Effective Date: 30 June 2025

Report Date:31 August 2025

HARMONY GOLD MINING COMPANY LIMITED

Technical Report Summary of the

Eva Copper Project

North West Queensland, Australia

Effective date: 30 June 2025

i

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

IMPORTANT NOTICE This Technical Report Summary ("TRS") has been prepared for Harmony Gold Mining Company Limited ("Harmony') in support of disclosure and filing requirements with the United States Securities and Exchange Commission (SEC) under Subpart 1300 of Regulation S-K and 229.601(b)(96) of Regulation S-K. The quality of information, estimates, and conclusions contained in this TRS apply as of the effective date of this TRS. Subsequent events that may have occurred since that date may have resulted in material changes to such information, estimates and conclusions in this summary. |

Effective date: 30 June 2025

ii

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

QP Consent and Sign-off

I have read and understood the requirements of:

•the South African Code for Reporting of Exploration Results, Mineral Resources and Mineral Reserves (the

"SAMREC Code, 2016 edition")

•the Harmony Guidelines on the Reporting of Exploration Results, Mineral Resources and Mineral Reserves

•Subpart 1300 (17 CFR 229.1300) of Regulation S-K, Disclosure by Registrants Engaged in Mining Operations

("Regulation S-K 1300")

I am a Competent Person as defined by the SAMREC Code, 2016 edition and the Qualified Person (“QP”) under

Regulation S-K 1300, having more than five years` experience that is relevant to the style of mineralisation and type of

deposit described in this TRS, and to the all activities for which I am accepting responsibility.

I am a member (Fellow) of the Australasian Institute of Mining and Metallurgy (AusIMM) and my registration is as

follows:

Greg Job

Executive General Manager - Growth and Resource Development

FAusIMM No. 111561

I have reviewed the tables, graphs and other information included for the Eva Copper Project Mineral Resource which

will be used in the 2025 Harmony Gold Mineral Resource and Mineral Reserve Report to which this Consent Statement

applies.

I acknowledge responsibility for all the Sections of this TRS and as the QP I relied on information provided by various

subject experts.

At the effective date of this TRS, to the best of my knowledge, information and belief, this TRS contains all scientific and

technical information that is required to be disclosed to make this TRS not misleading.

/s/ Greg Job

____________________________________

Mr Greg Job

BSc. MSc (Min Econ)

FAusIMM

Executive General Manager - Growth & Resource

Development

Harmony Australasia

Effective date: 30 June 2025

iii

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

List of Contents

1Executive Summary ....................................................................................................................................... | |

2Introduction .................................................................................................................................................. | |

2.1Report Section Responsibilities ...................................................................................................... | |

2.2Personal Inspection ........................................................................................................................ | |

2.3Effective Date ................................................................................................................................. | |

2.4Abbreviations and Units of Measure ............................................................................................. | |

3Property description ..................................................................................................................................... | |

3.2Land Use and Mining Tenure ......................................................................................................... | |

3.3Mining Leases ................................................................................................................................. | |

3.4Exploration Permits for Minerals ................................................................................................... | |

3.5Freehold Land ................................................................................................................................. | |

3.5.1Lot 37 (Agreement Numbers 355, 526, 1069, and 1070) ................................................ | |

3.5.2Lot 28 (Agreement Numbers 355, 1069, and 1070) ........................................................ | |

3.7Encumbrances ................................................................................................................................ | |

4Accessibility, climate, local resources, infrastructure, and physiography. ................................................... | |

4.1Accessibility and Infrastructure ...................................................................................................... | |

4.2Climate and Surface Water ............................................................................................................ | |

4.3Landforms and Vegetation ............................................................................................................. | |

4.4Local Mining Industry ..................................................................................................................... | |

5.1Prior Ownership and Changes ........................................................................................................ | |

5.2Mineral Resource Estimates History .............................................................................................. | |

