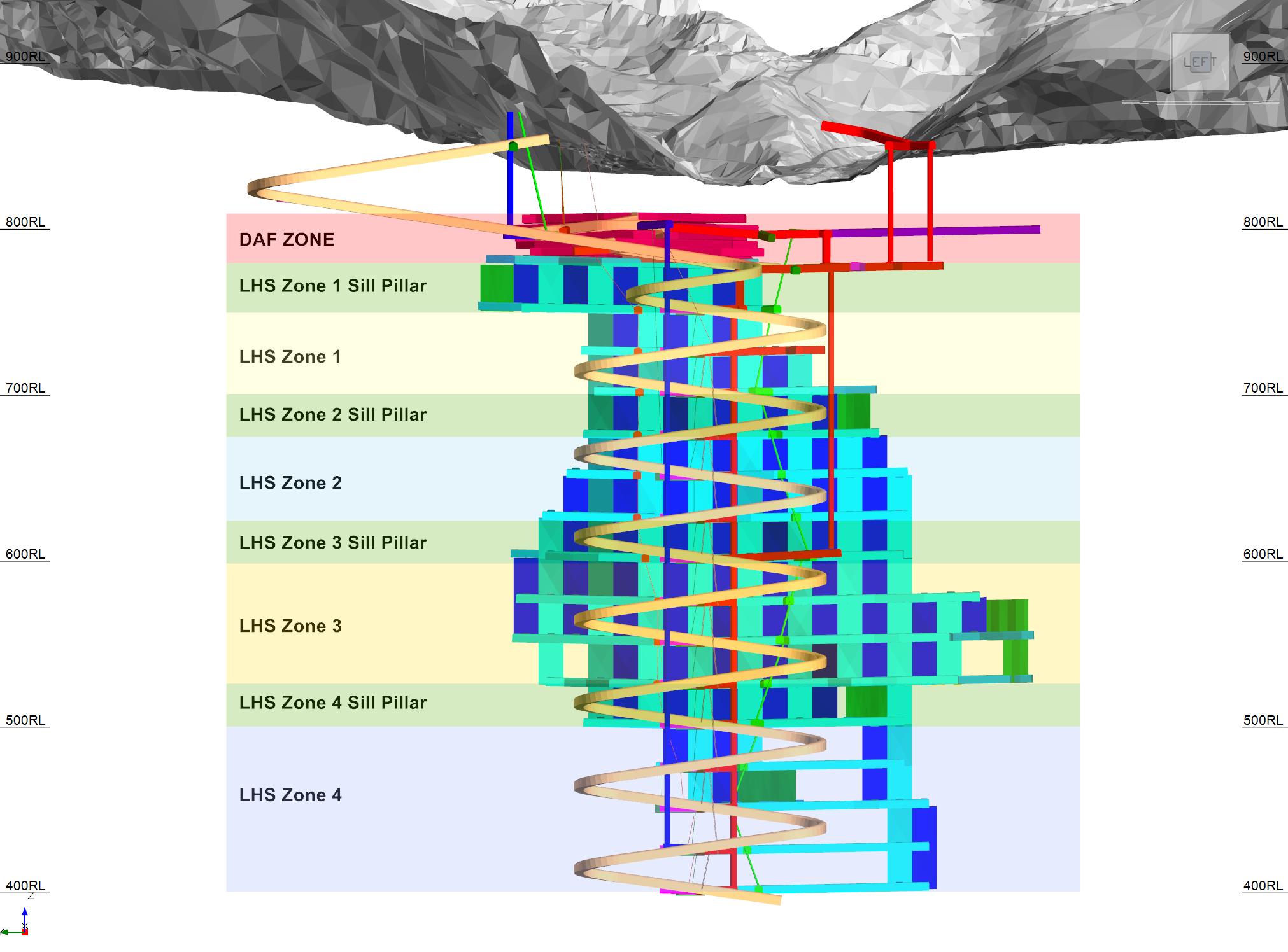

| Figure 13-23: Hod Maden Production Zones |

13-30 |

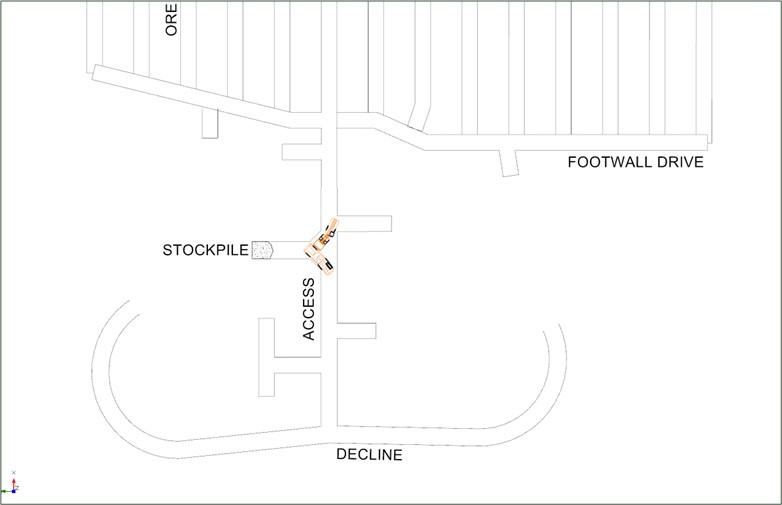

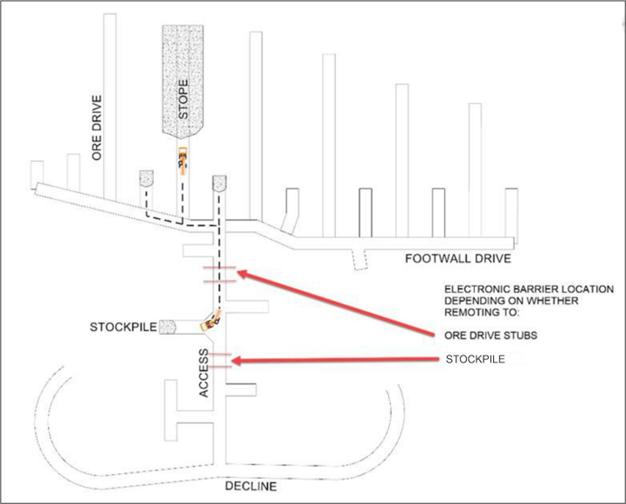

| Figure 13-24: DAF Development Sequence (Plan View) |

13-31 |

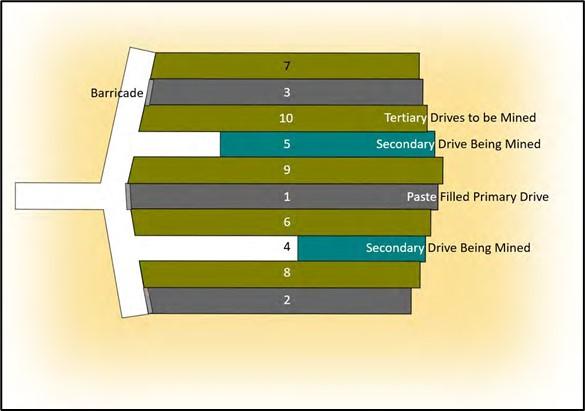

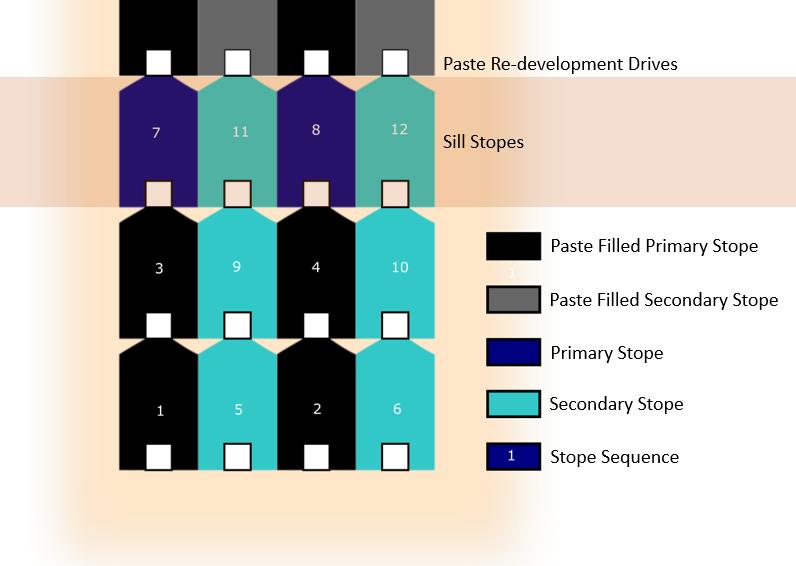

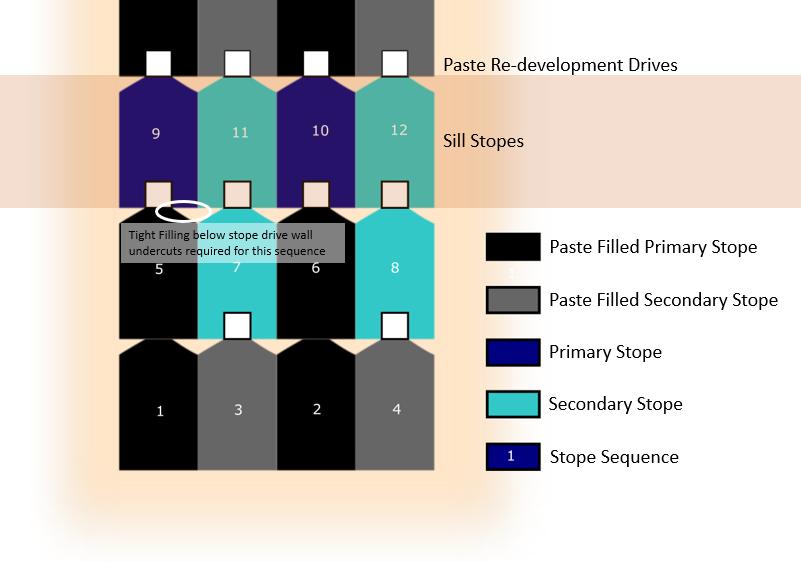

| Figure 13-25: Transverse LHS Level Layout |

13-32 |

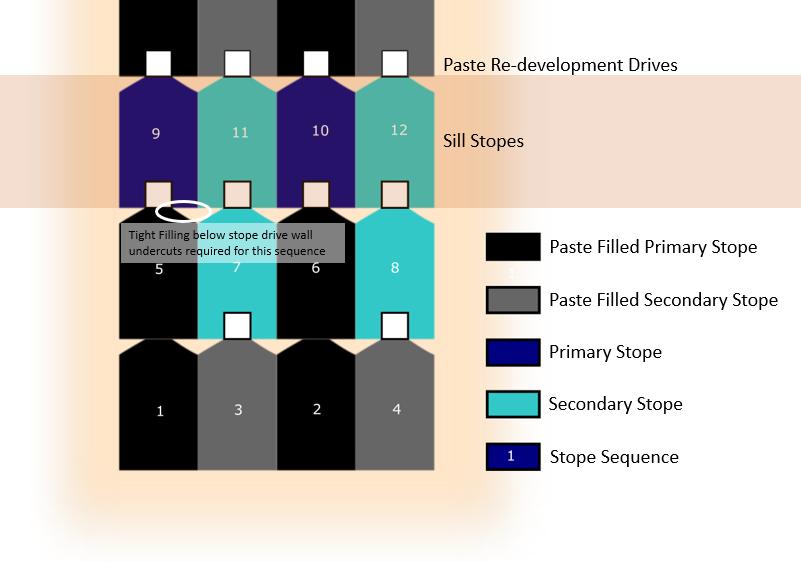

| Figure 13-26: Hod Maden Transverse Long Hole Stoping Preferred Sequence |

13-33 |

| Figure 13-27: Hod Maden Transverse Stoping Alternative Sequence |

13-34 |

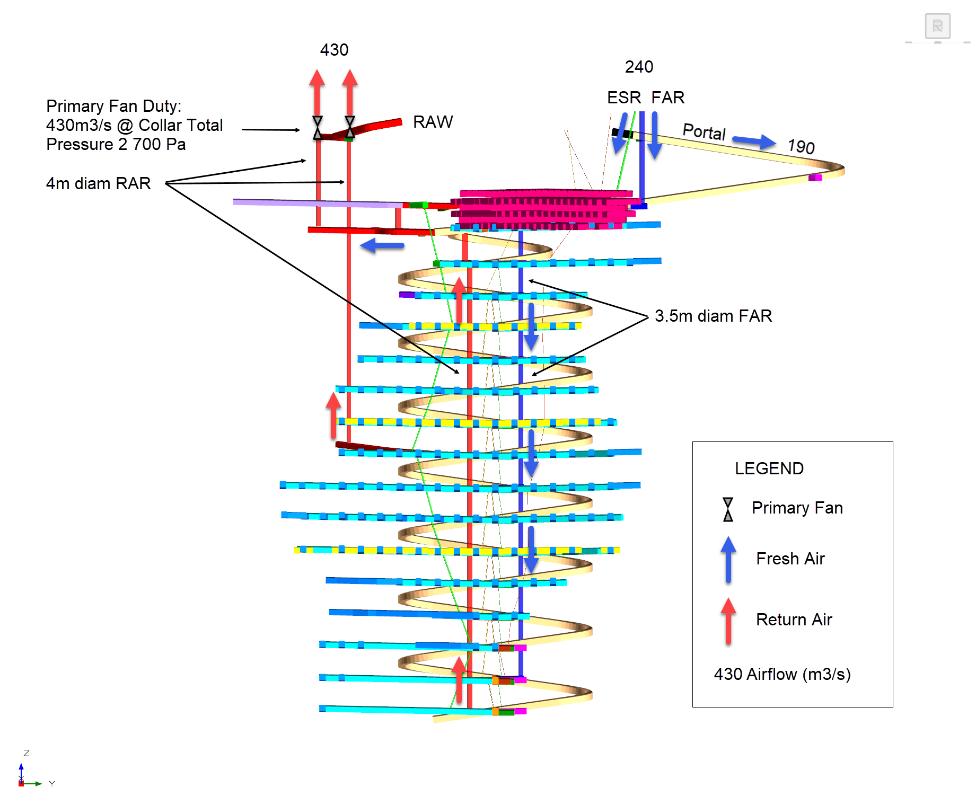

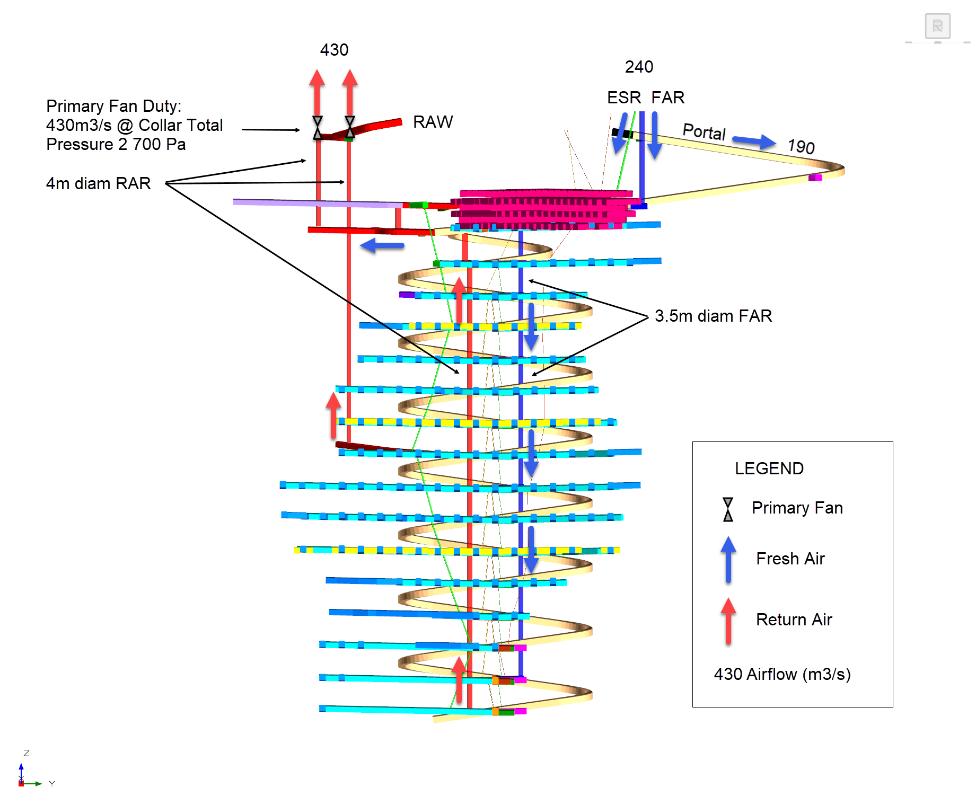

| Figure 13-28: Primary Ventilation System Overall Strategy |

13-37 |

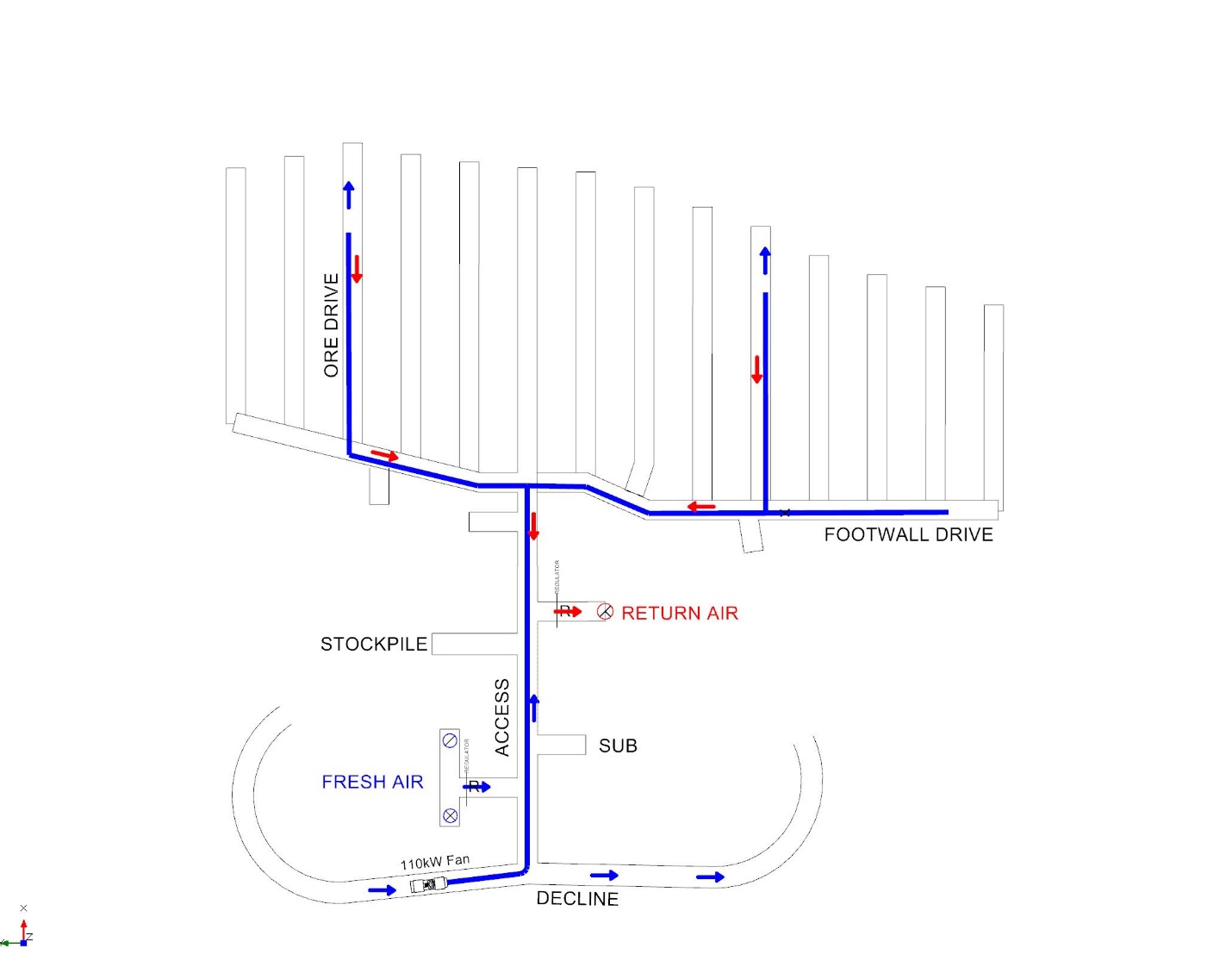

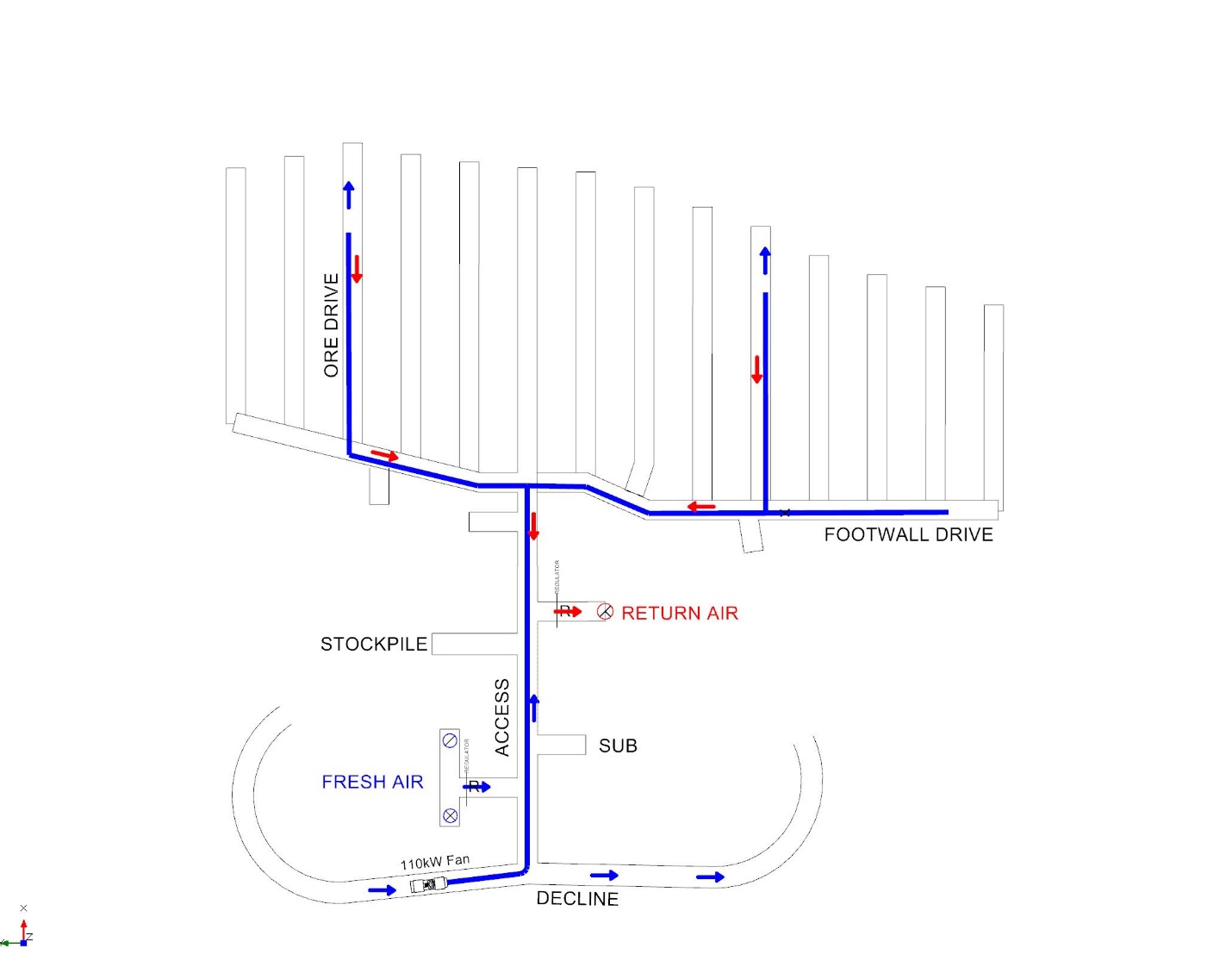

| Figure 13-29: Typical Level Ventilation – Return Air Raise Off-Access Drive - LHS |

13-38 |

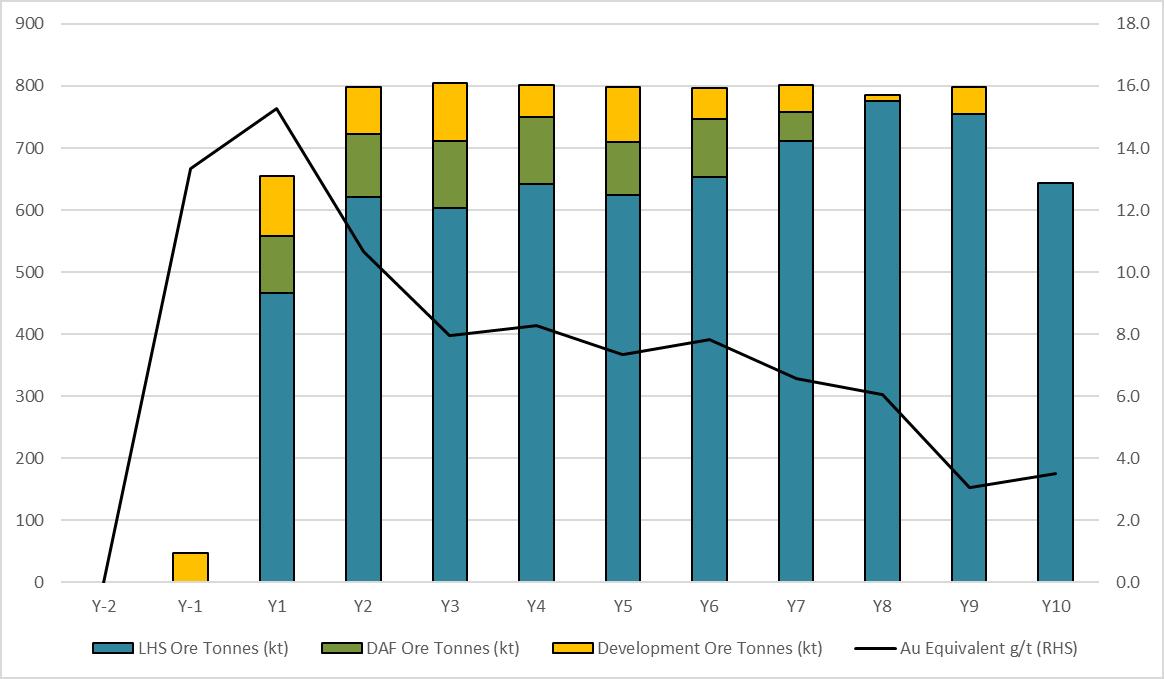

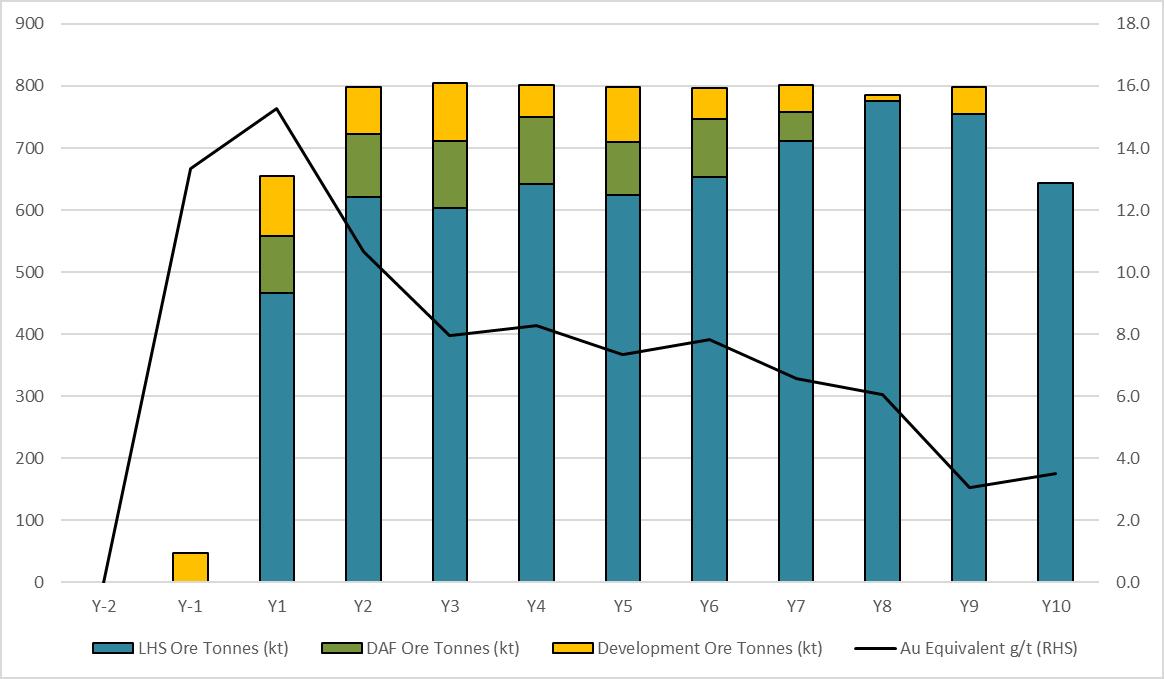

| Figure 13-30: Hod Maden LOM Production Profile |

13-44 |

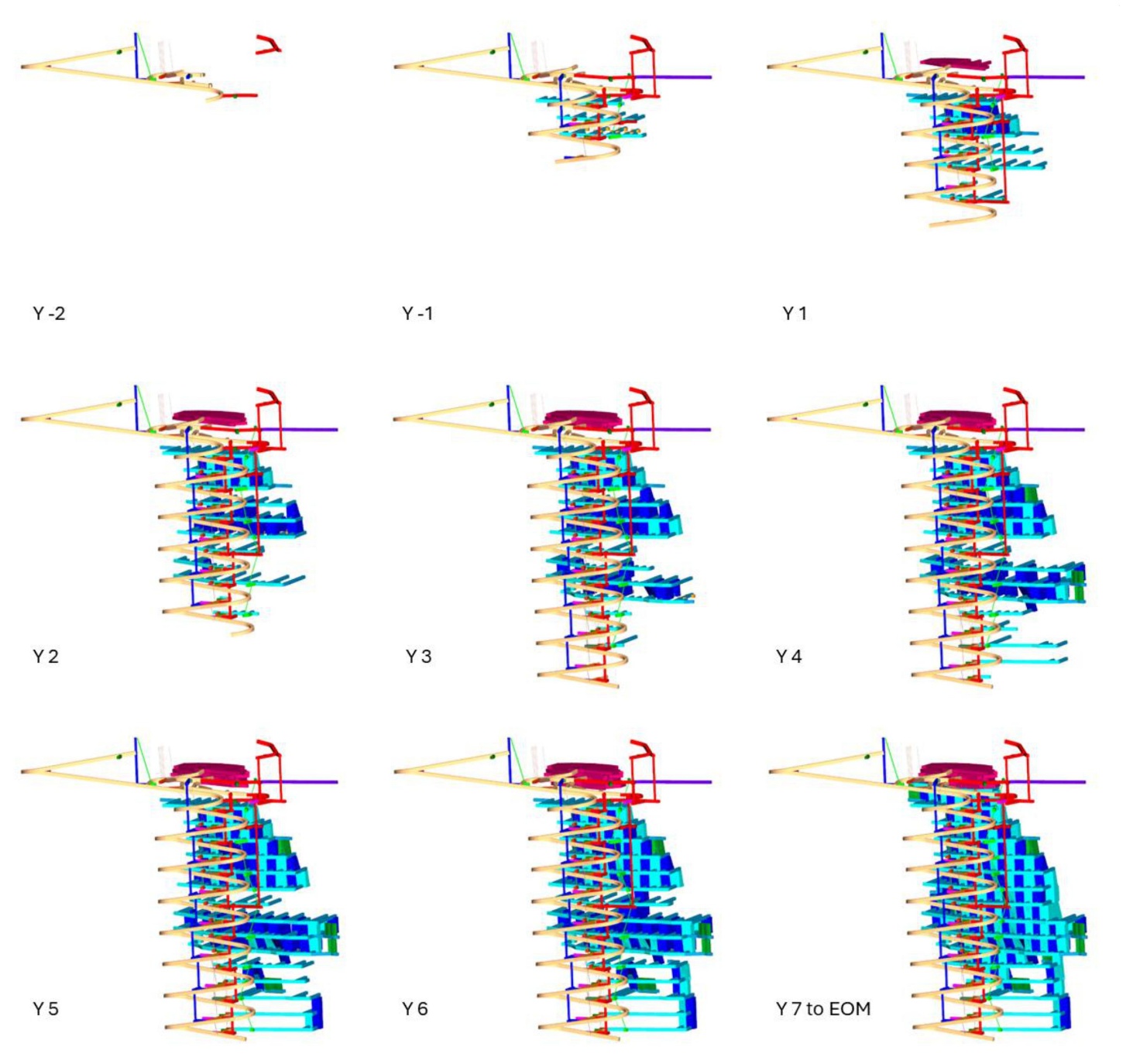

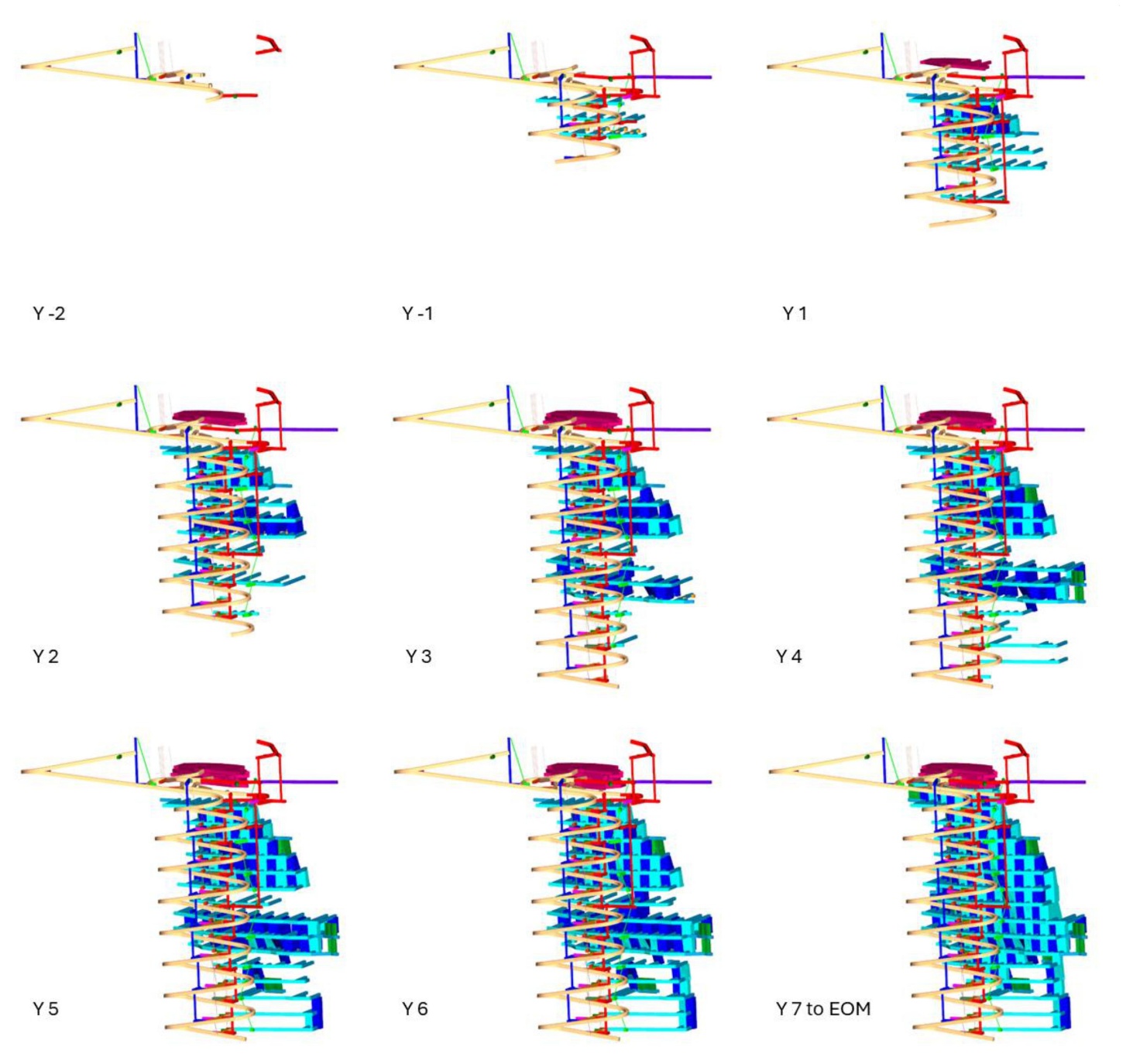

| Figure 13-31: Hod Maden LOM Illustrative Development Schedule - Looking East |

13-47 |

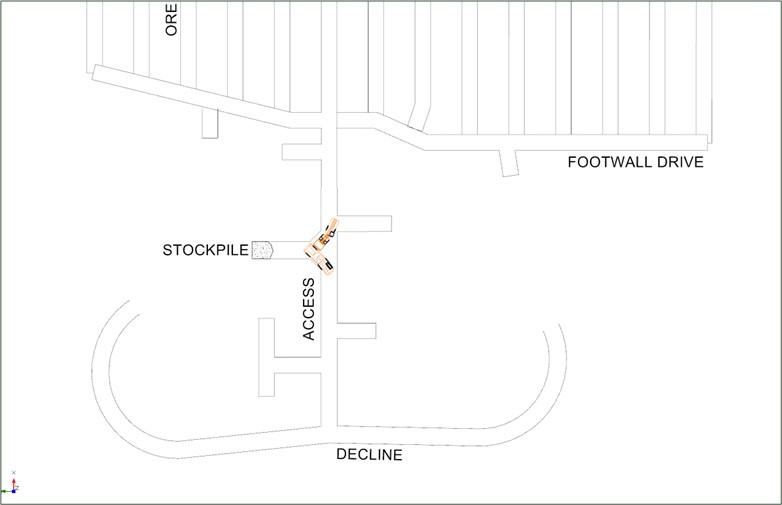

| Figure 13-32: Hod Maden Typical Truck Loading Area Layout |

13-52 |

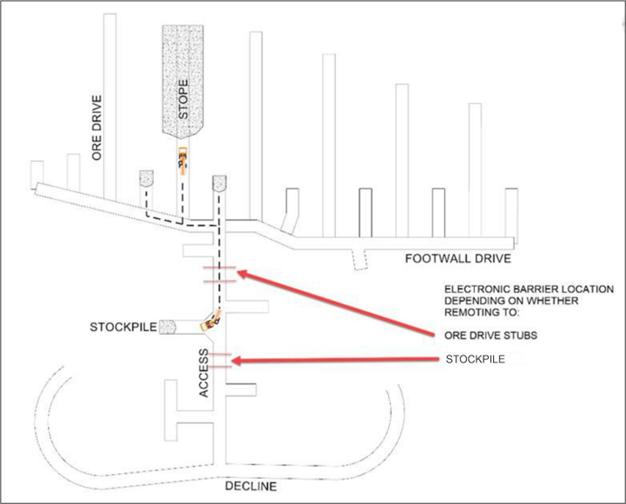

| Figure 13-33: Tele-remote Loading Arrangement to Ore Drive Stub or Stockpile |

13-53 |

| Figure 13-34: Mine Main Inter-Level Reticulation Layout |

13-56 |

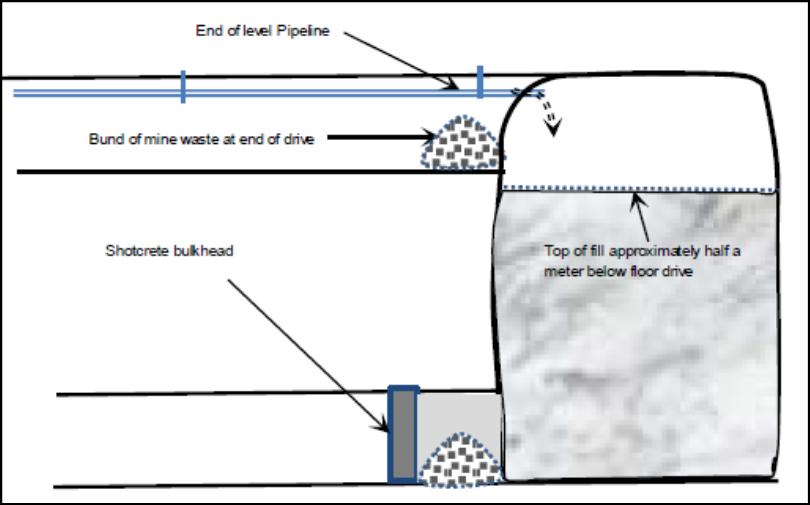

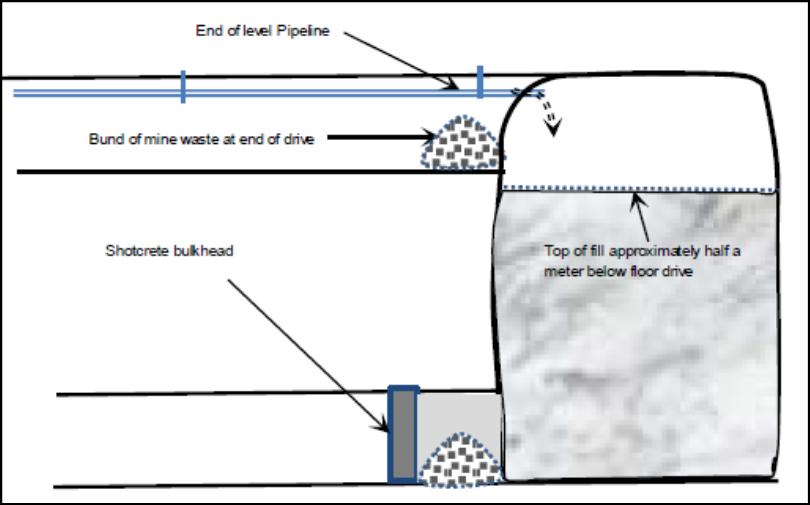

| Figure 13-35: Standard End of Line Fill Pour Set-up |

13-57 |

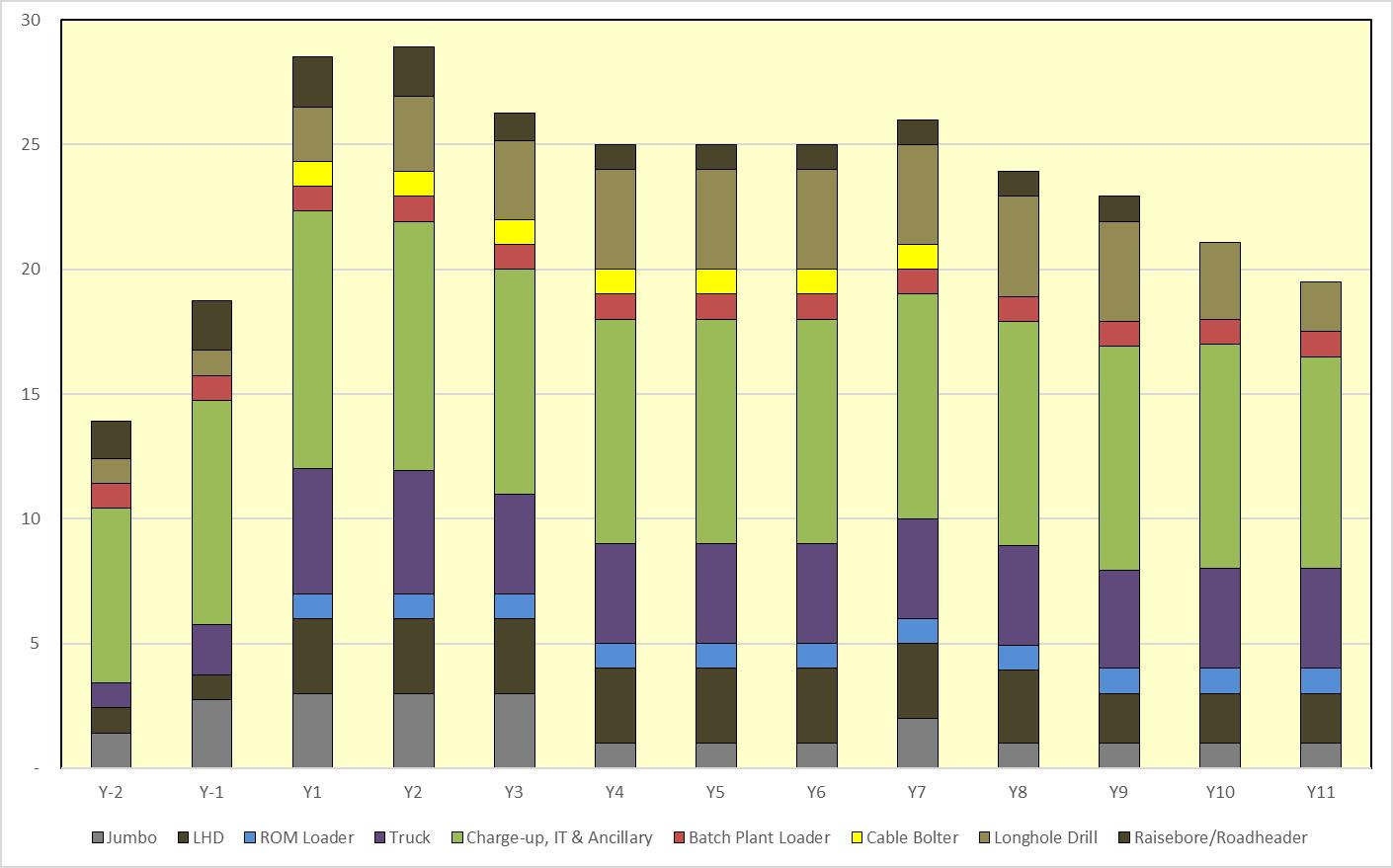

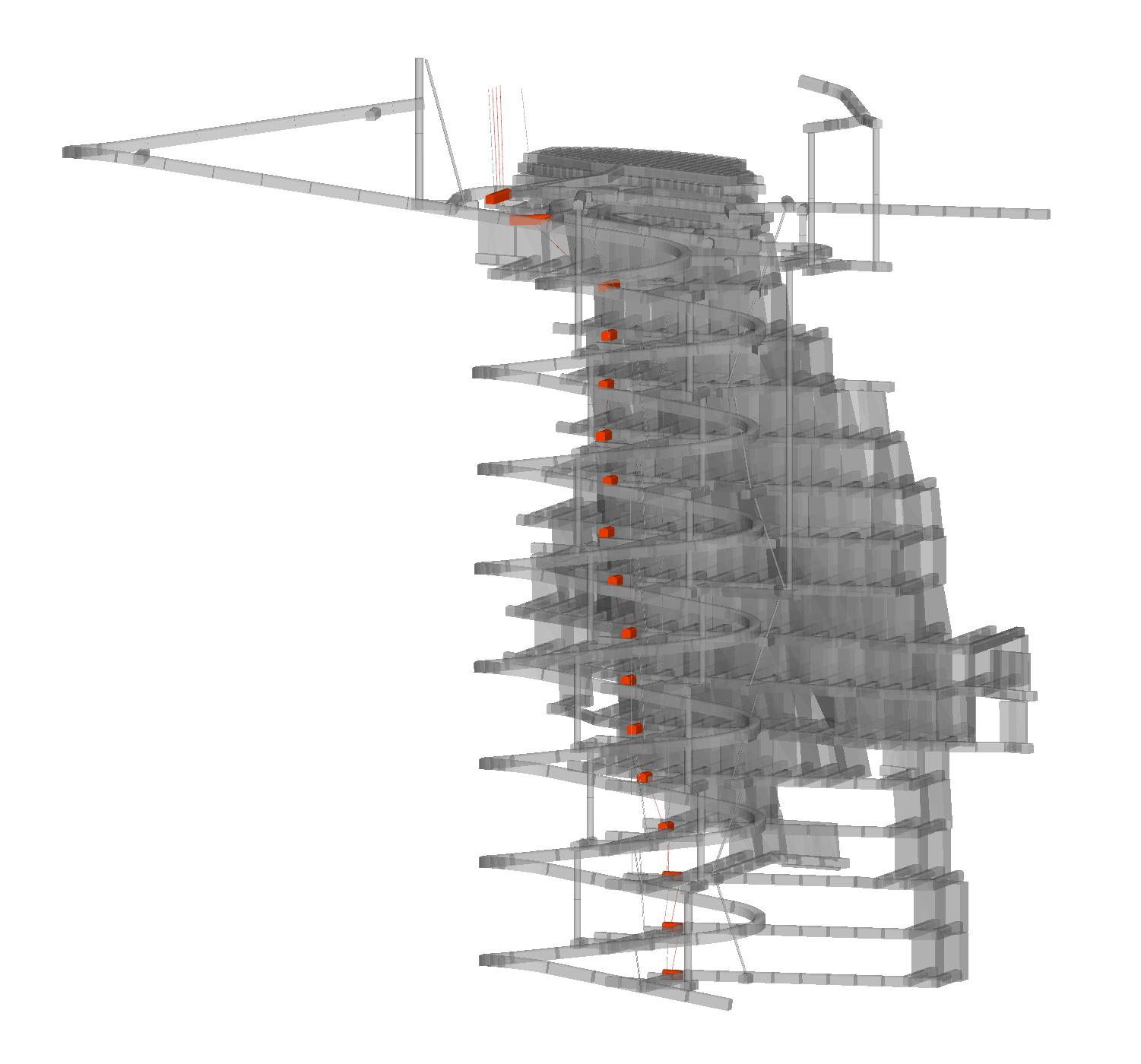

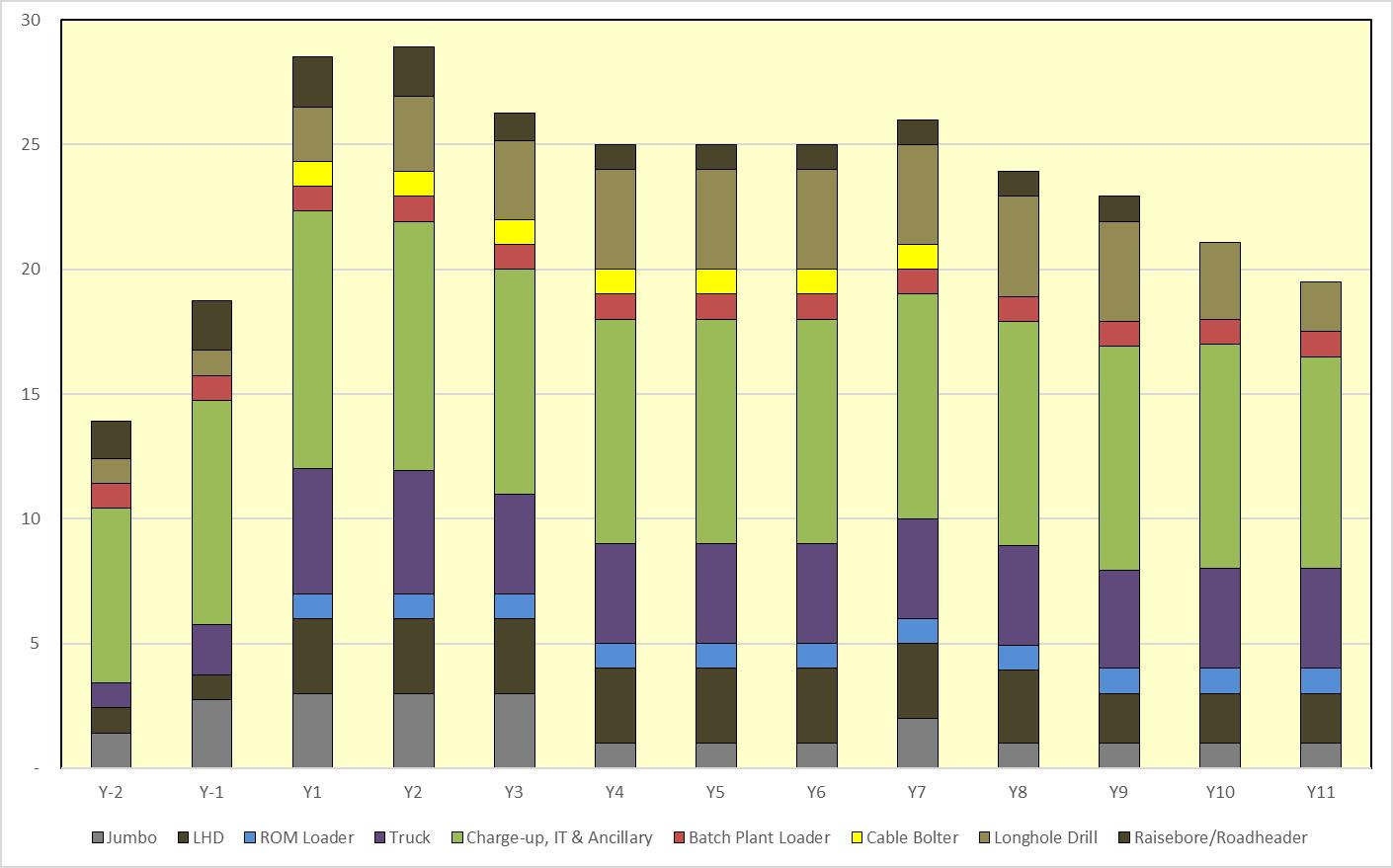

| Figure 13-36: Life of Mine Mobile Equipment Fleet - LHS |

13-60 |

| Figure 13-37: Underground Personnel Mining Roster |

13-63 |

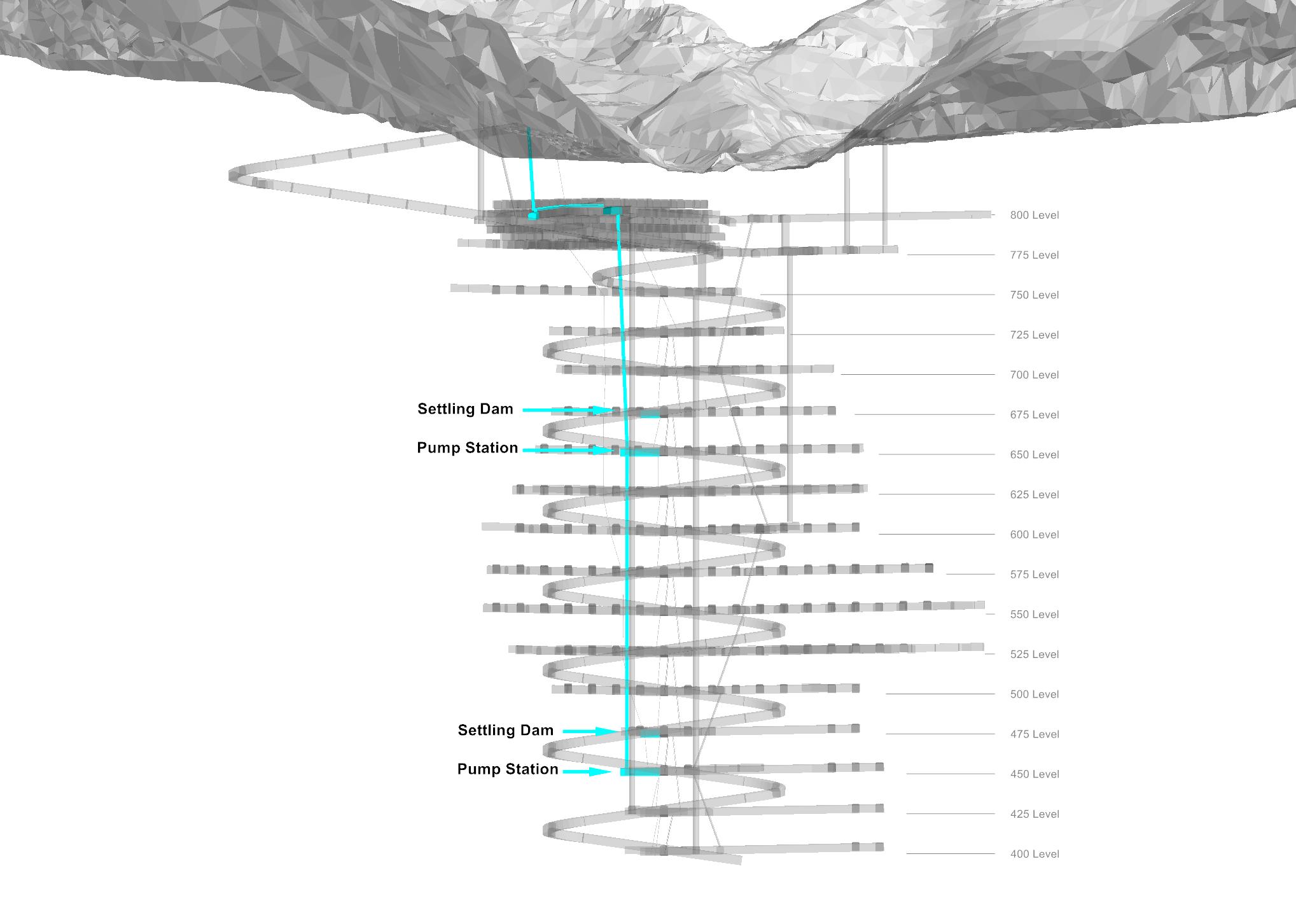

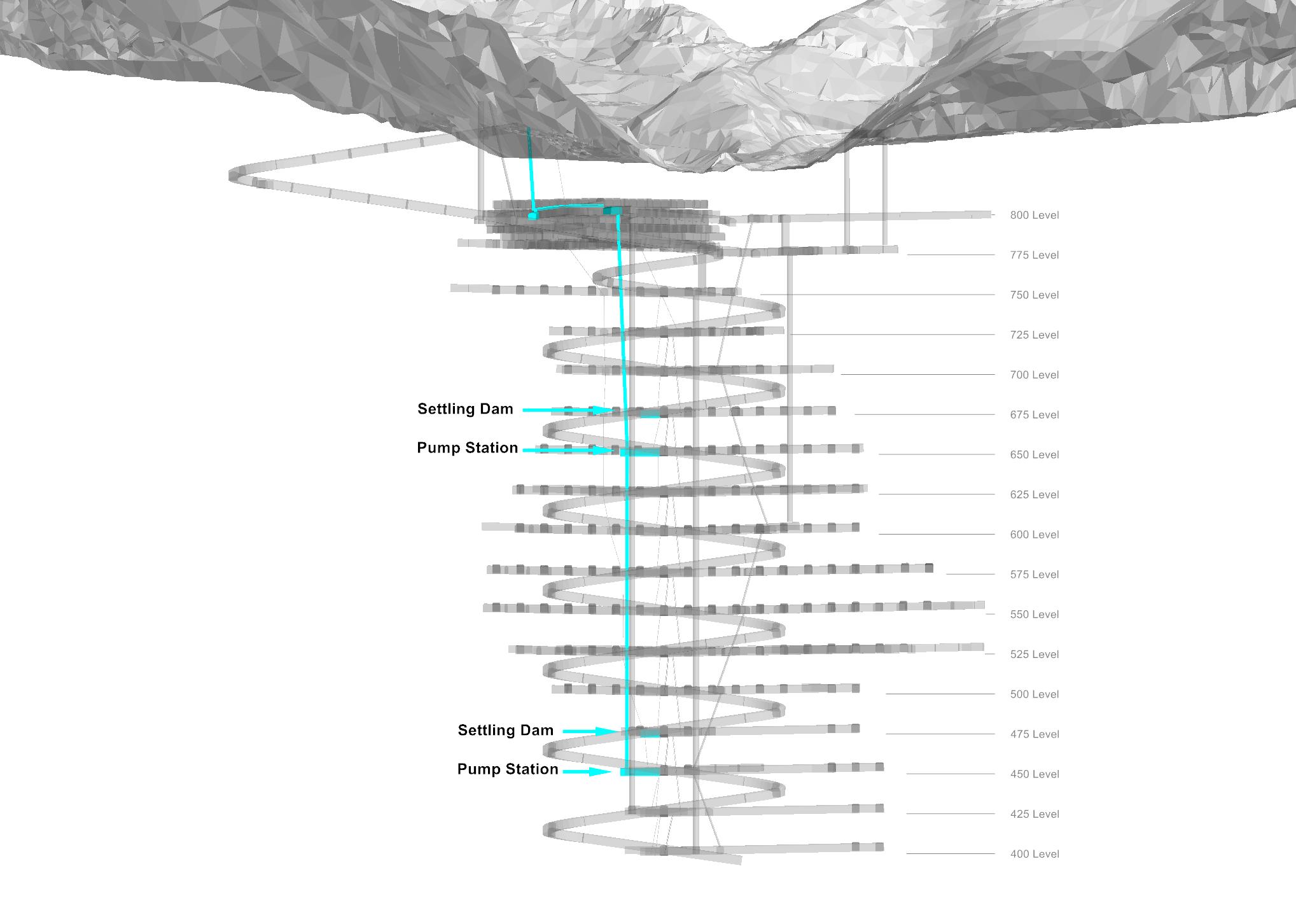

| Figure 13-38: Dewatering System |

13-64 |

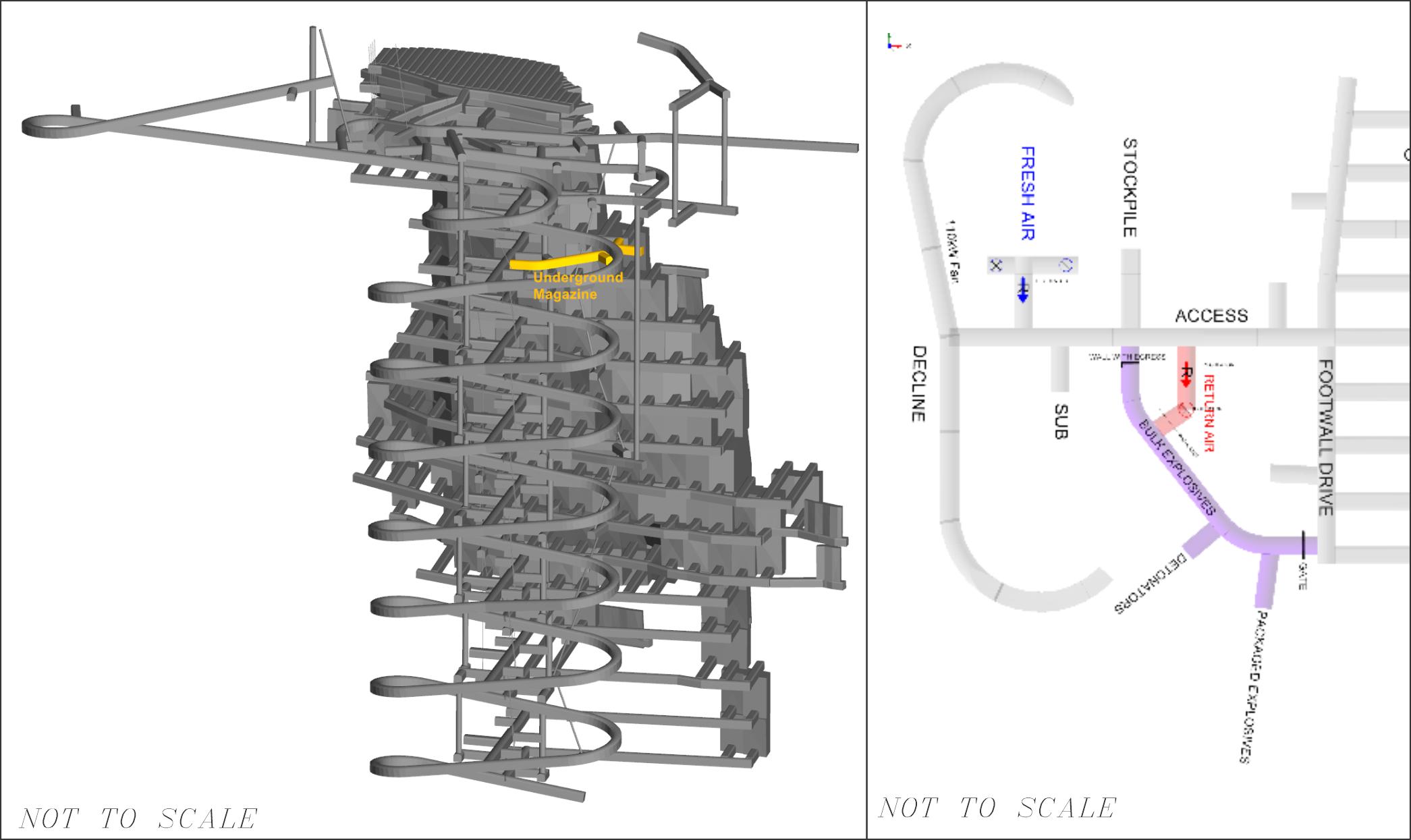

| Figure 13-39: 725 Level Explosives Magazine |

13-65 |

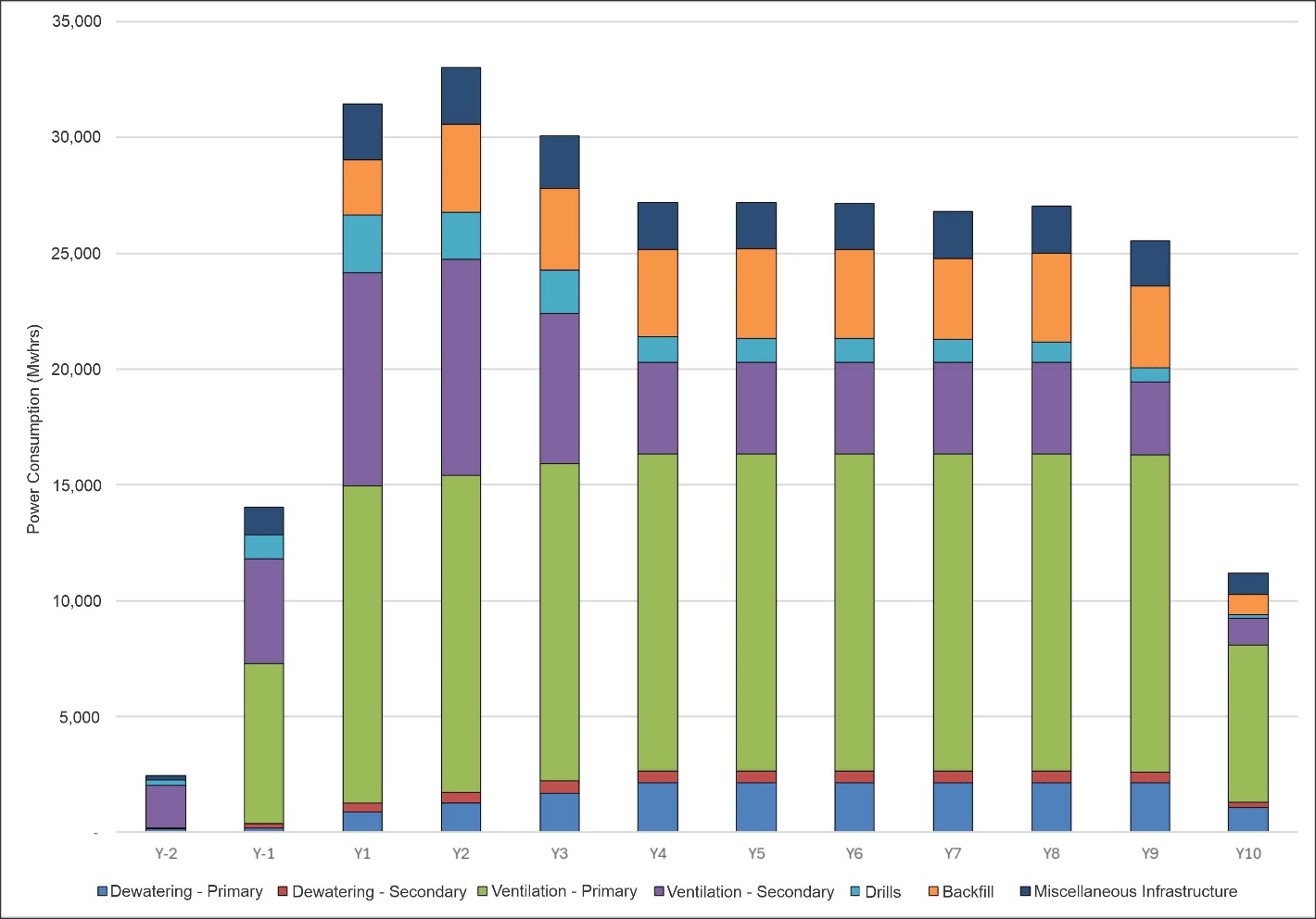

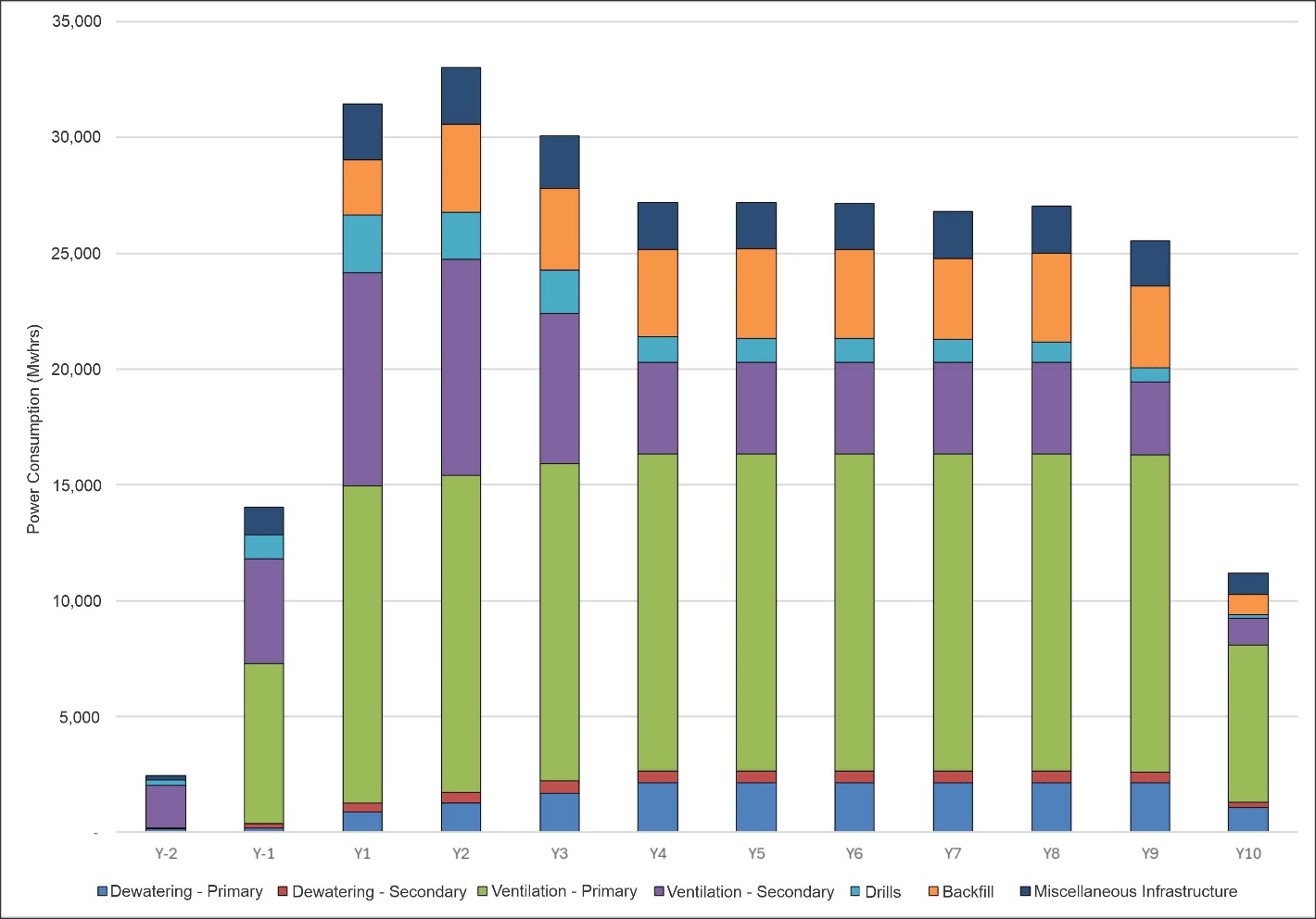

| Figure 13-40: Yearly Underground Electrical Power Requirements |

13-67 |

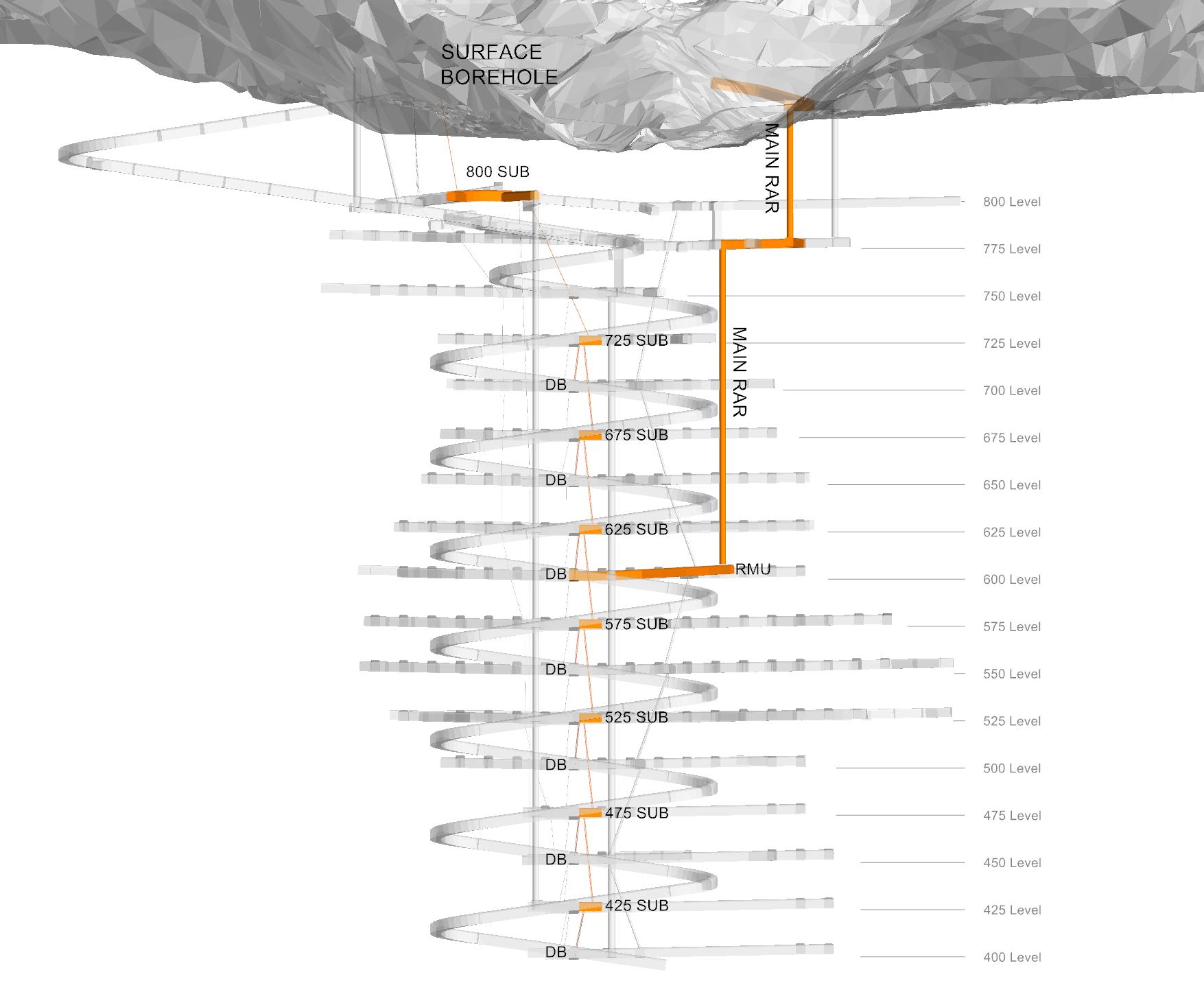

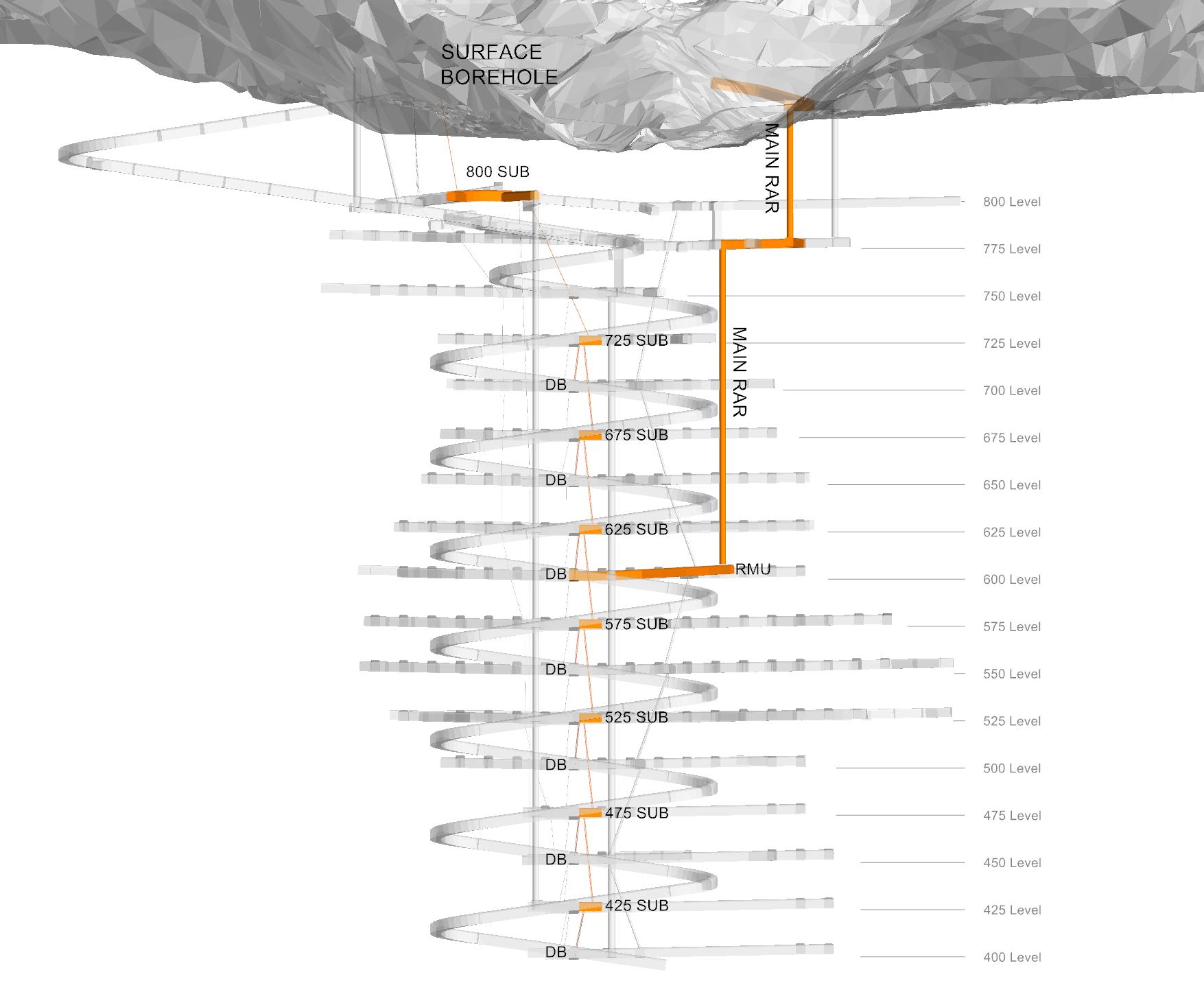

| Figure 13-41: Underground Electrical Infrastructure - Section View Looking Northeast |

13-68 |

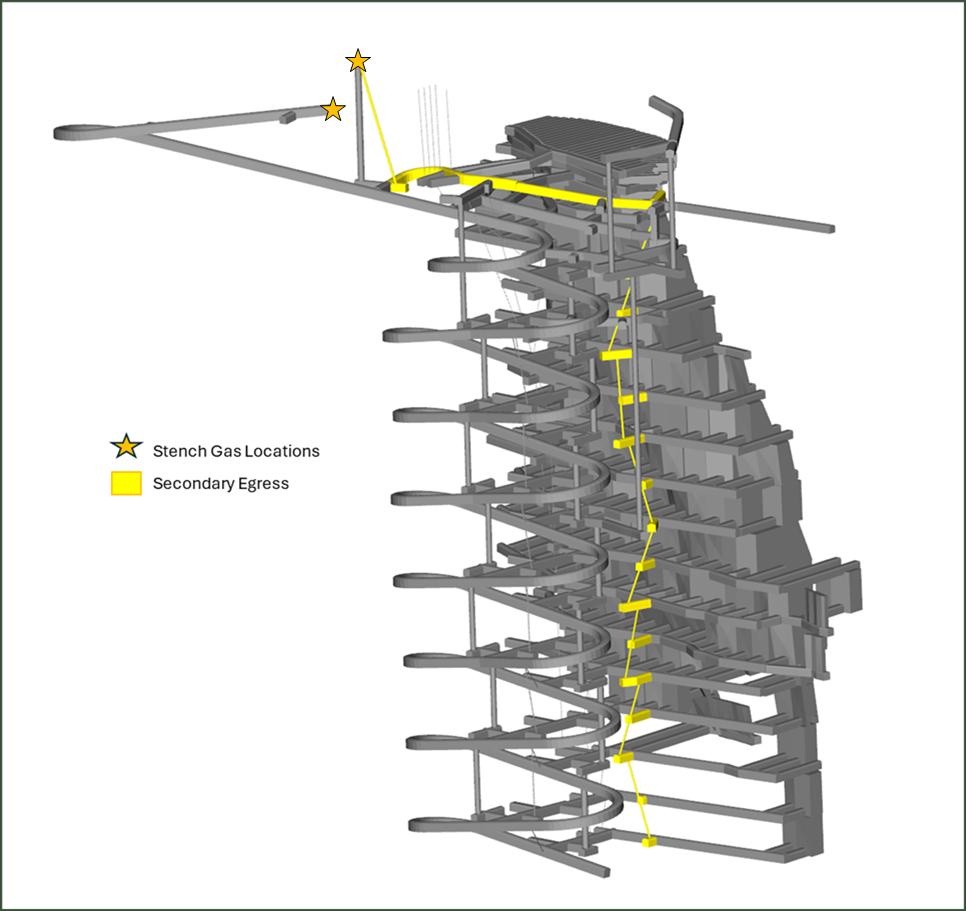

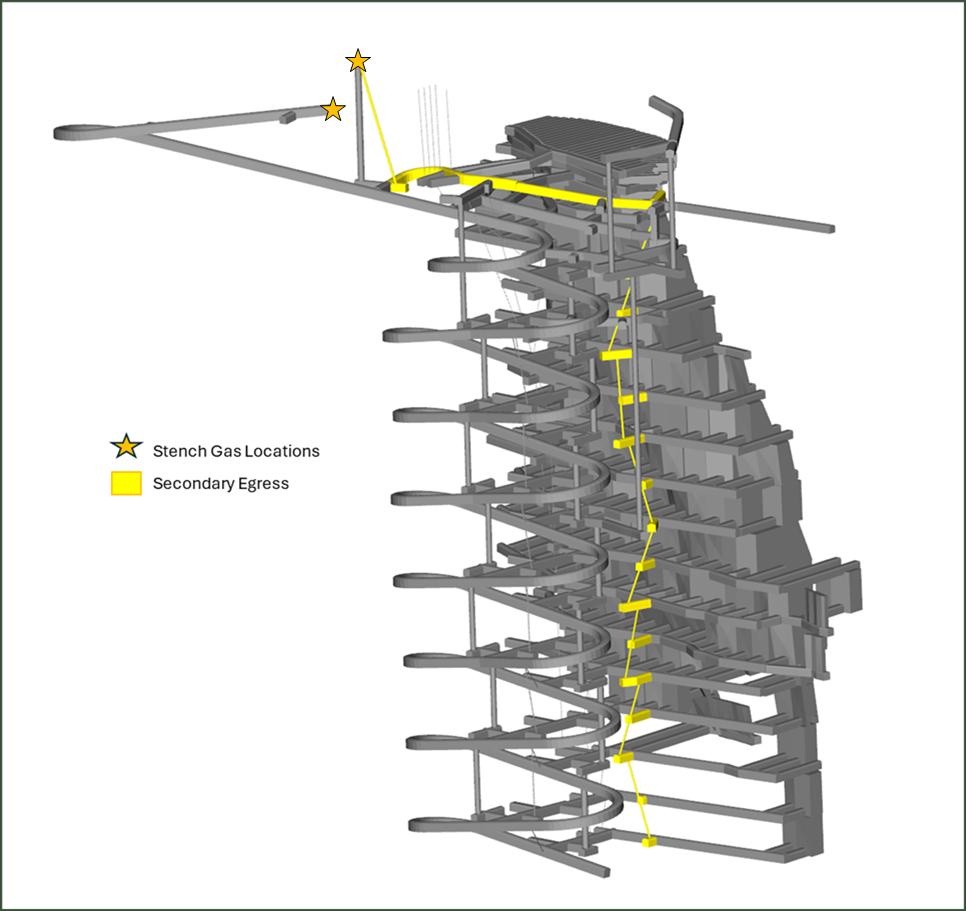

| Figure 13-42: Secondary Egress and Fixed Refuge Chamber Locations – 3D Schematic Looking Northeast |