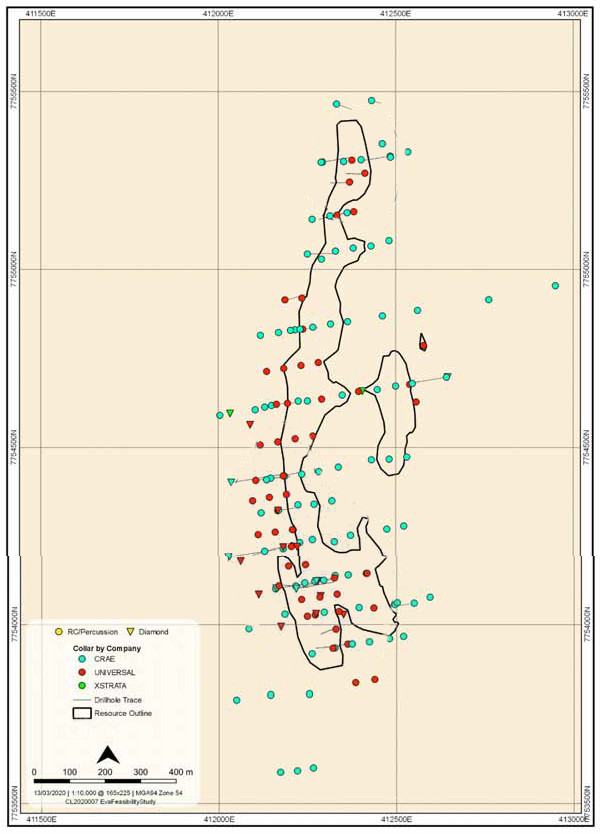

5.2.1Little Eva Deposit ............................................................................................................. | |

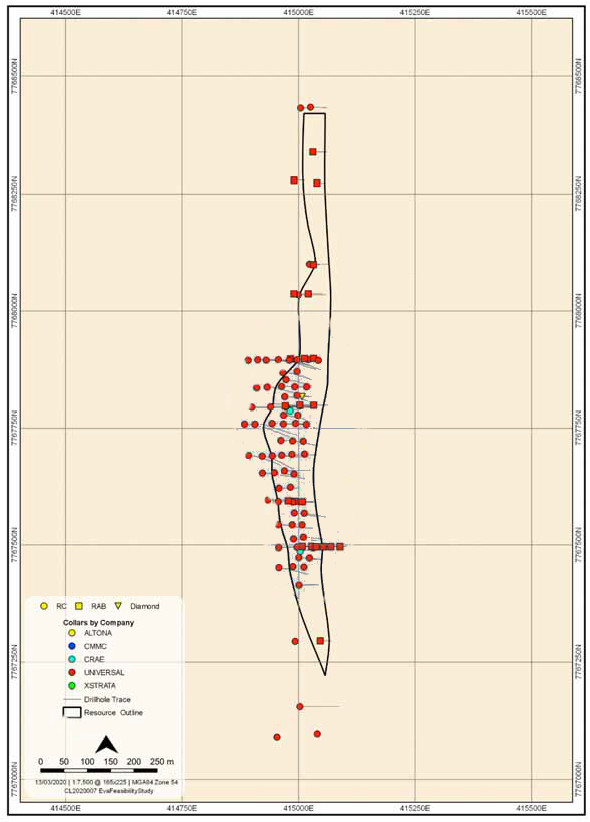

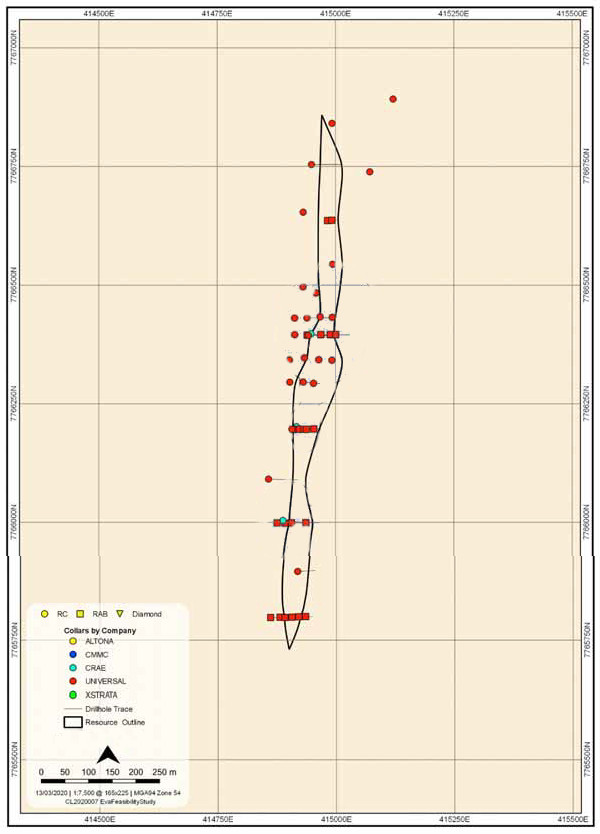

5.2.2Turkey Creek Deposit ....................................................................................................... | |

5.2.3Bedford Deposit ............................................................................................................... | |

5.2.4Lady Clayre Deposit ......................................................................................................... | |

5.2.5Ivy Ann Deposit ................................................................................................................ | |

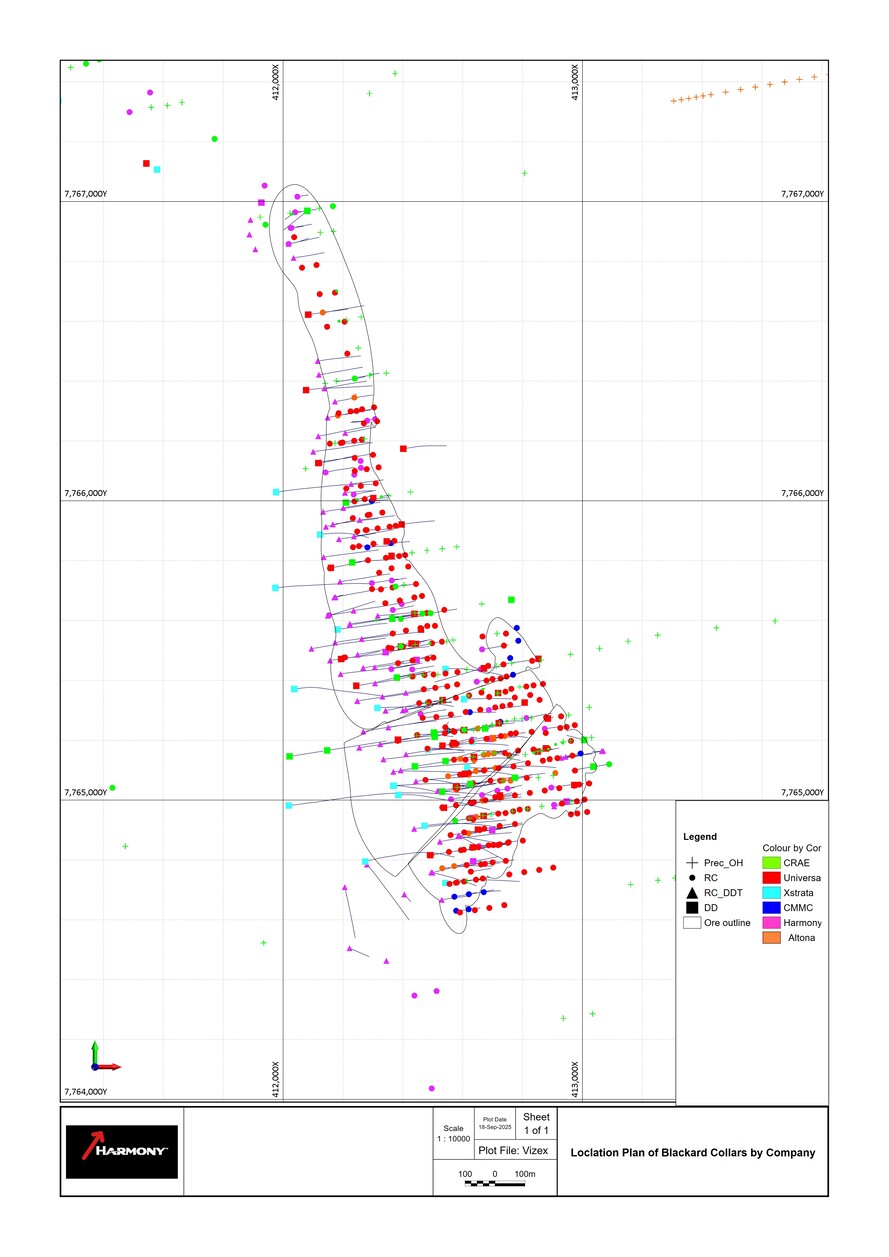

5.2.6Blackard Deposit .............................................................................................................. | |

5.2.7Scanlan Deposit ............................................................................................................... | |