13-70 |

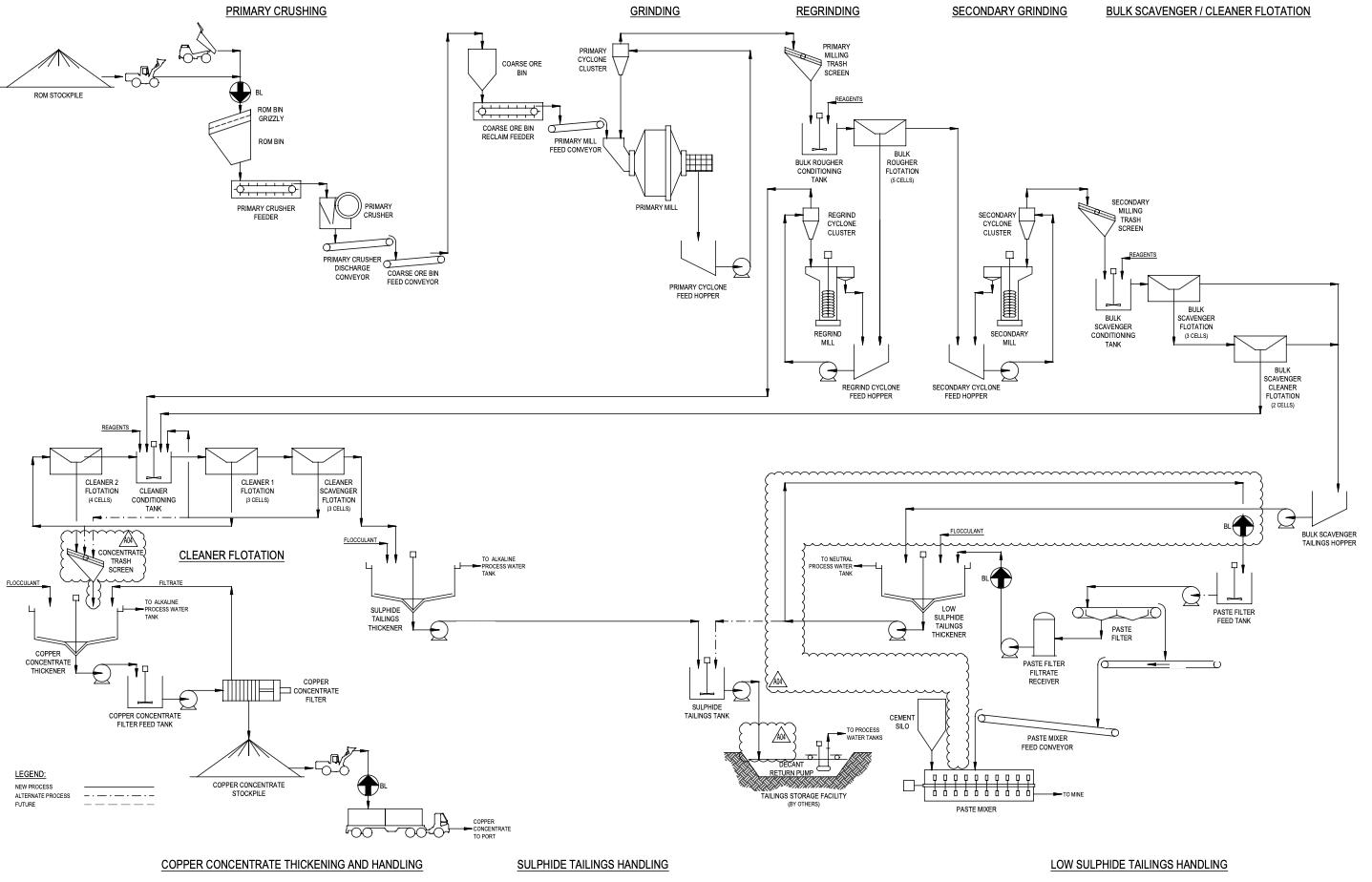

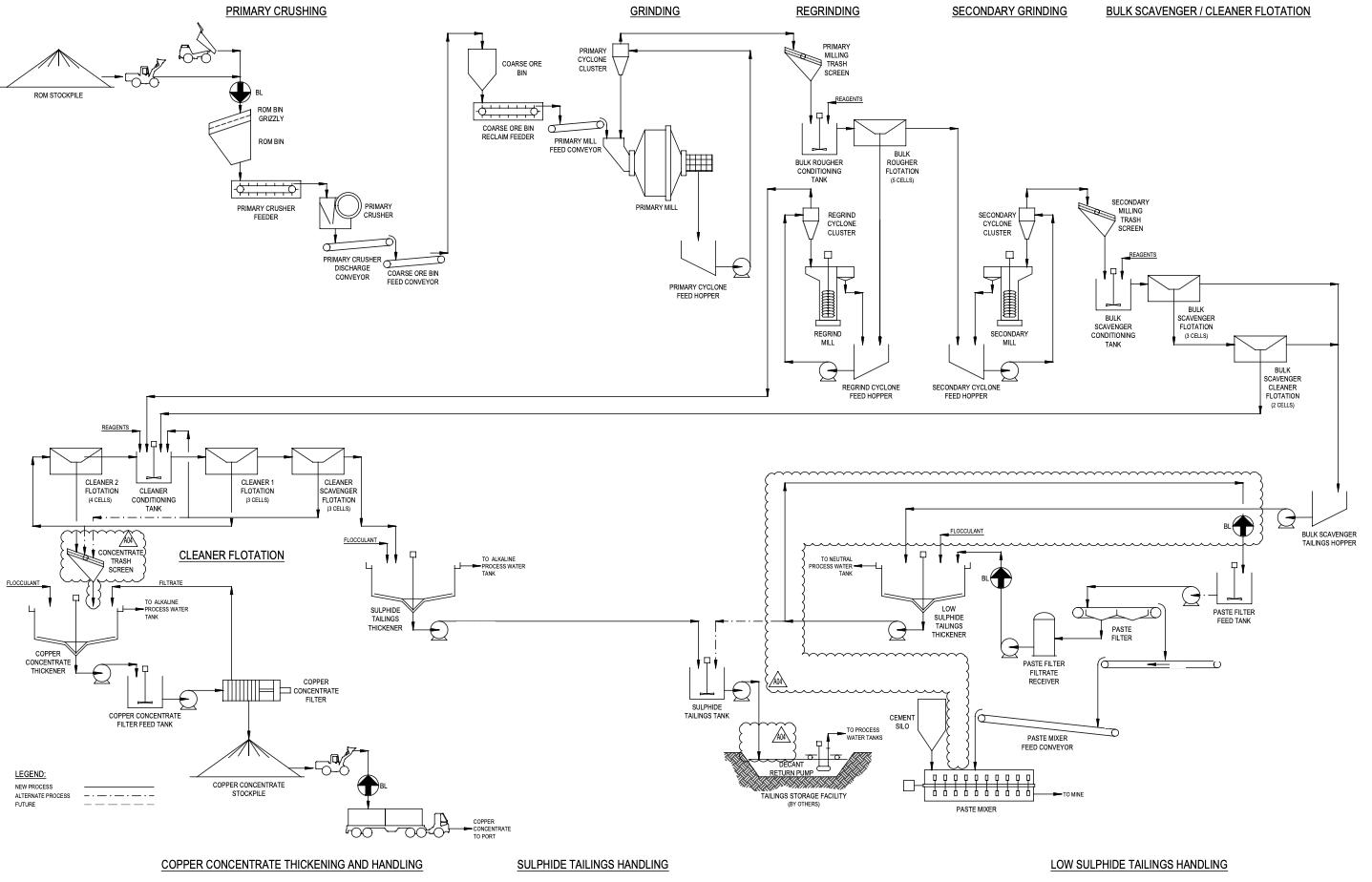

| Figure 14-1: Process Flow Sheet |

14-2 |

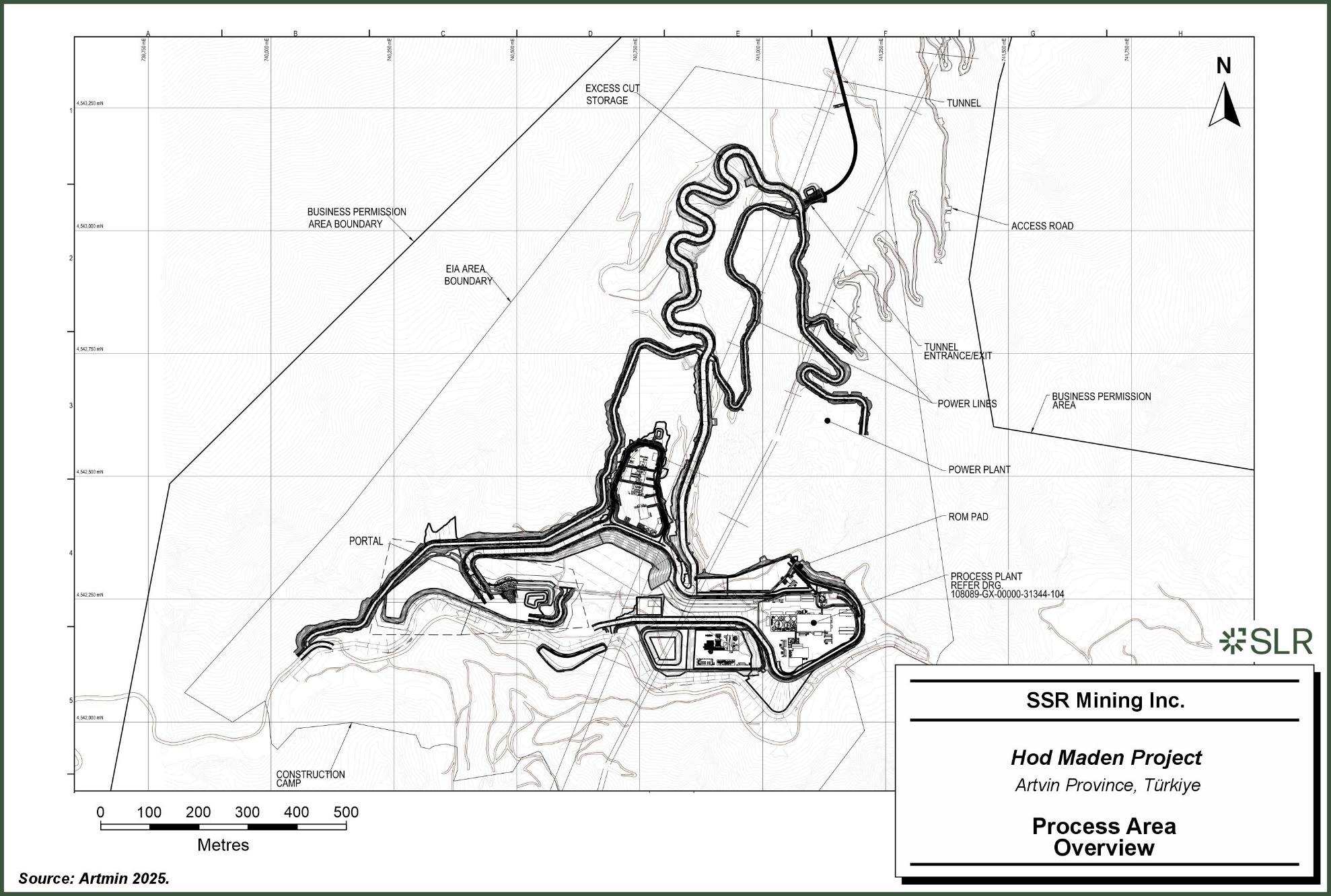

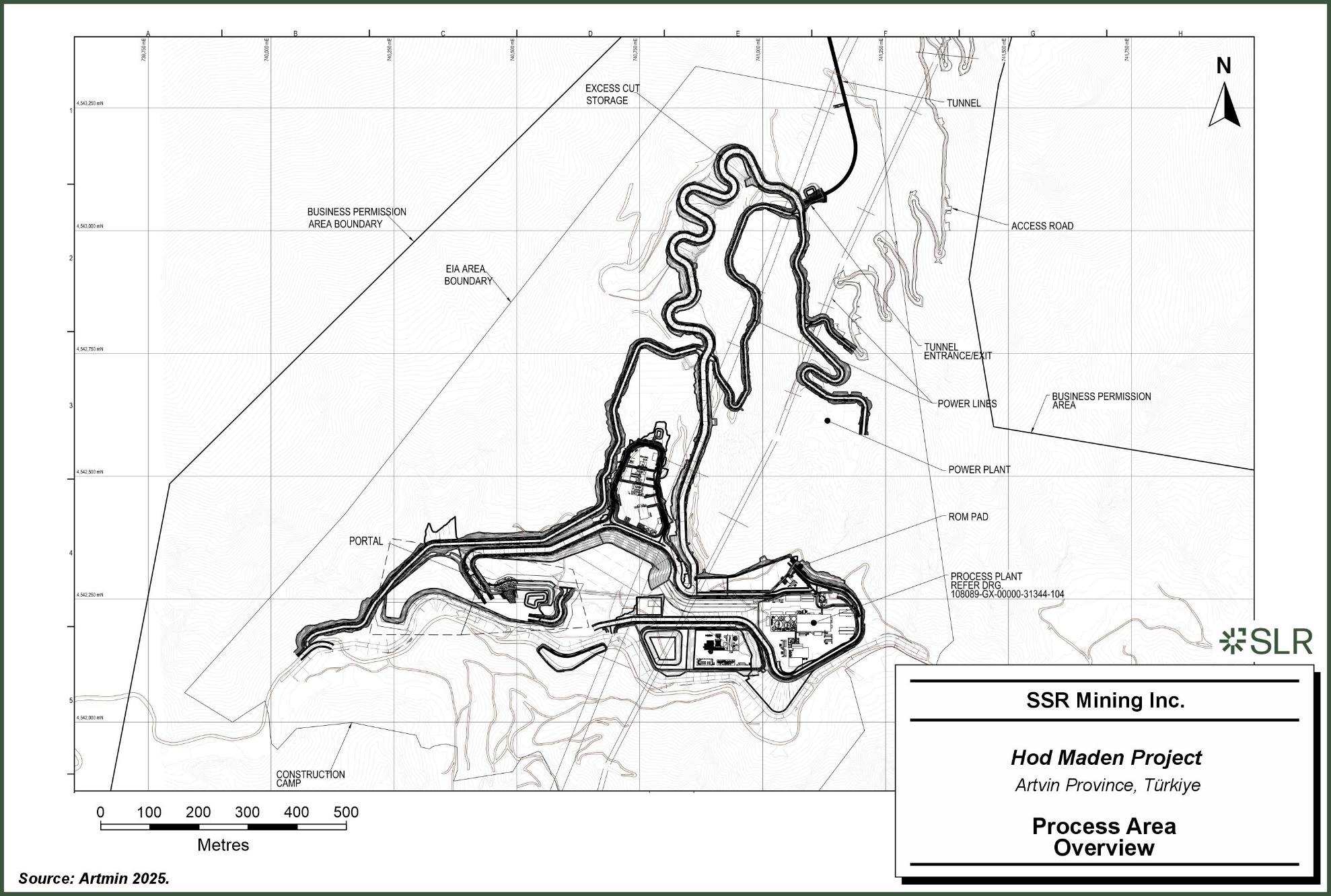

| Figure 14-2: Process Area – Overview |

14-3 |

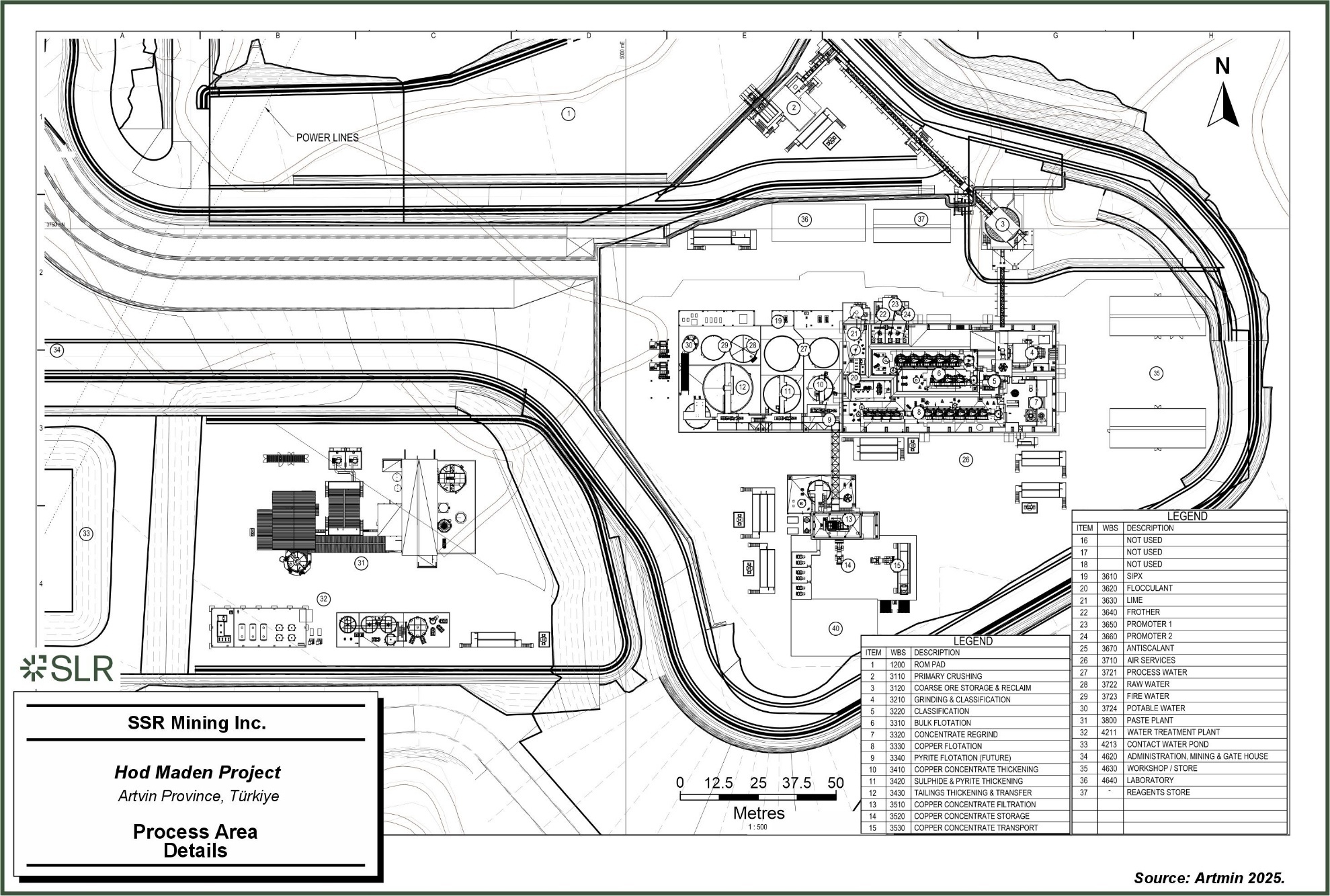

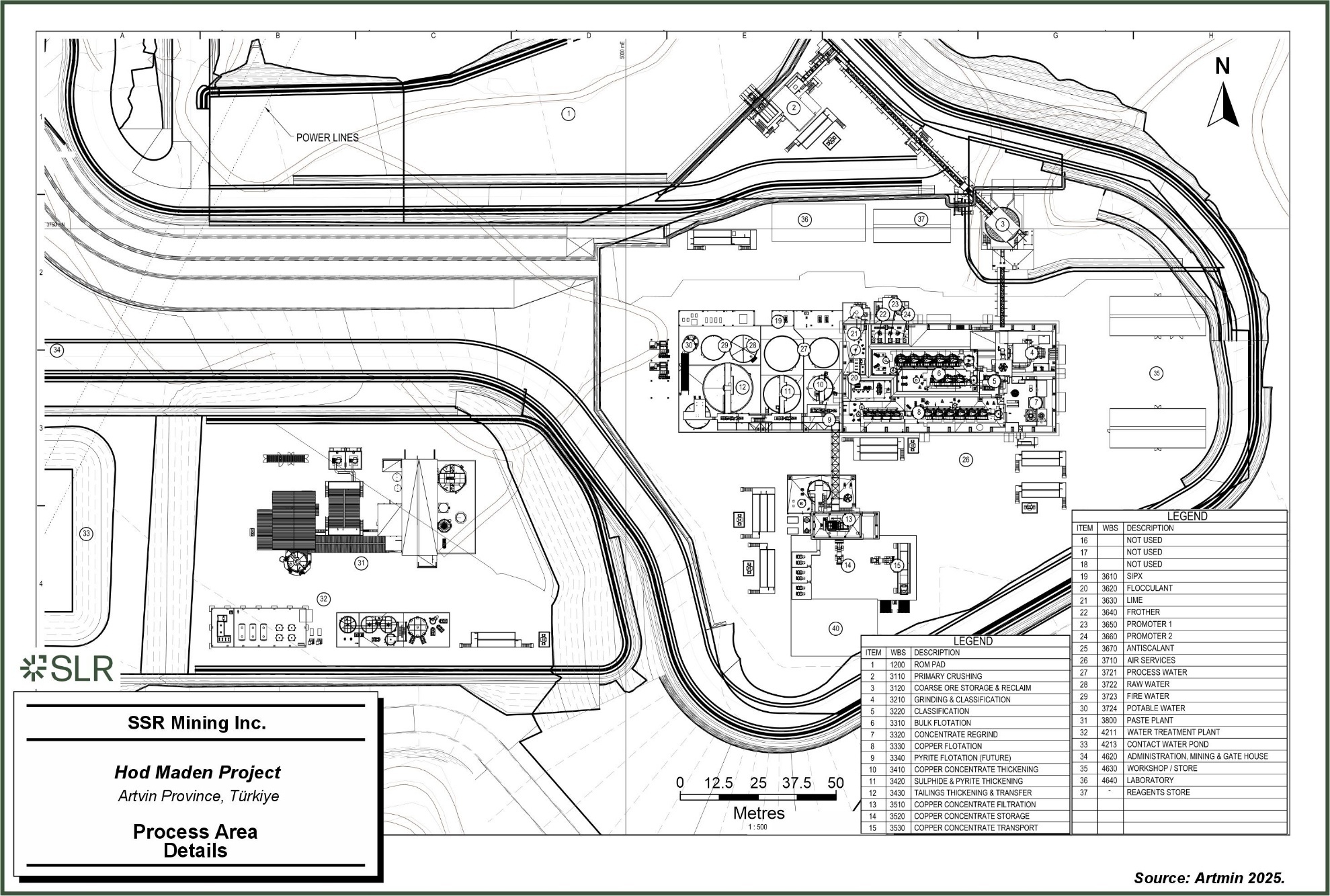

| Figure 14-3: Process Area – Details |

14-4 |

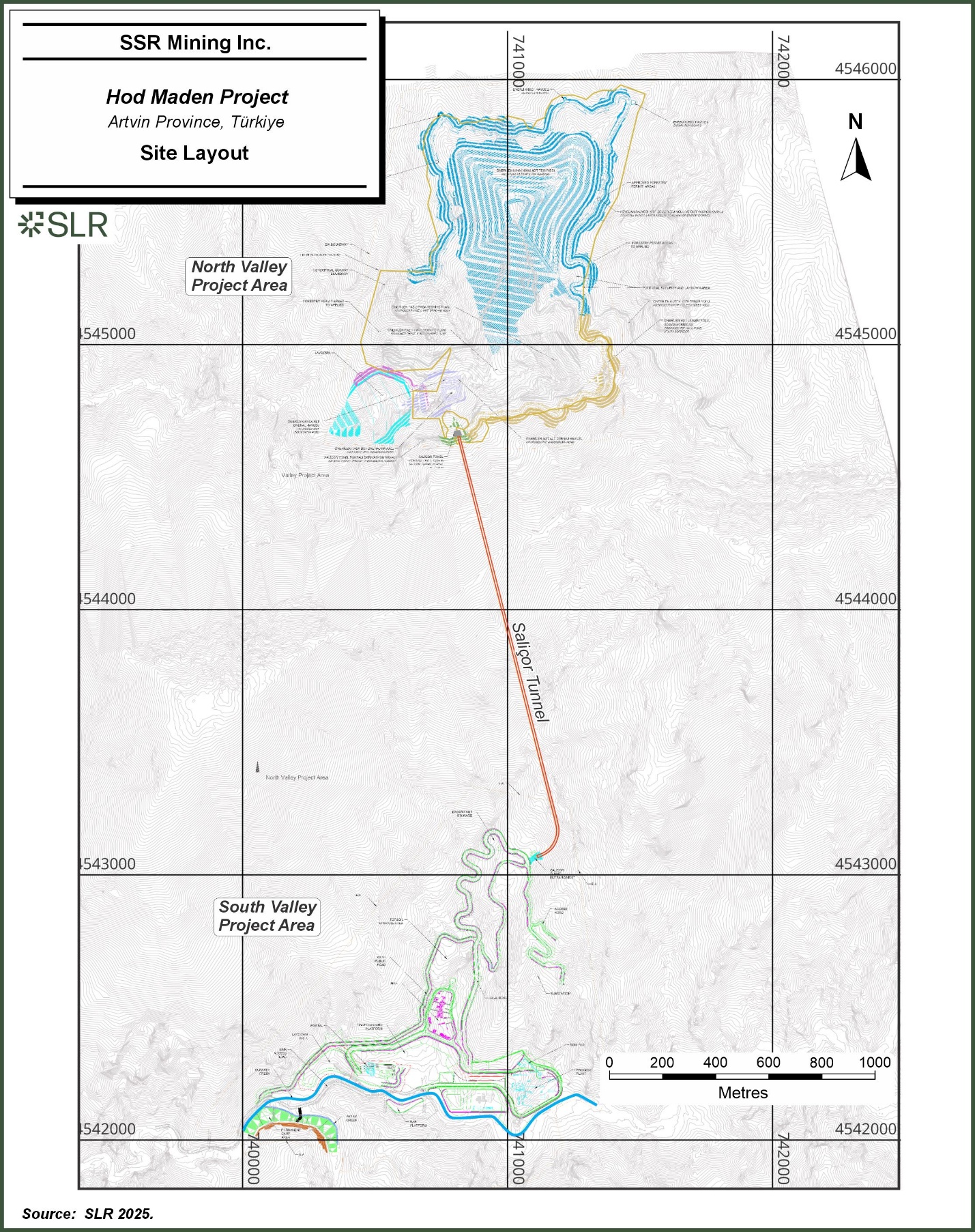

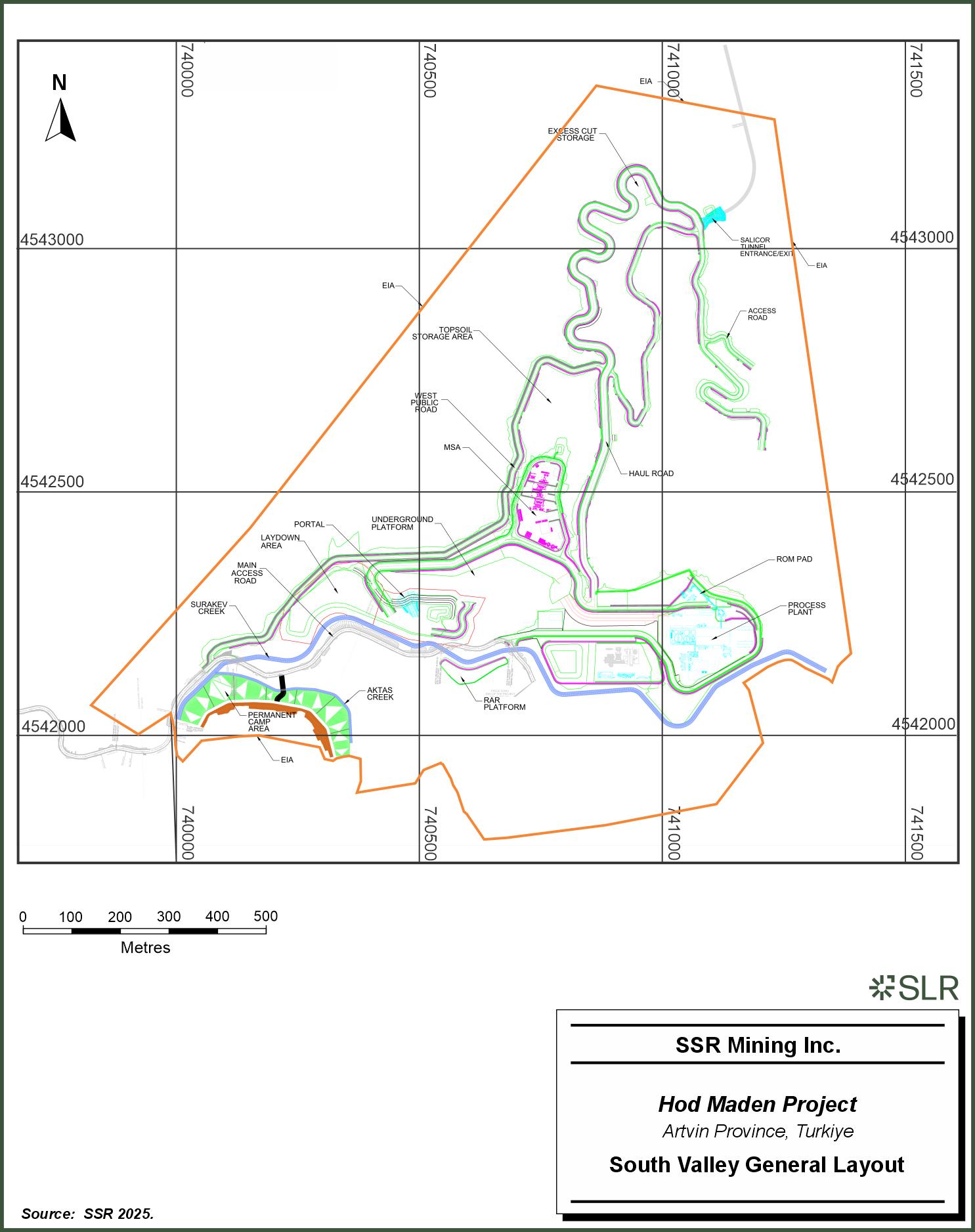

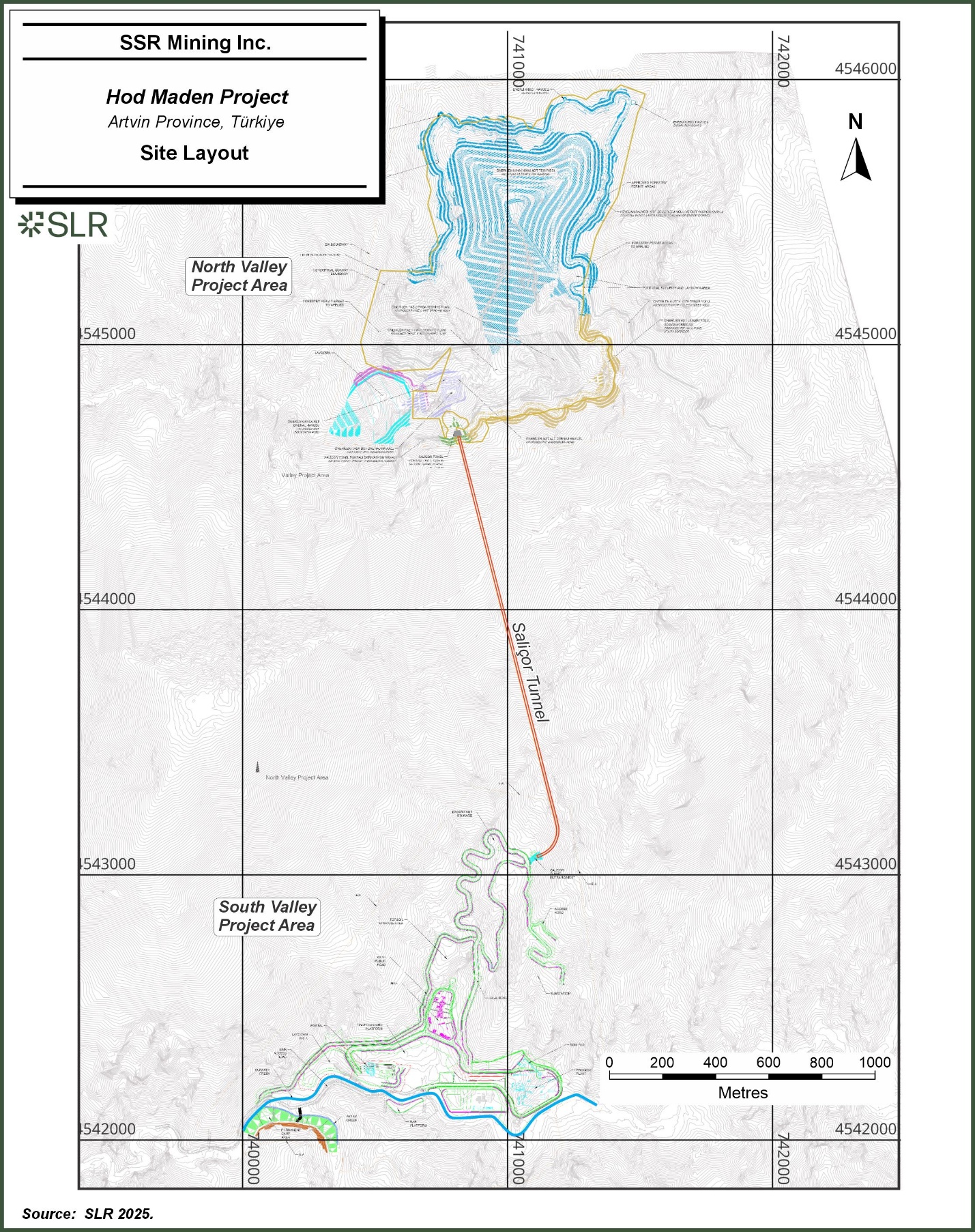

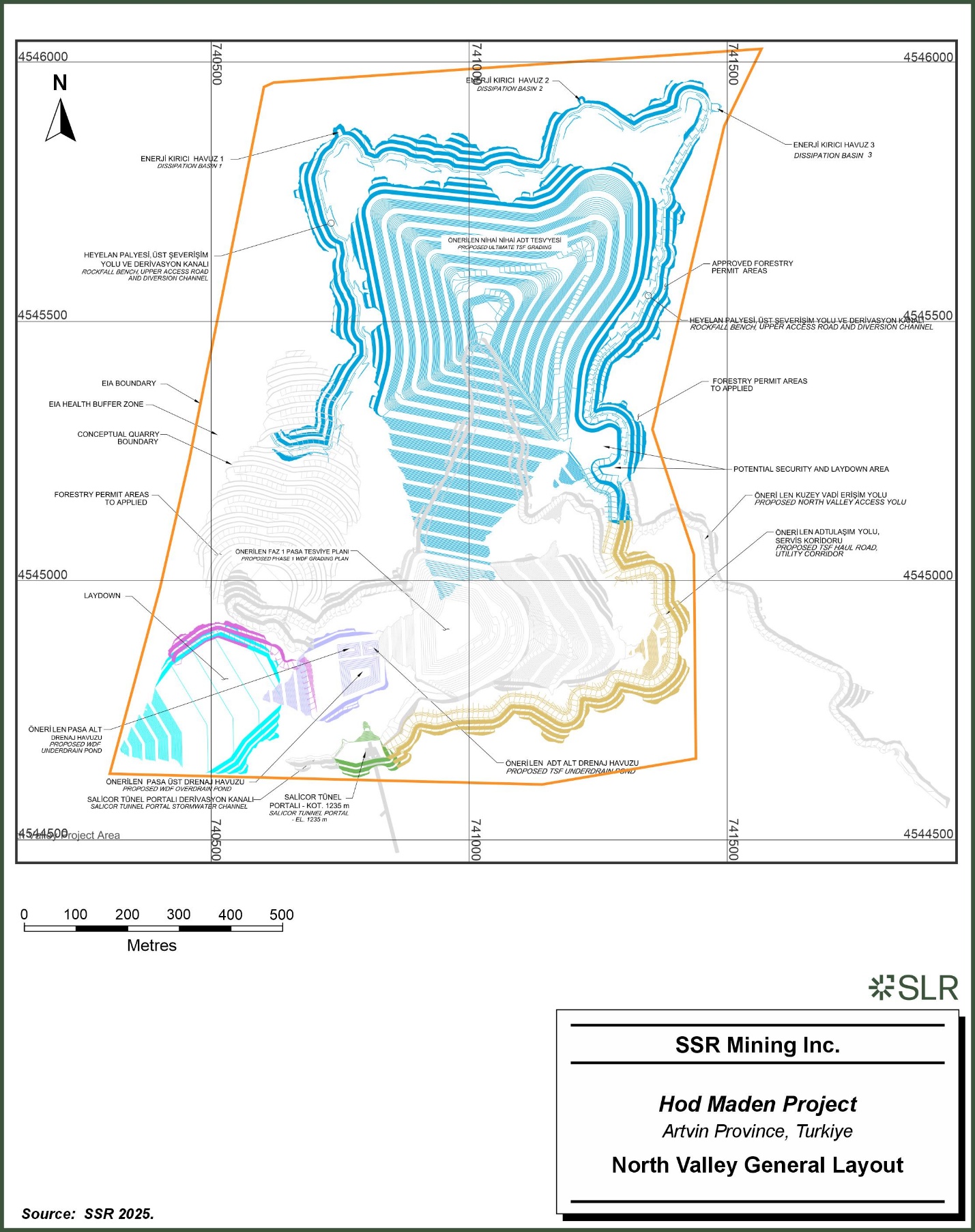

| Figure 15-1: Site Layout |

15-3 |

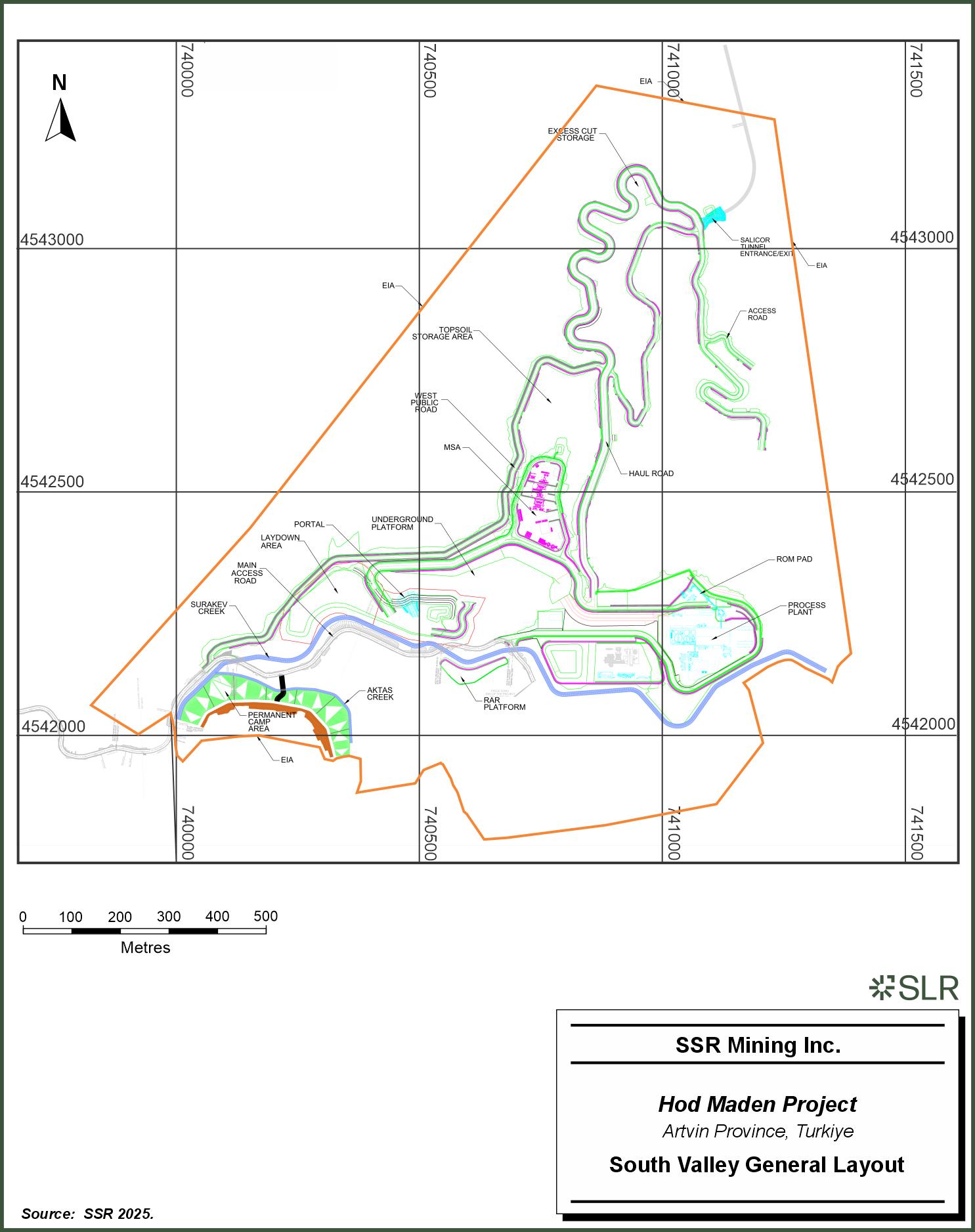

| Figure 15-2:

South Valley General Layout |

15-4 |

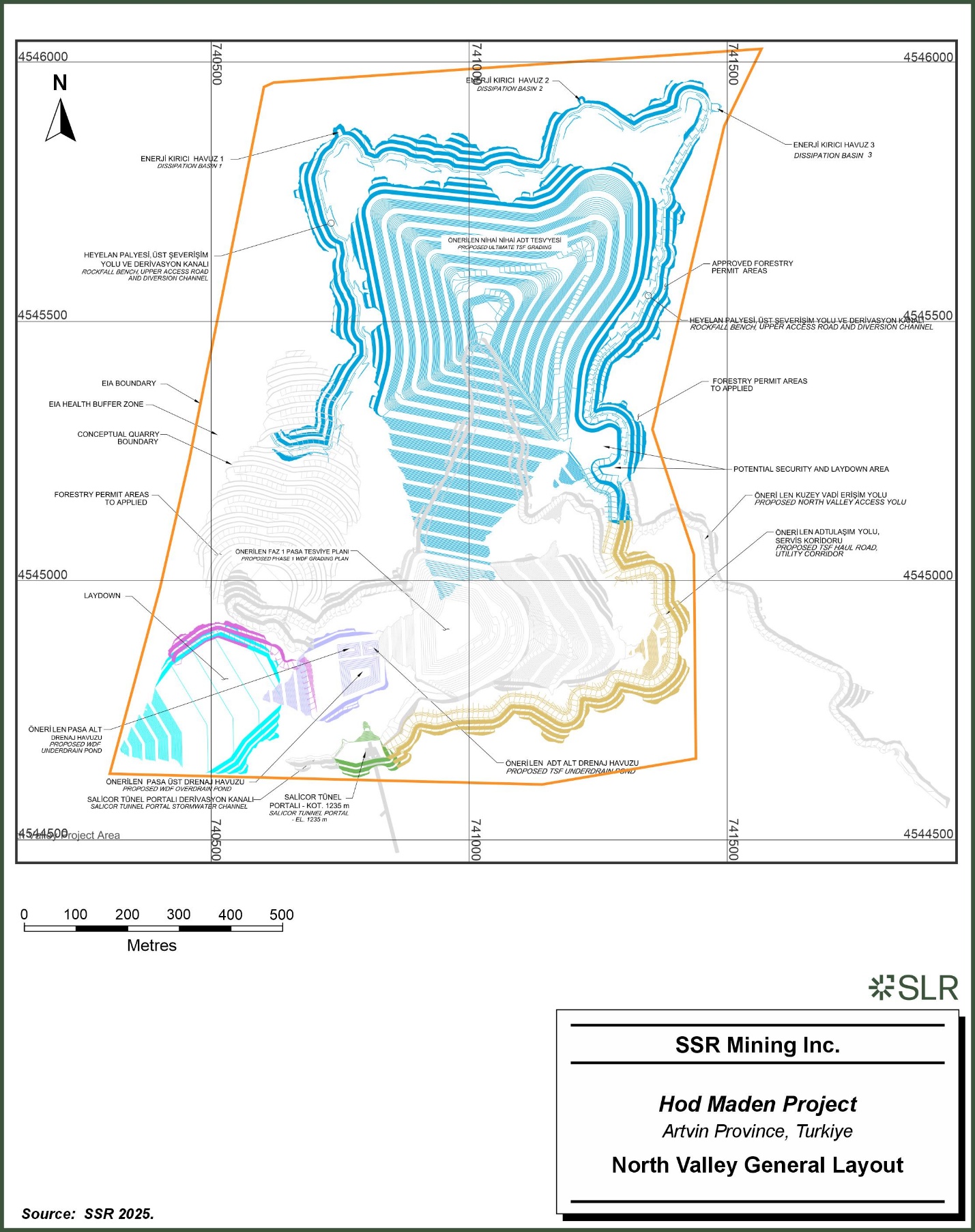

| Figure 15-3:

North Valley General Layout |

15-5 |

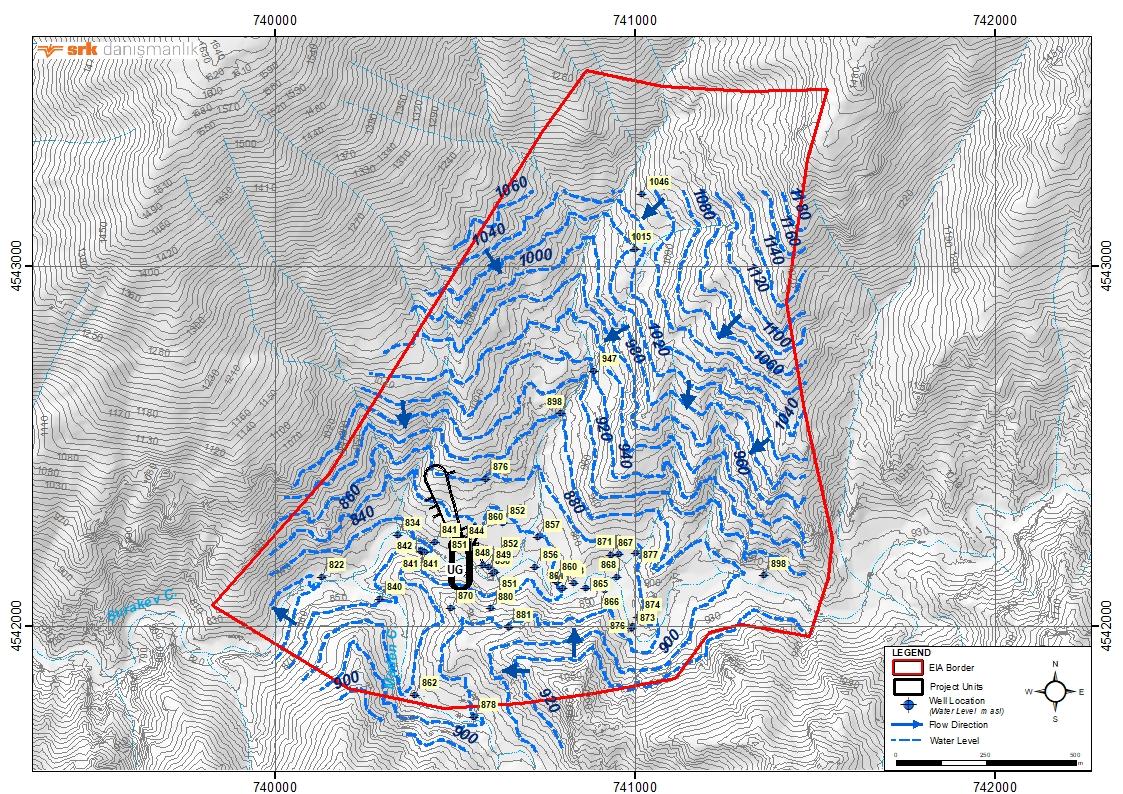

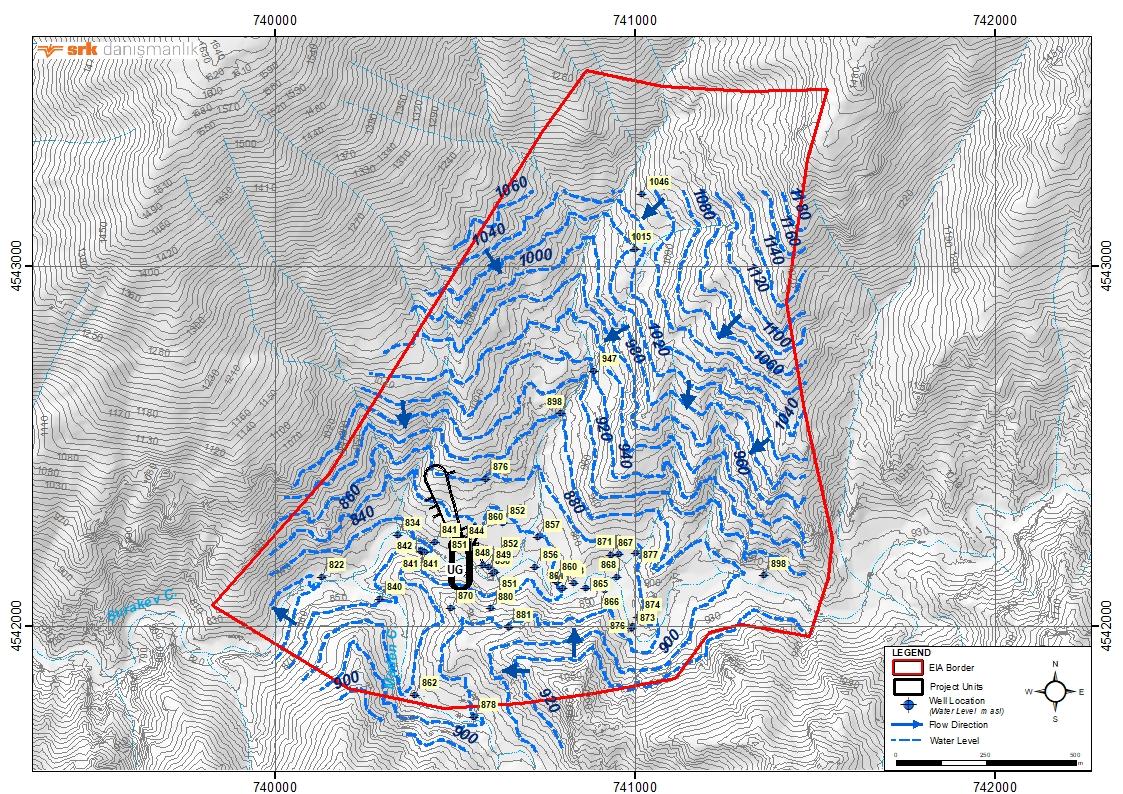

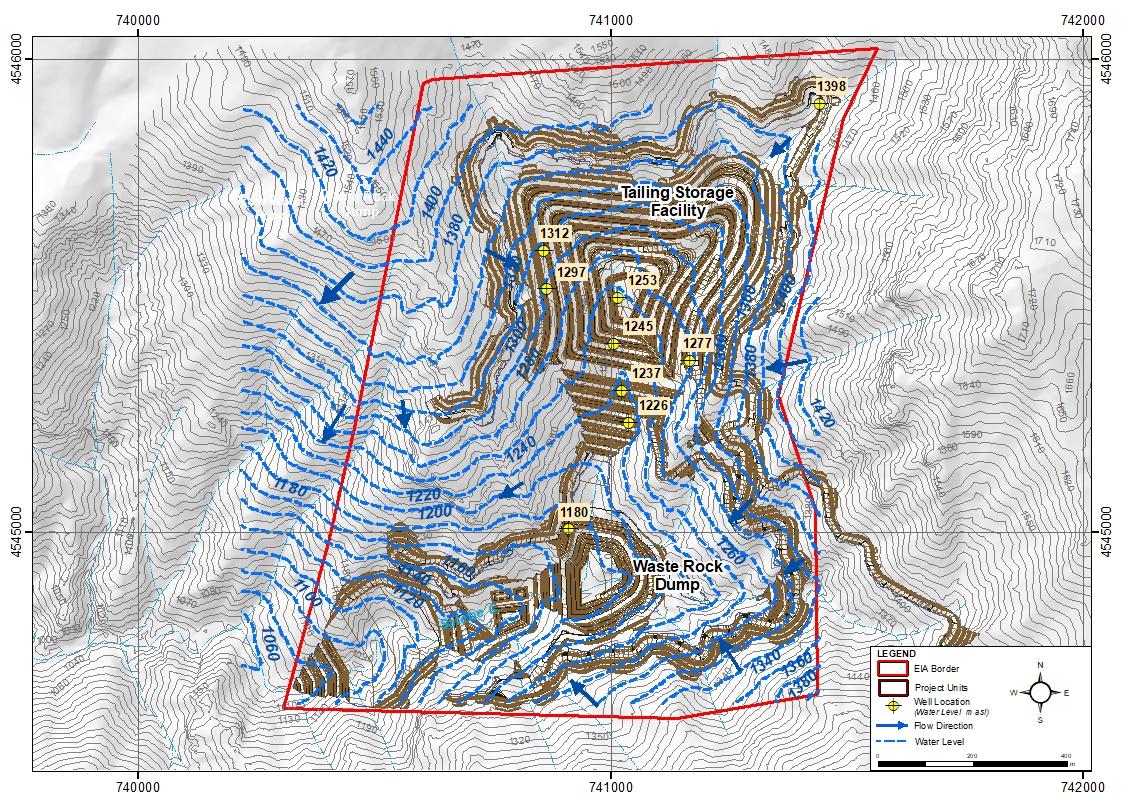

| Figure 15-4:

Groundwater Contours and Water Levels in the South Valley |

15-11 |

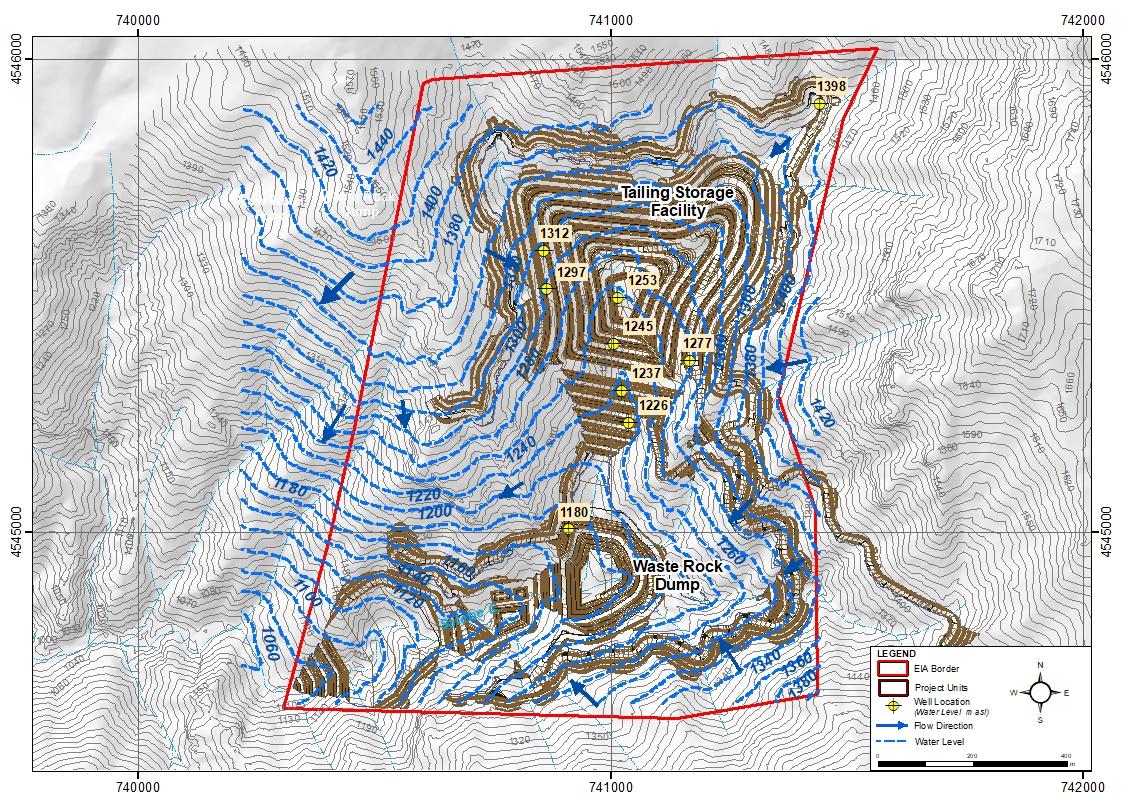

| Figure 15-5:

Groundwater Contours and Water Levels in the Northern Valley |

15-12 |

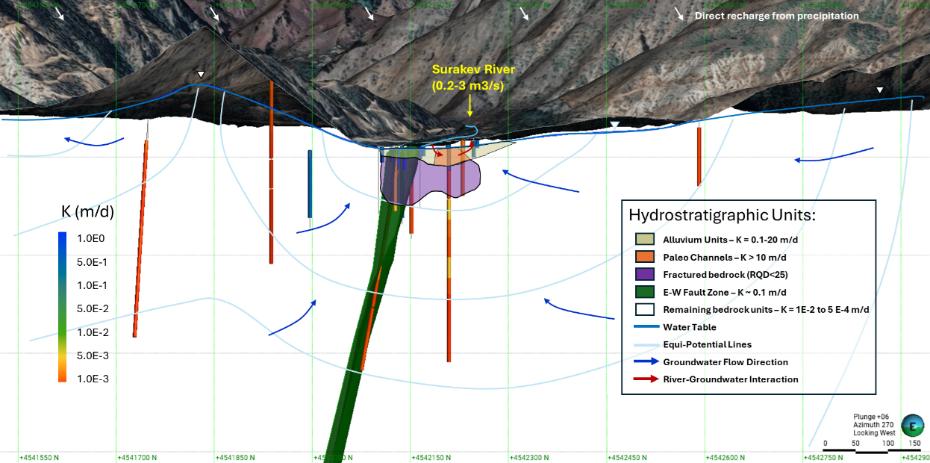

| Figure 15-6:

Conceptual Hydrogeological Cross-Section |

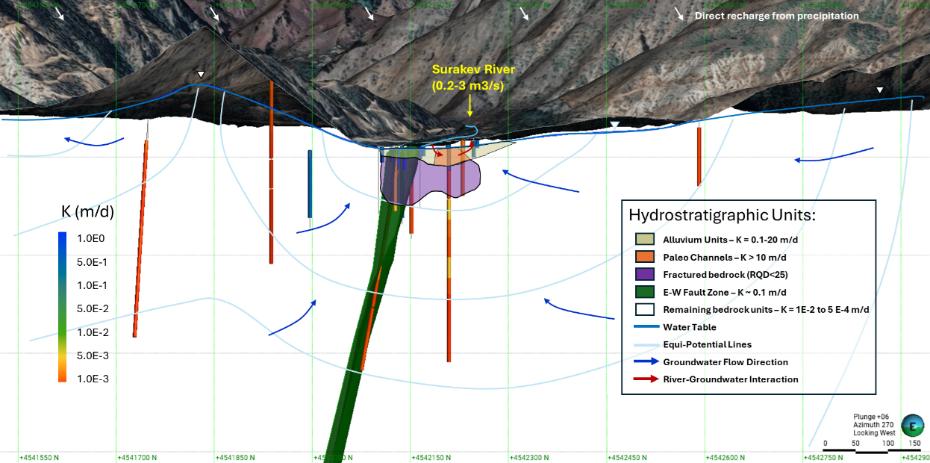

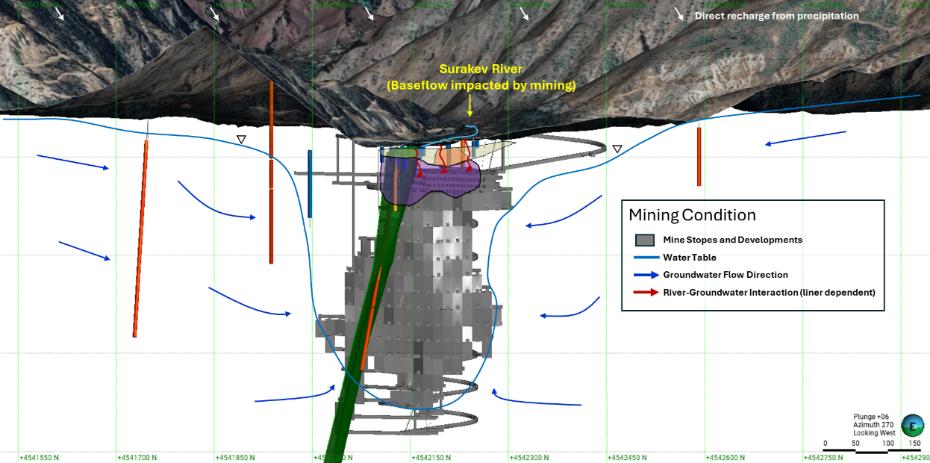

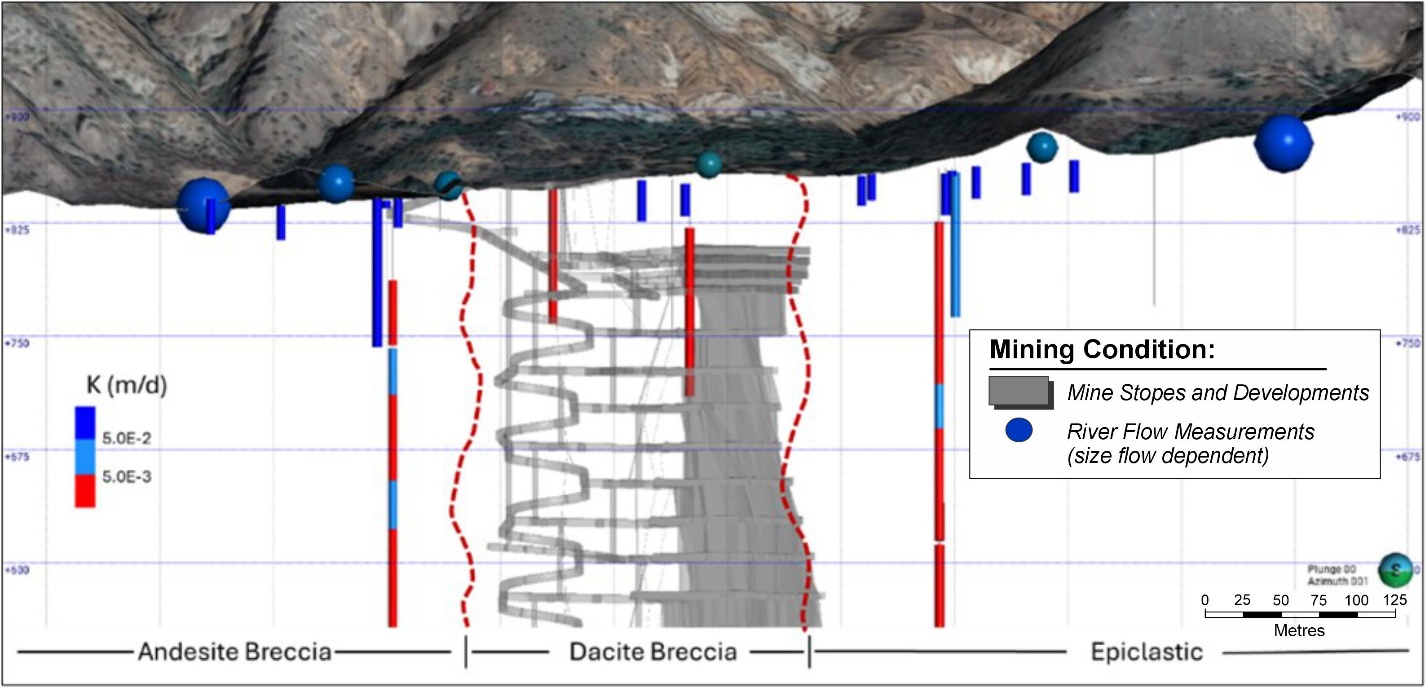

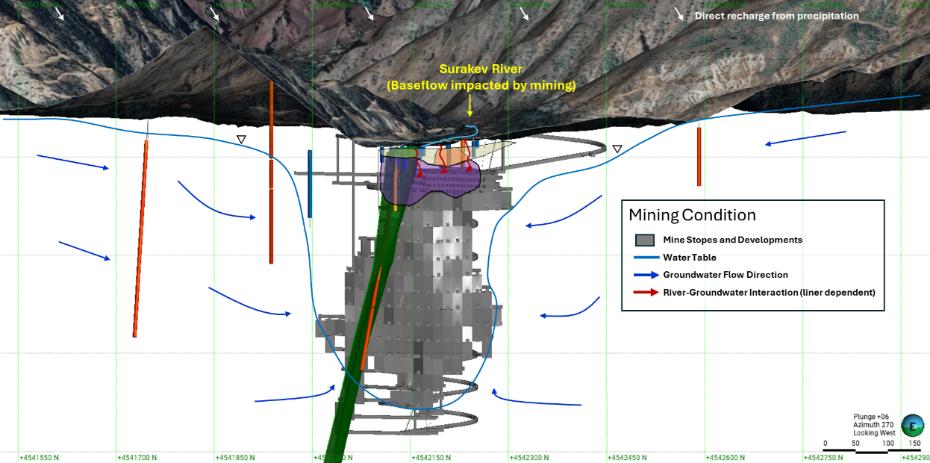

15-2 |

| Figure 15-7:

Conceptual Understanding of Shallow Groundwater System |

15-3 |

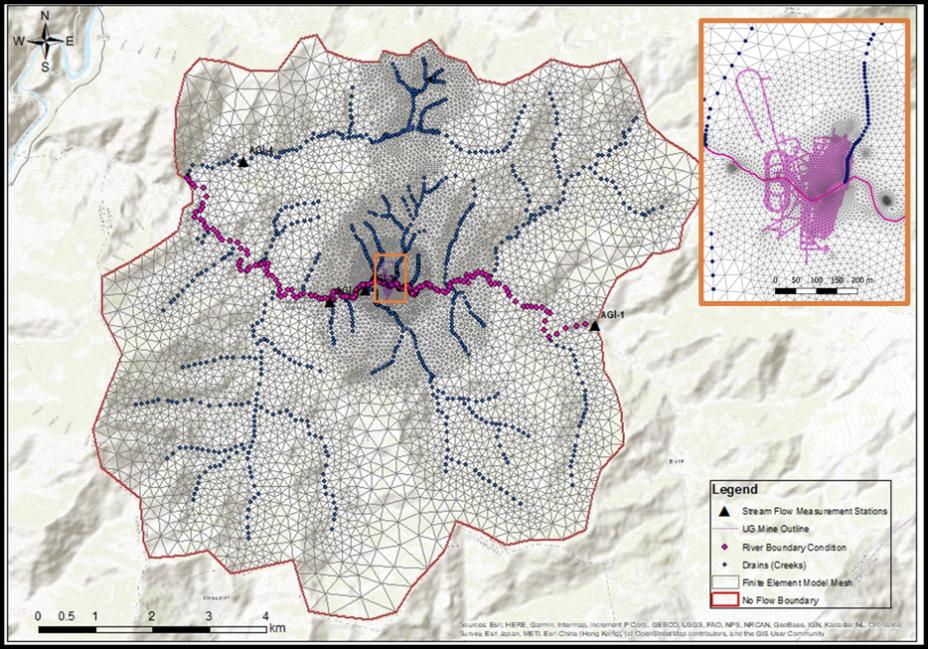

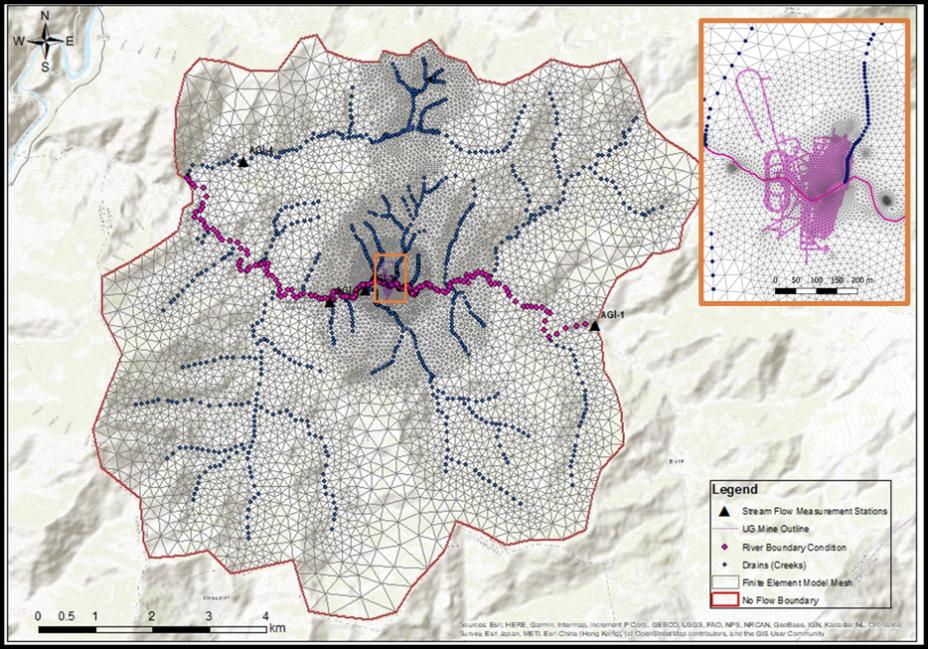

| Figure 15-8:

Model Extent and Mesh Discretization, Plan View |

15-4 |

| Figure 15-9:

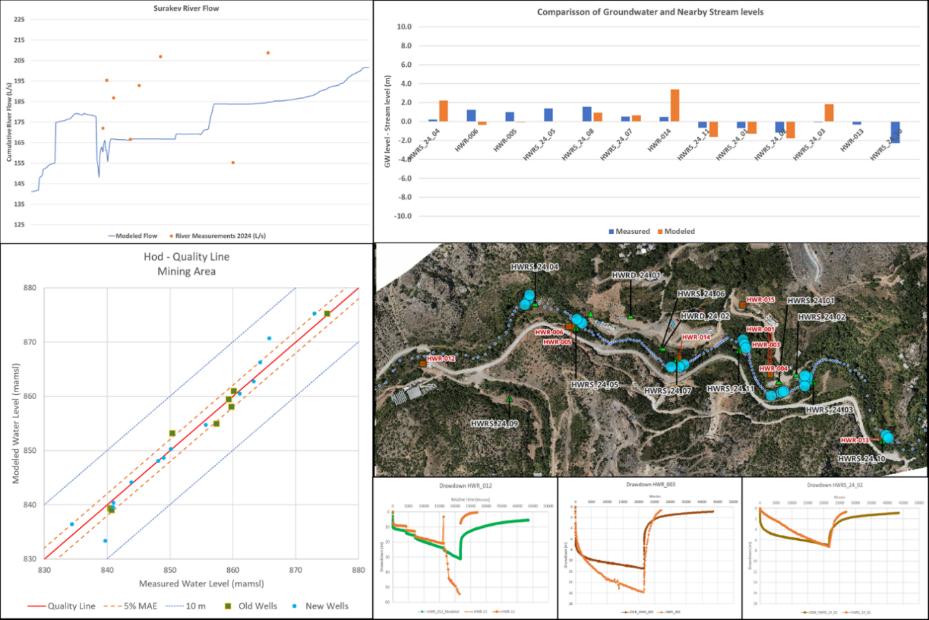

Example of New Calibration Targets Incorporated into Latest Model Update |

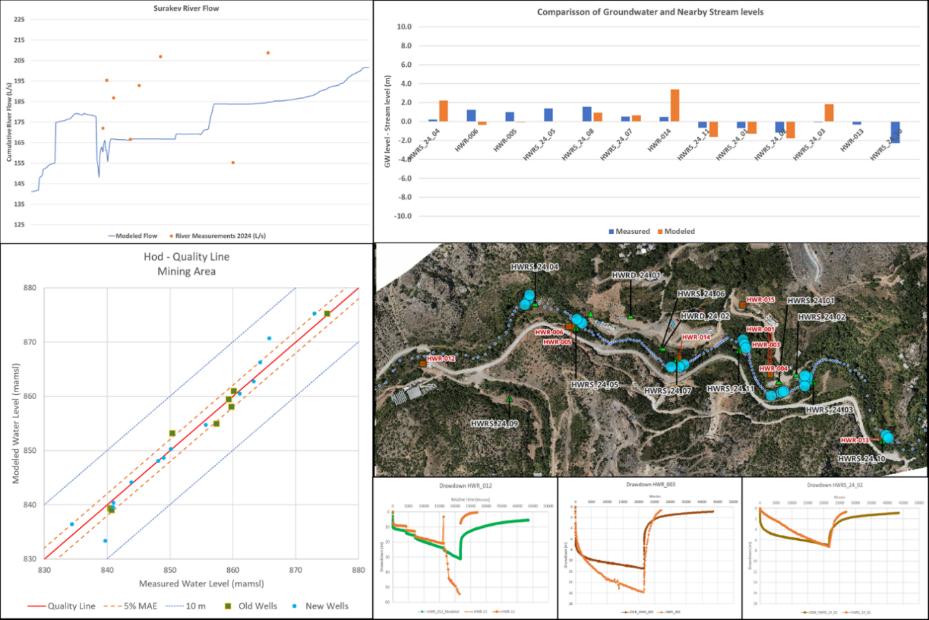

15-5 |

| | xiv |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

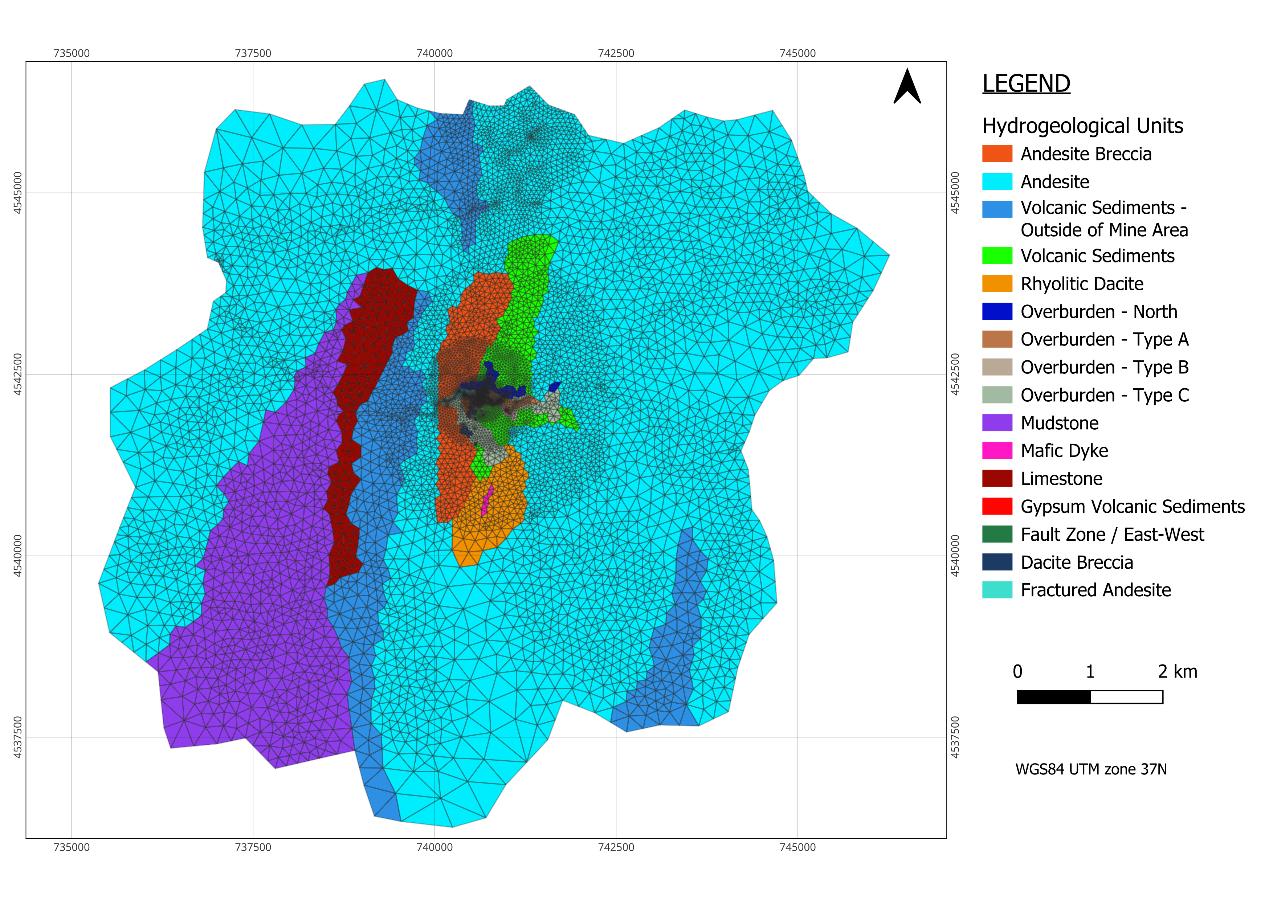

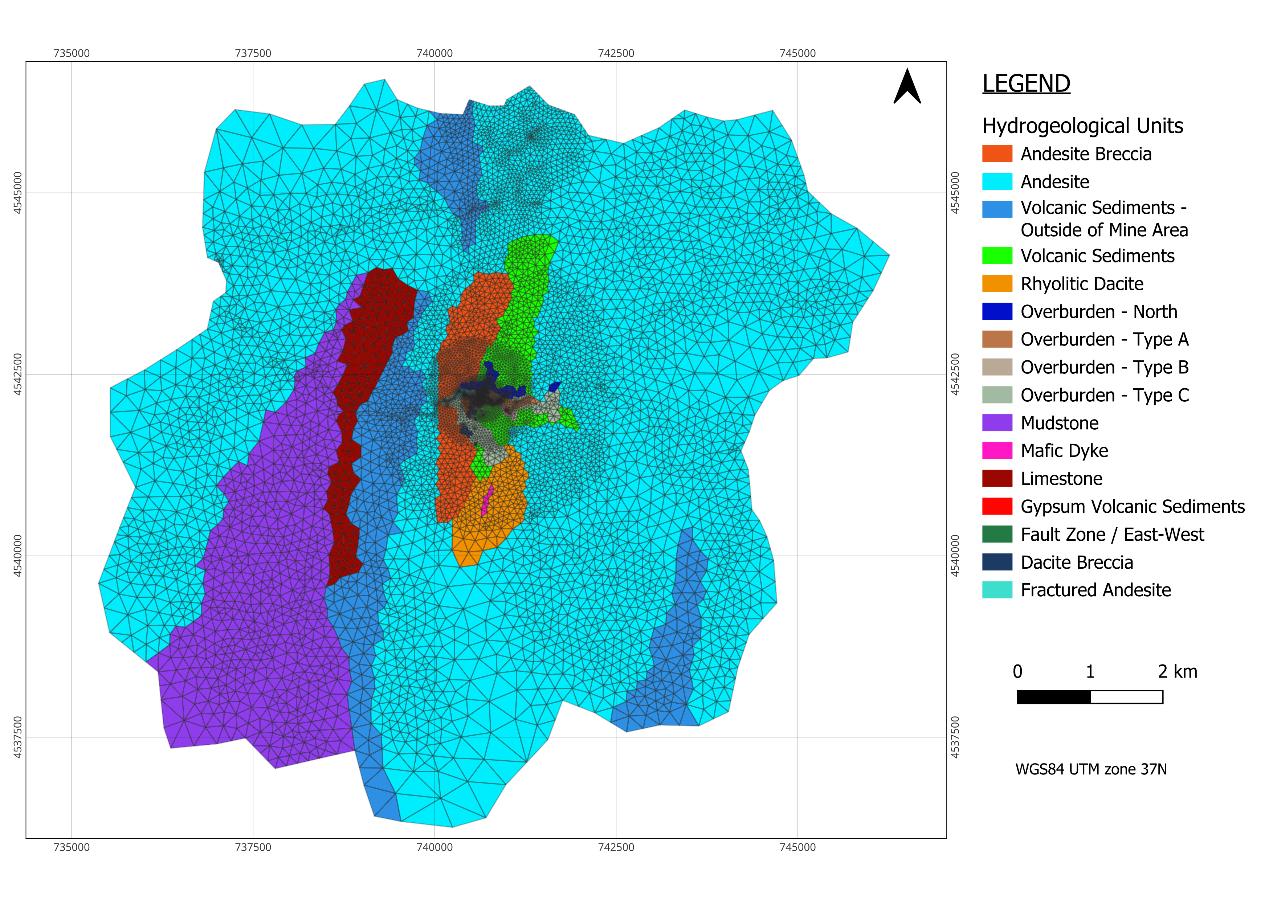

| Figure 15-10: Simulated Hydrogeological Units Shown in the Uppermost Model Layer |

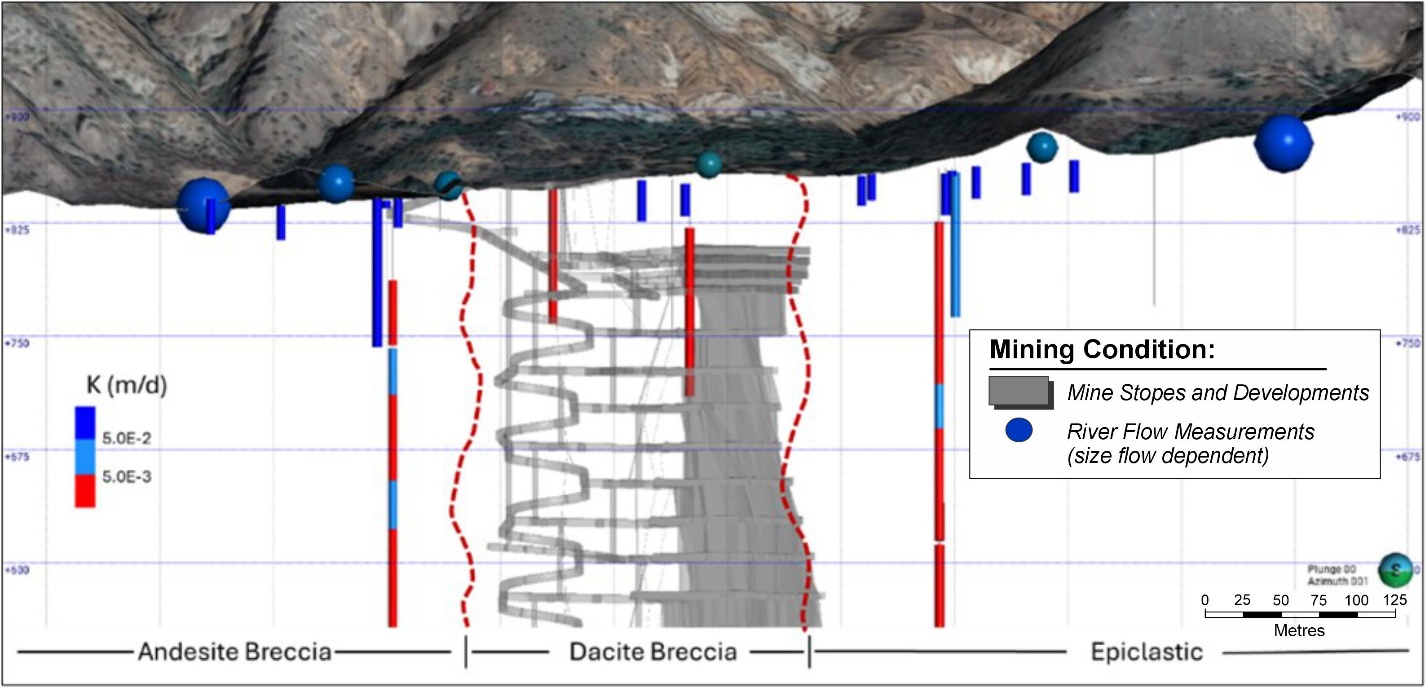

15-6 |

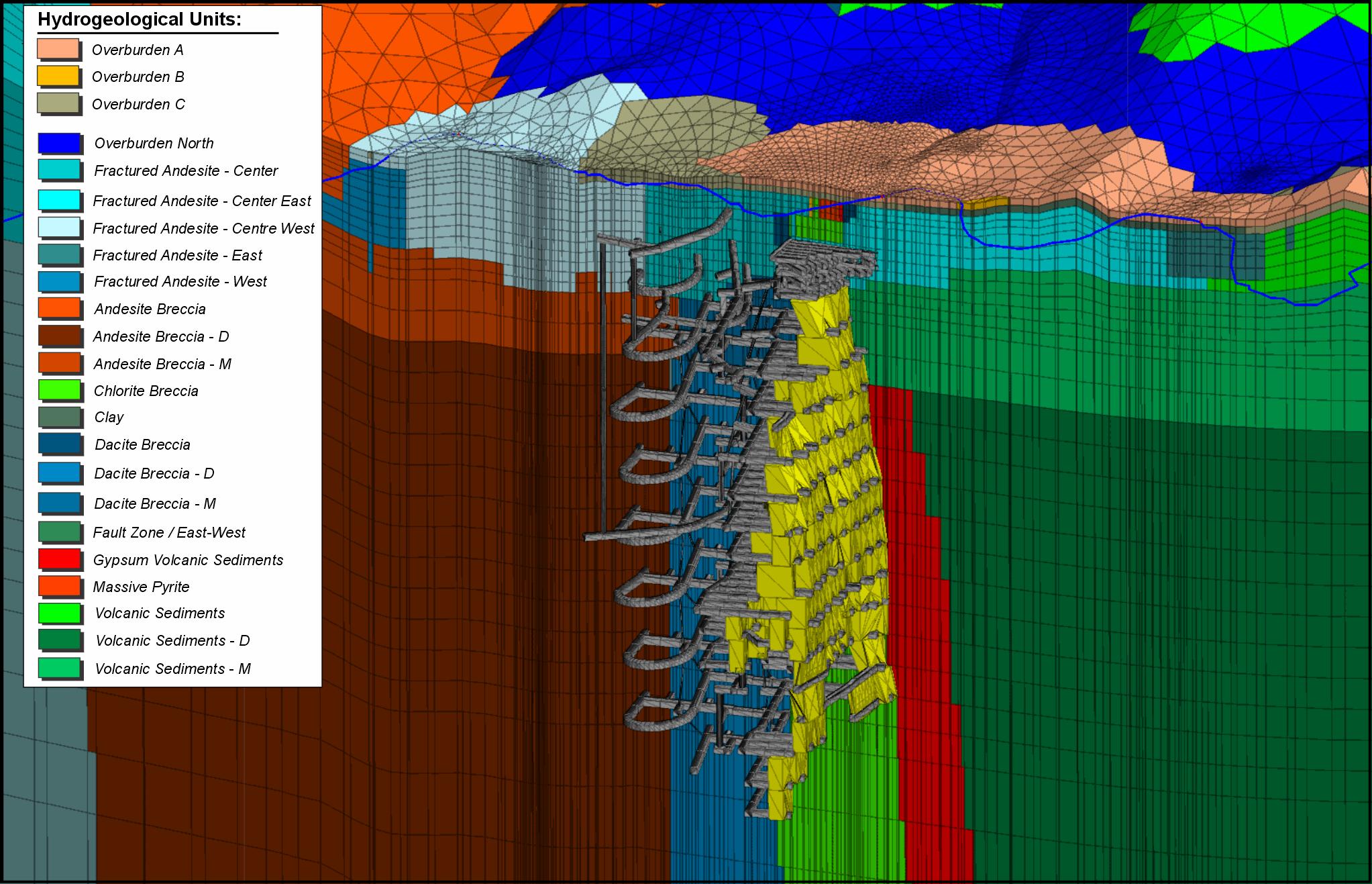

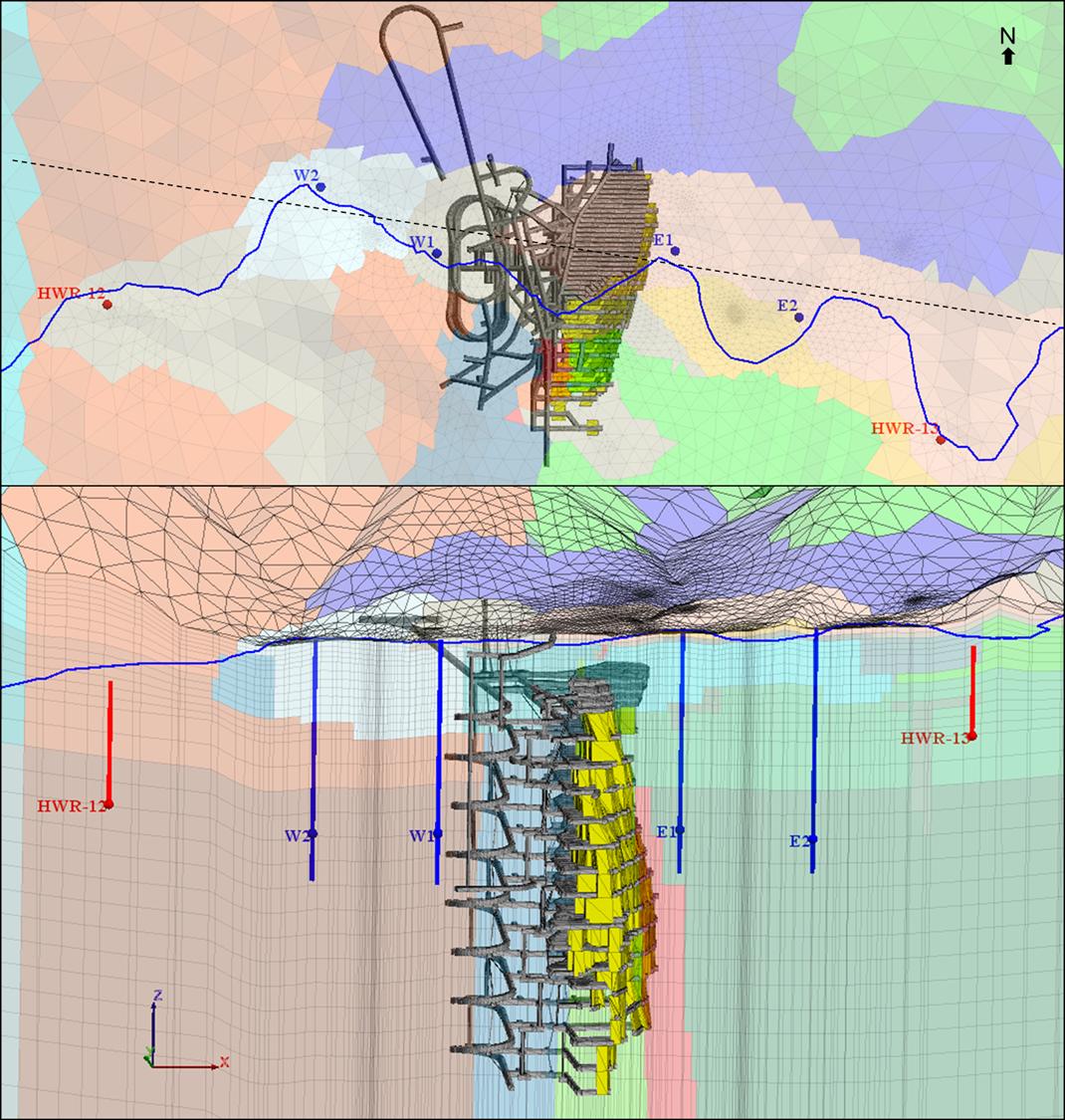

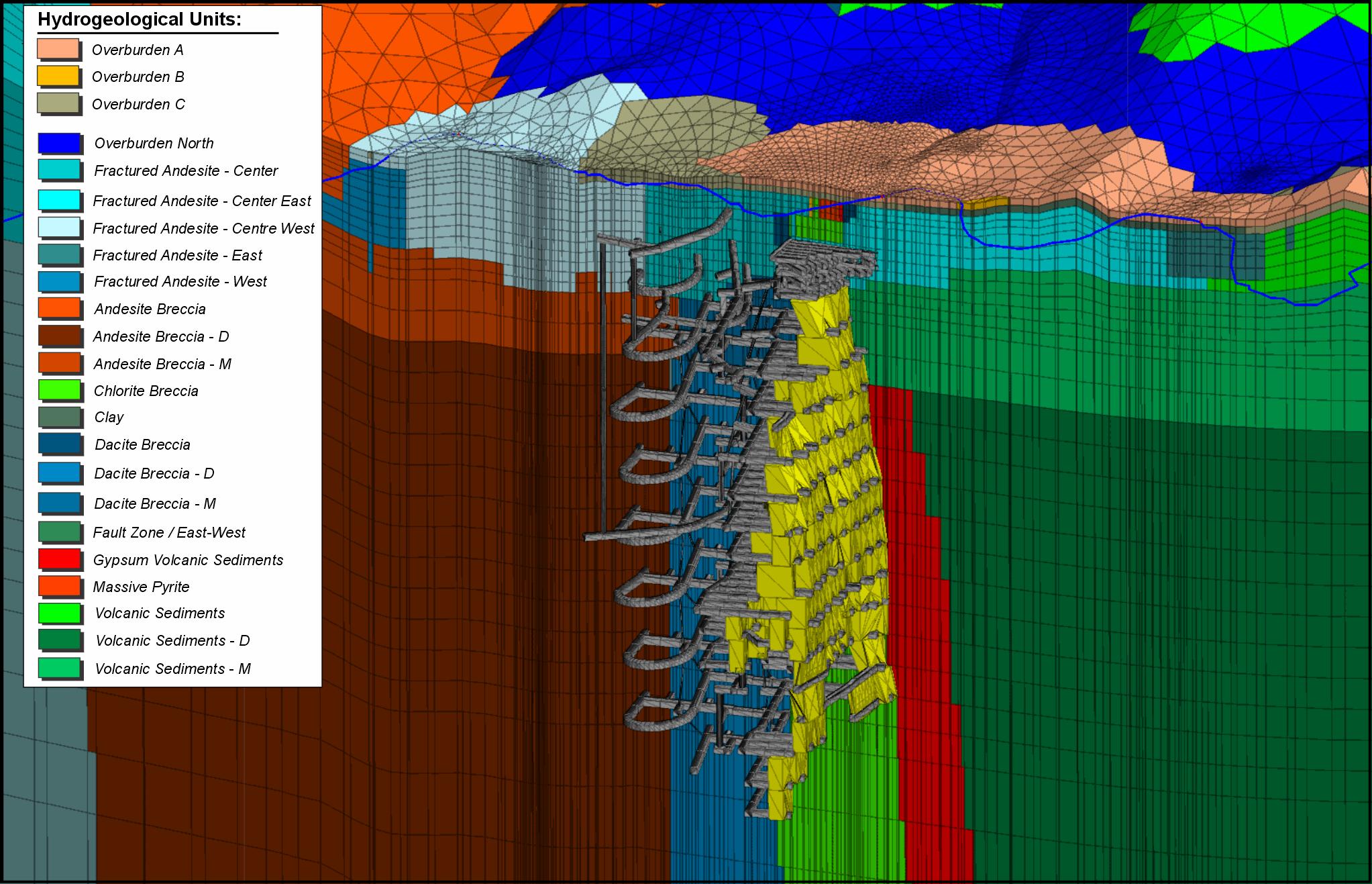

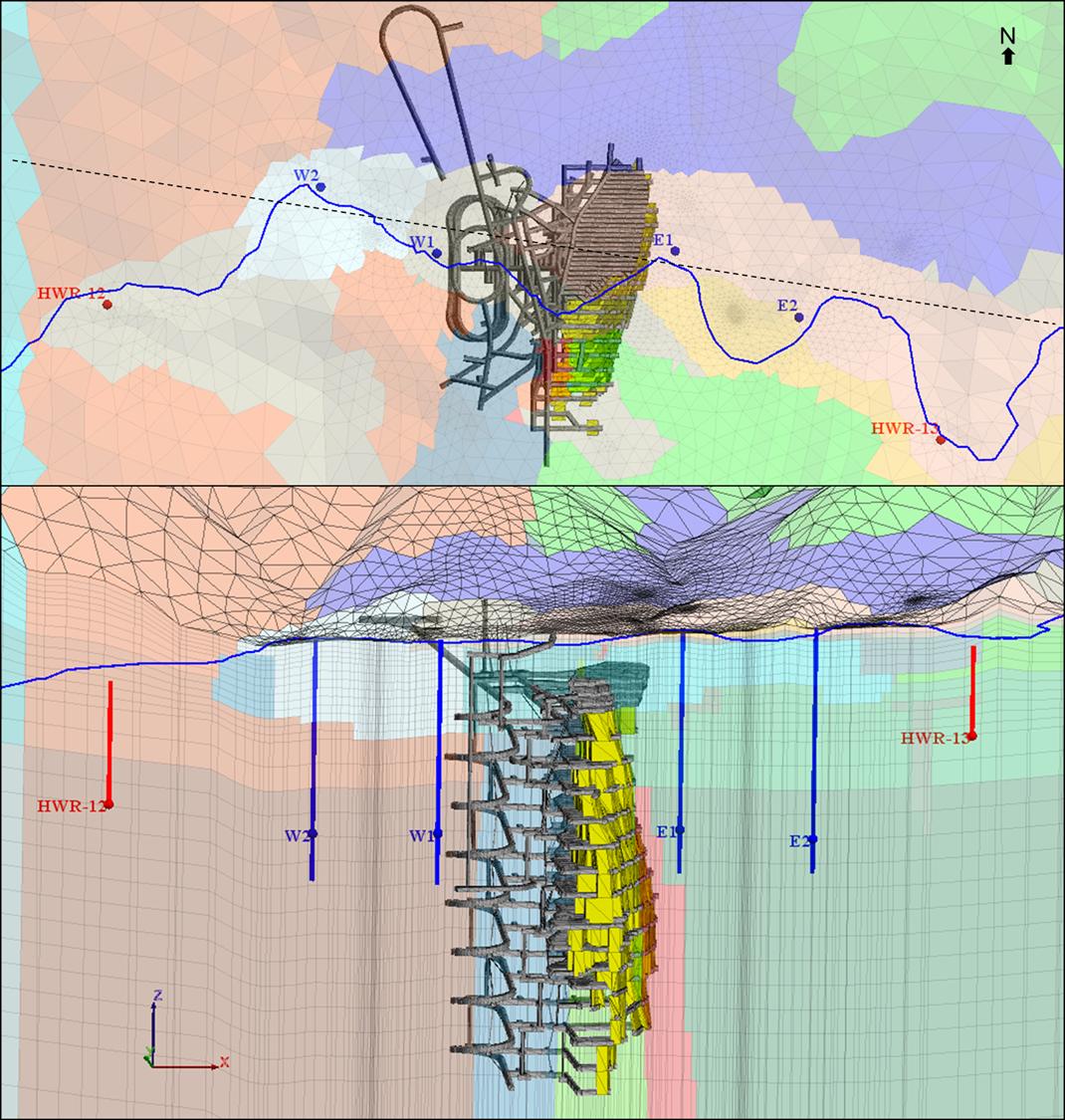

| Figure 15-11: Simulated Hydrogeological Units in Mine Area and the Numerical Model Mesh |

15-7 |

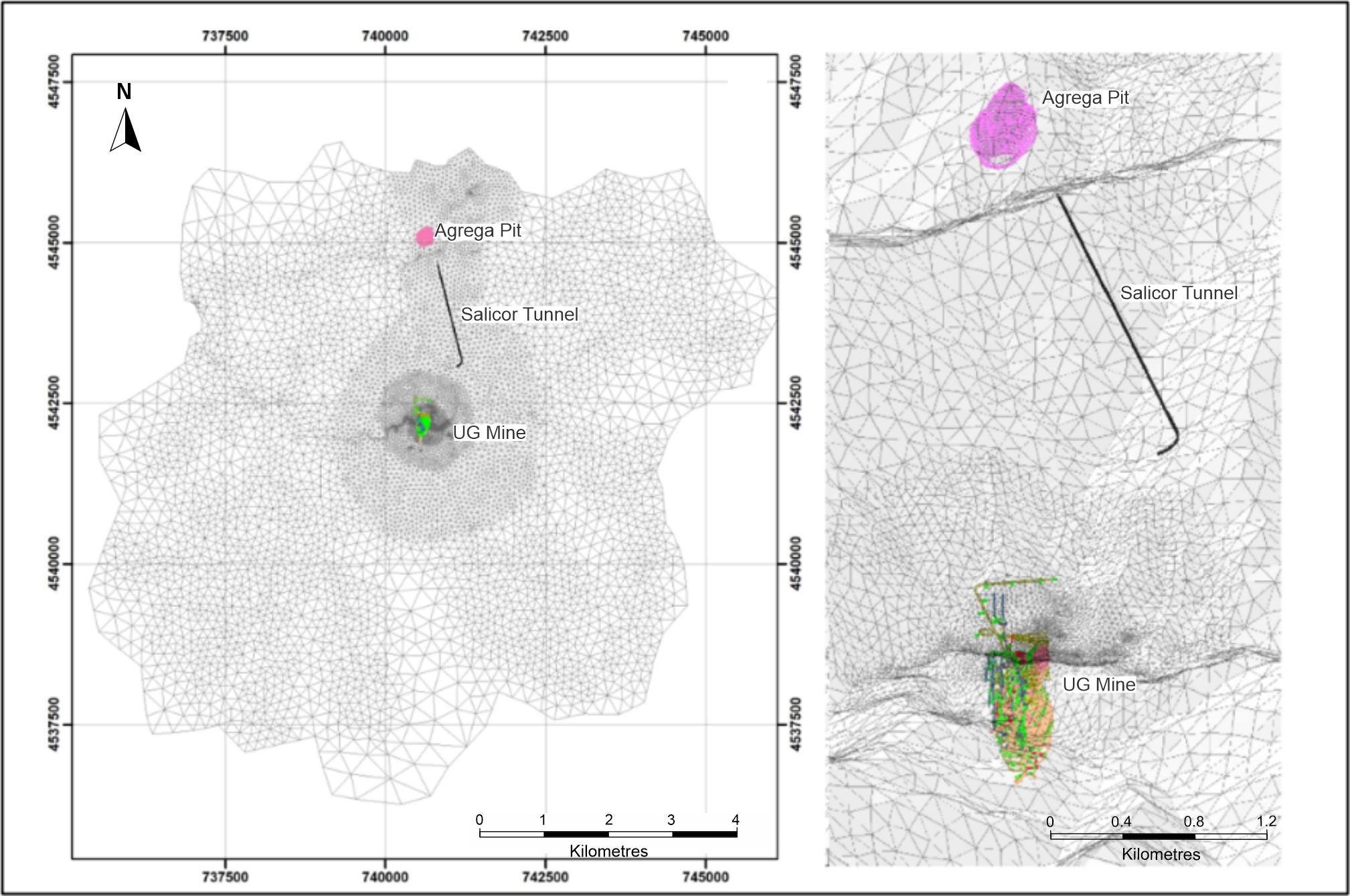

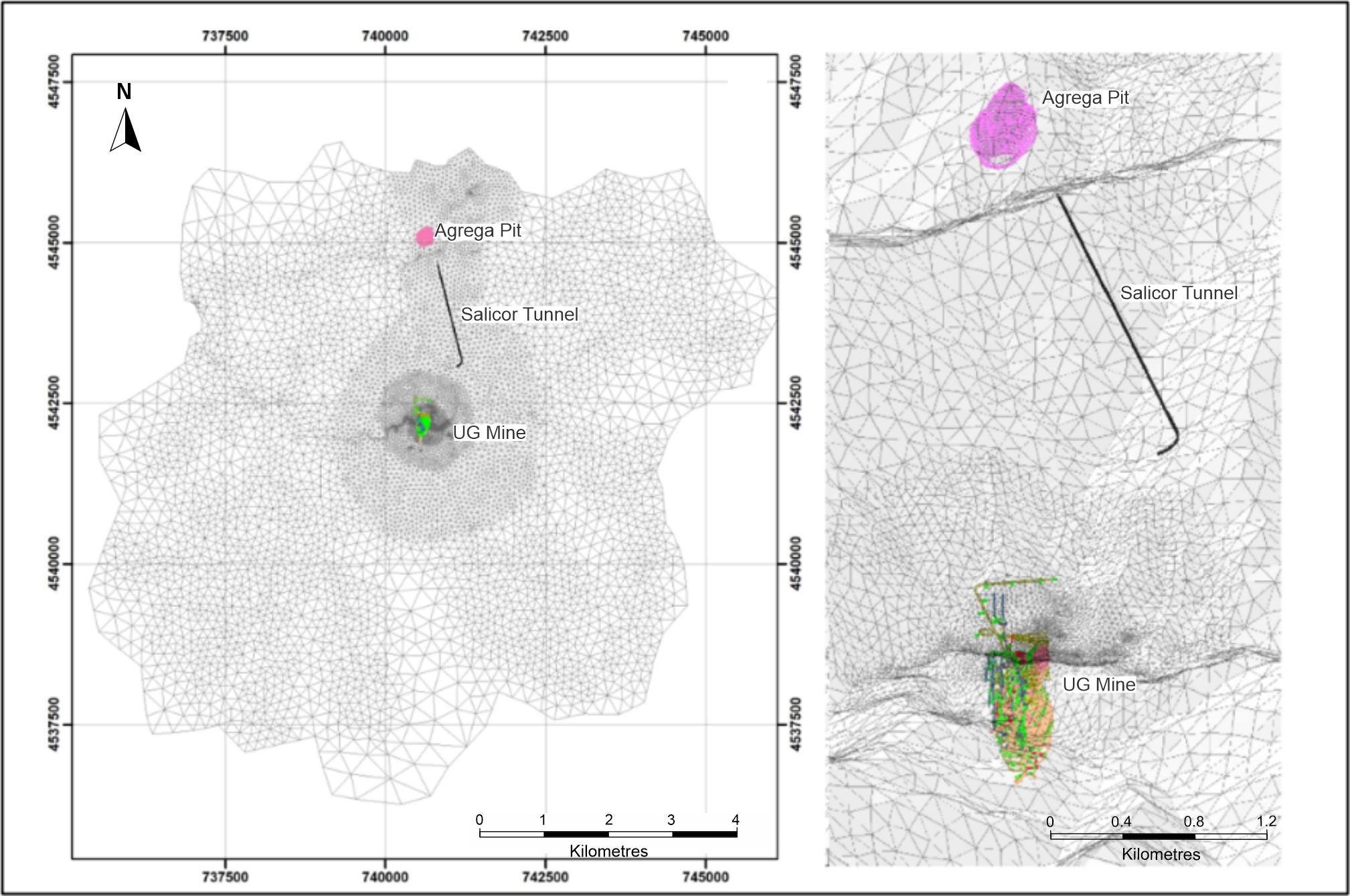

| Figure 15-12: Simulated Underground Mine Development, Agrega Pit and Saliçor Tunnel |