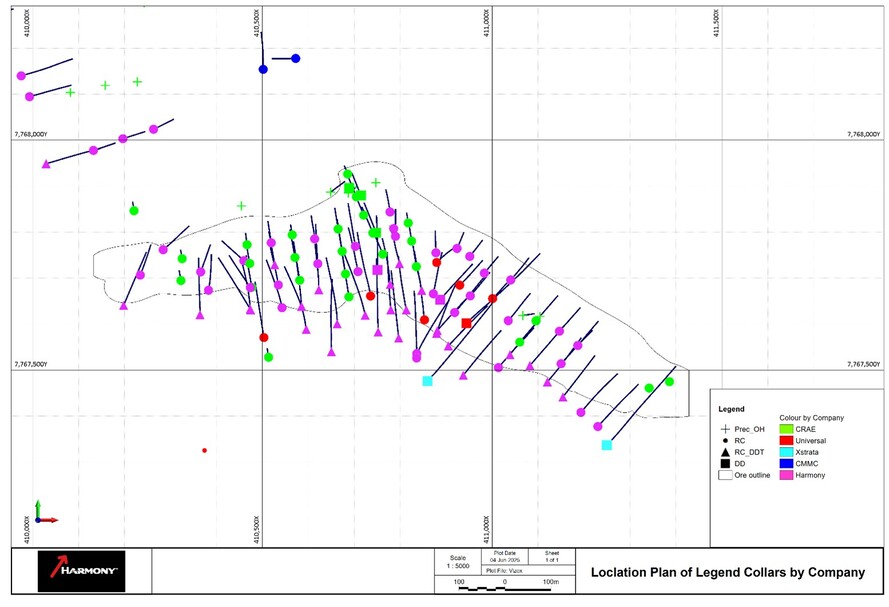

5.2.8Legend Deposit ................................................................................................................ | |

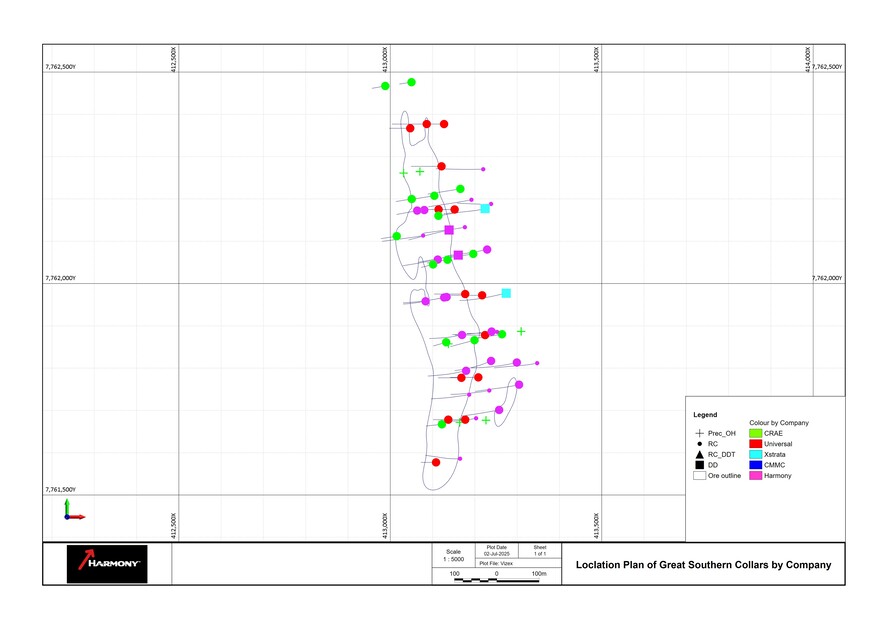

5.2.9Great Southern Deposit ................................................................................................... | |

6Geological setting, Mineralisation, and Deposit ........................................................................................... | |

6.1Regional Geology ............................................................................................................................ | |

6.1.1Regional Stratigraphy ...................................................................................................... | |

6.1.2Regional Deformation ...................................................................................................... | |

6.2Project Geology .............................................................................................................................. | |

6.2.1Little Eva Deposit Geology ............................................................................................... | |