15-9 |

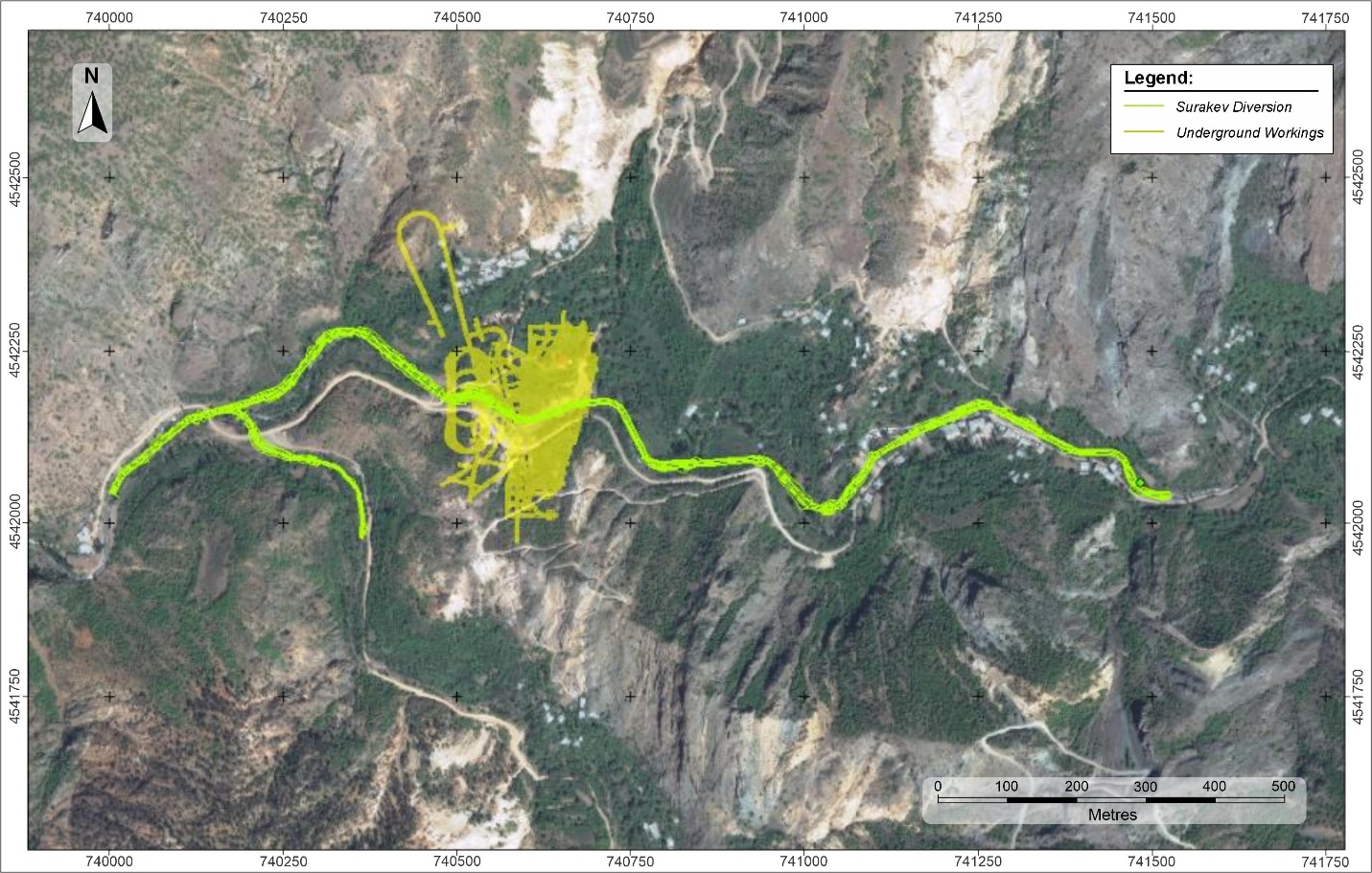

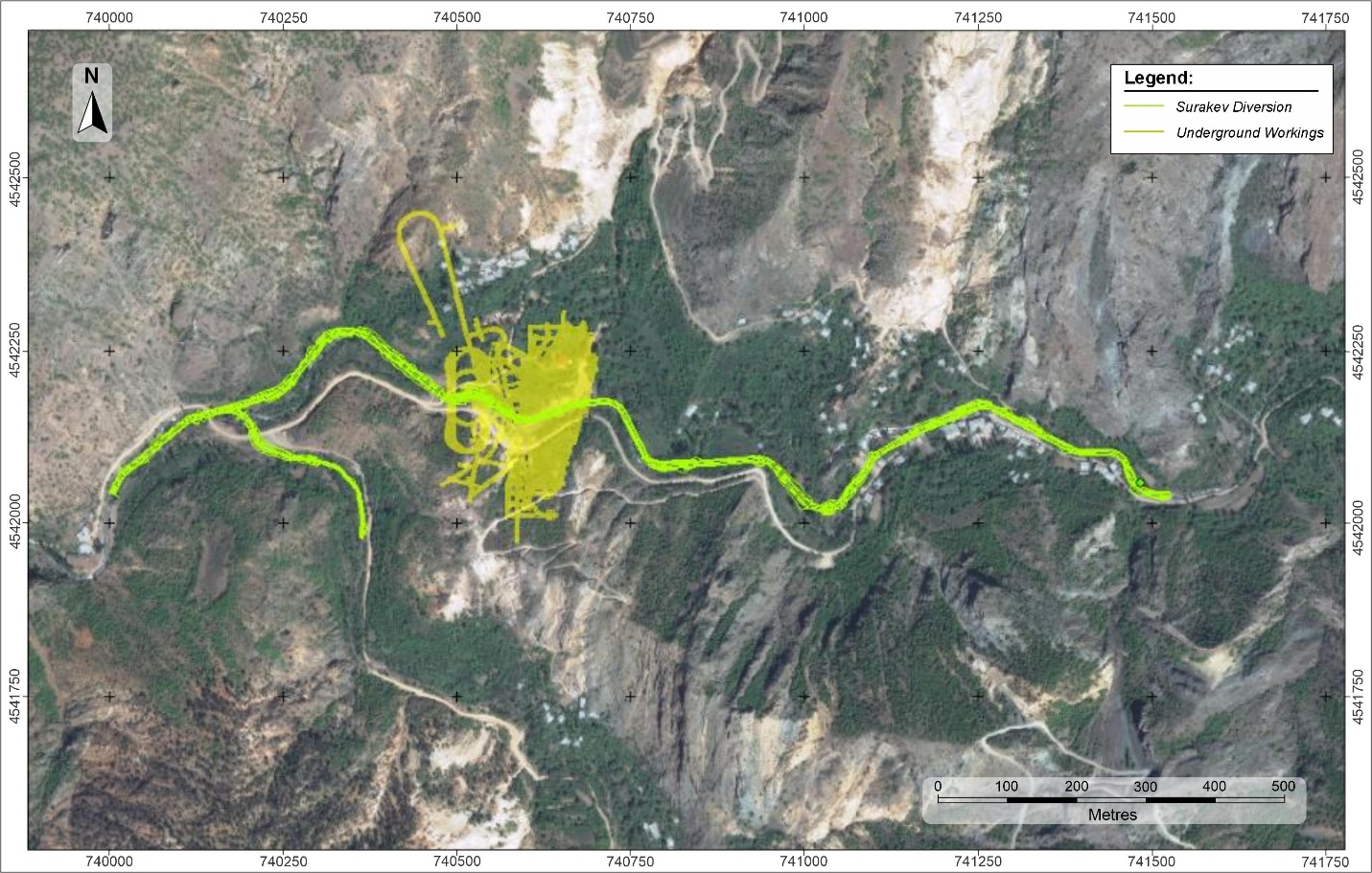

| Figure 15-13: Planned River Liner Extent (“Şurakev Diversion”) |

15-10 |

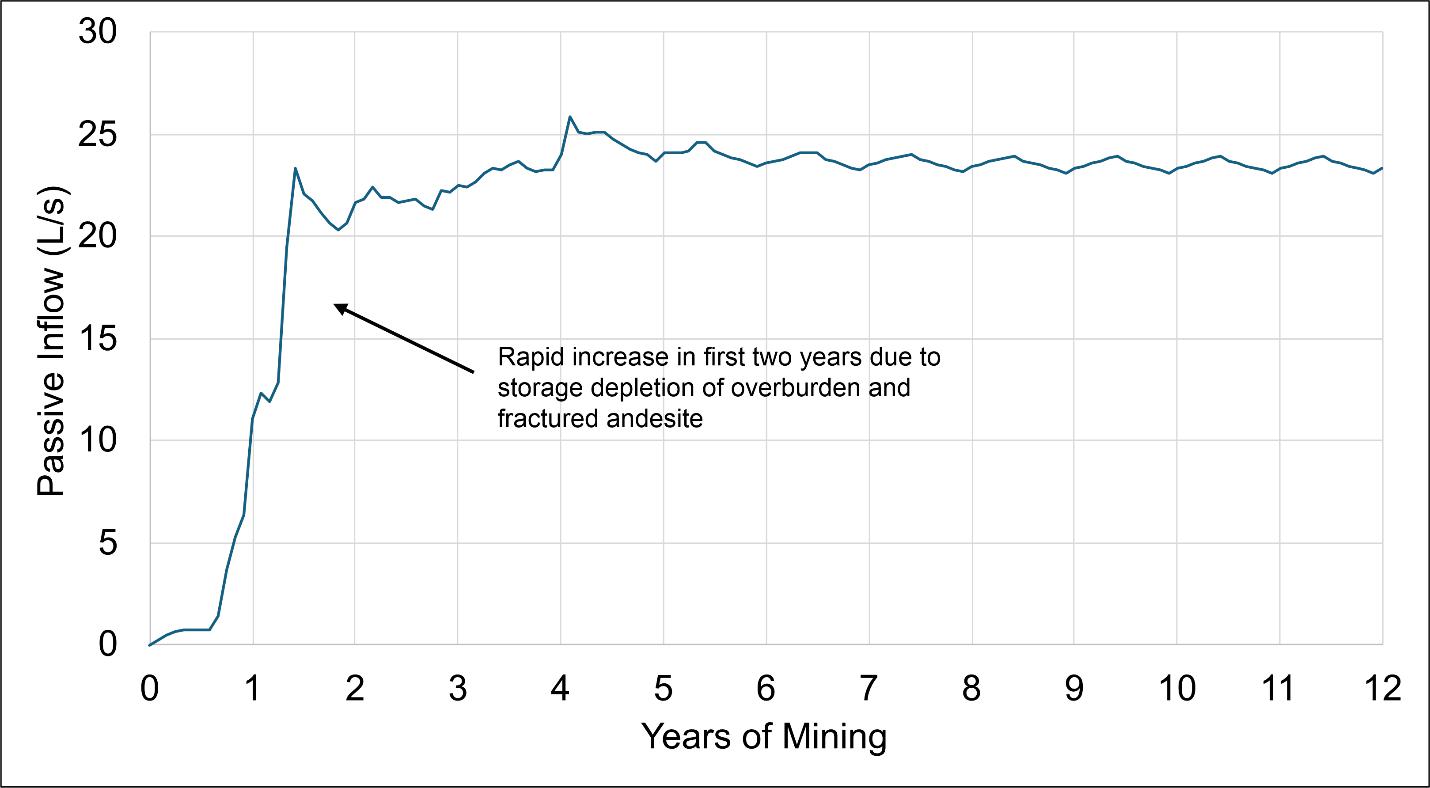

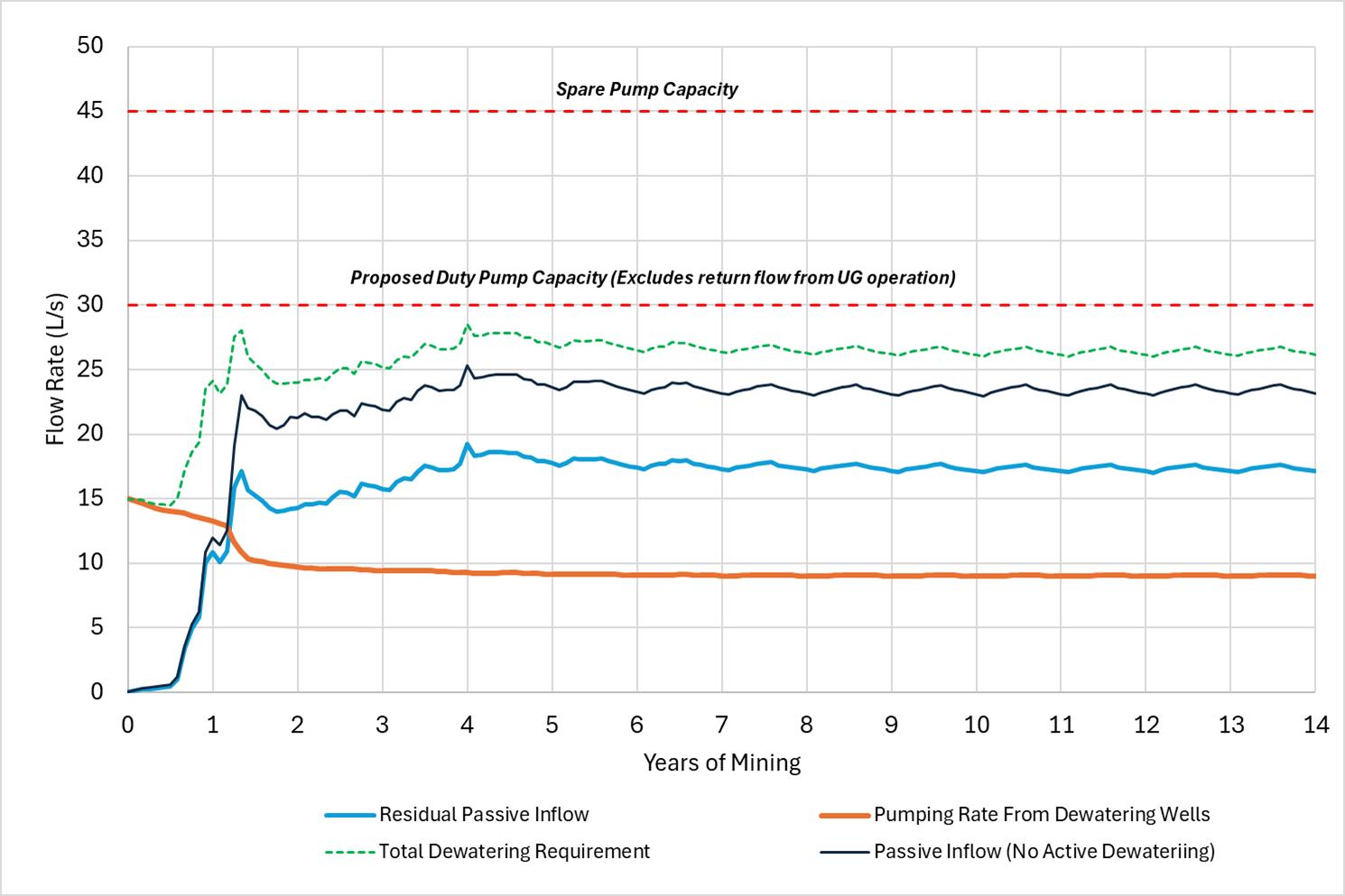

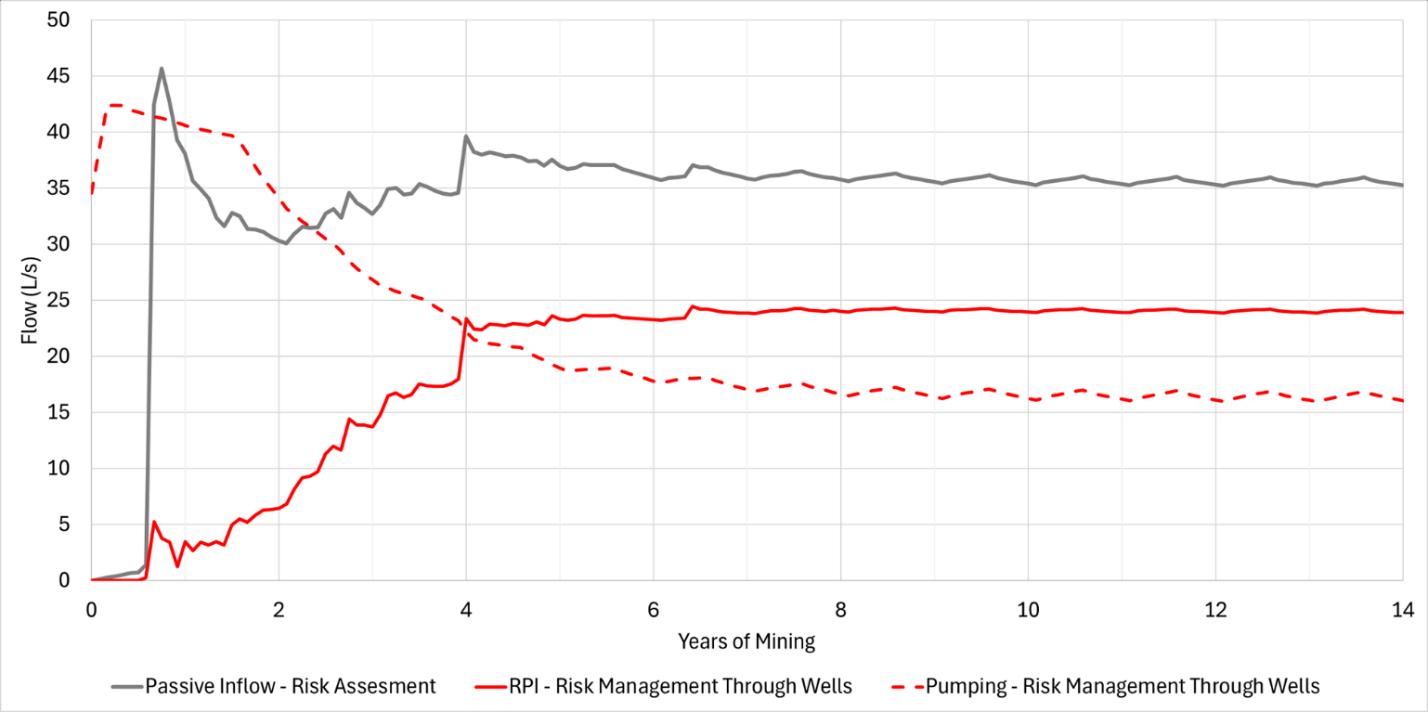

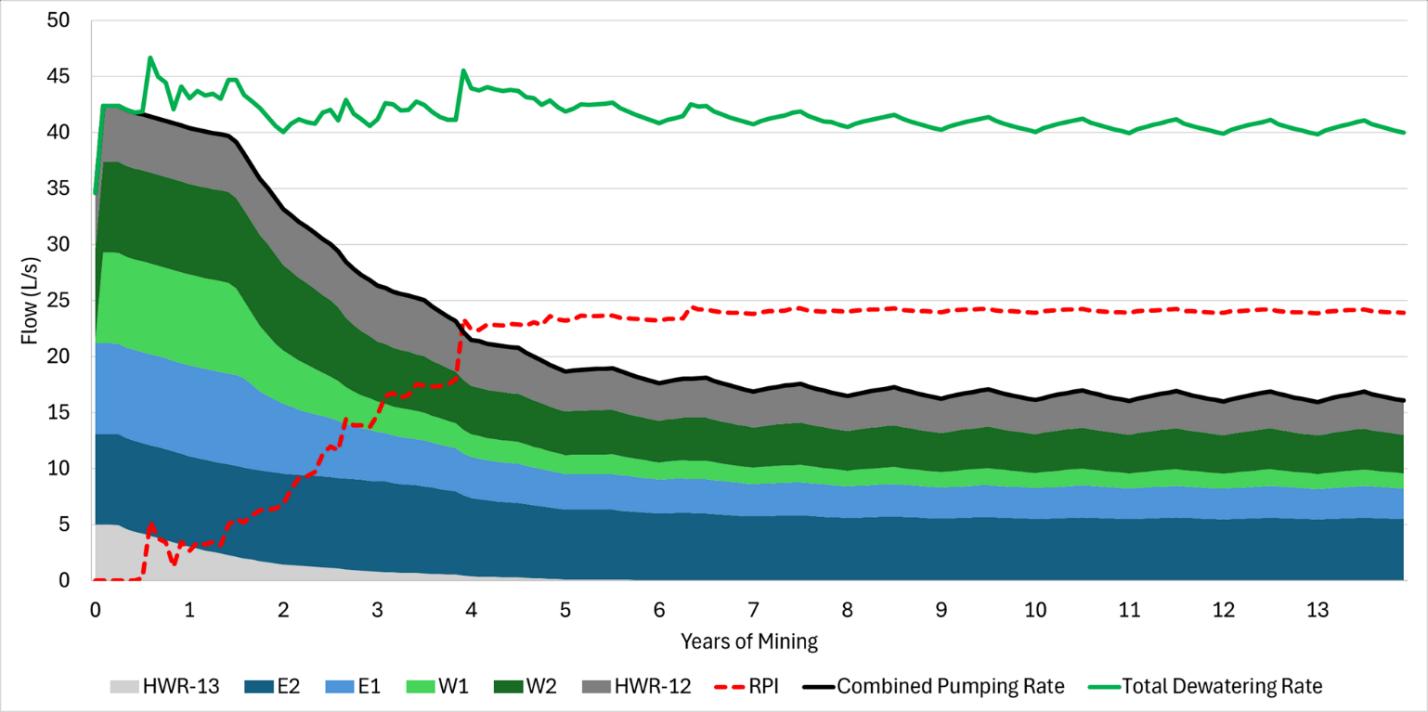

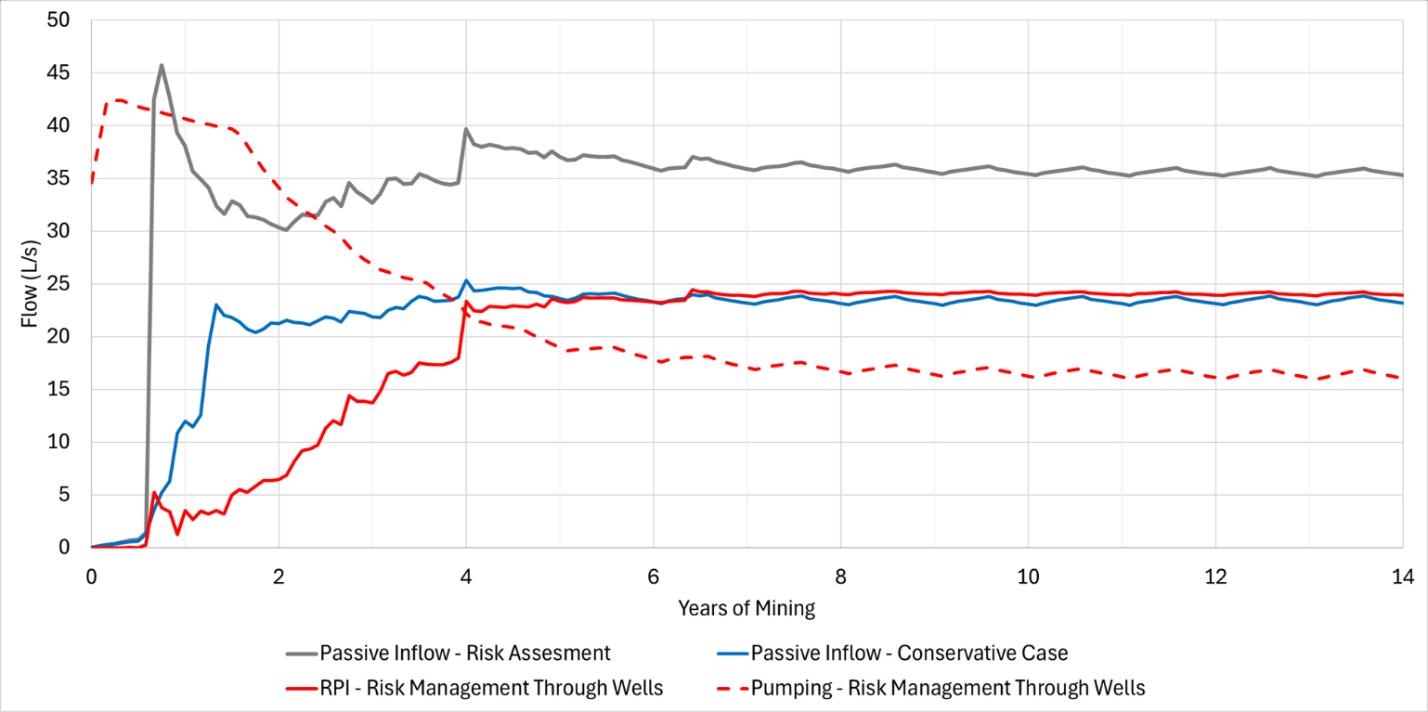

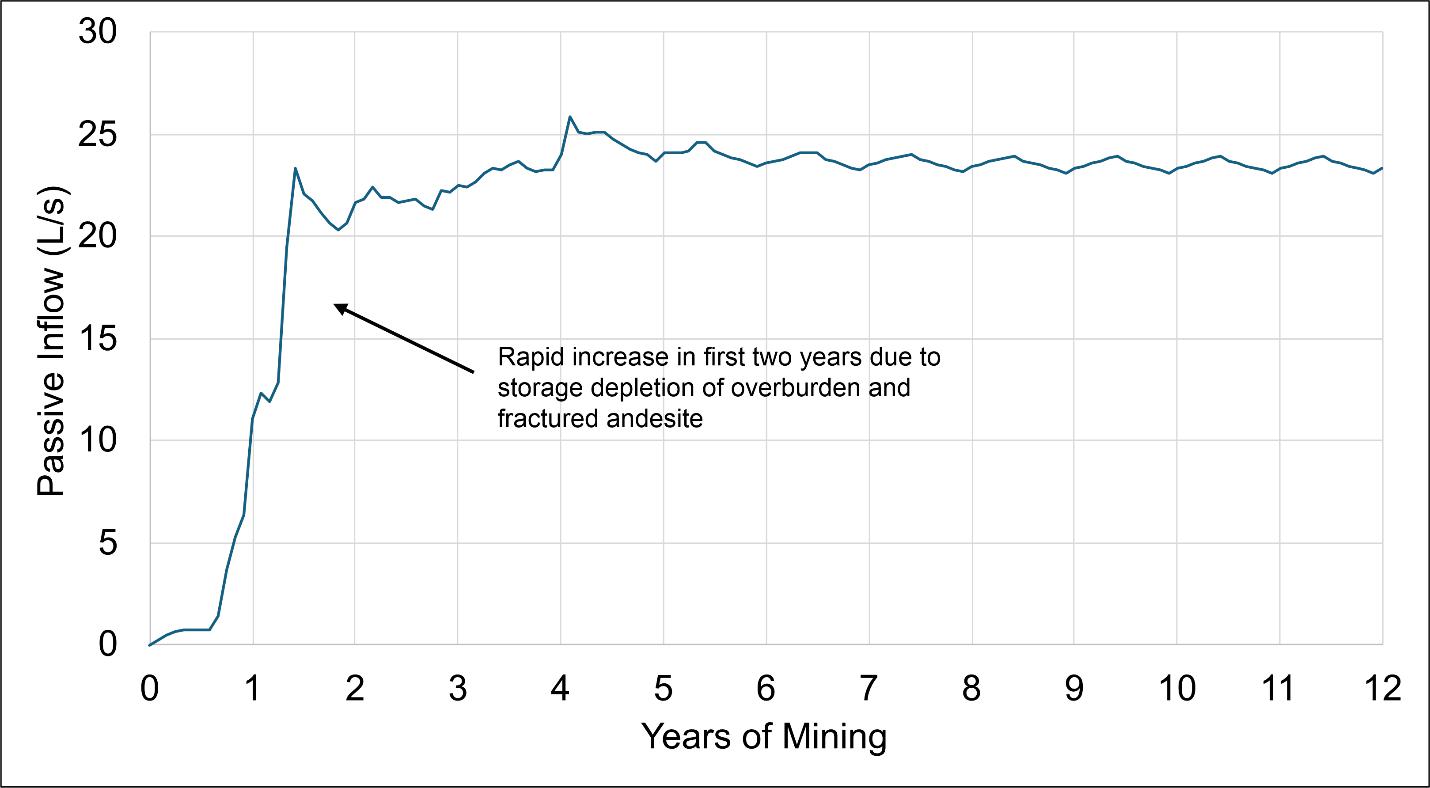

| Figure 15-14: Passive Inflow Predictions to the Underground Mine |

15-11 |

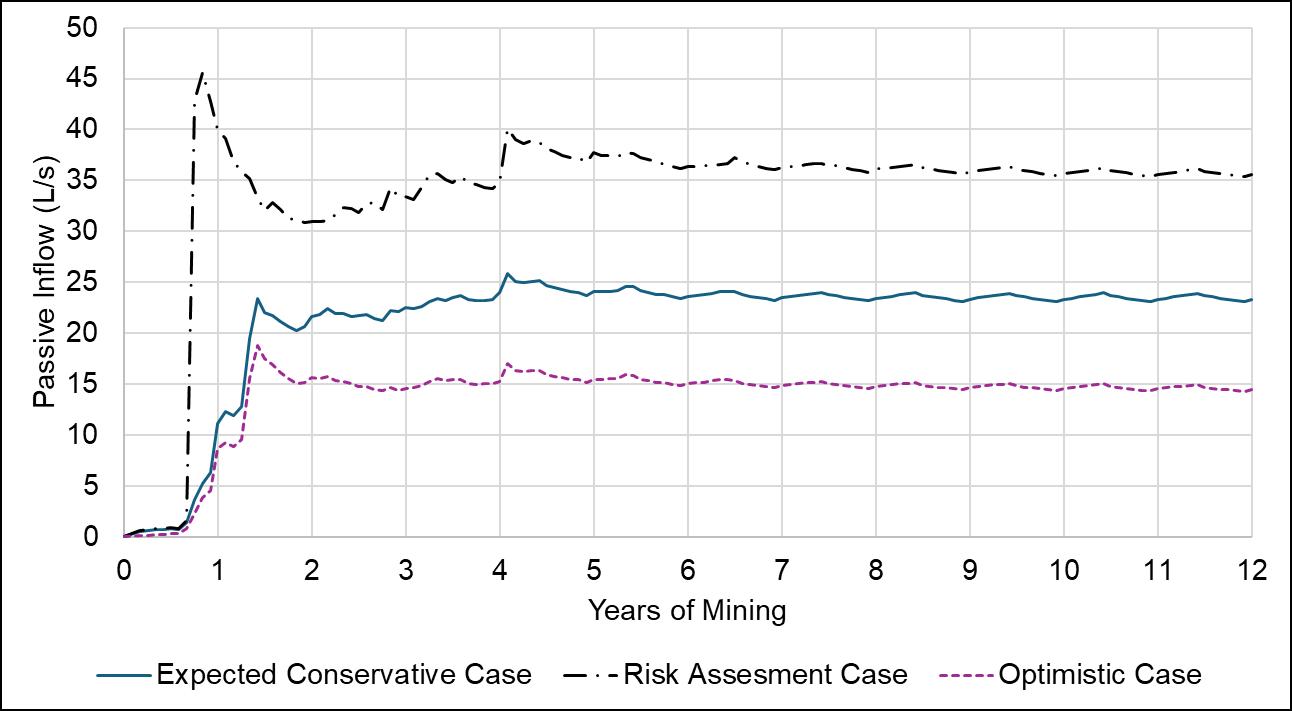

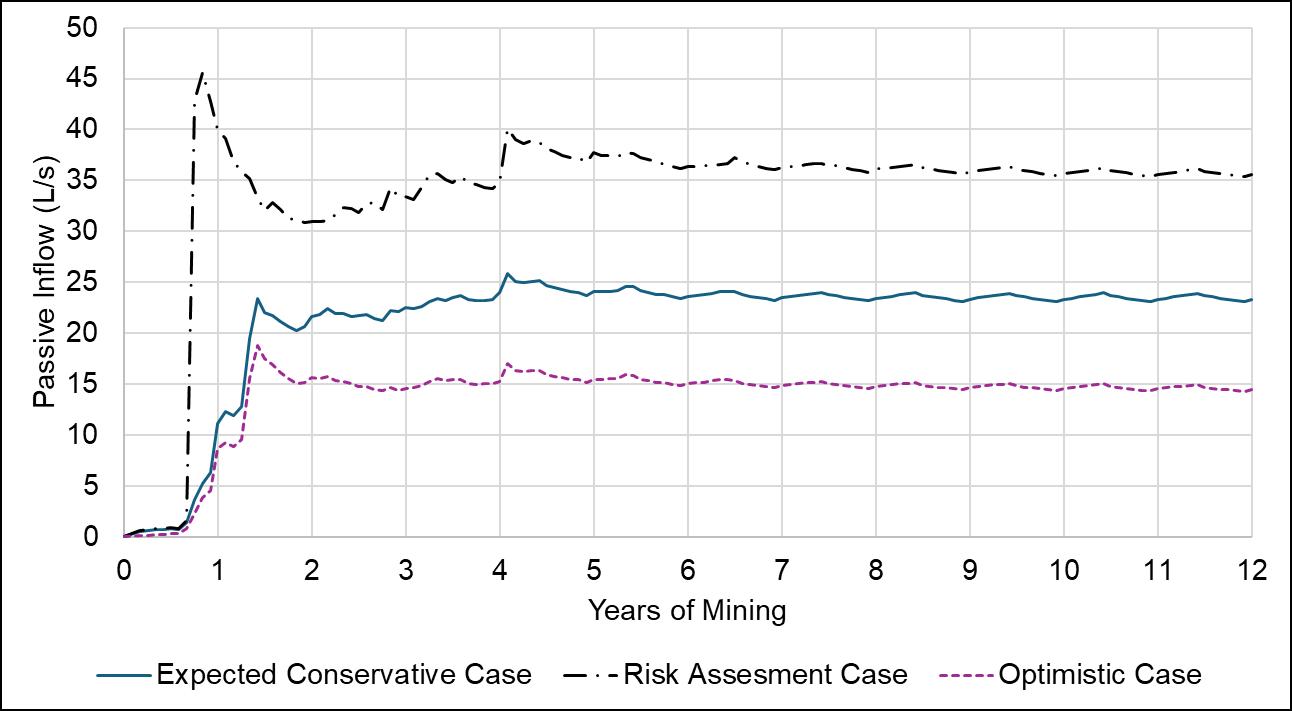

| Figure 15-15: Passive Inflow Sensitivity for Underground Mine |

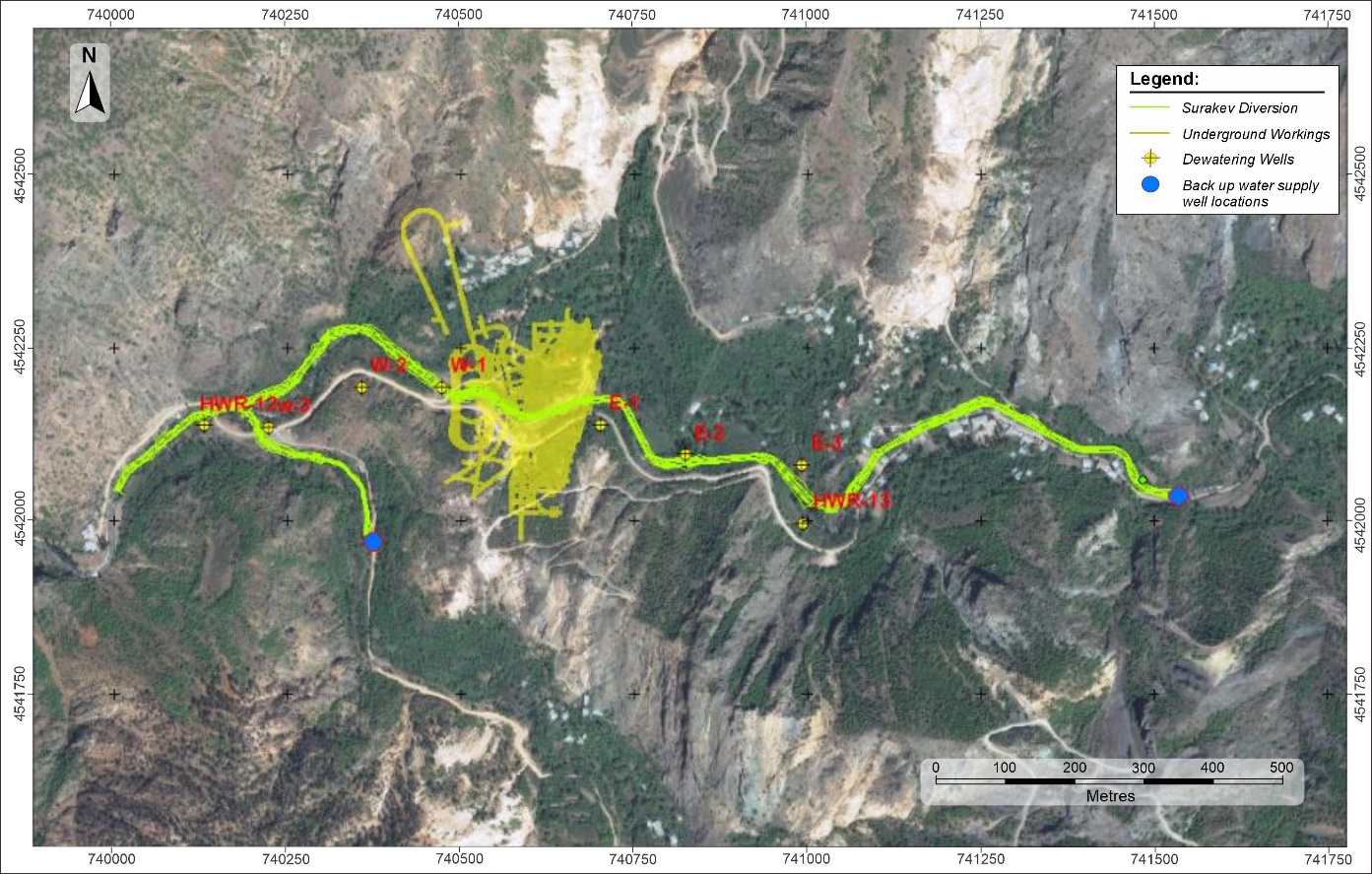

15-12 |

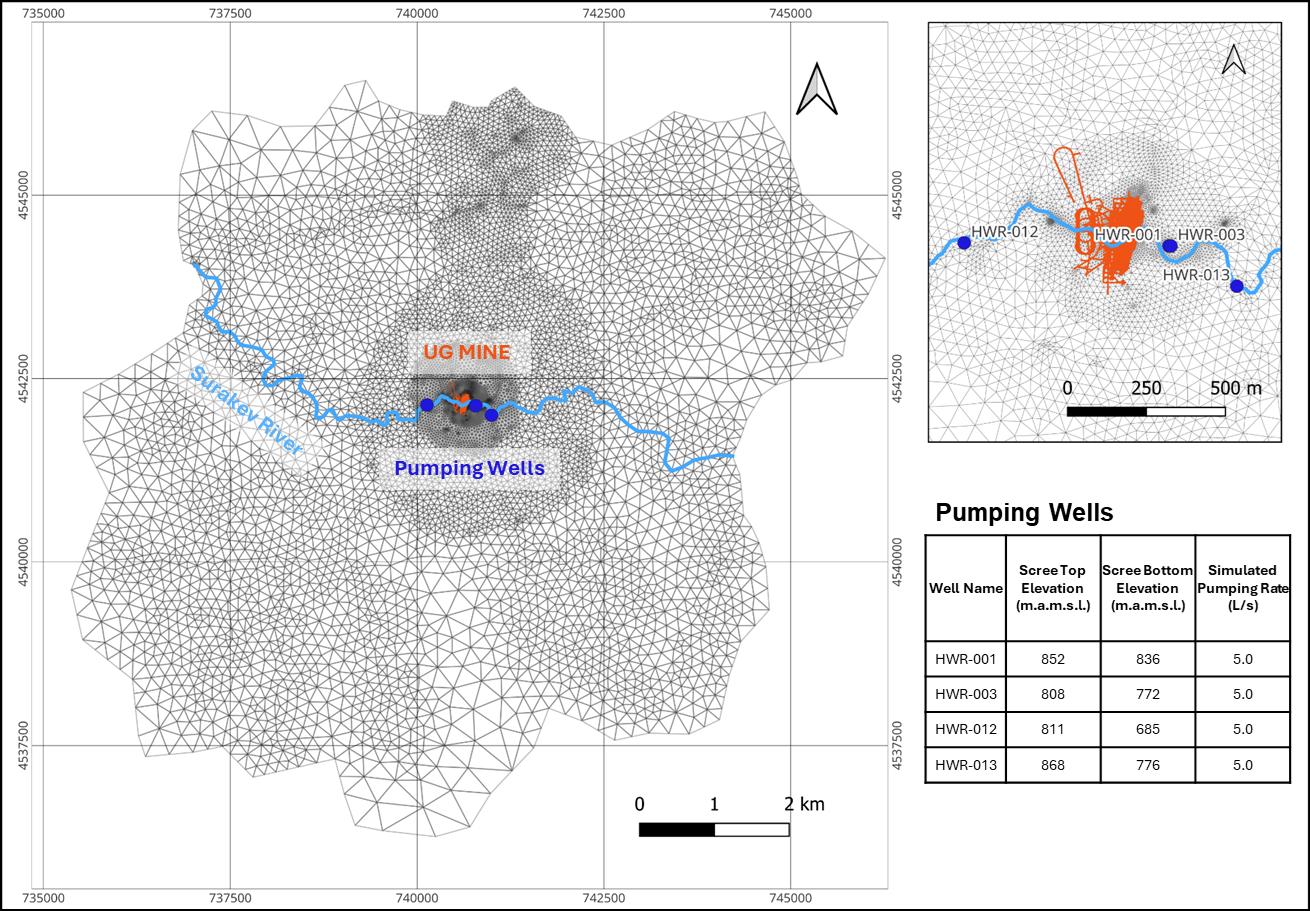

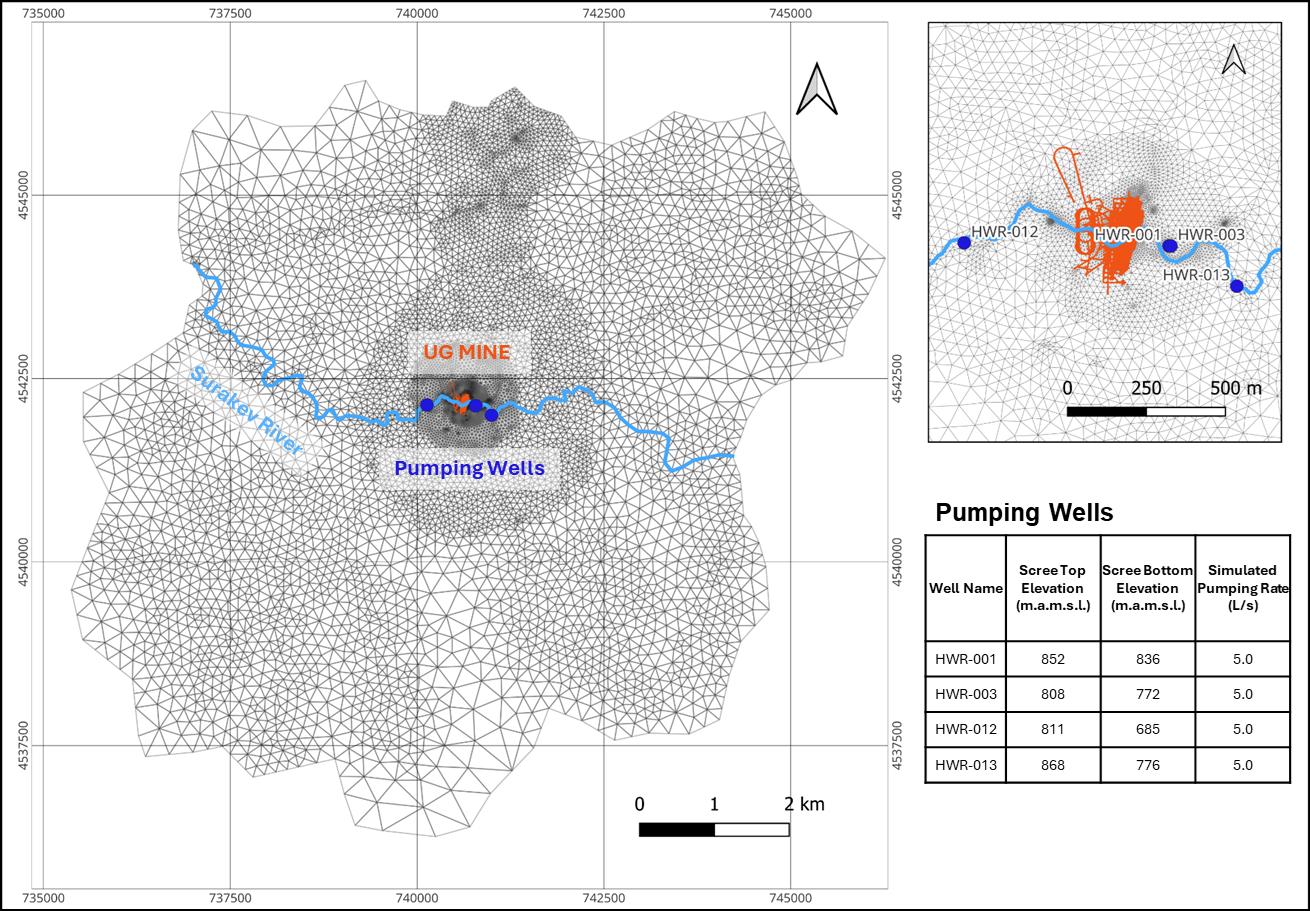

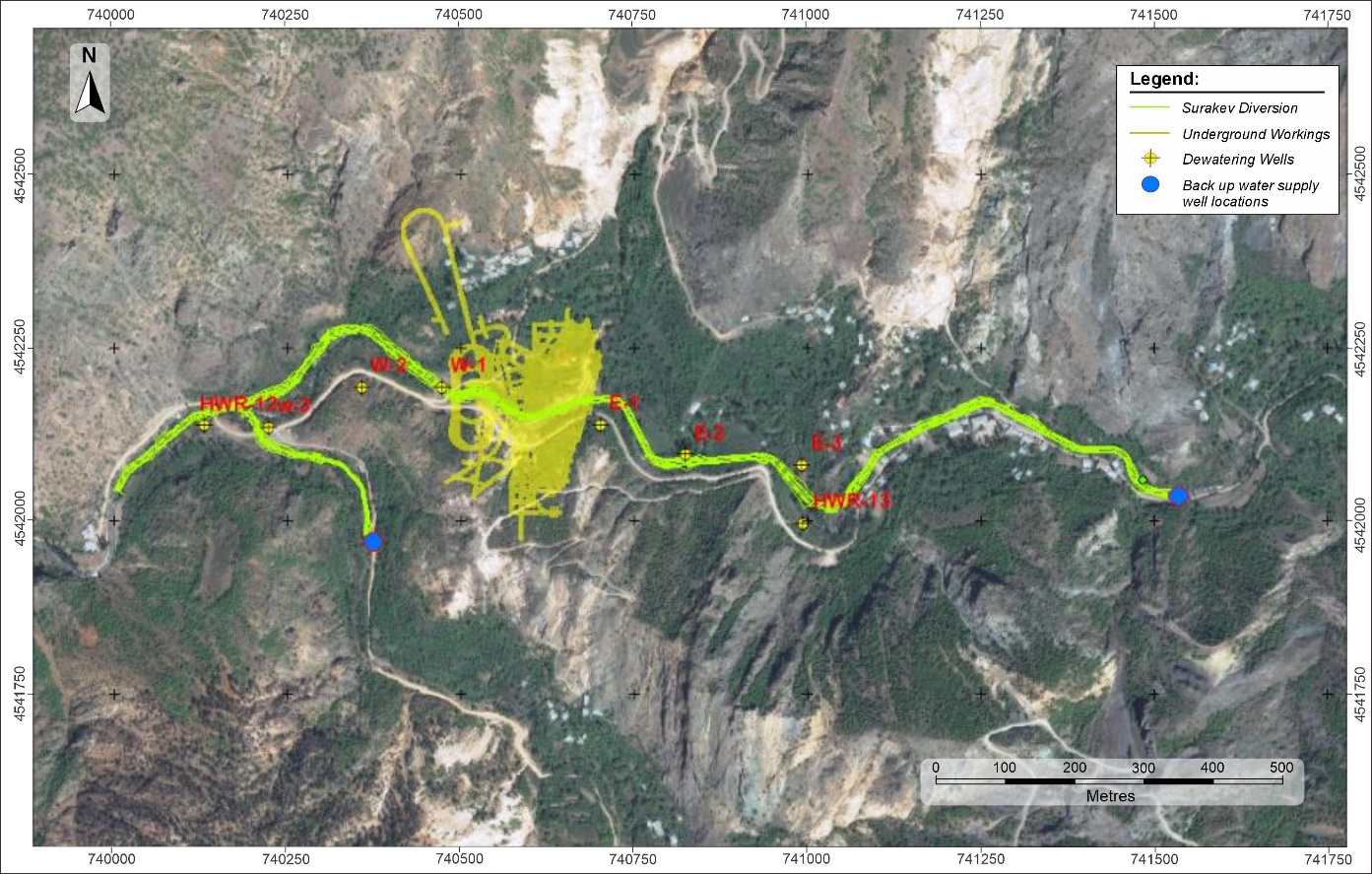

| Figure 15-16: Location of Simulated Dewatering Wells |

15-13 |

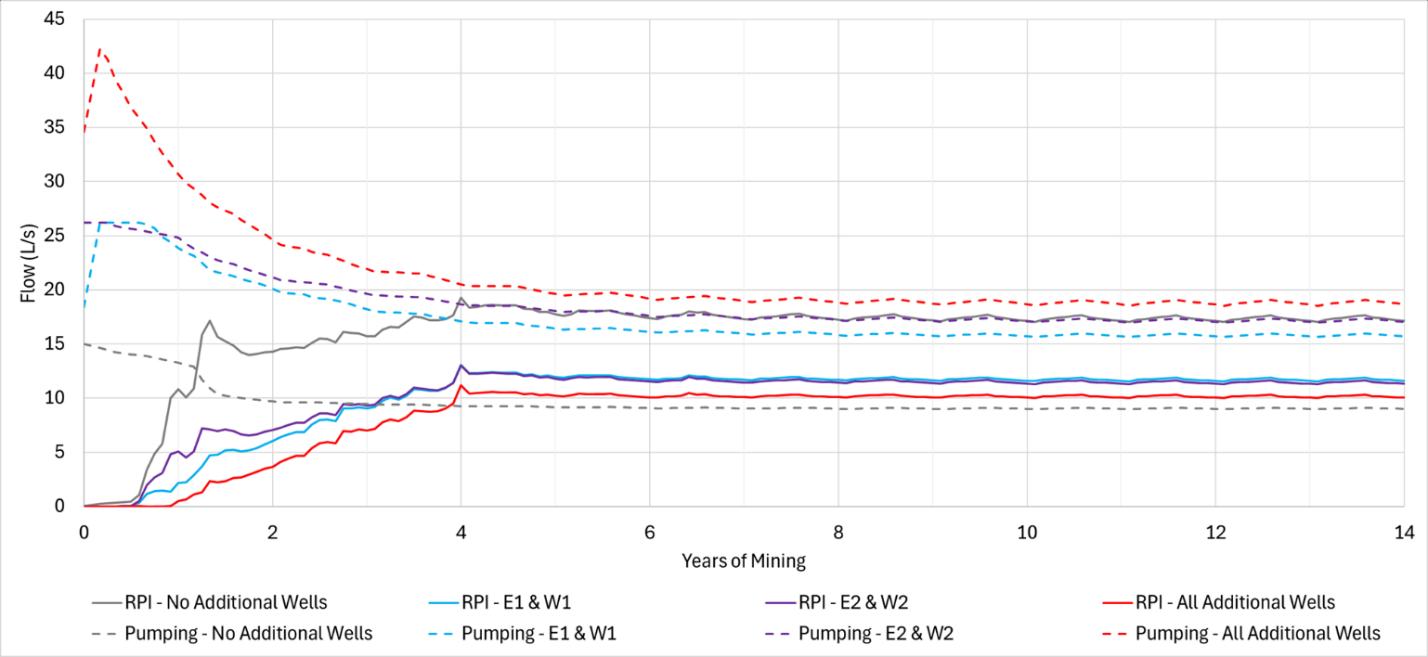

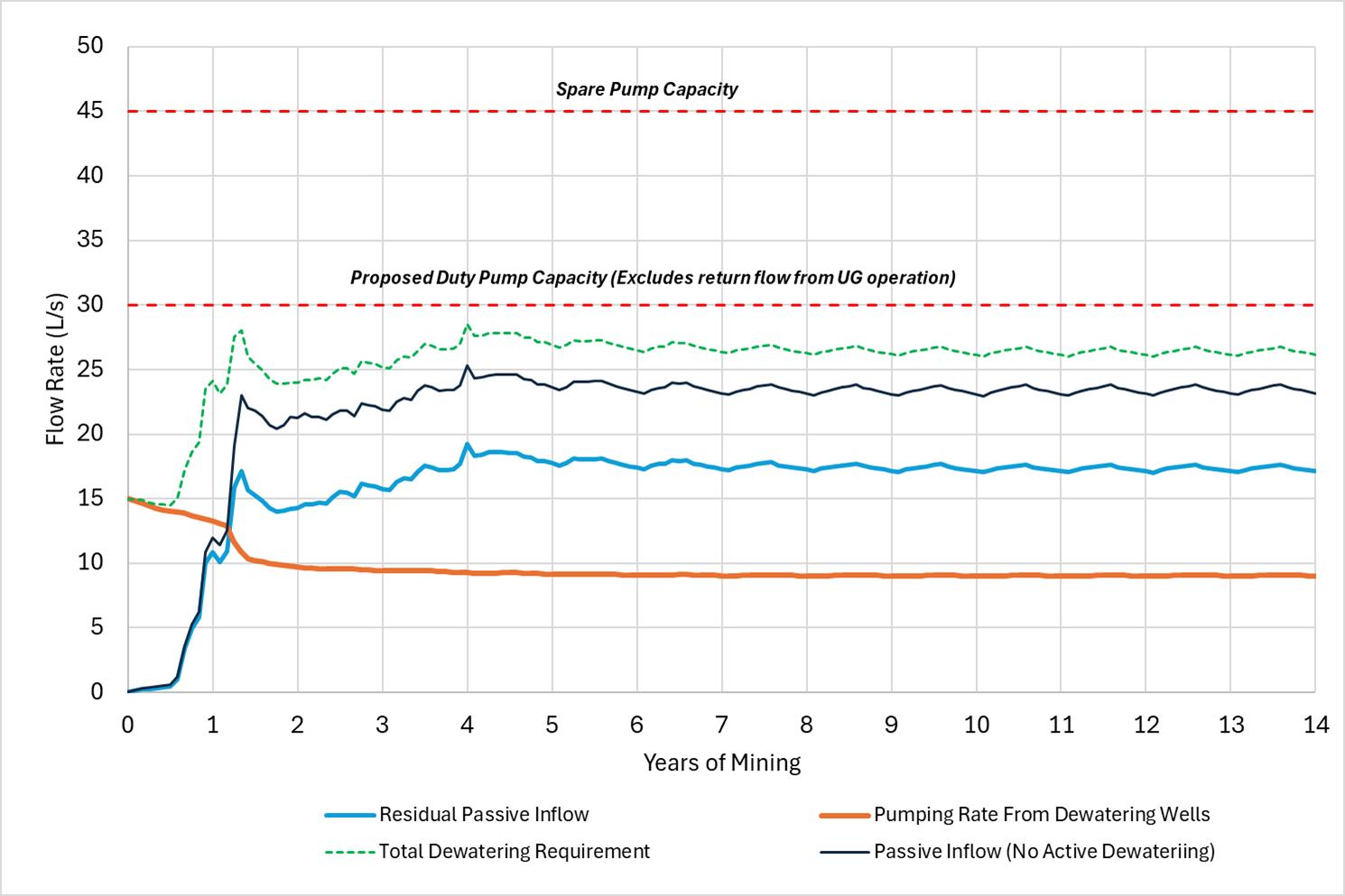

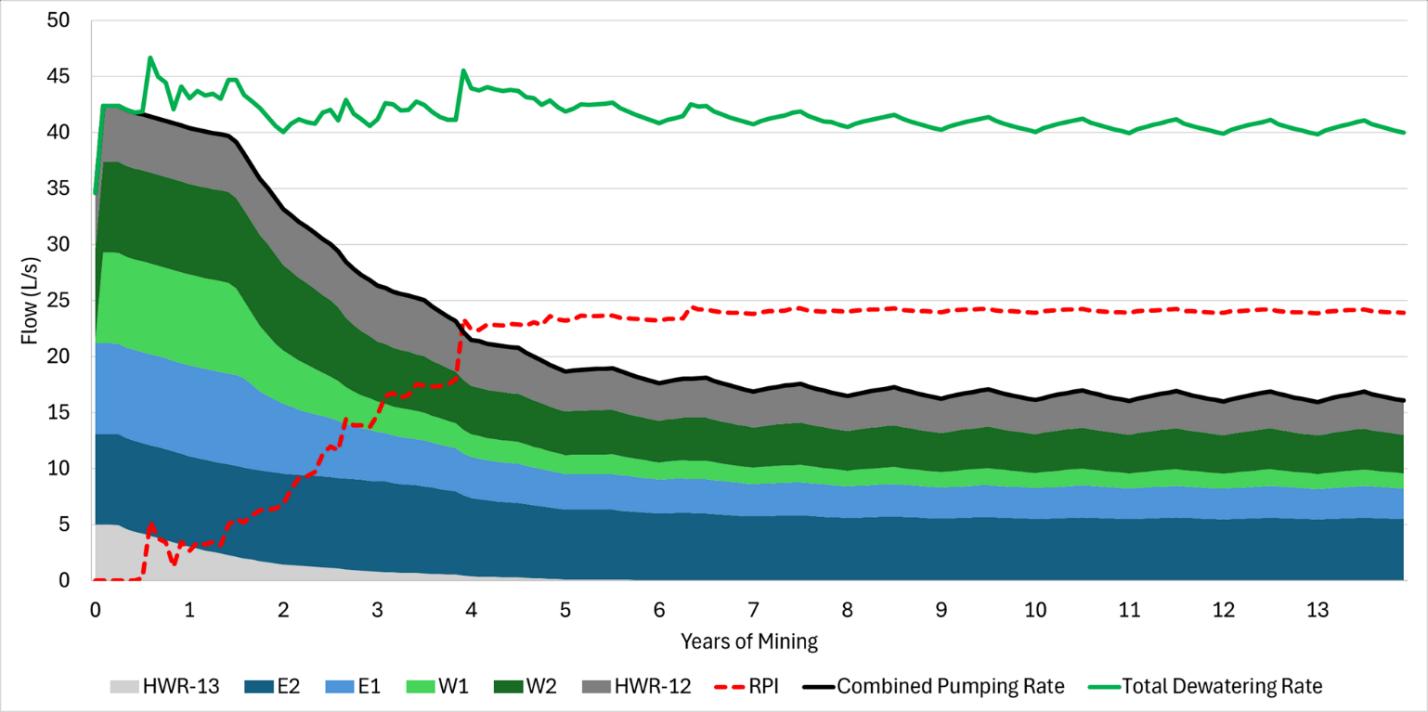

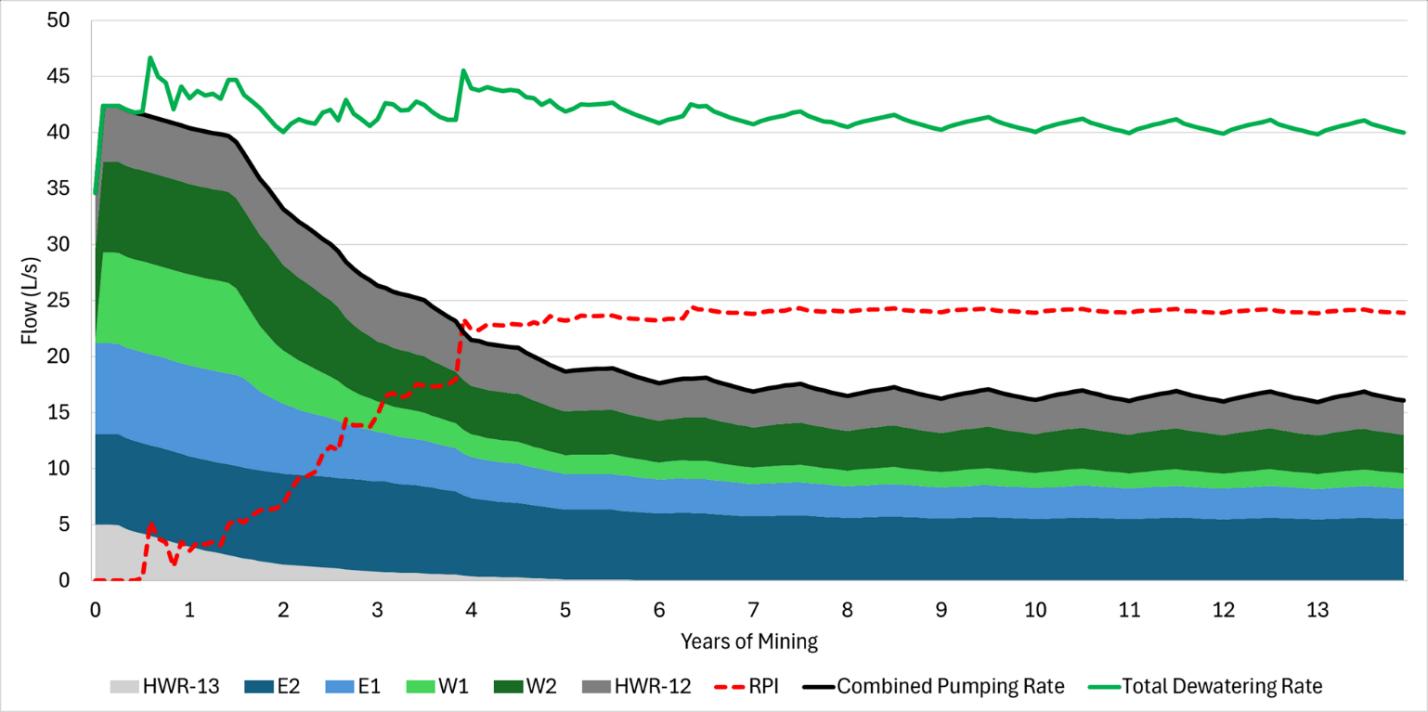

| Figure 15-17: Residual Passive Inflow to the Underground Mine |

15-14 |

| Figure 15-18: Additional Dewatering Wells Locations Assessed |

15-15 |

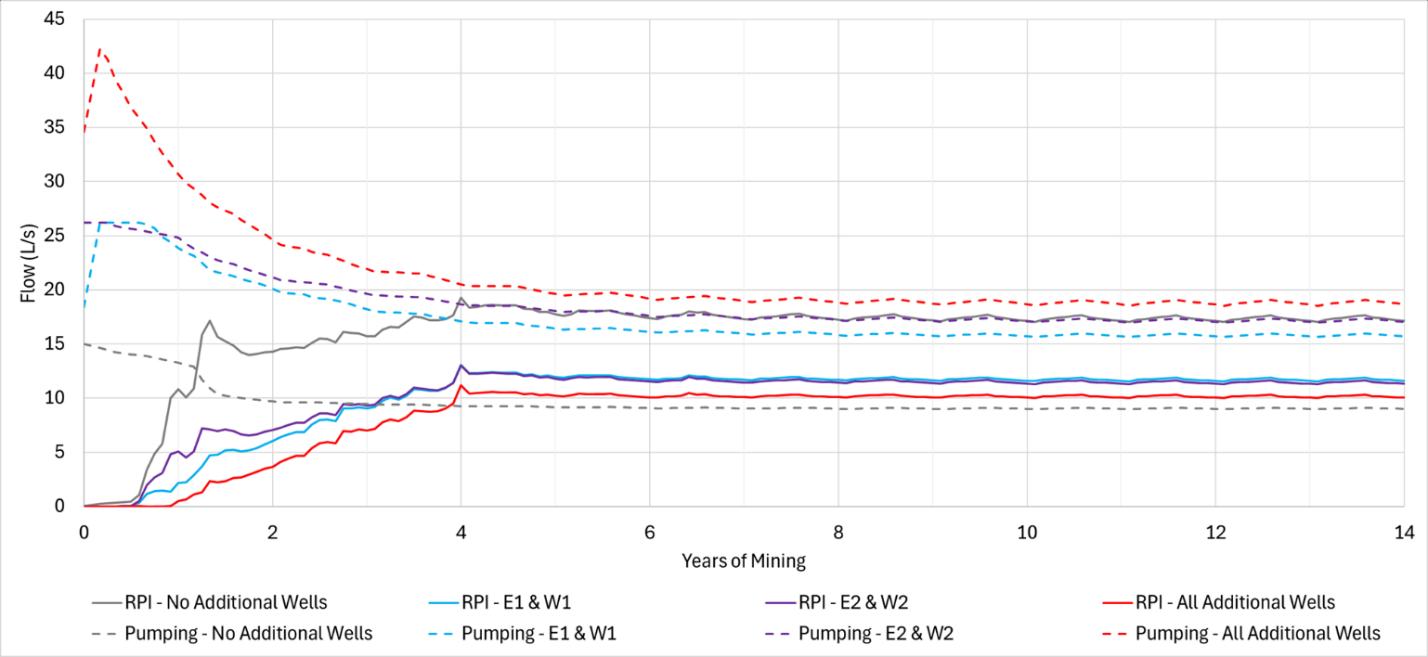

| Figure 15-19: Predictive RPI and Dewatering Rates for Additional Dewatering Infrastructure Scenarios |