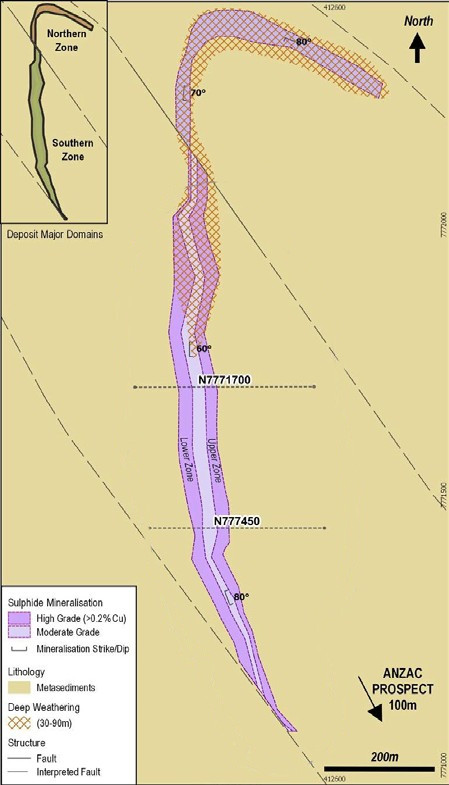

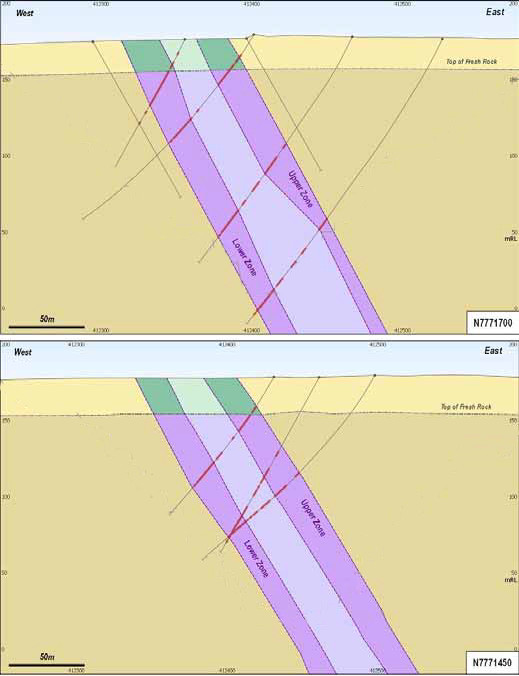

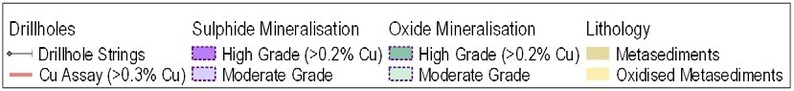

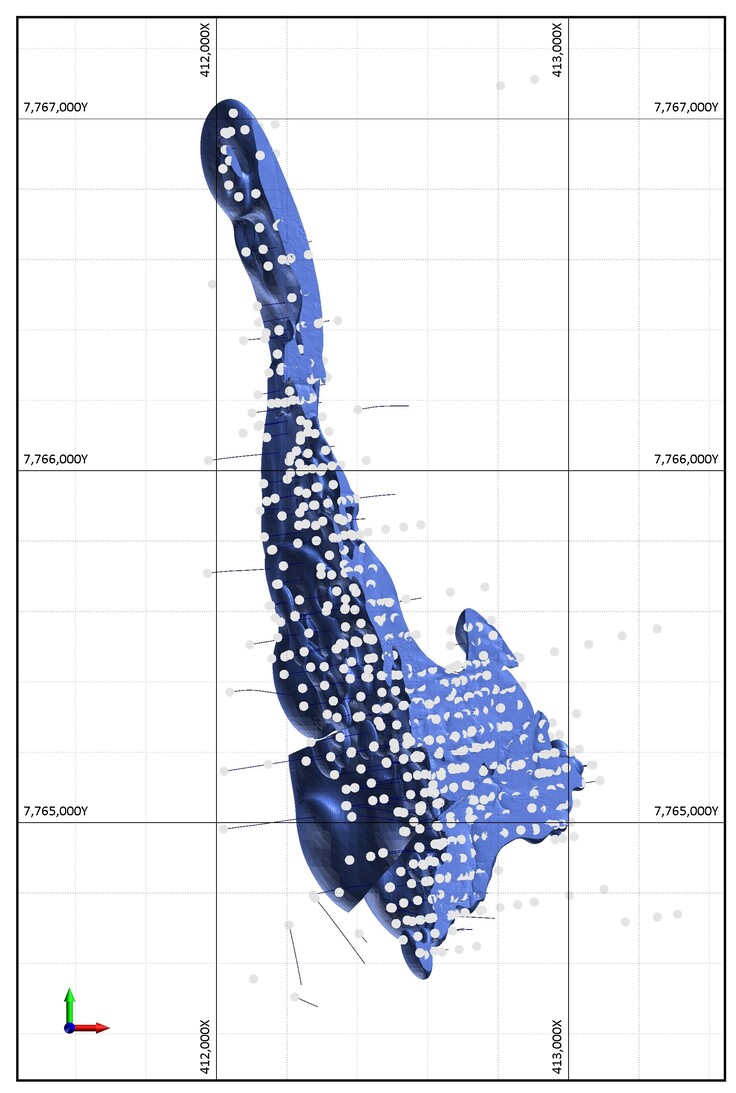

6.2.2Turkey Creek .................................................................................................................... | |

6.2.3Native Copper deposits ................................................................................................... | |

6.2.4Lady Clayre ....................................................................................................................... | |

6.3Deposit Types ................................................................................................................................. | |

6.3.1Copper-Gold Deposits ...................................................................................................... | |

6.3.2Copper-Only Deposits ...................................................................................................... | |

7Exploration .................................................................................................................................................... | |

7.1.1Drill Hole Data Description .............................................................................................. |

Effective date: 30 June 2025

iv

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

7.1.1.1Little Eva ............................................................................................................ | |

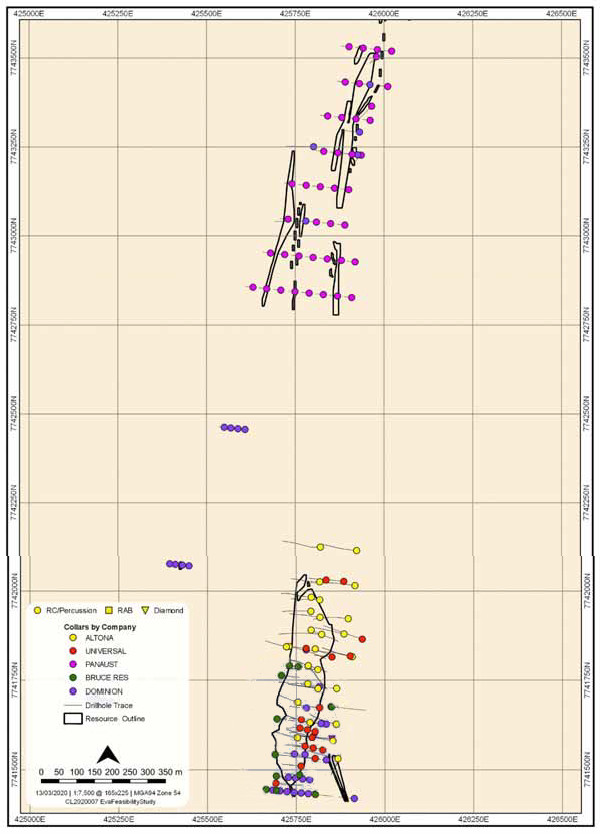

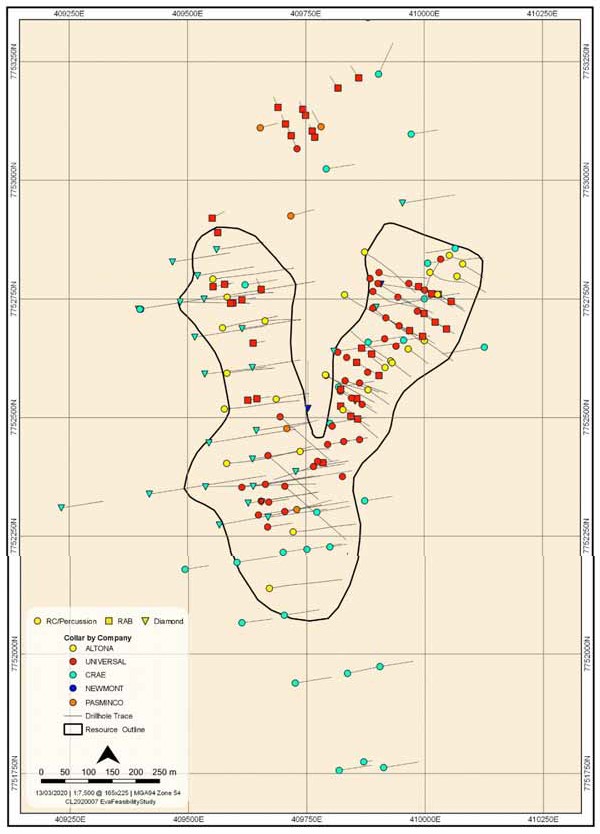

7.1.1.2Turkey Creek ..................................................................................................... | |

7.1.1.7Lady Clayre ........................................................................................................ | |

7.1.1.1Great Southern ................................................................................................. | |

7.1.2Drill Hole Collar Survey Control ....................................................................................... | |

7.1.2.1Little Eva ............................................................................................................ | |

7.1.2.2Turkey Creek ..................................................................................................... | |

7.1.2.7Lady Clayre ........................................................................................................ | |

7.1.3Downhole Surveys ........................................................................................................... | |

7.1.3.1Little Eva ............................................................................................................ | |

7.1.3.2Turkey Creek ..................................................................................................... | |