15-16 |

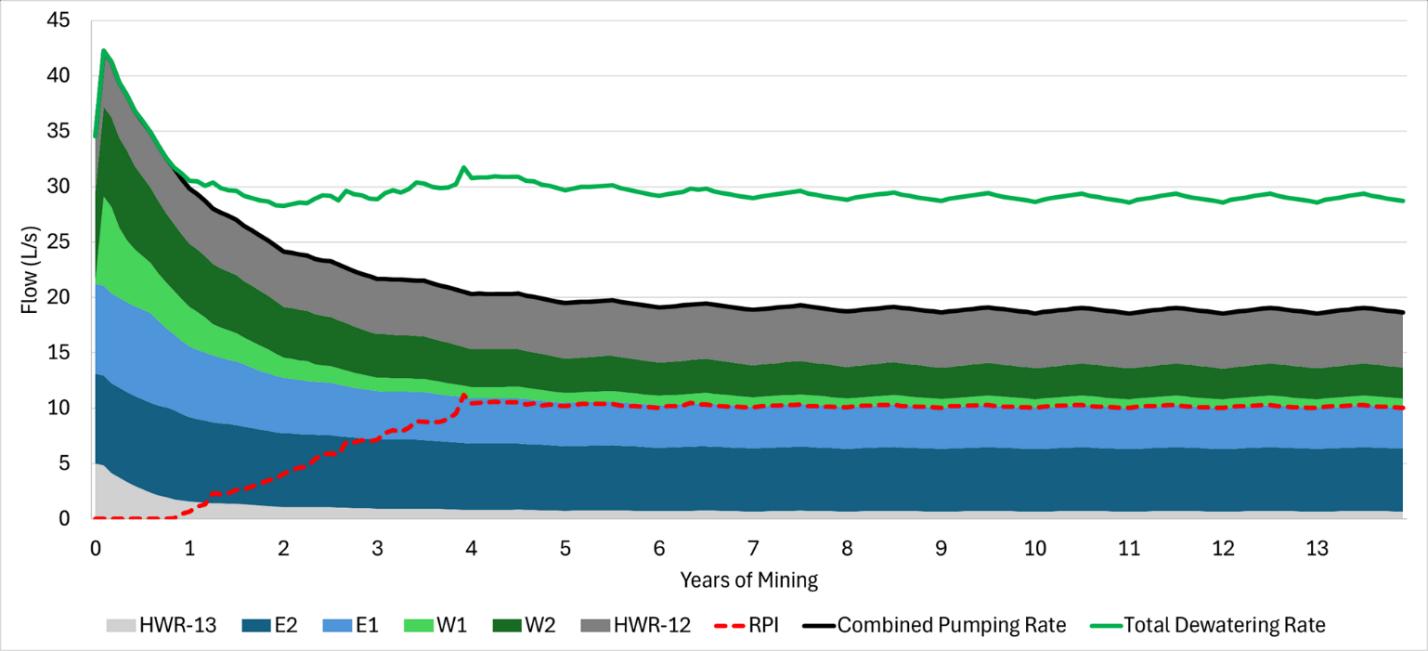

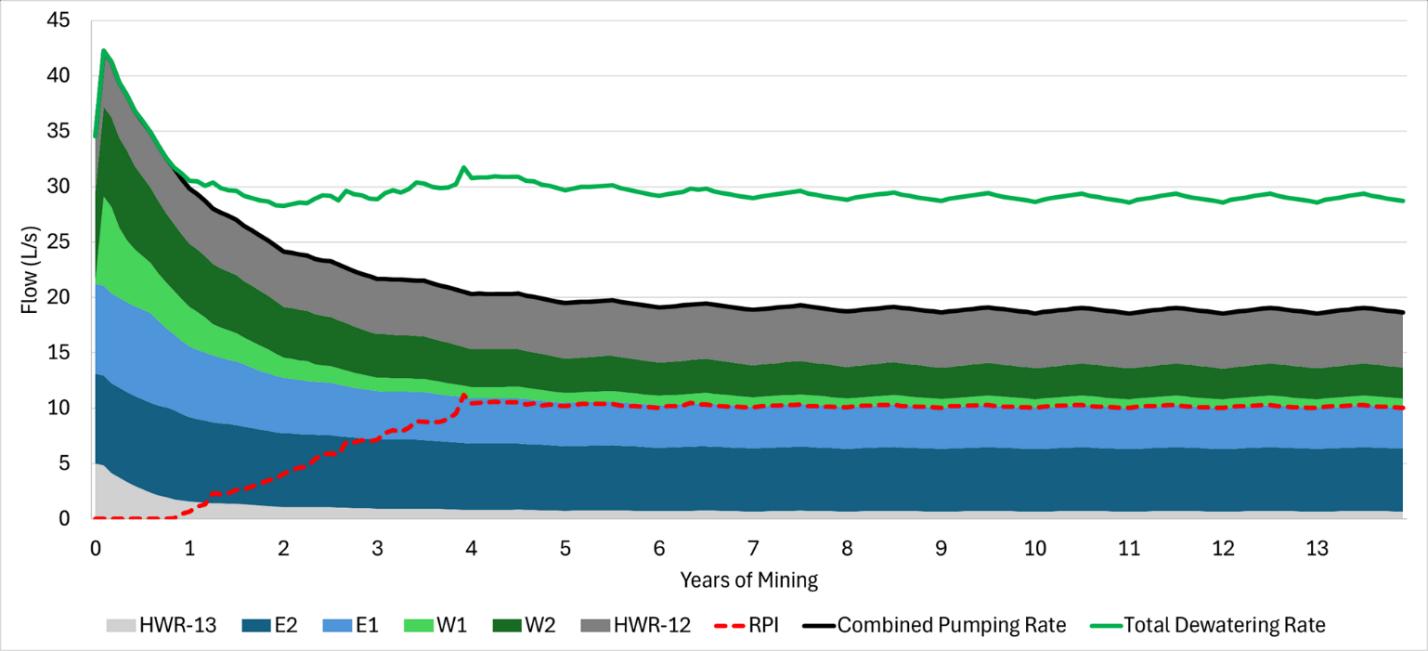

| Figure 15-20: Predictive Total Pumping Rate From All Wells (can be used for Water Supply) |

15-16 |

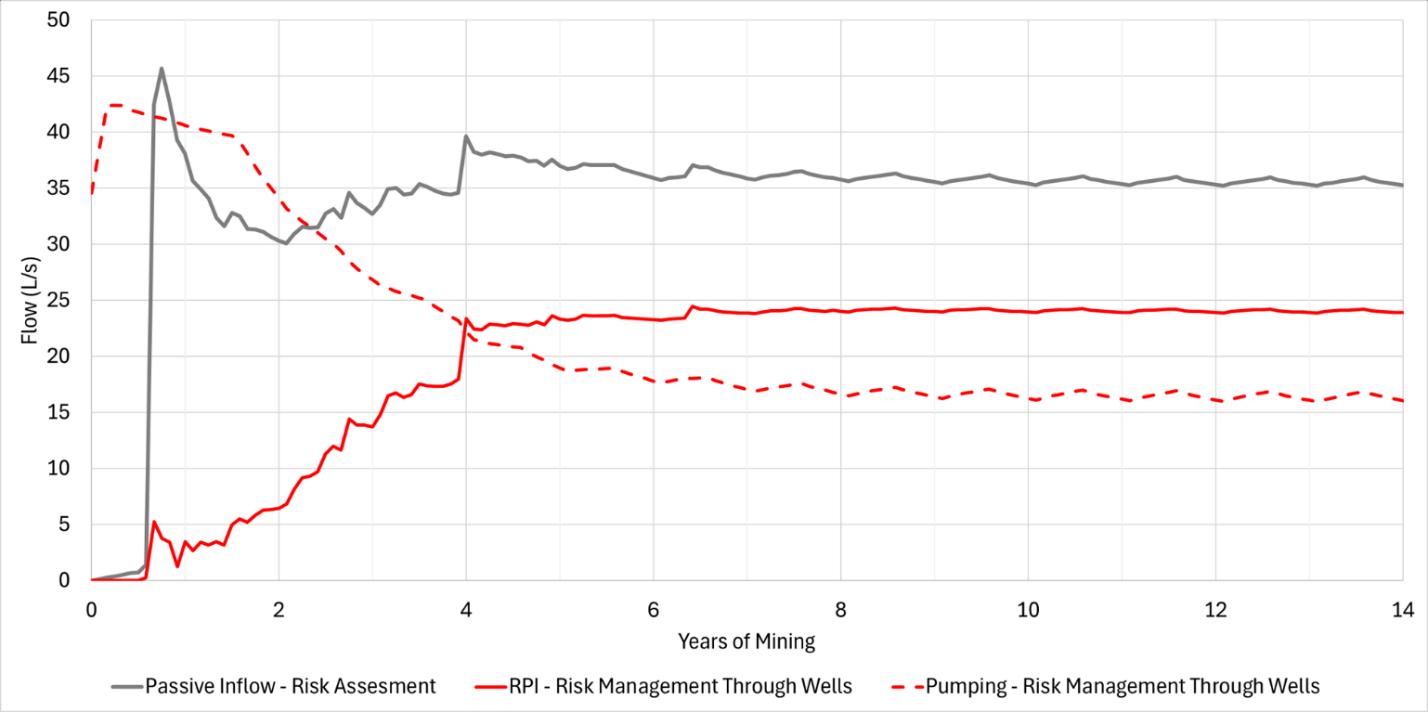

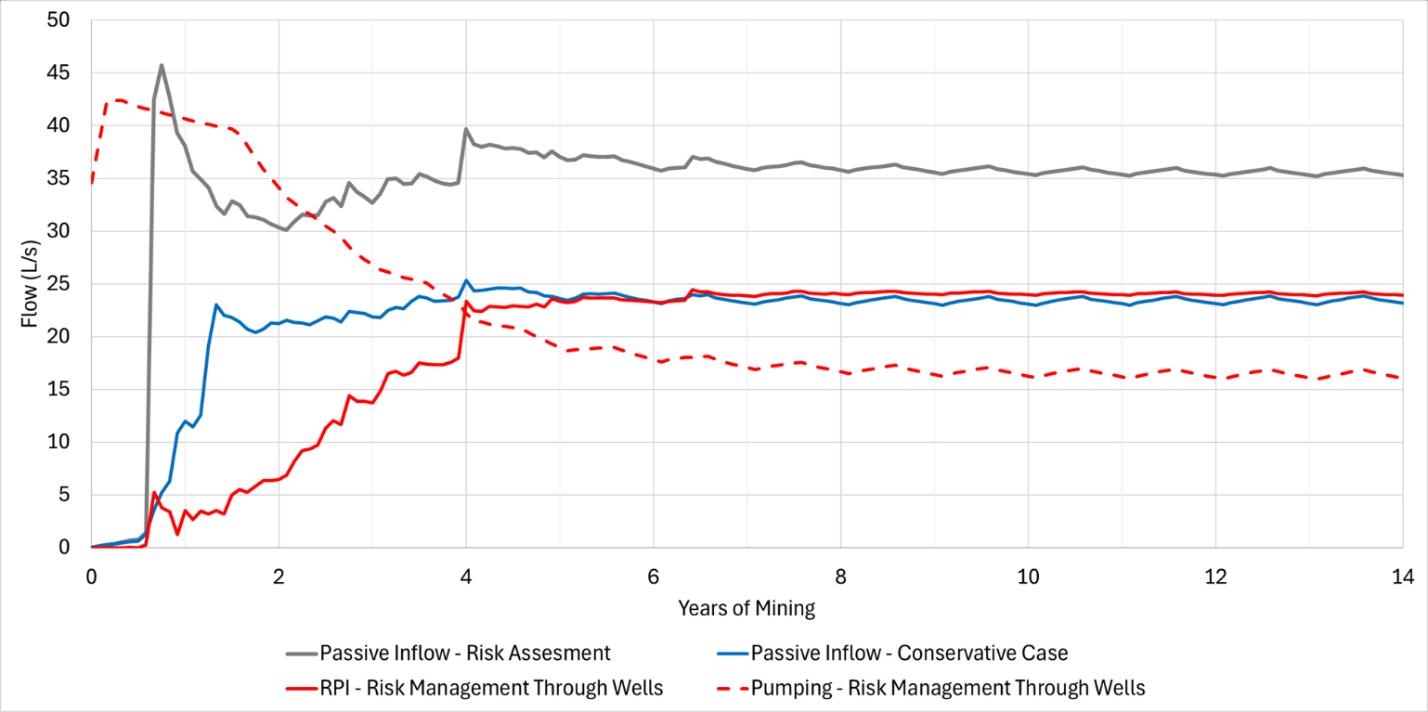

| Figure 15-21: Predictive RPI and Total Pumping Rate from Dewatering Wells - Risk Management Scenario |

15-17 |

| Figure 15-22: Predictive Total Pumping Rate From All Wells - Risk Management Scenario |

15-18 |

| Figure 15-23: Predictive RPI and Total Pumping Rate from Dewatering Wells - Risk Management Scenario |

15-19 |

| Figure 15-24: Predictive Total Pumping Rate From All Wells - Risk Management Scenario |

15-19 |

| Figure 15-25: Water Supply and Dewatering Well Locations |

15-21 |

| Figure 15-26: Location of Stream Gauges (AGI) |

15-23 |

| Figure 15-27: Monthly Average Streamflow Measurements (2018-2021) |

15-24 |

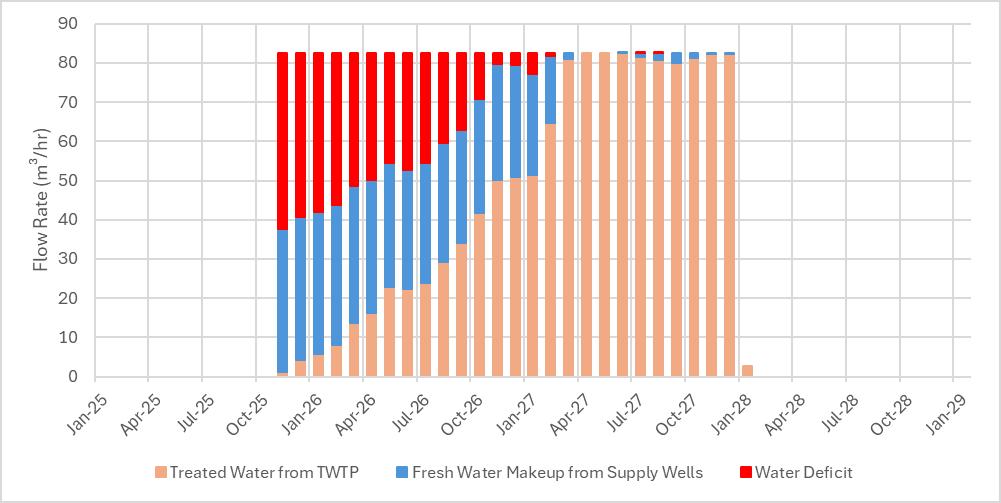

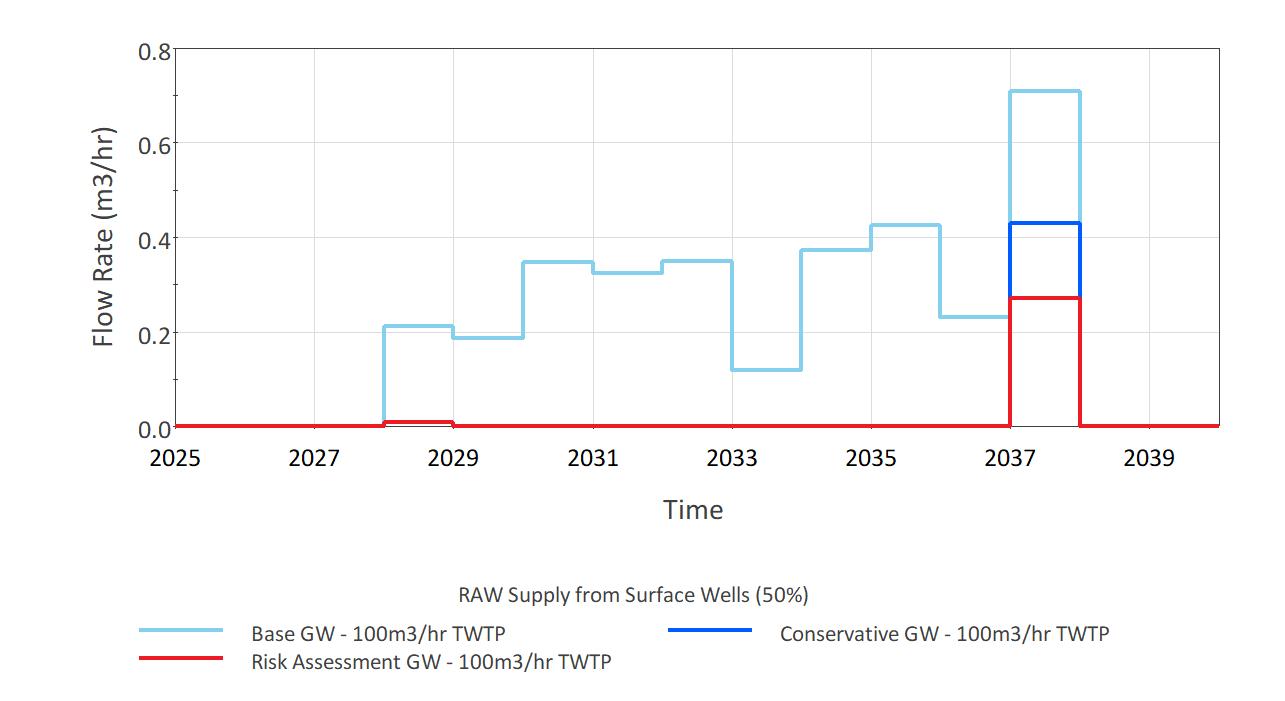

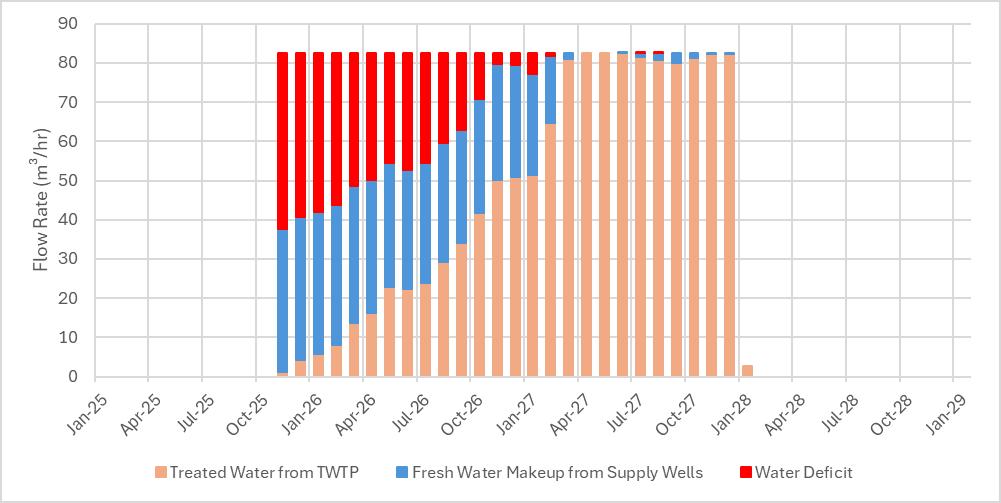

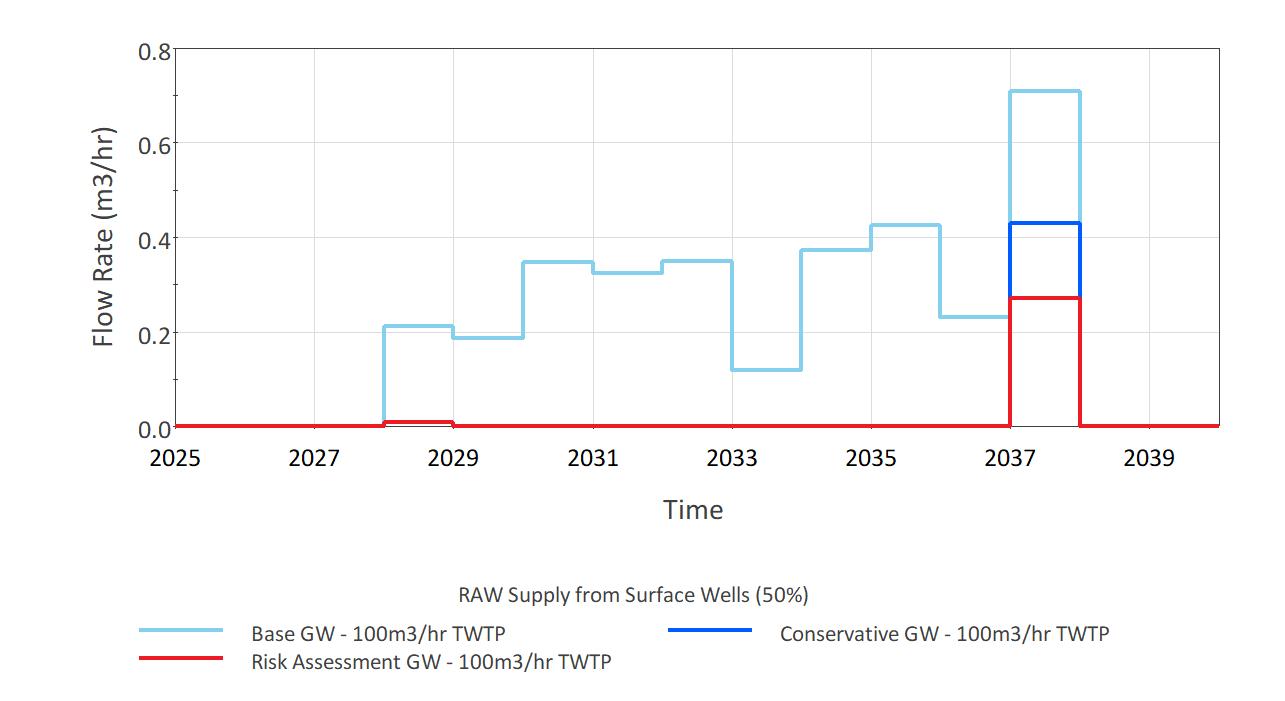

| Figure 15-28: Construction Water Supply Sources Under Current Licensed Well Capacity (Conservative GW - 100 m³/h

TWTP) |

15-28 |

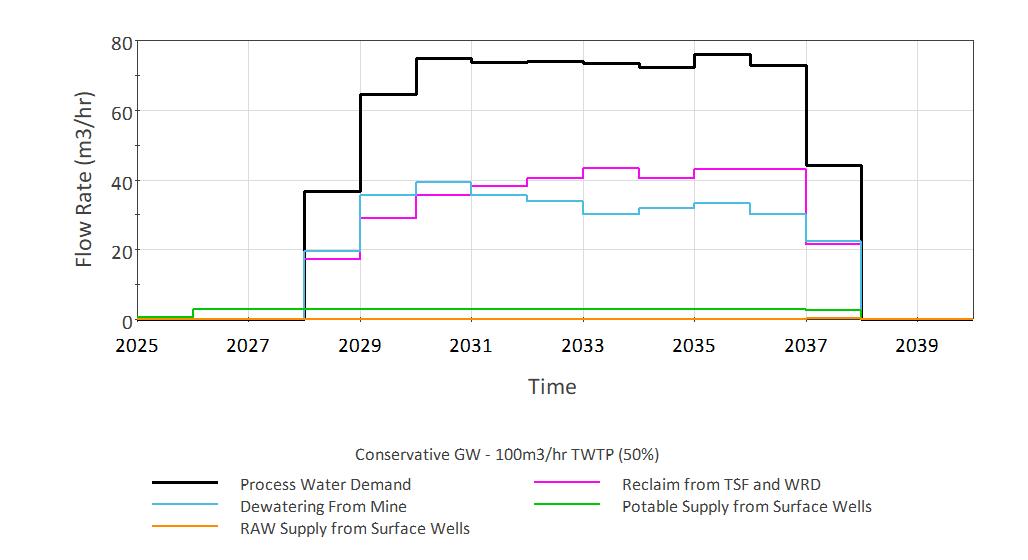

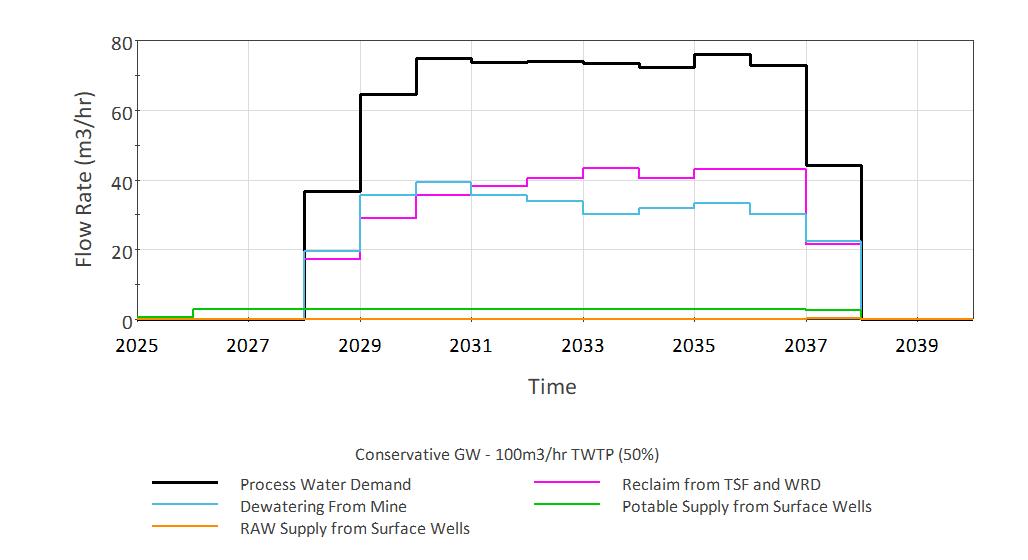

| Figure 15-29: Process Plant Makeup Sources Annual Average Rates (Conservative GW) |

15-30 |

| Figure 15-30: Supply

from Water Wells (All GW Scenarios, 50th Percentile) |

15-30 |

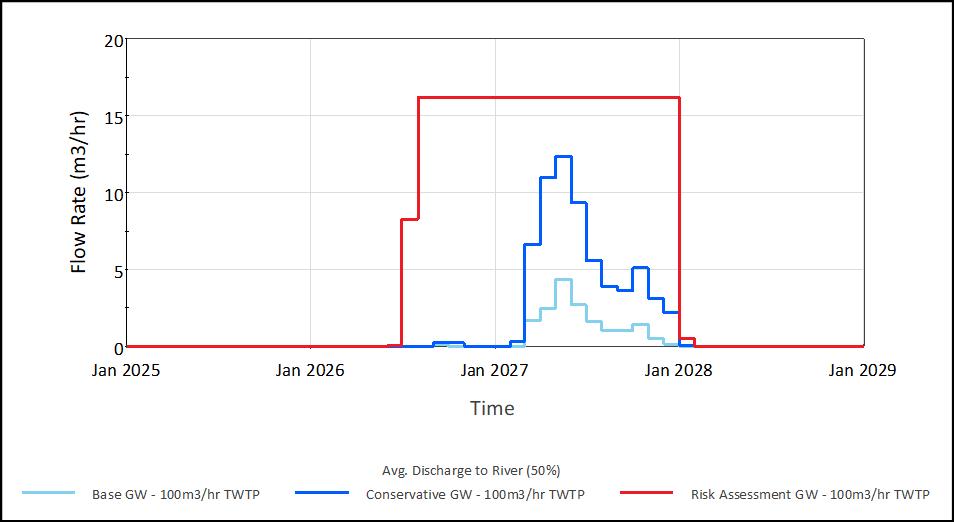

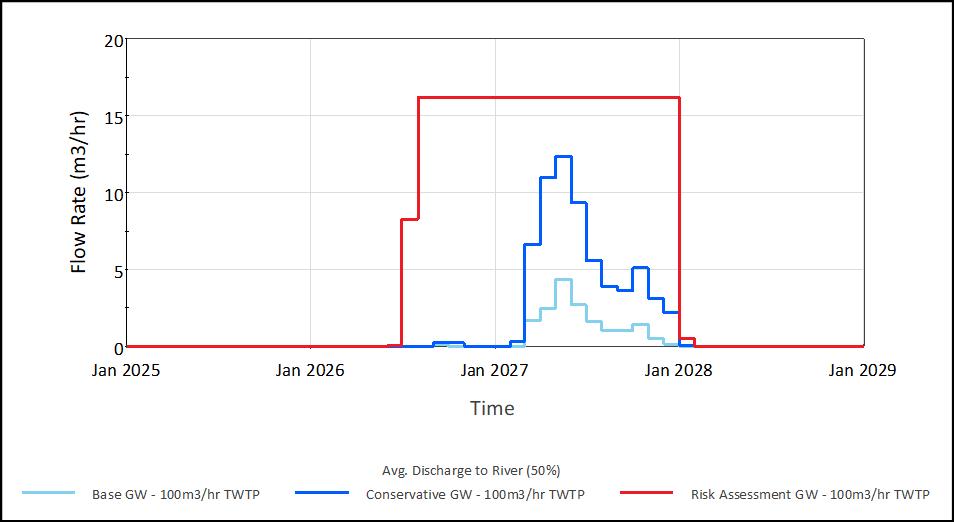

| Figure 15-31: Construction Phase Treated Water Discharge (All GW Scenarios, 50th Percentile) |

15-32 |

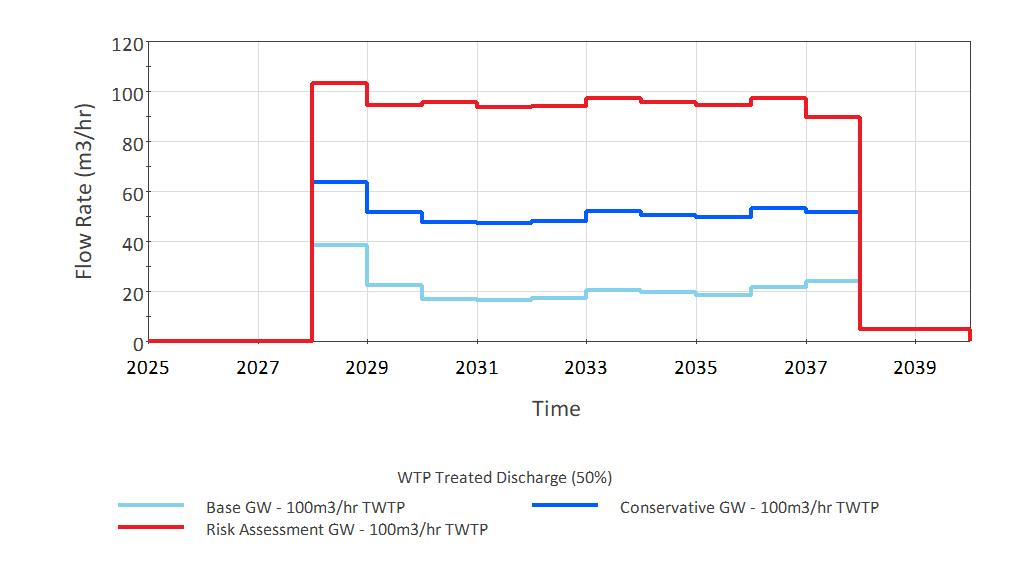

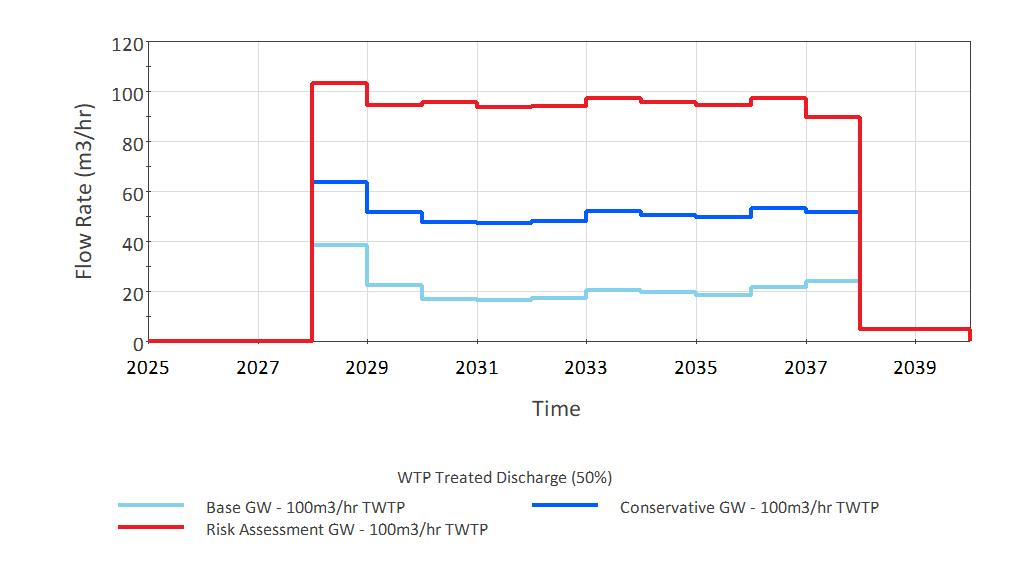

| Figure 15-32: Annual Average and Cumulative Effluent Discharge to Şurakev Creek (50th Percentile) |