7.1.3.3Blackard, Scanlan and Bedford ......................................................................... | |

7.1.3.5Lady Clayre ........................................................................................................ | |

7.1.3.6Legend and Great Southern .............................................................................. | |

7.1.4Drill Hole Logging ............................................................................................................. | |

7.1.4.1Little Eva ............................................................................................................ | |

7.1.4.4Lady Clayre ........................................................................................................ | |

7.1.5Core and RC Sampling Methods ...................................................................................... | |

8Sample Preparation, Analysis and Security ................................................................................................... | |

8.1Little Eva ......................................................................................................................................... | |

8.1.1URL 2002 programme ...................................................................................................... | |

8.1.2URL 2003–2006 programme ............................................................................................ | |

8.1.3URL 2007 programme ...................................................................................................... | |

8.1.4Altona 2011 programme ................................................................................................. | |

8.1.5Altona-Sichuan Railway Investment Group 2015 programme ........................................ | |

8.1.6CMMC 2018 to 2022 ........................................................................................................ | |

8.1.7Harmony Work 2023 to present ...................................................................................... | |

8.1.8Quality Control Procedures ............................................................................................. | |

8.2Turkey Creek ................................................................................................................................... | |

8.3Blackard, Scanlan, Legend and Great Southern ............................................................................ | |

8.6Lady Clayre ..................................................................................................................................... | |

9Data verification ............................................................................................................................................ | |

10Mineral Processing and Metallurgical testing ............................................................................................... | |

10.1Introduction .................................................................................................................................... | |

10.2Little Eva Deposit ............................................................................................................................ | |

10.2.1Mineralogy ....................................................................................................................... |

Effective date: 30 June 2025

v

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

11Mineral Resource Estimates ......................................................................................................................... | |

11.1Introduction .................................................................................................................................... | |

11.2Resource Estimation Procedures ................................................................................................... | |

11.3Geological and Mineralisation Models and Domains .................................................................... | |

11.3.1Little Eva .......................................................................................................................... | |

11.3.2Turkey Creek .................................................................................................................... | |

11.3.3Native Copper deposits ................................................................................................... | |

11.3.5Lady Clayre ....................................................................................................................... | |

11.3.7Block Models .................................................................................................................... | |

11.4Database and Statistical Analysis ................................................................................................... | |

11.4.1Drill Hole Database .......................................................................................................... | |

11.4.2Deposit Assay Data Statistics ........................................................................................... | |