15-33 |

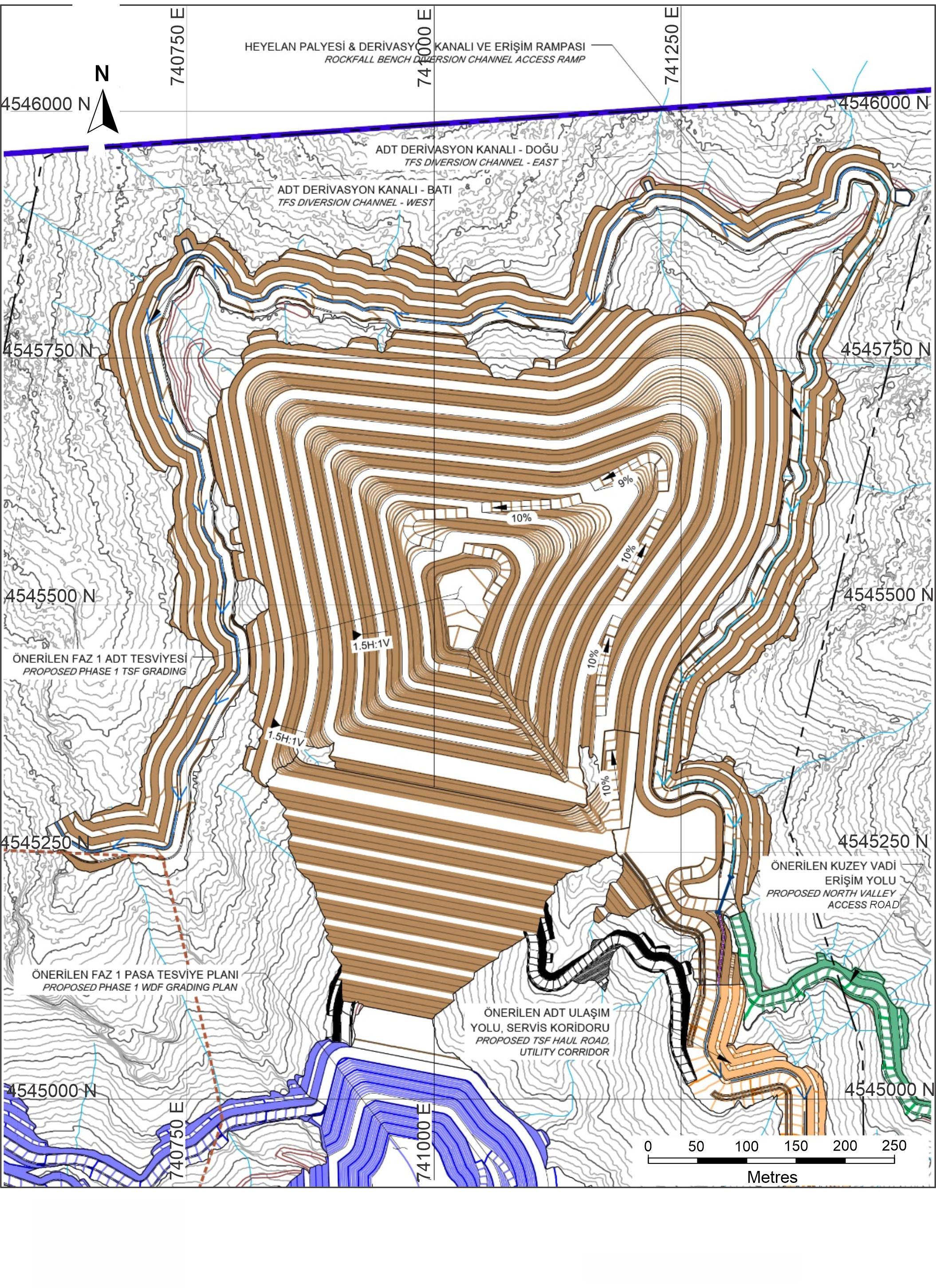

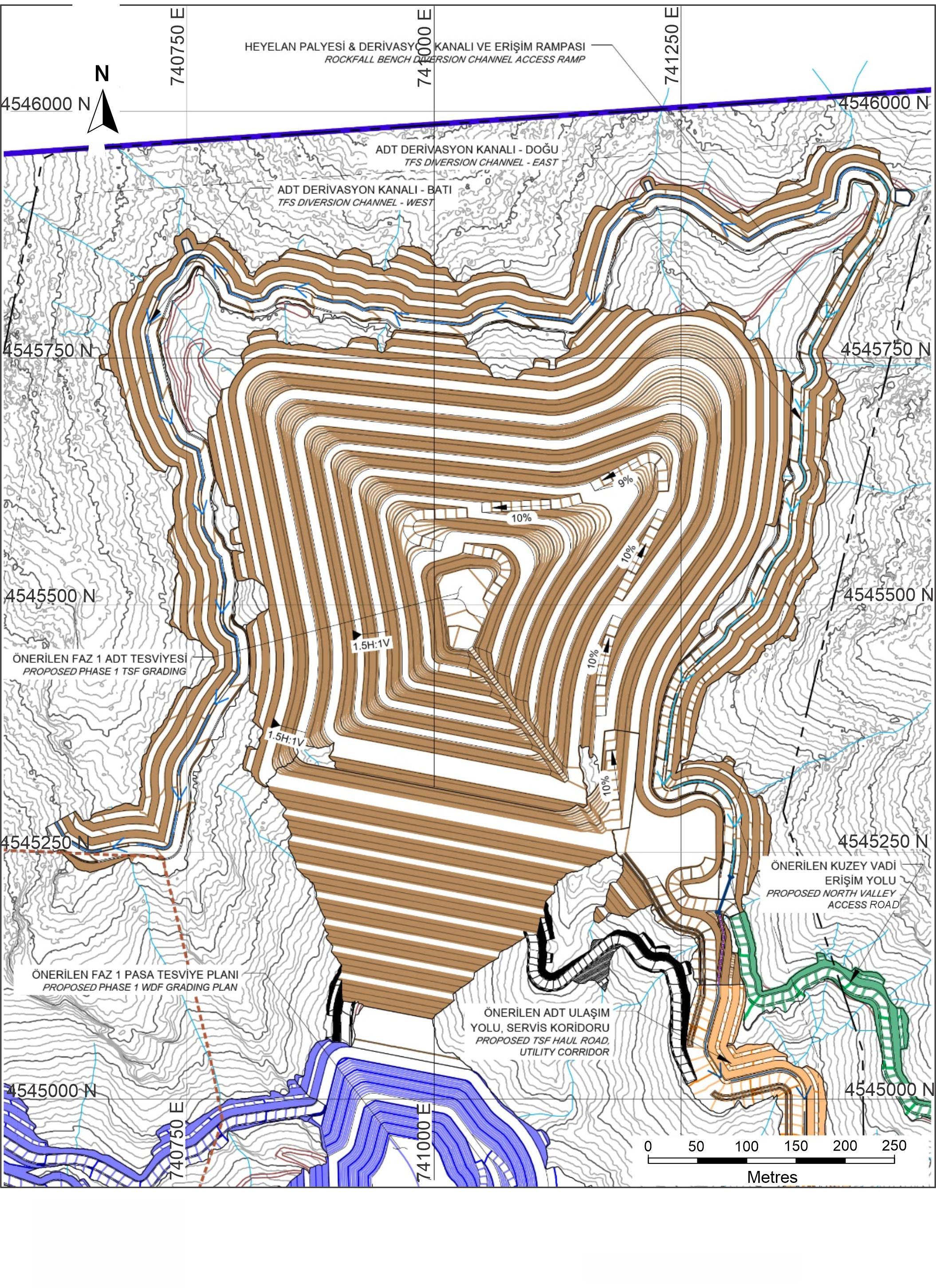

| Figure 15-33: TSF Ultimate Design |

15-39 |

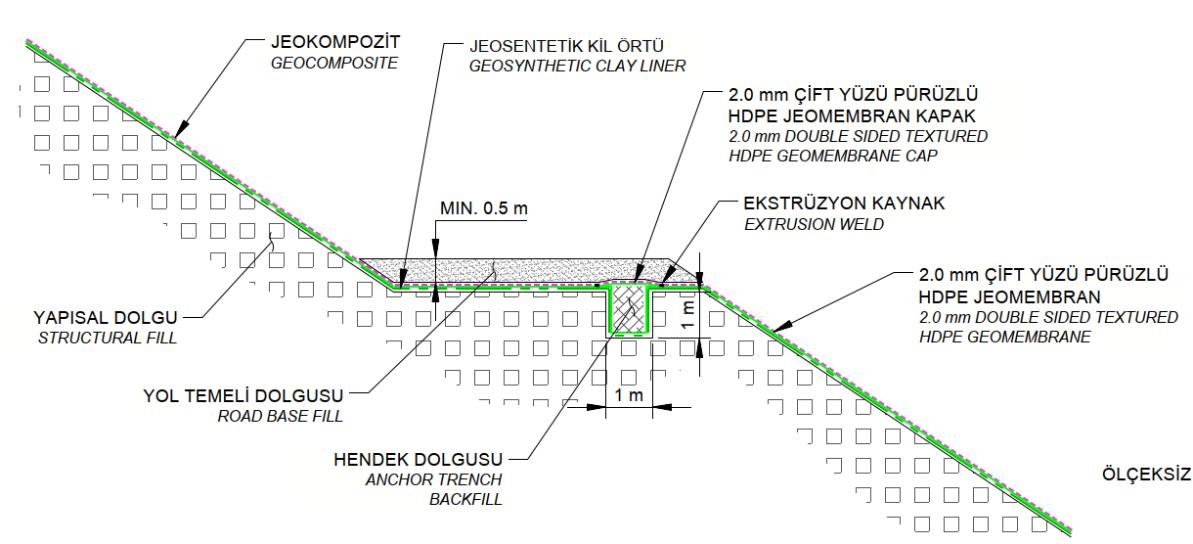

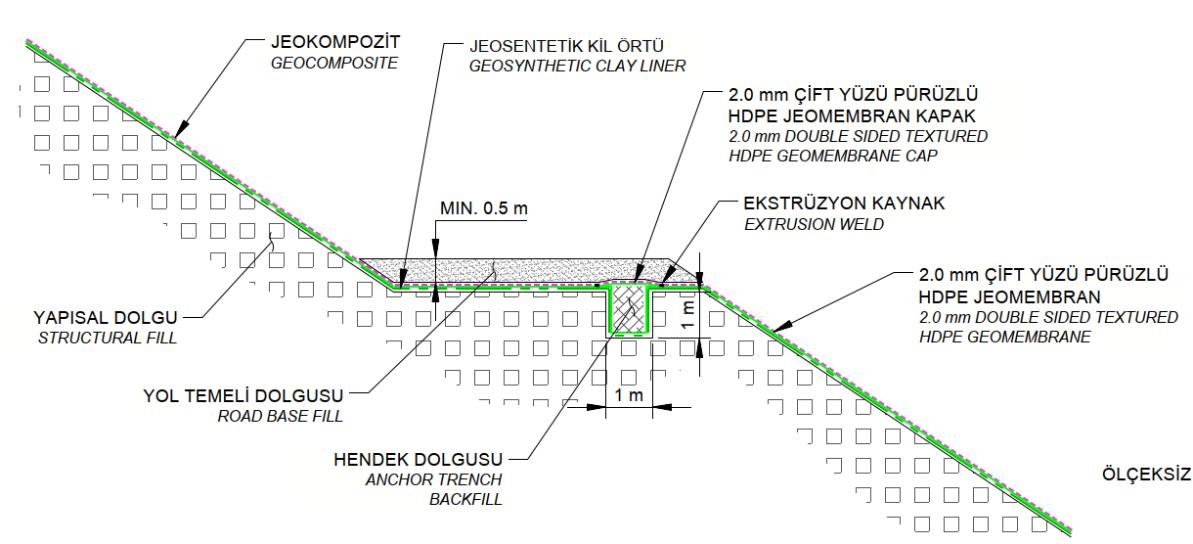

| Figure 15-34: Typical TSF Impoundment Liner Detail |

15-42 |

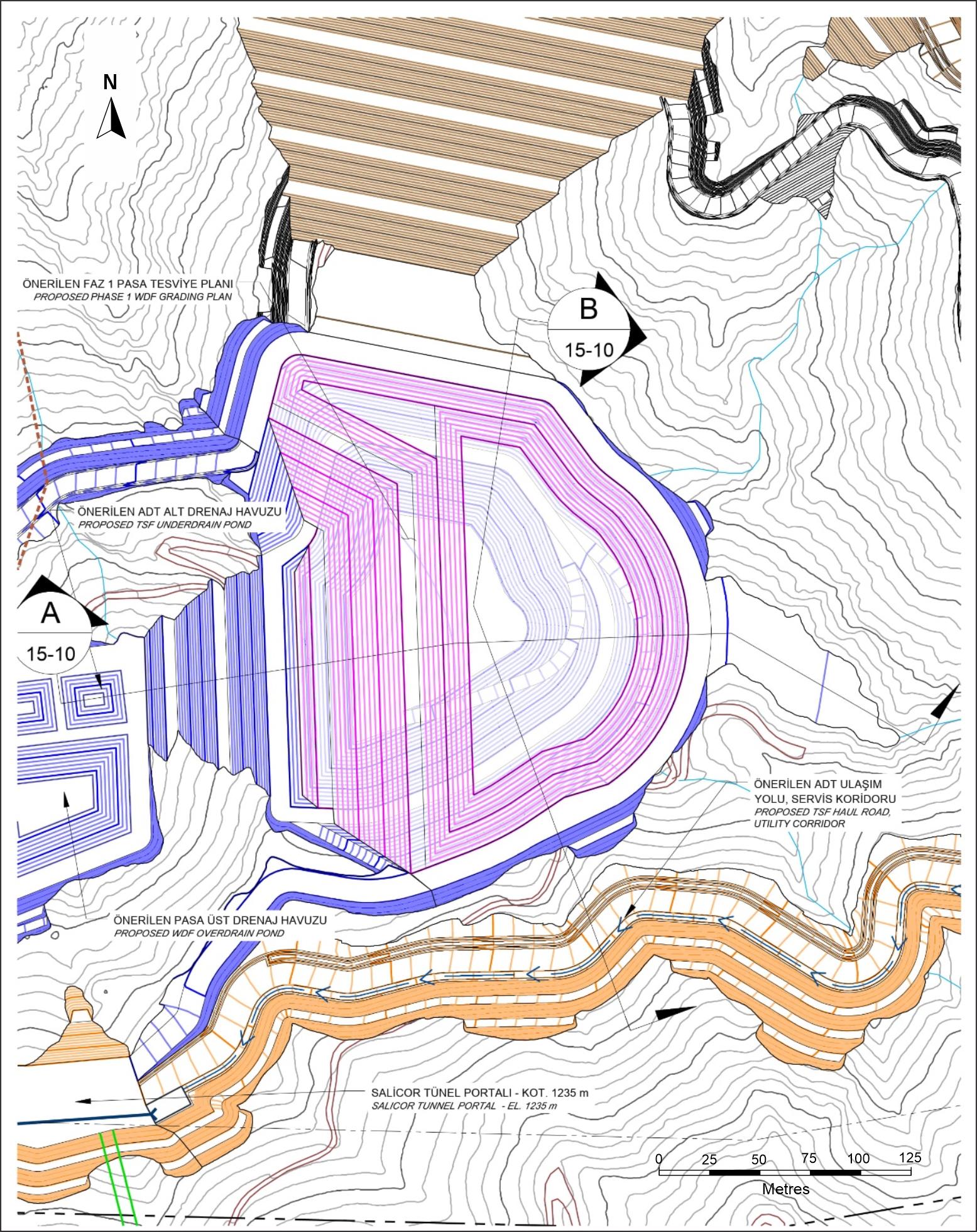

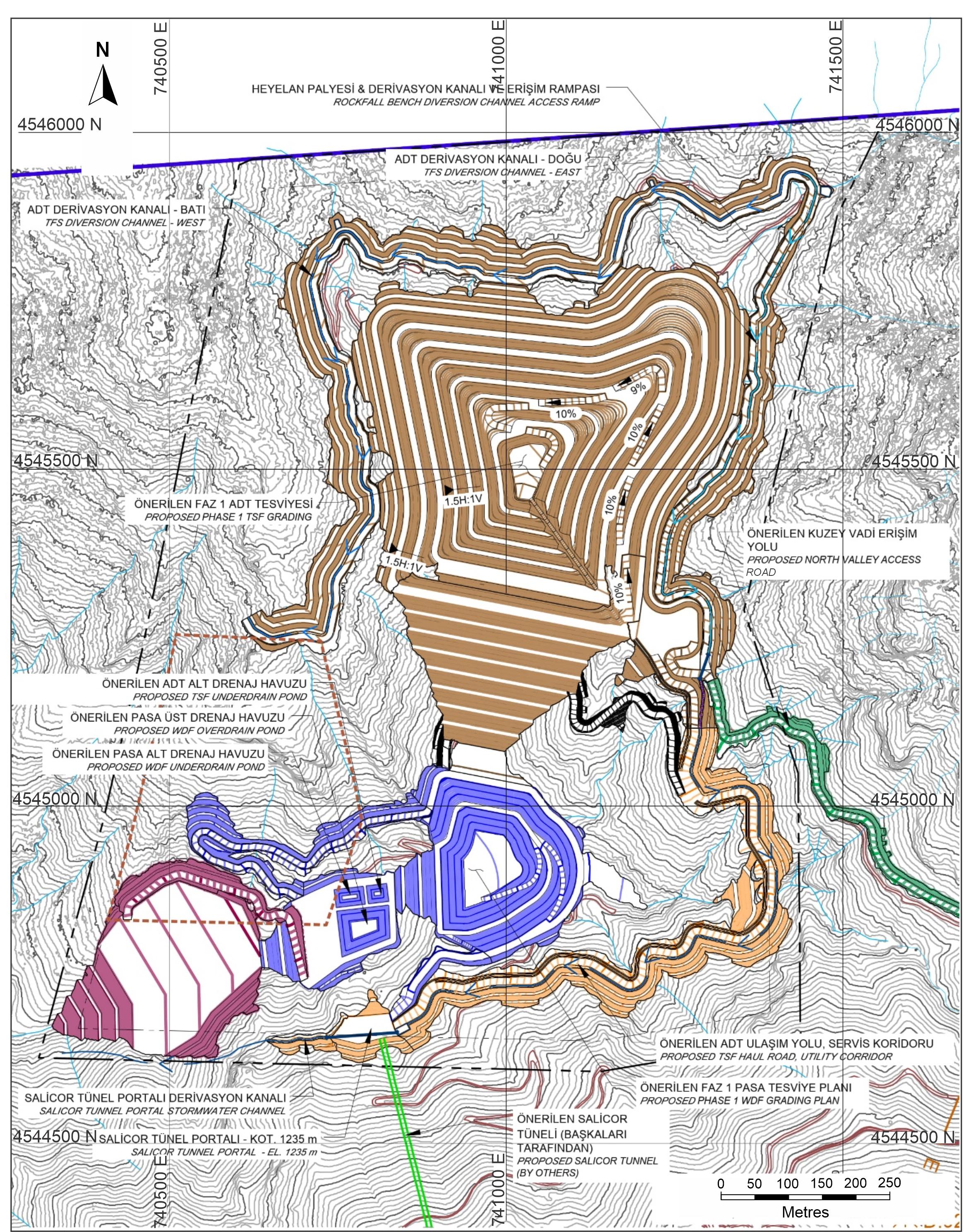

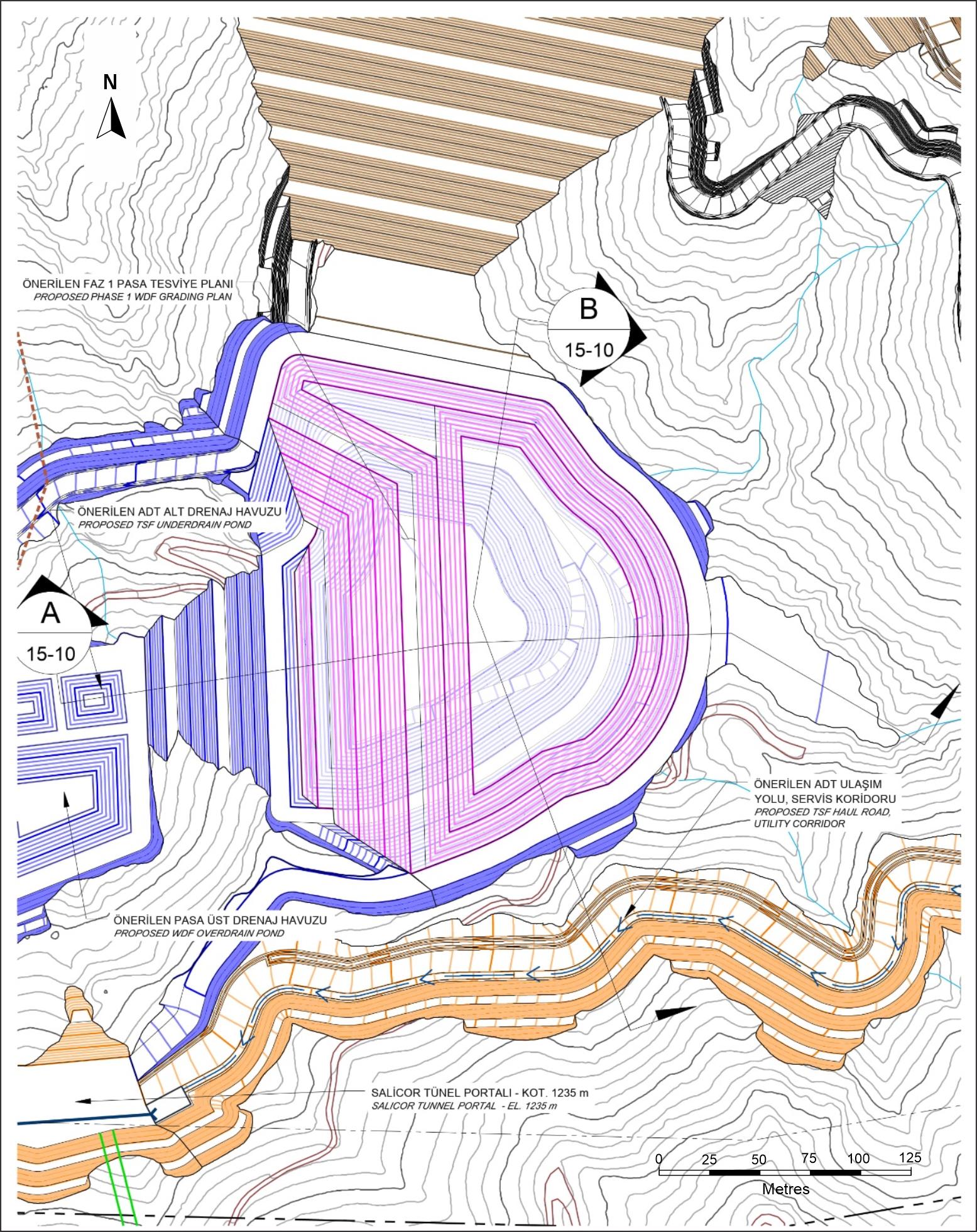

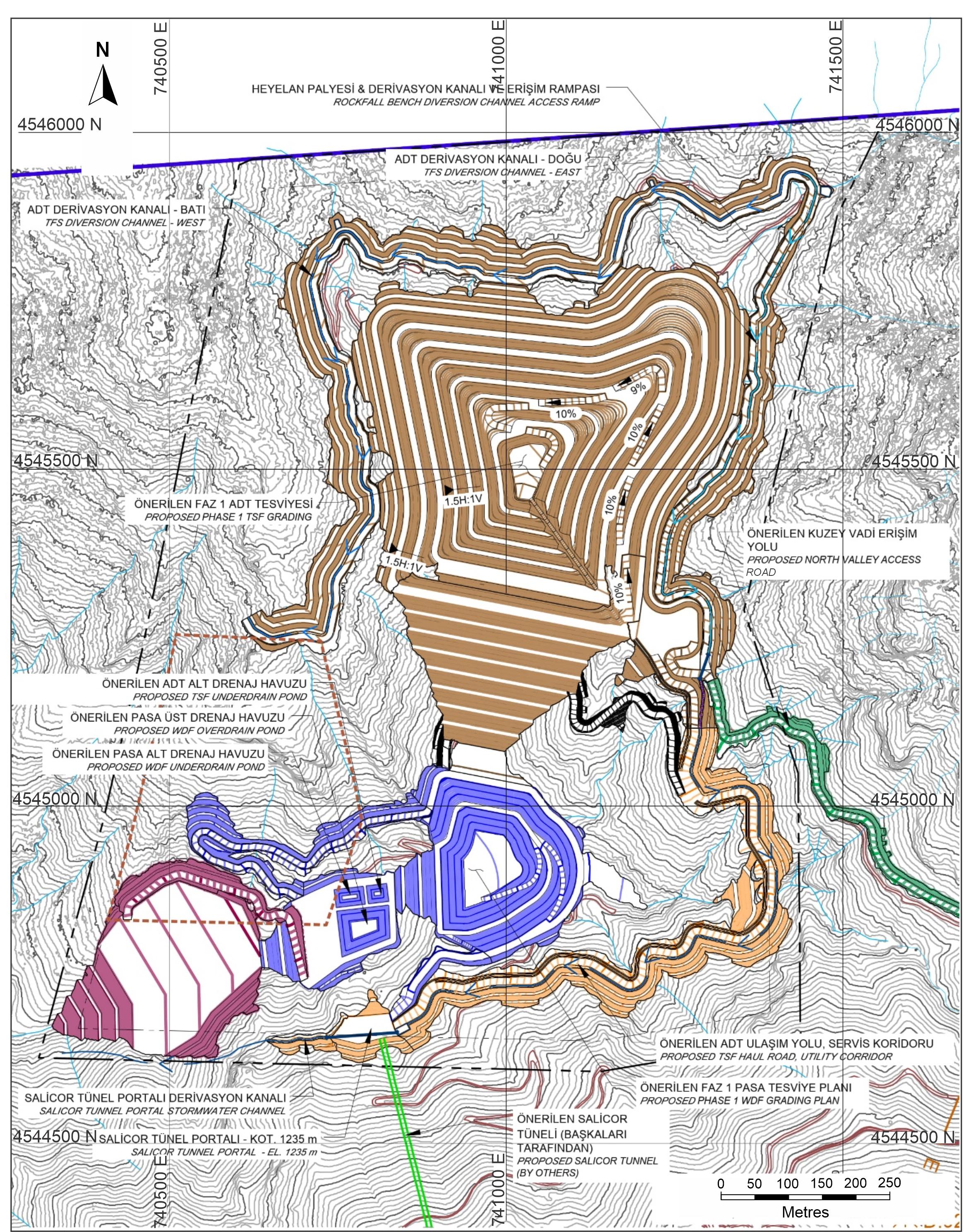

| Figure 15-35: WDF Conceptual Design – Plan View |

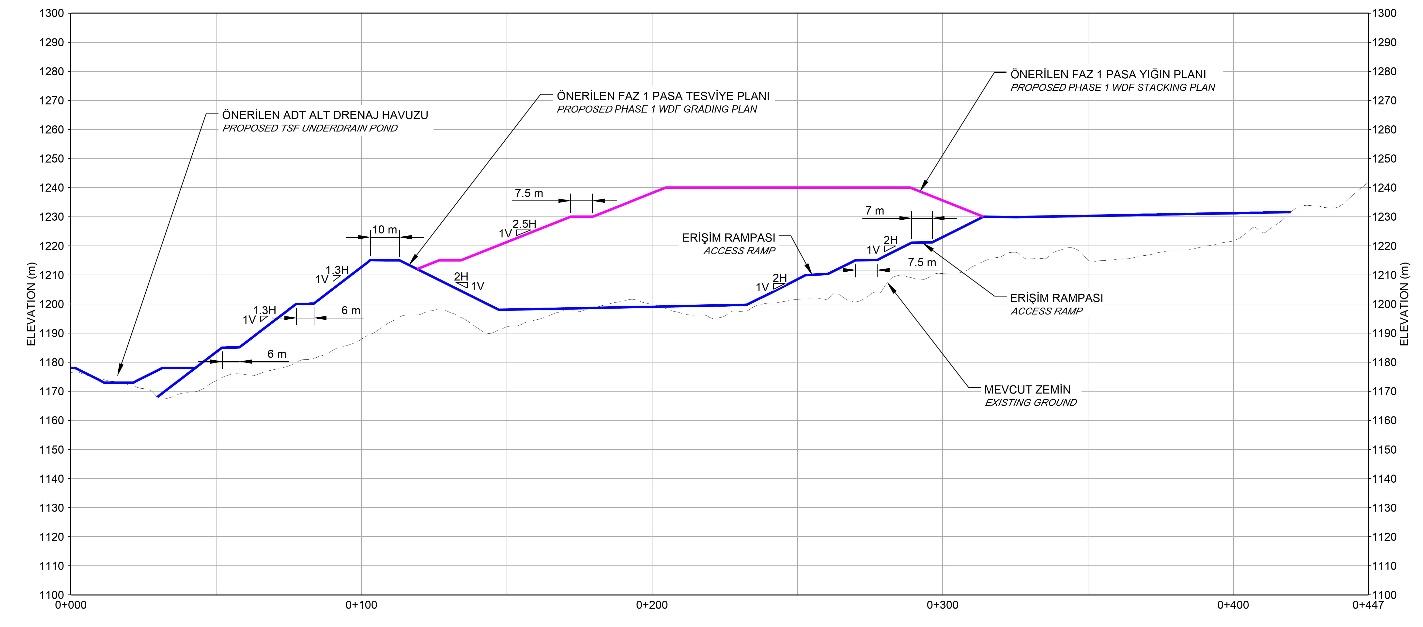

15-46 |

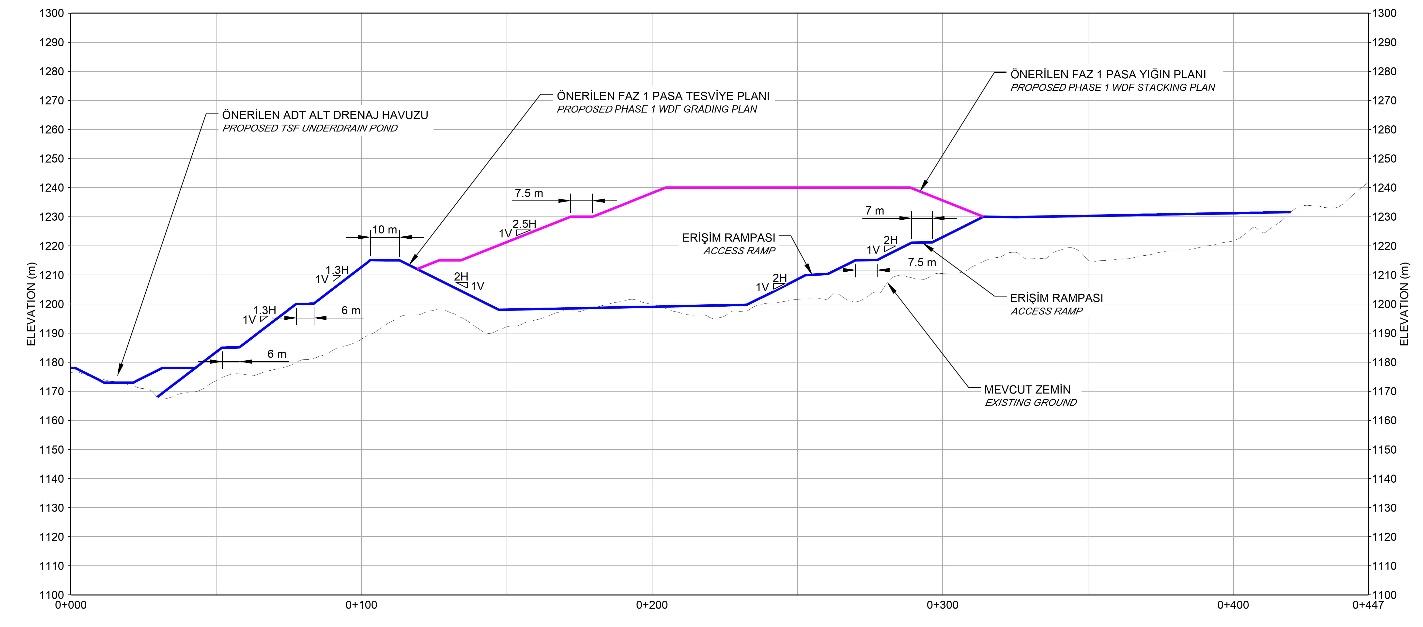

| Figure 15-36: WDF Longitudinal Section |

15-47 |

| Figure 15-37: Surface Water Management for North Valley |

15-49 |

| | xv |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

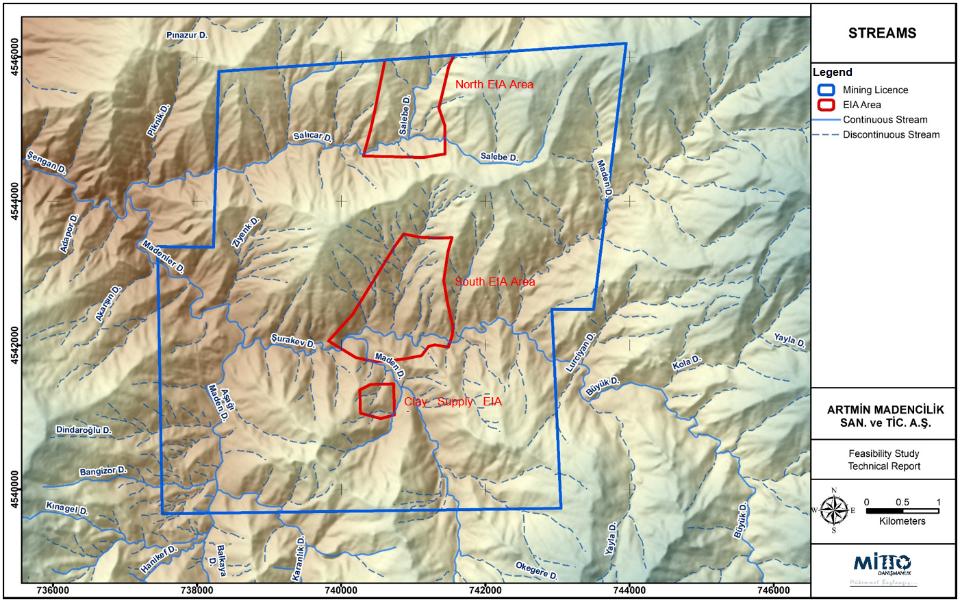

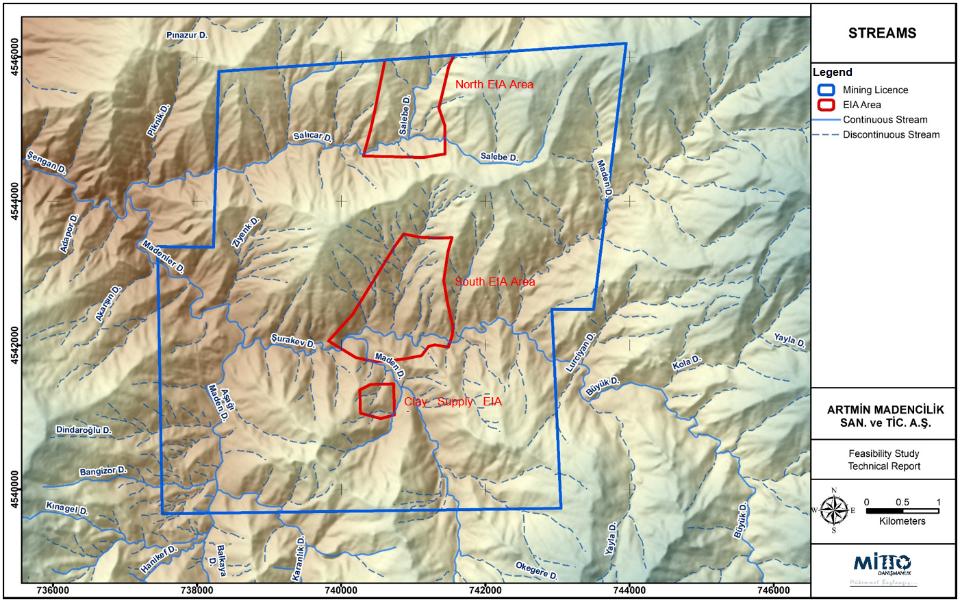

| Figure 17-1: Streams Map Showing the Project Site |

17-2 |

| Figure 19-1: After-Tax Annual Cash Flow Metrics |

19-4 |

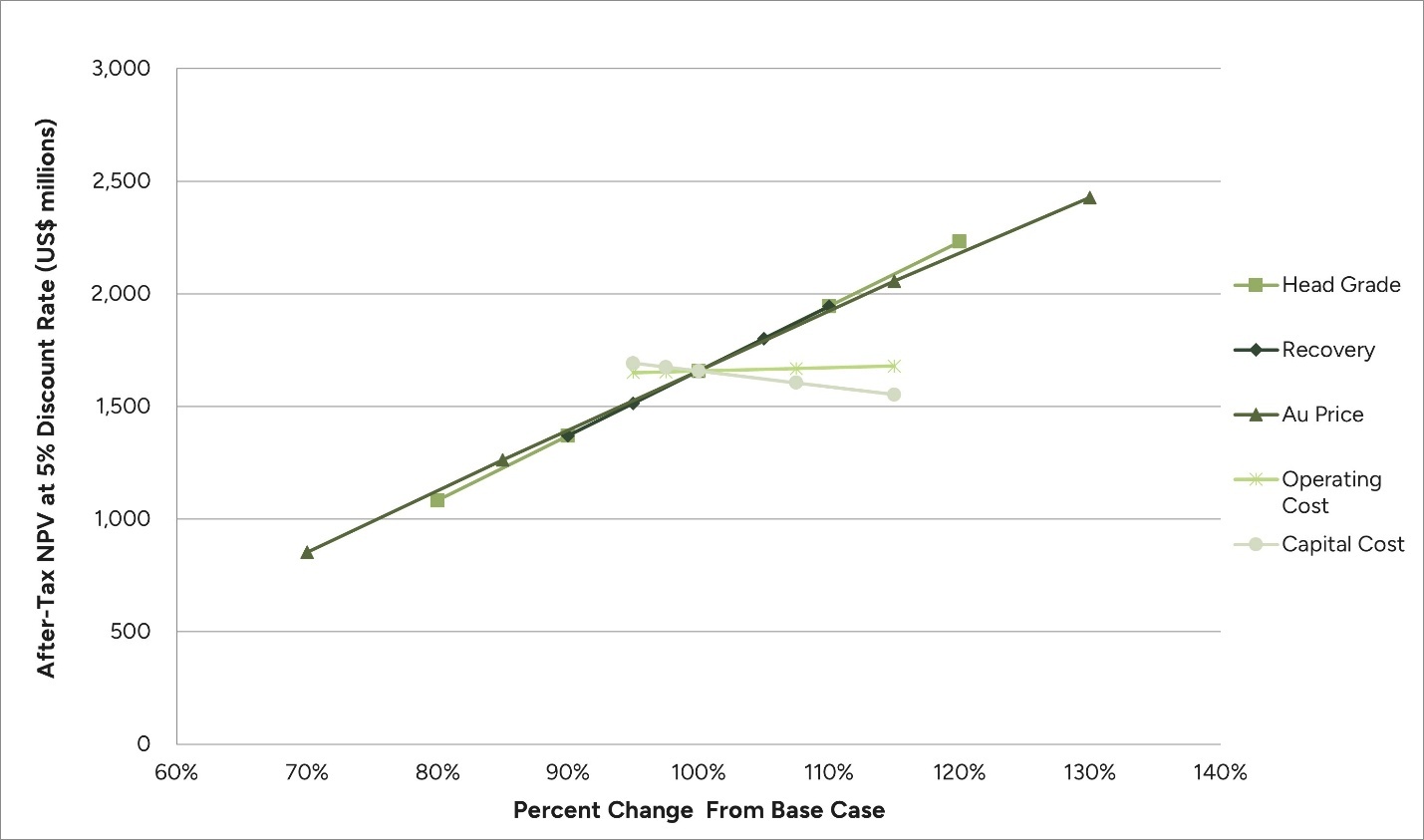

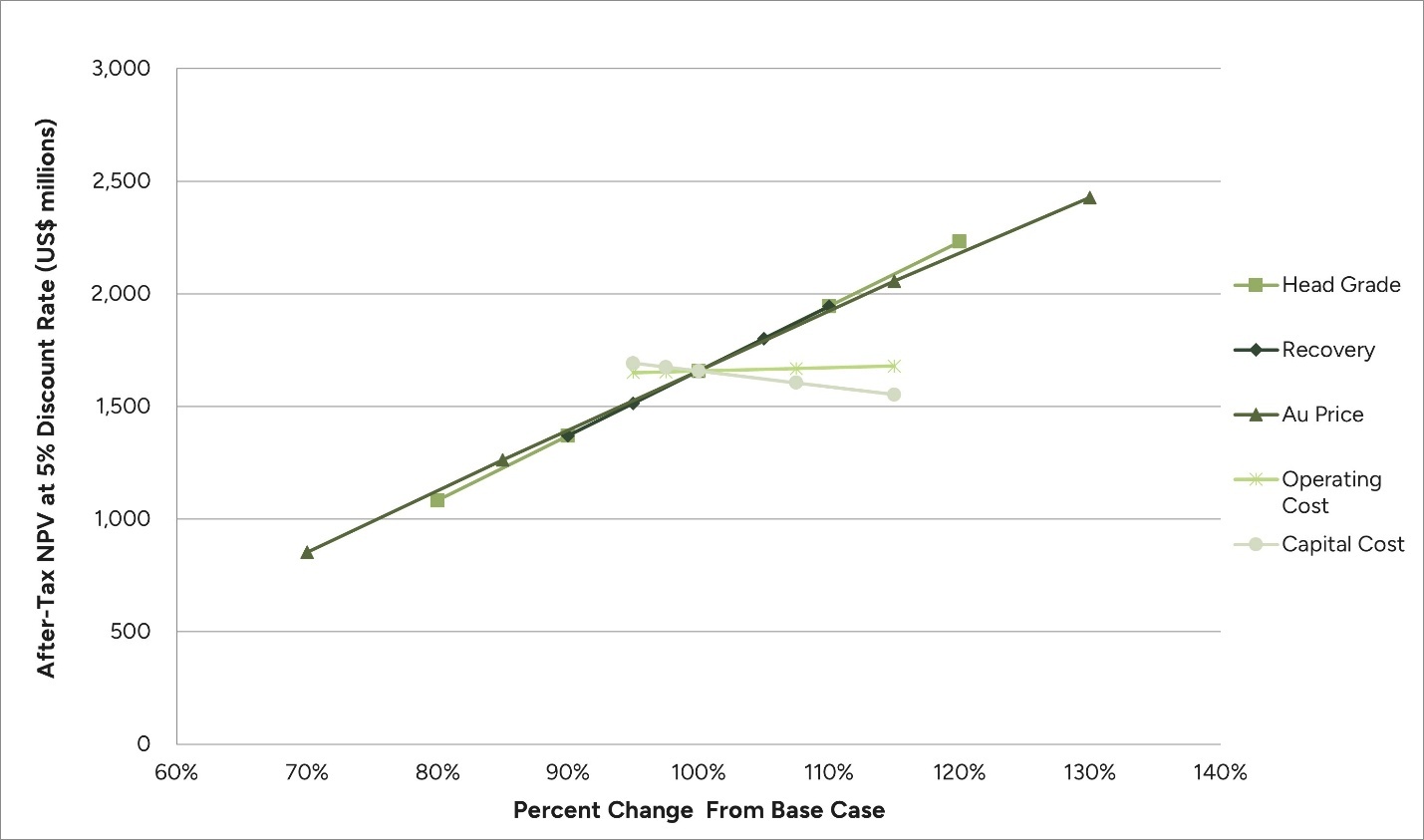

| Figure 19-2: After-Tax NPV Sensitivity Analysis |

19-7 |

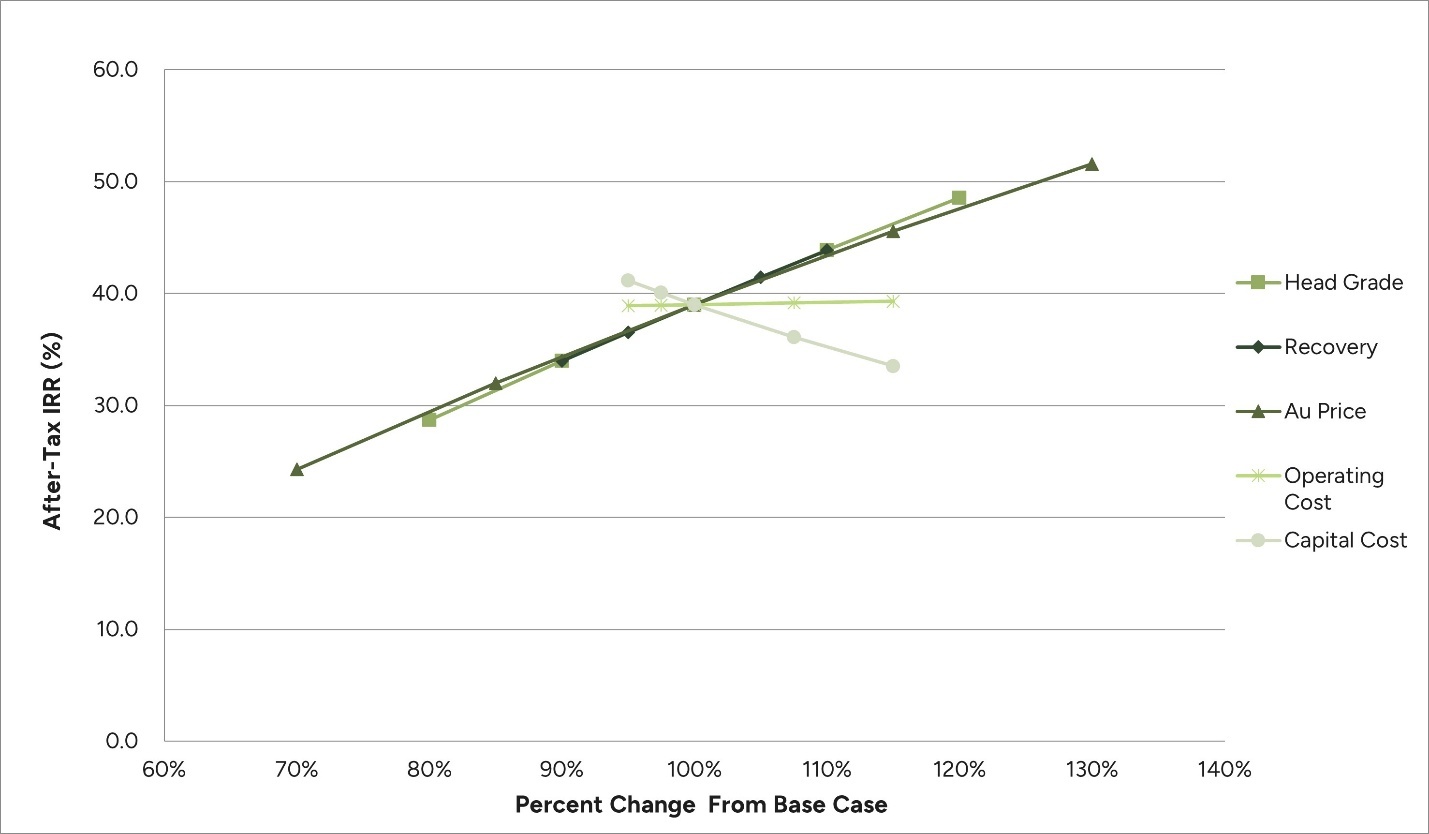

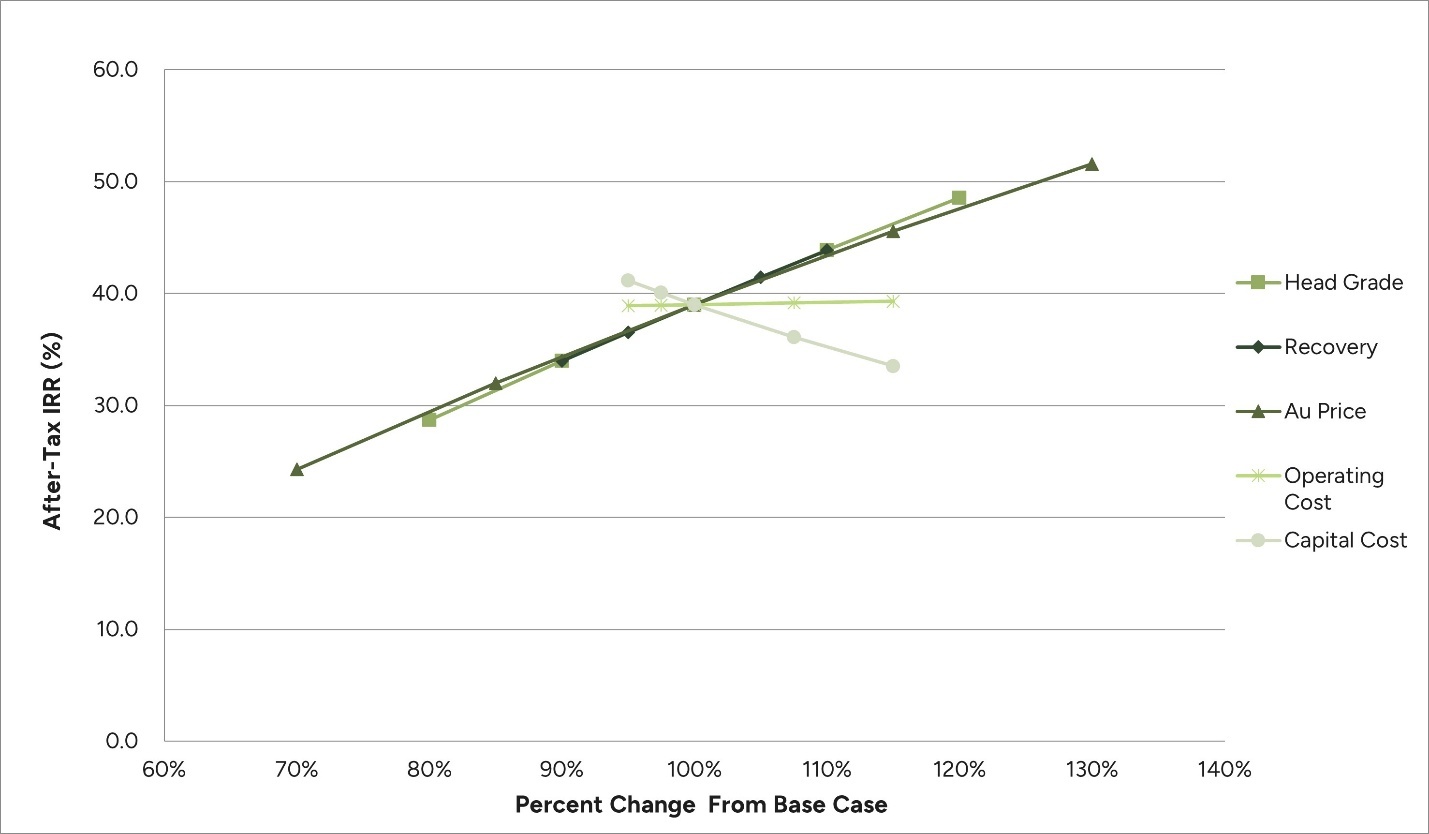

| Figure 19-3: After-Tax IRR Sensitivity Analysis |

19-7 |

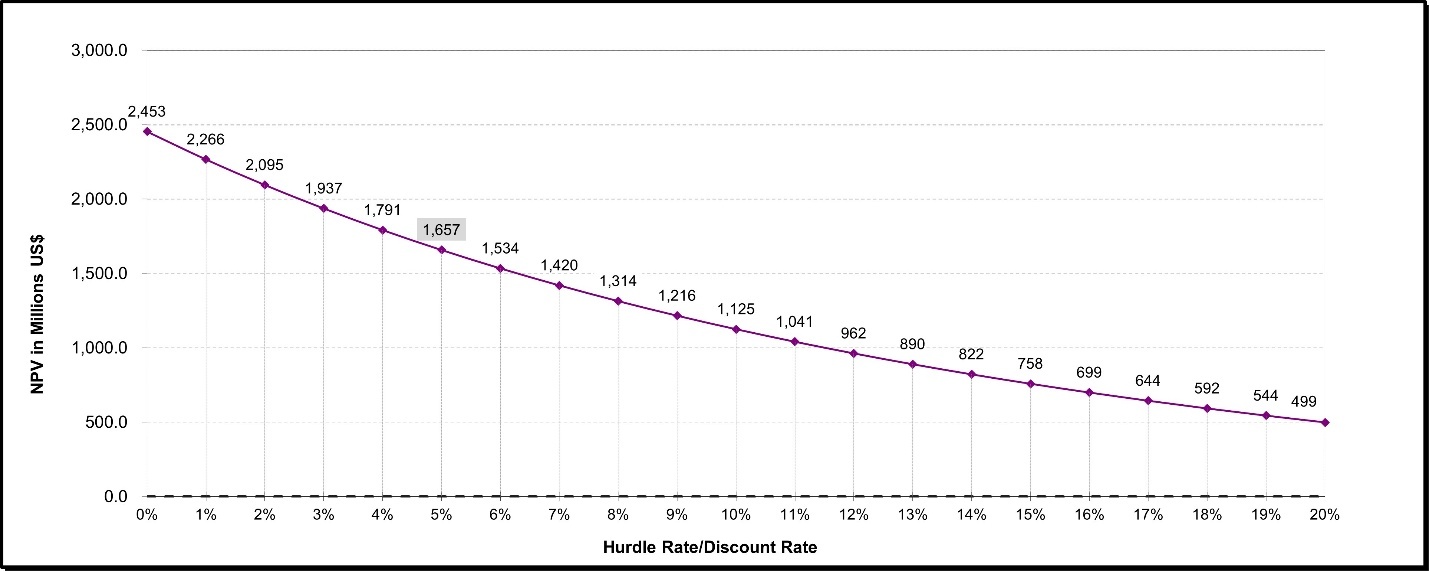

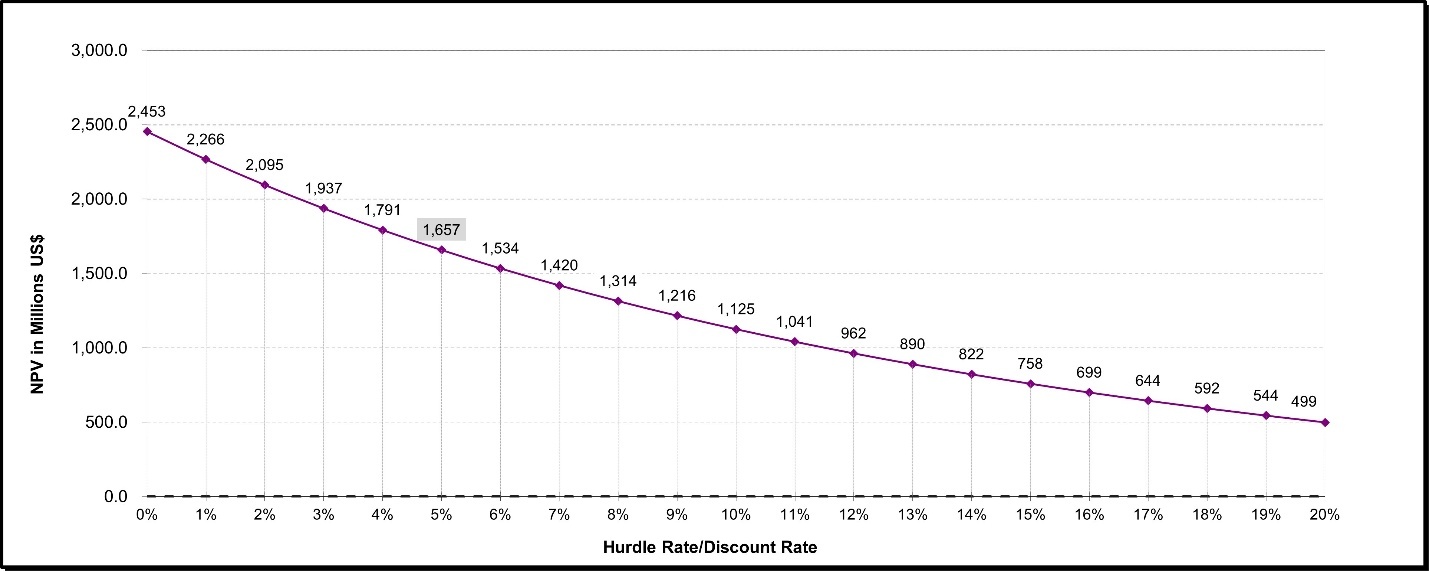

| Figure 19-4: After-Tax Discount Rate Sensitivity Analysis |

19-8 |

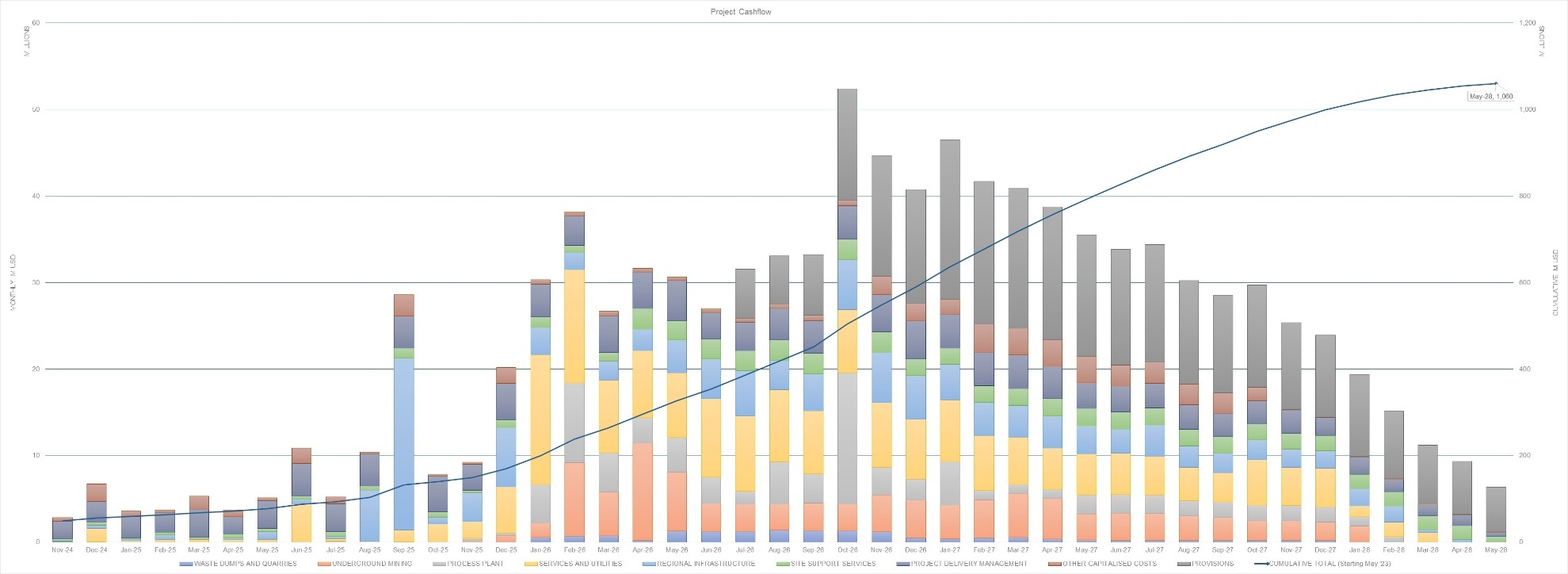

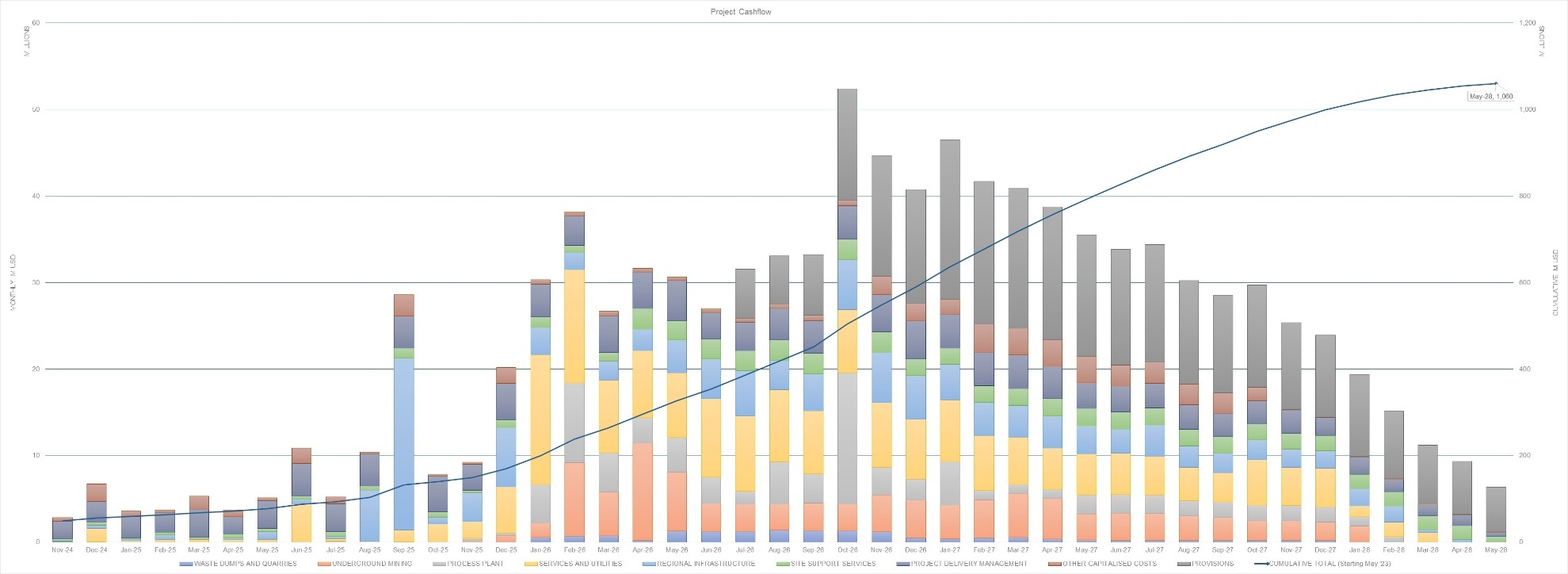

| Figure 21-1: Project Expenditures |

21-6 |

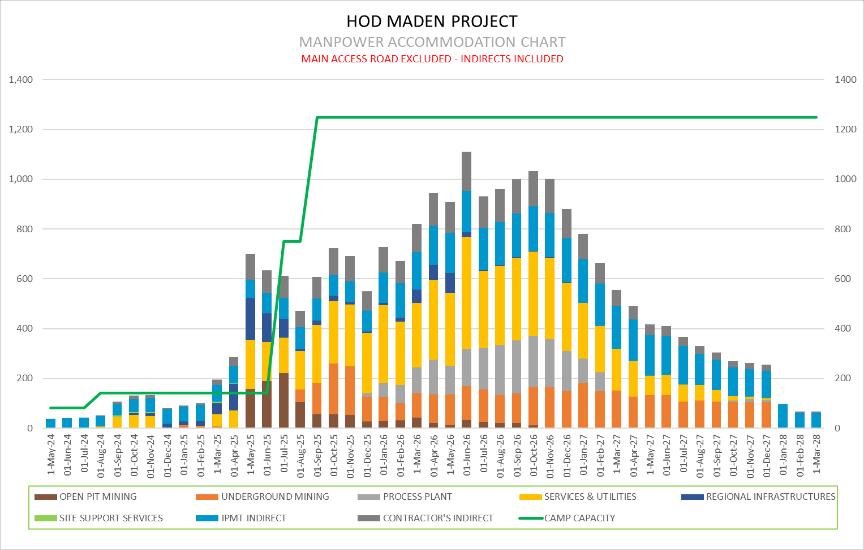

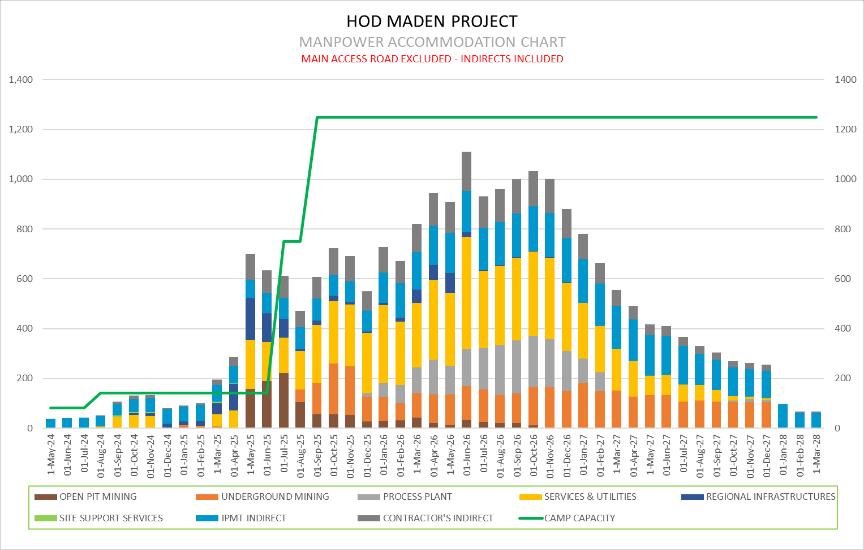

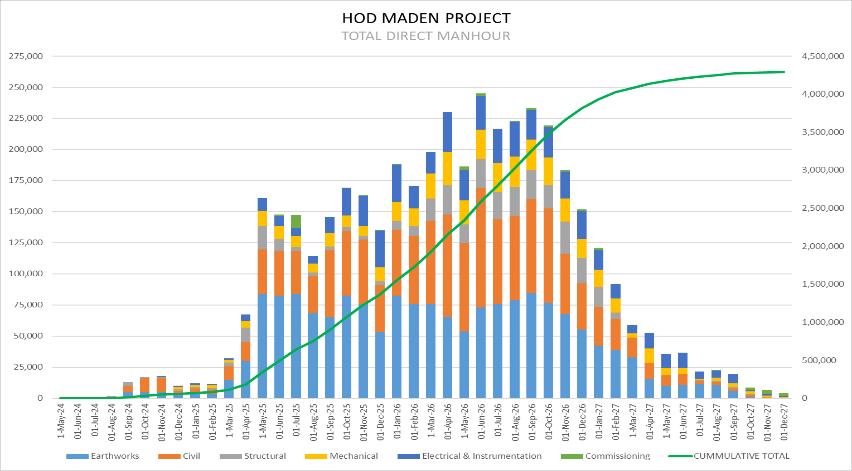

| Figure 21-2: Main Process Plant and Mine Site Area Manpower Curve |

21-8 |

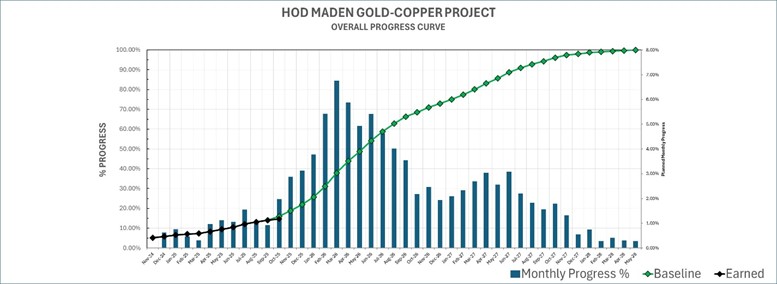

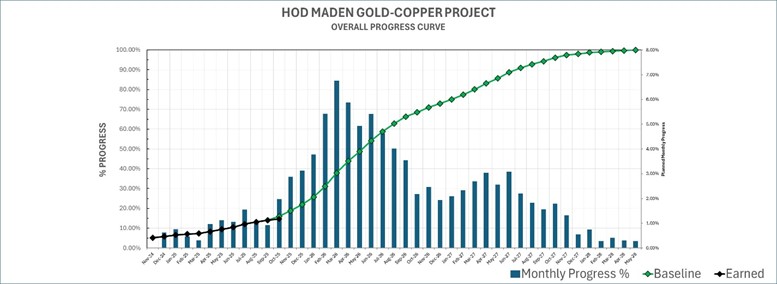

| Figure 21-3: Monthly Planned Progress as a Percentage of Project Total |

21-8 |

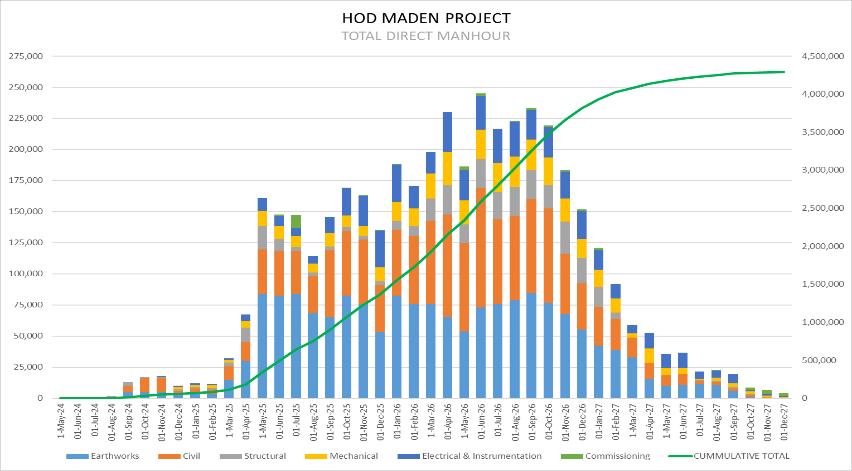

| Figure 21-4: Monthly Planned Project Labor Hours by Discipline |

21-9 |

| Figure 21-5: Project Management Framework |

21-11 |

| | xvi |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

SLR International Corporation (SLR) was retained by SSR Mining Inc.

(SSR) to prepare an independent Technical Report Summary (TRS) on the Hod Maden Project (the Project), located in Türkiye.

The purpose of this TRS is to disclose the results of an updated feasibility

study (the FS update) for the Project and to support the disclosure of the Mineral Resource and Mineral Reserve estimates for the Project,

effective as of August 31, 2025. This TRS conforms to the United States Securities and Exchange Commission’s (SEC) Modernized Property

Disclosure Requirements for Mining Registrants as described in Subpart 229.1300 of Regulation S-K, Disclosure by Registrants Engaged in

Mining Operations (S-K 1300) and Item 601 (b)(96) Technical Report Summary. SLR, RSC Consulting Ltd. (RSC), WSP USA Inc. (WSP), Ausenco

Services Pty Ltd (Ausenco), and SRK Consulting Inc. (SRK) are the qualified persons (QPs), as defined by S-K 1300, for this TRS. RSC visited

the Project from July 1 to July 5, 2024; SLR visited the property on August 12 and 13, 2024, and September 5 and 6, 2025; SRK visited

the Project on August 13, 2024, and September 5 and 6, 2025; and WSP visited the Project on August 12 and 13, 2024, and September 5 and

6, 2025.

The Hod Maden Project is 100% owned by Turkish company Artmin Madençilik

(Artmin), which is jointly owned by SSR, Royal Gold Inc. (Royal Gold), and Lidya Madençilik (Lidya). SSR currently holds a 10%

interest in the Project; per the joint venture agreement (May 8, 2023), SSR will earn-in to 40% ownership of the Project and serve as

the Project operator.

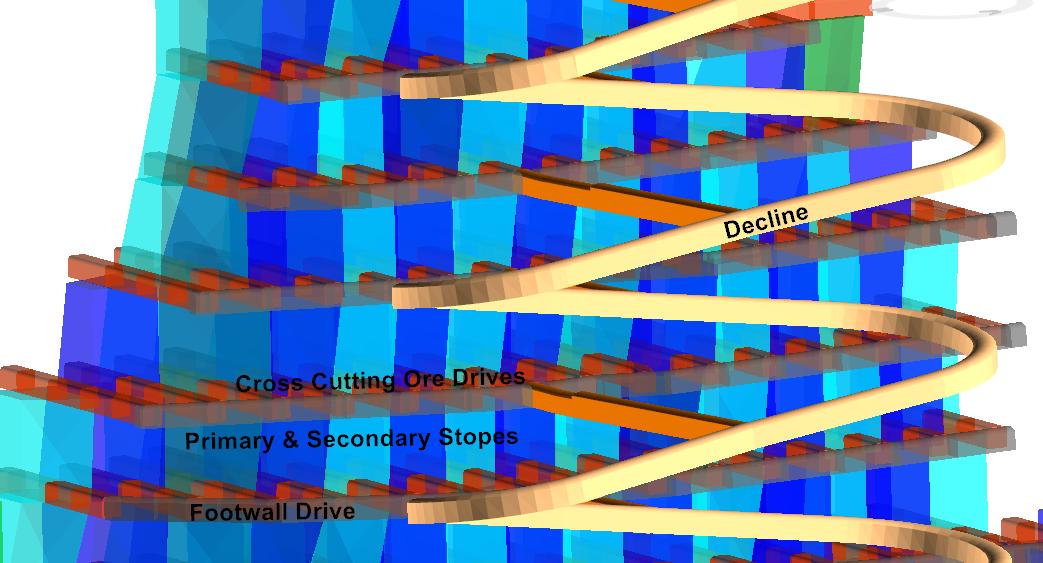

The Project is envisioned as an underground mining operation using drift

and fill (DAF) and long hole stoping (LHS) mining methods. The processing facility (the Process Plant) will have a throughput capacity

of 800,000 dry metric tonnes per annum (tpa) of run-of-mine (ROM) ore. The Process Plant incorporates crushing, grinding, and flotation

to produce a single gold-copper concentrate that will be transported off-site for further processing.

This TRS supersedes the “Hod Maden Project, Feasibility Study

– Technical Report NI 43-101”, dated December 15, 2021 (the 2021 FS), compiled by GR Engineering Services Limited (GR Engineering)

for Sandstorm Gold Inc. (now Royal Gold).

The QPs offer the following conclusions by area:

| 1.1.1.1 | Geology and Mineral Resources |

| · | There are currently three geologically distinct models explaining the geology of Hod Maden, two of which have specific geologic attributes

whereas the third combines aspects of the first two models: |

| o | Structurally controlled intermediate sulfidation epithermal vein stockwork deposit with local semi and massive sulfide lenses |

| o | Hybrid gold-rich volcanogenic massive sulfide (VMS)-epithermal deposit formed in shallow water with high-temperature clay alteration |

| o | Cretaceous aged syn-VMS overprinted by younger high-level epithermal vein stockwork |

| | 1-1 |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| · | The Hod Maden Project has been explored using modern exploration techniques starting in 2014, and a total of 90,410 m of drilling

has been completed in a total of 403 drill holes. |

| · | The RSC QP has estimated and prepared the Mineral Resources, including classification of Mineral Resources, in accordance with S-K

1300. |

| · | Mineral Resource estimates were prepared using a domain-controlled, ordinary kriging (OK) technique with verified drill hole location,

density, and sample data derived from exploration activities conducted by various companies from 2014 to 2024. |

| · | In the opinion of the QP, based on the assessment of legacy data, verification of data and materials on site, the sample preparation,

security, and analytical procedures meet industry standards for data quality and integrity; however, protocols and processes are poorly

documented, and this should be remedied. |

| · | The data informing the Mineral Resources are collected using core drilling. Overall, the RSC QP is of the opinion that the samples

are representative of the source materials. |

| · | In the RSC QP’s opinion, the sample preparation, security, and analytical procedures are adequate and meet industry standards,

and the QA/QC program, as designed and implemented at Hod Maden is adequate. The assay results within the drill hole database are within

acceptable levels of accuracy and precision, and the resulting database is sufficient for the purpose of Mineral Resource estimation and

classification in relevant categories. |

| · | The RSC QP was provided unlimited access by SSR for data verification purposes during the site visit. The RSC QP’s database

verification of the Hod Maden Project indicates that data collection procedures mostly comply with industry standards and are adequate

to support classification of at least Indicated Mineral Resources. In 2024, SSR initiated a re-logging study, which is in progress as

of date of publication of this TRS. |

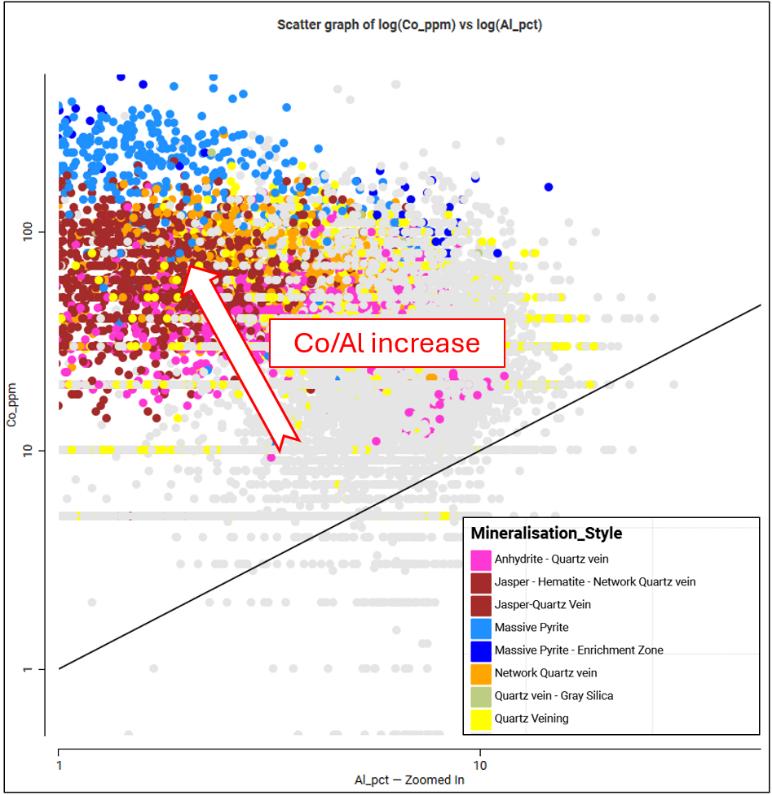

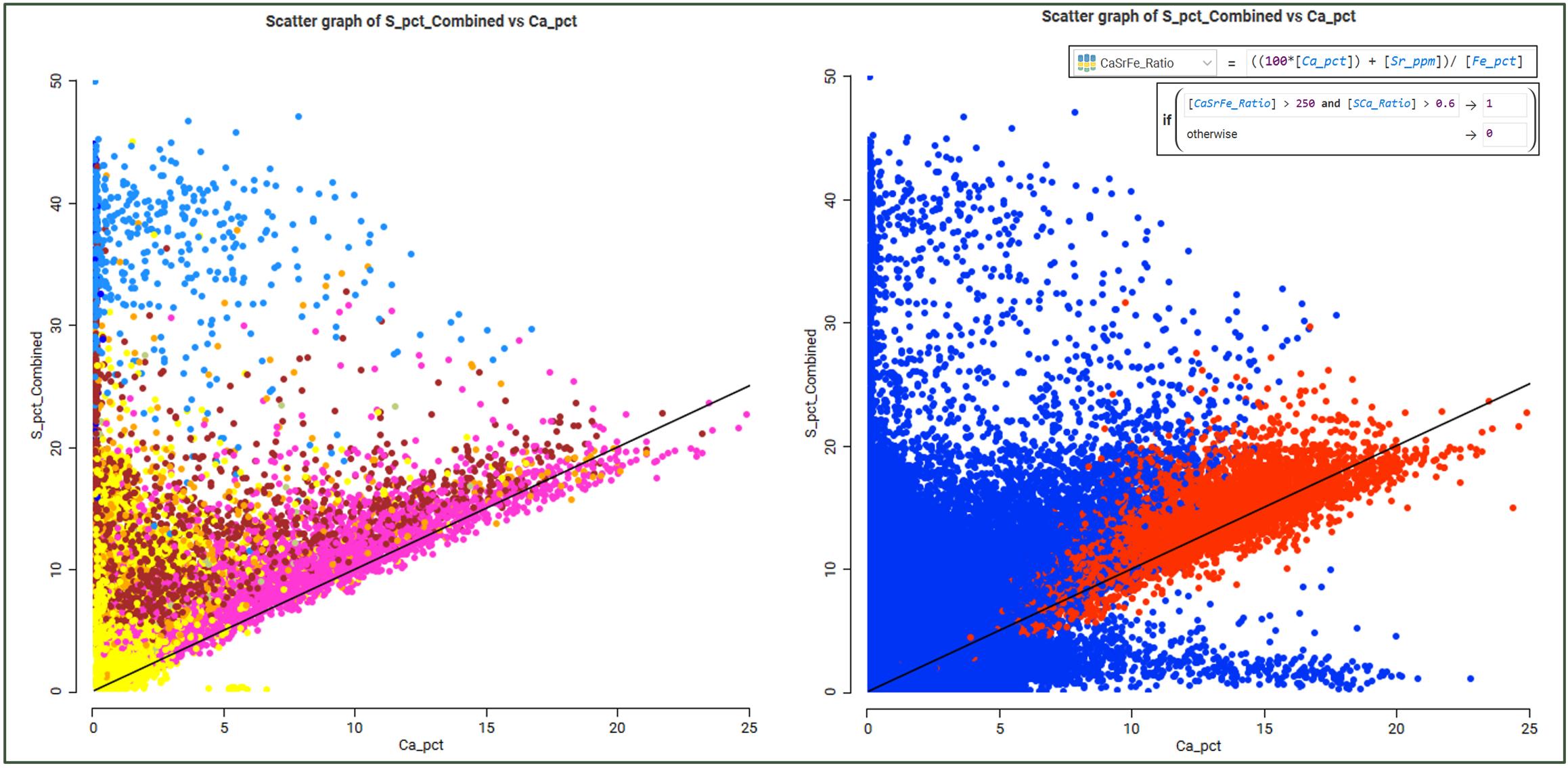

| · | The RSC QP has domained massive pyrite with logged intervals, and this was confirmed in core by the RSC QP when on site. There is

a strong correlation of high silica + high sulfide zones and massive sulfide with the Co/Al ratio, and the RSC QP considers proxy model

for the high silica + high sulfide zones mineralization robust. Sensitivity to the modeling cut-off was found to be minimal with respect

to the global Mineral Resource estimate. More work is required to link the chemical proxy to core observations to better understand what

exactly the proxy represents and if the proxy model can be improved in future resource updates. |

| · | The Mineral Resource was classified based on confidence in geological understanding, drill spacing, and kriging quality metrics. Sensitivities

to domaining and gold grade capping parameters remain relatively high for a Measured classification and the RSC QP considers this a moderate

risk. |

| · | The Mineral Resource estimates for Hod Maden have an effective date of August 31, 2025. |

| · | Appropriate cut-off grades, stope optimizing and pit optimization parameters have been used to establish those portions of the block

models that meet the requirement for reasonable prospects for economic extraction for this style of gold-copper deposit and mineralization.

In assessing the potential of economic extraction, the RSC QP reviewed mining, metallurgical, economic, environmental, social and geotechnical

factors. |

| | 1-2 |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| · | The Hod Maden Mineral Resources estimate, exclusive of Mineral Reserves, is reported below on a 100% basis; SSR‘s attributable

share is 10%: |

| o | 1,722 thousand tonnes (kt) Measured and Indicated Mineral Resources at an average grade of 11.9 g/t (Au) and 1.7% Cu, containing 658

thousand ounces (koz) gold and 65 million pounds (Mlb) copper. |

| o | 2,574 kt Inferred Mineral Resources at an average grade of 3.4 g/t (Au) and 0.5% Cu, containing 281 koz gold and 26 Mlb copper. |

| 1.1.1.2 | Mining and Mineral Reserves |

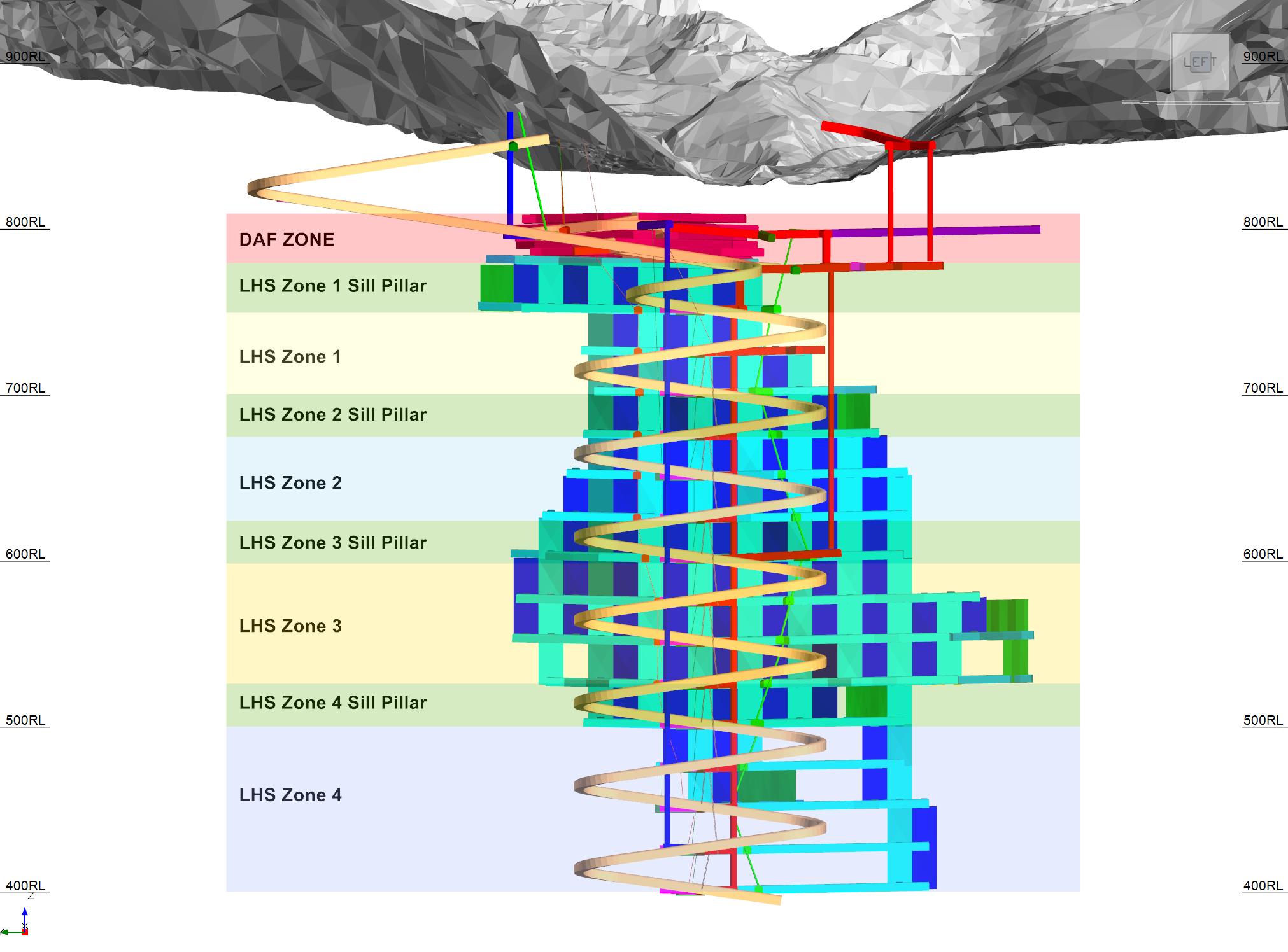

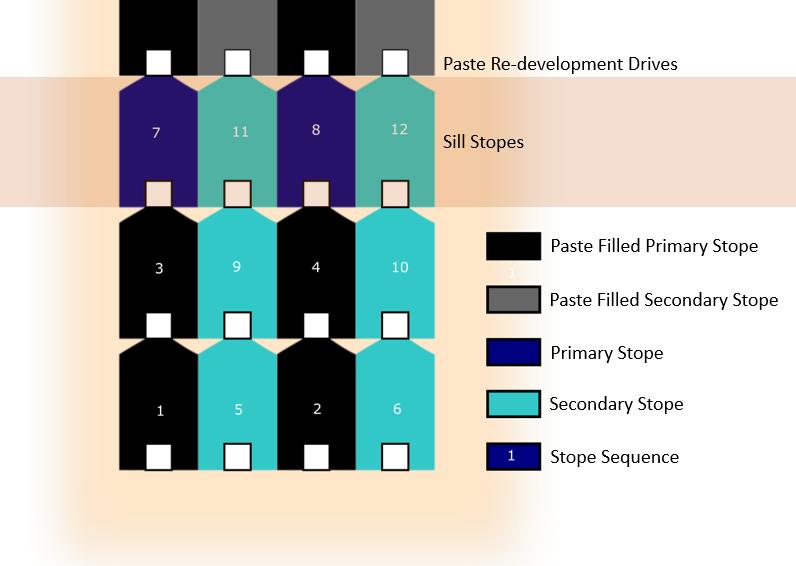

| · | The deposit is proposed to be mined using underground techniques, specifically long hole stoping (LHS) below 780 meters above sea

level (masl) elevation and modified drift and fill (DAF) methods above the 780 masl elevation. Access to the mine will be via a decline.

Mining zones are divided based on rock quality and depth, with electric-hydraulic equipment used for development. LHS level spacing is

25 m and the DAF level spacing is 5 m. |

| · | Two geotechnical drilling programs were conducted. Rock strength varies, especially in argillic alteration zones, and significant

testing was performed to characterize rock properties and overburden materials. Stress measurements were assumed due to the lack of direct

measurements. The underground mine elevations range approximately 380 m from approximately 805 masl (at the surface) down to 400

masl. The lateral extent of the underground workings is approximately 330 m (W-E) by 240 m (N-S). |

| · | It is noted that geotechnical stability within the crown pillar and hanging wall is a key concern, particularly because persistent

faulting in the hanging-wall sequence increases the potential for dilution or premature stope closure if not properly managed. To mitigate

this risk, the DAF mining areas will be developed with an elevated ground-support standard and will be paste filled promptly after extraction.

Subsequent underhand cut-and-fill stopes will also be paste filled as they advance. This mining sequence ensures that the crown pillar

is never left unsupported or exposed in a manner that could lead to instability or failure. |

| · | The ground support will be bolts and fibrecrete, with the potential for mesh and spiling bars as well. Successful ground support depends

on sourcing qualified project management and staff. |

| · | Poor ground conditions in the DAF could impact production. |

| o | Mining excavation techniques, such as a road header or other form of rock cutting technology, with low impact on excavation stability

will be employed as appropriate. Road headers typically have advance rates of 1 to 2 meters per day. |

| o | Where pockets of harder ground are encountered, drill and blast will be used with short rounds and the use of spiling bars. |

| · | Over 10 years, the total ore mined at the Project (100% basis) will be approximately 7.7 million tonnes (Mt), containing approximately

1,896 koz gold and 101 kt copper. There is a two-year ramp up period associated with the underground mine. The life of mine waste

production is projected to be 1.5 Mt. |

| · | The Project's production ramp-up is closely tied to contractor performance, specifically their ability to maintain the scheduled advance

rate of 21 m per week. The Definitive Feasibility Study (DFS) completed in 2020 (the 2020 FS, GR Engineering 2020) used a decline advance

rate of 130 m/month. This has been reduced to 90 m/month because of the shorter available time resulting from the legally proscribed shift

schedule and to mitigate the risk of using contractors. Delays in the contractor’s equipment or workforce availability could negatively

impact the Project's production timeline. |

| | 1-3 |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| · | The potential for surface subsidence from mining activities and blast vibrations could affect sensitive buildings such as a local

mosque. Site-specific testing for blast vibration is necessary to mitigate these risks. It is assumed that the graveyard and mosque will

be re-located. |

| · | Studies have been carried out to include groundwater movement, hydraulic conductivity, and dewatering plans for the mine. Several

dewatering scenarios were simulated by SRK, including lining options for the Surakev Creek, and active dewatering options. |

| · | Inflows from groundwater are expected up to 30 L/s for the lined option, and 50 L/s in conservative scenarios. Load from underground mining

operations is calculated as 5 L/s. |

| · | Pump stations will be specified for the lined option without active dewatering of the host strata. In the early stages of mining,

face pumps will keep up, and the pump stations will be set up with two duty pumps to pump 35 L/s, a spare for an additional 17 L/s, plus

civil construction for an additional pump for expansion to cope with any additional flow. |

| · | Stability assessments were completed to determine mining dimensions, with recommendations on ground support; composed of shotcrete,

bolting, and the use of cable bolts. |

| · | The Project’s Mineral Reserves are reported in accordance with S-K 1300 as of August 31, 2025, using breakeven NSR cut-off values

of US$160/t for DAF and US$108/t for LHS, with an incremental cut-off value of US$82/t applied for material that could be accessed on

the way to the breakeven cut-off inventory. |

| · | Total Proven and Probable Mineral Reserves at Hod Maden, on a 100% ownership basis (SSR‘s attributable share is 10%), are estimated

to be 7,714 kt at 7.6 g/t Au and 1.3% Cu, containing 1,896 koz gold and 223.1 Mlb copper. |

| 1.1.1.3 | Mineral Processing |

Metallurgical Test Work

| · | Test work programs have been carried out at various levels of project definition, including prefeasibility, feasibility, and for this

FS update. Test work has adequately characterized the mineralization, and has included engineering tests such as comminution, Levin tests,

Metso Jar tests, flotation, thickening, filtration, transportable moisture limit (TML), and Self-Heating capacity tests to derive design

parameters for the process plant |

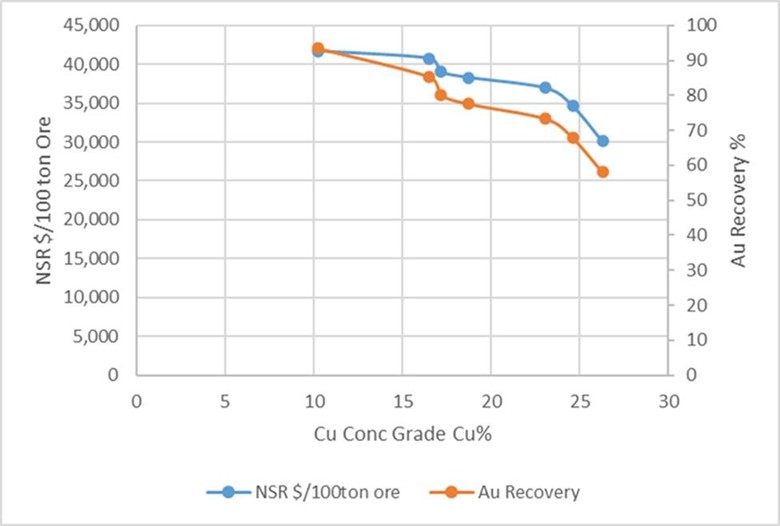

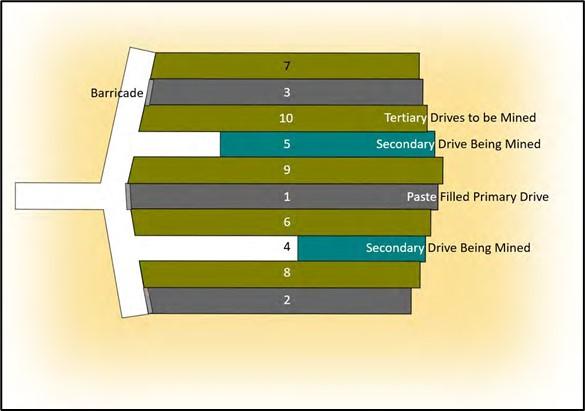

| · | In the FS update, the flowsheet was updated to reflect a single-product flotation circuit comprising rougher flotation and cleaning

to a lower-grade (>13% Cu) concentrate but containing more pyrite at increased gold recoveries to the concentrate. This work, supported

by marketing assessments, has justified the selection of a simpler, single-product flotation circuit producing a low-grade copper concentrate

with significant precious metal (gold) credits. Copper concentrate grade and gold recovery to the concentrate, as well as payability of

gold and copper is managed by the mine plan, production profile, and pH control in the plant, with further opportunities to blend out

of spec concentrates if required from time to time. |

| | 1-4 |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| · | The rock breakage parameter (A × b) of the ore types ranged between 33.4 to 98.1 and Bond Ball Milling Work indices (BWi) ranged

between 10.4 kWh/t and 20.6 kWh/t, indicating that the samples were in hard to medium hardness range according to the JKTech database.

The softest samples were from the massive pyrite (MPY) lithology, and the hardest from Dacite Breccia lithology. The eightieth percentile

of A × b and BWi were 45 kWh/t and 16 kWh/t, respectively. |

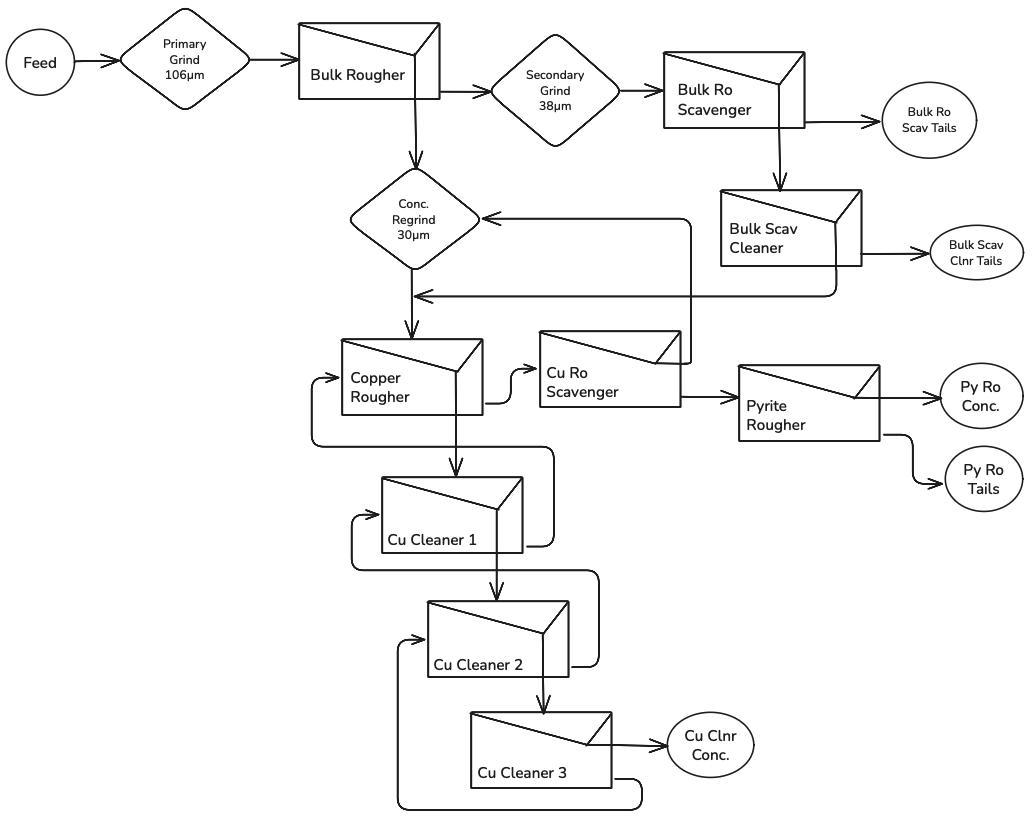

| · | The optimum flotation flowsheet and conditions were developed during the Preliminary Feasibility Study (PFS) phase are carried through

to the current Project. The design is based on sulfide mineral flotation (mill-float-mill-float [MF2] mode of operation; mill to a P80

of 106 µm – rougher float – mill to a P80 of 38 µm – scavenger float). The rougher concentrate

is then reground to a P80 of 30 µm. pH is controlled to produce a +13% Cu copper concentrate and maximize gold recovery

to the copper concentrate whilst keeping copper grades above payability thresholds. |

| · | The mine plan indicates that a +13% Cu concentrate can be produced without significant pyrite rejection (and associated gold loss)

on a monthly basis, however, short term grade excursions will need to be managed. The process plant is designed for the maximum expected

mass pull of approximately 10% to concentrate. |

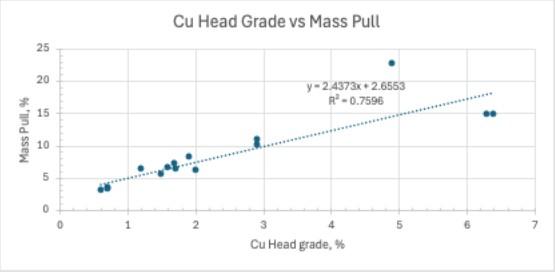

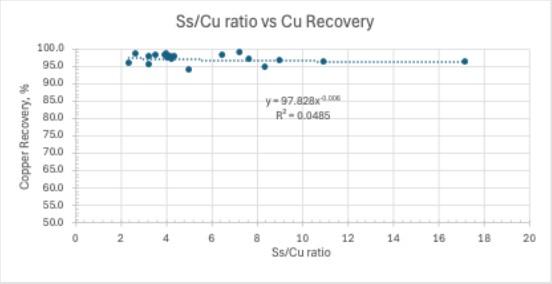

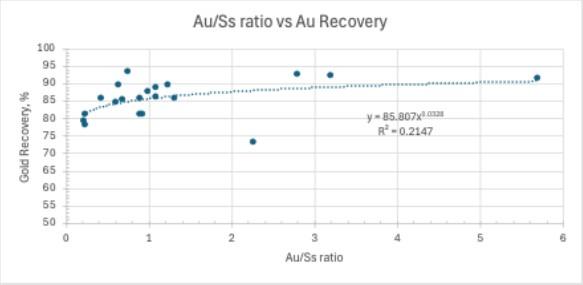

| · | Gold and copper recovery relationships appear to be independent of lithology, and more related to the flotation conditions and the

extent of sulfur flotation or rejection from the flotation circuit. Feed grade and mass pull to the concentrates were the main parameters

affecting the grade and recovery. |

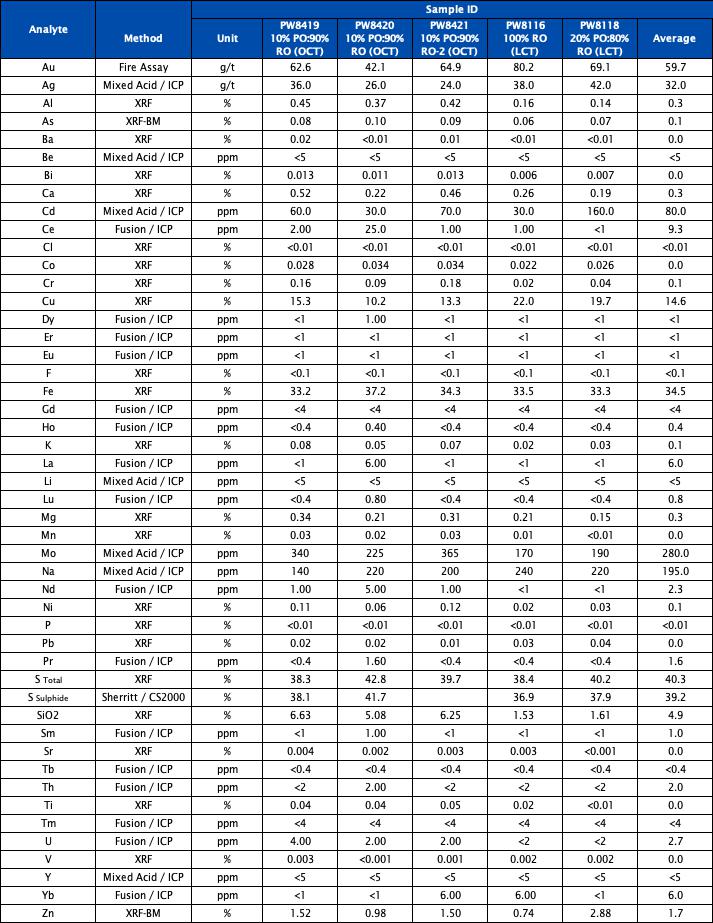

| · | Detailed chemical analyses show that concentrations of penalty elements in concentrate are low and are unlikely to negatively affect

marketing. |

| · | Thickening and filtration tests showed that copper concentrate can be dewatered to approximately 1.5% w/w lower than the Transportable

Moisture Limit (TML). The TML of the concentrate was measured as 11%, and the filter cake product was 9.5% w/w moisture. The self-heating

tests showed that concentrate was not classified as Material Hazardous in Bulk (MHB) or Dangerous Goods (DG) Class 4.2 for the purposes

of bulk transport; |

| · | Results of simulated open cleaner flotation (OPC) and locked cycle flotation (LCT) tests were used to establish grade versus recovery

curves for copper and gold. These equations were used to calculate concentrate production over the life of mine. The average gold and

copper recoveries are calculated as 87% and 97%, respectively. |

| · | The entirety of the rougher scavenger tailings will be used for the production of paste. After thickening, the paste plant will filter

a portion of the tails to meet the target paste concentration of 68.5% w/w solids after addition of a dry binder. |

| · | Gypsum scaling over time is expected at Hod Maden, however it is not expected to be significant enough to warrant dosing of antiscalant

outside of the alkaline water system. |

Processing and Recovery Methods

| · | The processing plant will have the capability of treating 800,000 dry tonnes per year of ROM ore. The plant design incorporates crushing,

grinding, and flotation to maximize the recovery of copper and gold from the ore. |

| · | Various utility and plant infrastructure such as water supply, reagents supply and distribution, air services, electrical energy supply

and distribution, roads, communications and site buildings will support the Project. |

| | 1-5 |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| · | The roads from Artvin to the intersection on State Road D.950 to the site access road are generally in good condition; major upgrades

will be implemented for the Yukarιmaden access road to ensure safe and efficient

long-term operations. The road upgrades will incorporate tunnels and bridges to navigate challenging terrain, thereby improving both traffic

safety and accessibility for the public. Overall, these improvements are crucial not only for operational efficiency but also for mitigating

risks associated with construction and ongoing mining activities. |

| · | The Project will establish a new 154 kV/11 kV substation to connect to the existing high voltage network. The Project will build the

power distribution system and have a standby diesel generator. |

| · | The surface water management strategy for the Project emphasizes minimizing contact water volumes through effective diversion and

treatment systems while ensuring proper management of both contact and non-contact water. The contact water management system will focus

on directing all contact water to a designated pond for treatment, with non-contact water diversion systems constructed around the Project

area. Updates to the site-wide water balance model and the development of an integrated surface water management plan have been used and

need to be maintained to ensure the effectiveness of this strategy and compliance with regulatory requirements. |

| · | The design of the Tailings Storage Facility (TSF) for the Hod Maden mine adheres to Canadian Dam Association (CDA) Dam Safety Guidelines.

The phased downstream construction approach allows for the effective containment of the tailings, accommodating an ultimate design capacity

of 5 Mm³ across all phases. |

| · | The stability analyses indicate acceptable factors of safety for both static and dynamic conditions, ensuring the TSF's structural

integrity throughout its operational lifespan. Ongoing monitoring and recommended mitigation measures, such as the installation of catch

benches and artificial support, have been used and need to be maintained to manage localized hazards within the TSF basin. |

| · | The design and management of the North Valley Waste Dump Facility (WDF) have been planned to address the challenges posed by the potentially

acid-generating (PAG) waste rock from the underground mining operation. The WDF design incorporates industry standards throughout its

operational life and closure phase. Ongoing geotechnical assessments and a focus on a “design for closure” approach have been

used and need to be maintained to mitigate risks and ensure the long-term integrity of the facility |

| · | The implementation of overdrain and underdrain systems will facilitate efficient water management for the North Valley infrastructure

while mitigating potential risks associated with water quality and hydraulic pressures on the liner system. Continuous monitoring and

adaptive management practices have been used and need to be maintained to ensure the effectiveness of these systems and to protect the

surrounding environment throughout the project's lifecycle. |

| · | Infrastructure design updates within the North Valley include an improved access road and utility corridor from the Saliçor

Tunnel to the crest of the TSF to facilitate surface water controls, safe operations and access to the tailings pipeline and general construction

and operational access. Additional consideration during early construction has considered the design and location of topsoil storage areas. |

| | 1-6 |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| · | The average concentrate grades produced at the Project are expected to be very high grade at 113 g/t gold and 22% copper credit

with very little deleterious elements; however, variability in the ore will lead to periodic production of low copper concentrate grades

(>14% Cu, >70 g/t Au), which should be easily sold as the gold concentration is still very high. An Expression of Interest from

a commodity trader for the lower concentrate grade has been procured. |

| · | Negotiations with potential customers are still in early stages; therefore, assumptions around concentrate freight and commercial

costs are still at an early stage. |

| 1.1.1.6 | Environment & Social |

| · | Artmin undertook environmental and social baseline studies in the Project area between 2013 and 2021. The baseline studies conducted

from 2018 to 2021 considered the International Finance Corporation Performance Standards (IFC PS) for key aspects of the Project, including

biodiversity. |

| · | The Project holds environmental approval-in-principle. The Project’s Environmental Impact Assessment (EIA) was approved by regulatory

authorities on November 17, 2021. |

| · | Key environmental and social (E&S) aspects of the Project include biodiversity, surface and groundwater quality, and land acquisition. |

| · | Land acquisition and expropriation are at an advanced stage, with most of the land already acquired or expropriated. |

| · | Artmin has compiled a set of draft Environmental and Social Management Plans (ESMPs) that aim to comply with host country requirements,

including EIA commitments and conditions of approval, European Union directives, and the International Finance Corporation (IFC) Performance

Standards (PS). These plans cover biodiversity and water management. Engagement with local communities and stakeholders began during exploration

and continues. Much of the engagement focuses on land acquisition and resettlement. |

| · | The Project has a Conceptual Mine Decommissioning and Closure Plan that includes a closure cost estimate. The Government of Türkiye

will require a financial guarantee. |

| 1.1.1.7 | Capital and Operating Costs |

| · | The SLR QP is of the opinion that the capital cost estimate for the Hod Maden Project has been well prepared and appears to be realistic

for the scope of the Project. The estimate is considered an AACEi class 3 estimate. |

| · | The total initial development costs for the Project are estimated to be US$1,060 million, of which, US$149.2 million has been already

spent. |

| · | The Project team has developed a Basis of Estimate (BoE) document. It is well-prepared and consistent with industry standards. |

| · | The contingency as a percentage of direct plus indirect costs is appropriate, especially when considering allowances for potential

quantity growth. |

| · | There is a high level of design completion for the stage of the Project. |

| | 1-7 |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| · | The capital cost estimate is based on a very high level of budgetary quotations or actual awards. |

| · | Approximately 64% of the initial capital costs has been quoted in Turkish Lira with approximately 29% quoted in USD. |

| · | Bulk earthwork scopes of work often exceed budget due to the uncertain nature of ground conditions. The Project is commencing the

Main Access Road bulk earthworks prior to other bulk earthworks. |

| · | The Project team has prepared a Project Execution Plan that clearly outlines the scope of the major contractual packages and purchase

orders, the management team roles and responsibilities, and the execution strategy. |

| · | The Project will be executed using an Integrated Project Management Team (IPMT) that will include the Owner’s Team, the engineering

and procurement (EP) contractors, various construction contractors by scope, and engineering consultants for specific specialist scopes. |

| · | The selected overall execution model for the construction phase of this Project is optimal for the size and scope of the Project. |

| · | The Project is currently on schedule with three overall indicators of project progress indicating the Project is on time. These indicators

are overall cashflow, overall commitments, and construction progress. This timely execution not only reflects well on the overall execution

team but also on the execution strategy of direct execution with an integrated project team. |

The QPs offer the following recommendations by area:

| 1.1.2.1 | Geology and Mineral Resources |

| 1 | Carry out an infill drilling to improve the confidence of ore that will be mined during the first four years of the life of mine (LOM),

Resource extension, Resource sterilization and assay programs as recommended below. The proposed budget for the 2025 infill drill program,

which includes 16,300 m of drilling as well as other related activities, is US$5.09 million. The recommended and planned infill drill

program for 2025 includes the following activities: |

| a) | Carry out twin-drilling for hole HTG-002 to confirm grade tenors and reduce dependence of the estimate on this hole. |

| b) | Implement standard operating procedures for all data collection procedures including the drilling, logging, density measurements and

sample preparation steps. |

| c) | Revise the geological logging process to encapsulate the broad understanding of mineralization to yield logging that is fit for the

purpose of geological and estimation domaining. |

| d) | Backflag estimation domains on drilling and assess if high-grade sub-populations can be linked to core observations that can be incorporated

into the new logging framework. |

| | 1-8 |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| e) | Collect additional Sulfide S data from available pulps to improve the imputation model and better understand the low-S high-Fe population. |

| f) | Re-sample the remaining quarters as a matter of priority to yield at minimum half-core support for all samples. The RSC QP has made

recommendations for holes that should be prioritized in the re-sampling work. |

| g) | Discuss the likely 1% to 2% high-bias in Au results at ALS Loughrea with the laboratory management. |

| h) | Conduct additional check sampling for Cu to test the hypothesis that the apparent bias observed in the 2024 Cu check analyses was

associated with a single batch. |

| i) | Conduct check measurements for bulk density (e.g., by the core tray method) to benchmark measurements from the water-immersion method. |

| j) | Conduct check measurements for bulk density on the top and bottom 10% of the dataset. |

| 2 | The RSC QP agrees with the objectives and overall scope of these planned activities. |

| 1.1.2.2 | Mining and Mineral Reserves |

| 1 | Re-run and optimize the underground mining development and production schedule, as per the normal course of business. |

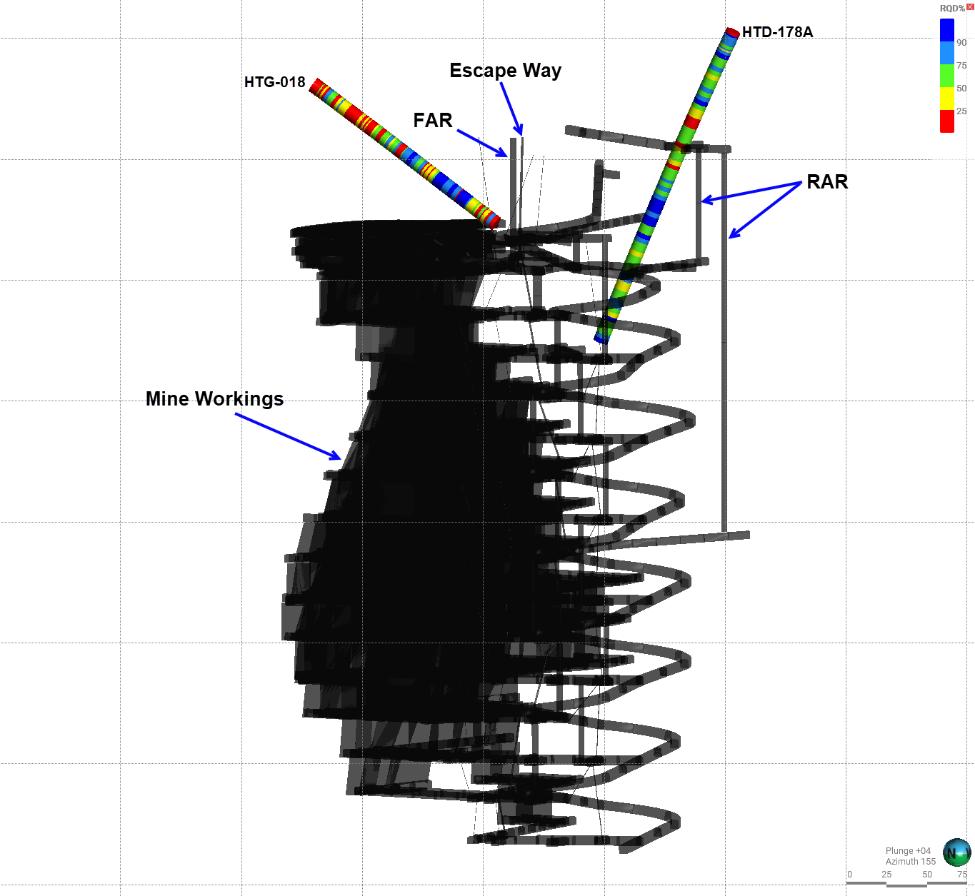

| 2 | Complete geotechnical drill holes along the centerlines of the fresh air (FAR), escapeway, and return air (RAR) ventilation shafts

to ensure a detailed design for construction. These holes have been drilled, and additional analyses are progressing. This work is crucial

for underground mining contract tender documents. |

| 3 | Reinforce all initial FAR and RAR ventilation shafts with a remote-controlled shotcrete machine. |

| 4 | Conduct tests to determine if the Hod Maden sulfide ores are compatible with ammonium nitrate,

especially for reactive ores that may require specific explosive products. This information is also necessary for the underground mining

contract tender documents. A Turkish Explosive Consultant, Madser, has been retained to assist with these type of risks. |

| 5 | Re-calibrate numerical modeling using results from pilot dewatering in the center of the Hod Maden deposit (DAF zone), which is expected

to be finished in Q4 2025. This will help refine the underground mine dewatering needs. |

| 6 | Carry out additional underground paste backfill testing using representative deposit samples. This will include material characterization,

rheology, and strength tests, with future testing incorporating process water samples, if available. An update from Minefill, a paste

fill plant test work consultant, is almost complete as of the date of this TRS. |

| 1.1.2.3 | Mineral Processing |

| 1 | Consider re-testing, investigation, and inclusion of gravity recoverable gold circuit. A non-trivial quantity of free gold is present

after secondary grinding which may be captured and either mixed with copper concentrate or sold as gold concentrate as needed. |

| | 1-9 |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| 1 | Undertake comprehensive hydrological and geotechnical assessments for critical project infrastructure components to support detailed

design and ensure long-term stability. This scope should include: |

| o | The main Yukarιmaden access road and its associated tunnel alignments,

as well as the Saliçor Valley (i.e., North Valley) access tunnel |

| o | The process plant site, with emphasis on zones featuring structural walls and exposed bedrock |

| o | Additional focus areas to include the alignment and condition of internal site roads and external access roads including the updated

utility and tailings pipeline corridor in the North Valley from the Saliçor tunnel exit to the crest of the TSF |

| o | Continue with additional geotechnical boreholes and foundation characterization in the North Valley WDF, utility corridor and main

access roads, including geochemical characterization |

| o | Continue to perform waste characterization for both geotechnical and geochemical properties planned for disposal in the North Valley

WDF |

| o | Additional boreholes to confirm the groundwater elevations with the TSF basin, at the junction of the North Valley Access Road and

the TSF, and within the WDF footprint |

| o | The designated topsoil storage facility |

| o | The spoil deposition area for road construction materials |

| o | The footprint of the high-voltage (HV) substation installation |

| o | All water non-contact water diversions, contact water collection/storage structures, and sediment management structures. |

| o | The main construction camp. |

| 1 | Periodically update and validate the numerical groundwater model as mining advances (e.g., following decline construction, Saliçor

Tunnel development, and other major infrastructure changes) |

| 2 | Update and finalize necessary simulations addressing paste fill permitting and contaminant transport predictions to ensure regulatory

alignment and support informed decision-making |

| 3 | Expand the on-site meteorological network with precipitation, temperature, snowpack, and evaporation stations across both valleys

at multiple elevations to improve data coverage and hydrological model calibration. |

| 4 | Update the design rainfall analysis at least every three years using on-site data or sooner following any significant or extreme rainfall

event. |

| 1 | Reinstate the damaged stream gauges (AGI) and maintain continuous streamflow monitoring in line with EIA commitments for runoff validation

and model updates. |

| 2 | Expand the climate change assessment to include stochastic variability and projected changes in short-term rainfall and storm intensities

for future design evaluations. |

| | 1-10 |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| 3 | Update the site-wide water balance model to reflect ongoing South Valley design revisions (including waste dump locations, PAG management

etc.), outcomes of the stormwater management design (such as updated diversion channels, sediment ponds, and process water facilities),

the latest mine plan, production schedules, waste and tailings placement details, and updated groundwater inflows and dewatering configurations. |

| 4 | Incorporate updated geochemical and water quality data into the source terms and revise the load balance accordingly to maintain consistency

with the overall water balance framework. |

| 1 | Continue to negotiate with potential customers and obtain more Expressions of Interest (EOI) to support assumptions around concentrate

freight and commercial costs. |

| 1.1.2.7 | Environment and Social |

| 1 | Continue to budget appropriately to update environmental approvals and permits to reflect potential changes to the Project definition

arising from optimization studies, and ensure that the Project execution schedule allows for these activities. |

| 2 | Revise the environmental approval and permitting tracking tool to clearly state the relevant law or regulation, the type of approval

needed, the decision maker (regulator), summarize the application requirements, and specify the expected time frame for obtaining the

approval or permit. Update this tool to reflect changes in the Project definition. For approvals and permits already obtained, include

the date of issuance and the expiry date. |

| 3 | Develop and implement a compliance tracking tool to ensure compliance with legal requirements and identify any non-compliance requiring

corrective action. |

| 4 | As appropriate, update environmental and social baseline studies in response to possible changes in the Project definition. |

| 5 | As appropriate, update the 2023 ESIA and the draft ESMPs according to the revised Project definition to support Project financing. |

| 6 | Continue engagement with local communities and stakeholders as Project development plans evolve. |

| 7 | Track the success of land acquisition and resettlement in line with IFC PS5, and address any grievances raised by the communities. |

| 8 | Update the Closure Plan and closure costing regularly as required by law and also to address the evolving Project definition. |

| 1.1.2.8 | Capital and Operating Costs |

| 1 | Select the main contractors for North Valley bulk earthworks and start as soon as possible (and in the year 2025) small scopes of

work with different equipment mixes in order to evaluate productivities and unit costs in the difficult terrain. These scopes of work

and the evaluation of productivities should be completed prior to the commencement of the main work inside the North Valley. |

| 2 | Closely monitor quantities for each contractor and area during the bulk earthworks. |

| | 1-11 |  |

| SSR Mining Inc. | Hod Maden Project | | January 7, 2026 |

| Technical Report Summary | | SLR Project No.: 123.000320.00001 |

| 3 | Monitor changes in unit rates due to potential impacts of escalation/inflation. |

| 4 | Synchronize operating costs and sustaining capital estimates between project team members and finance group, especially with capitalized

underground development costs |