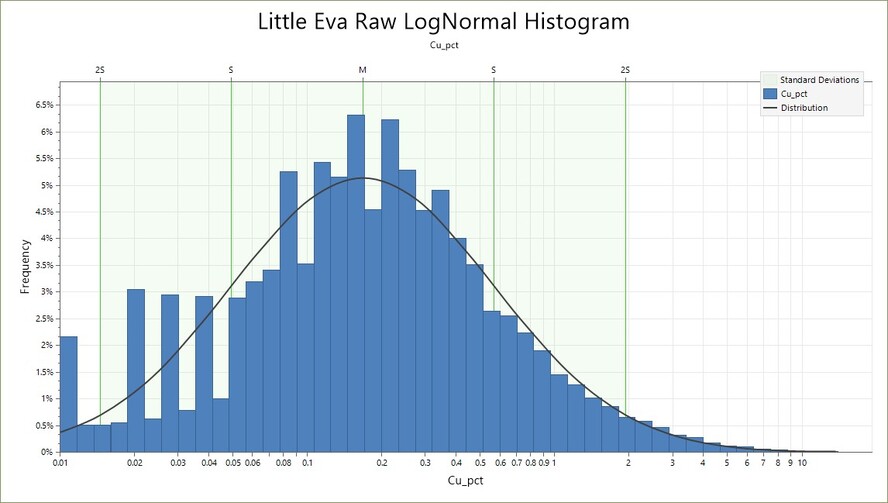

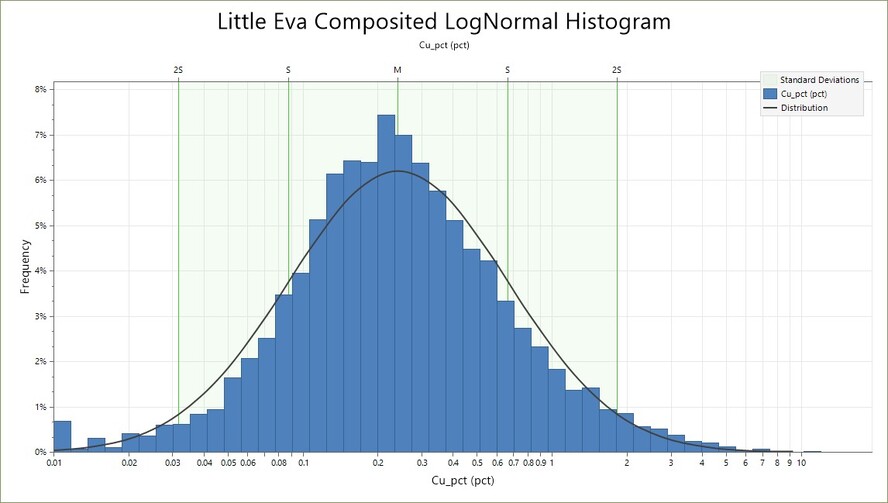

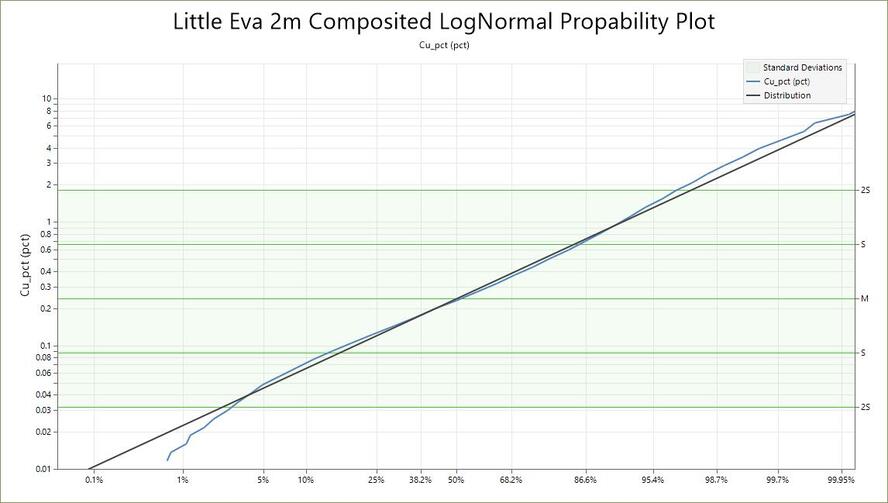

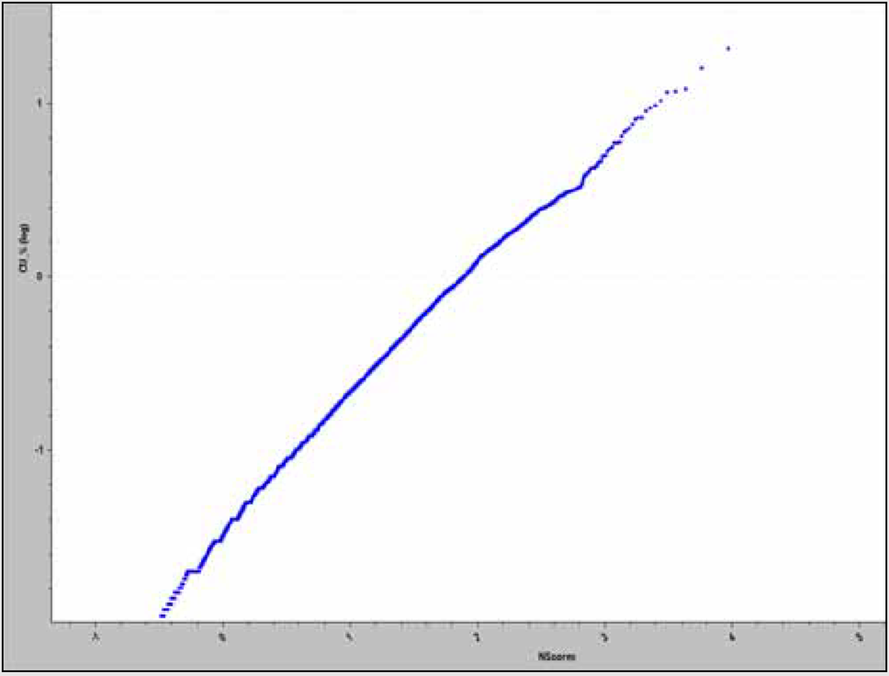

11.4.2.1Little Eva Deposit .............................................................................................. | |

11.4.2.2Blackard Deposit ............................................................................................... | |

11.4.2.3Scanlan Deposit ................................................................................................. | |

11.4.3Data Conditioning and Assay Composites ....................................................................... | |

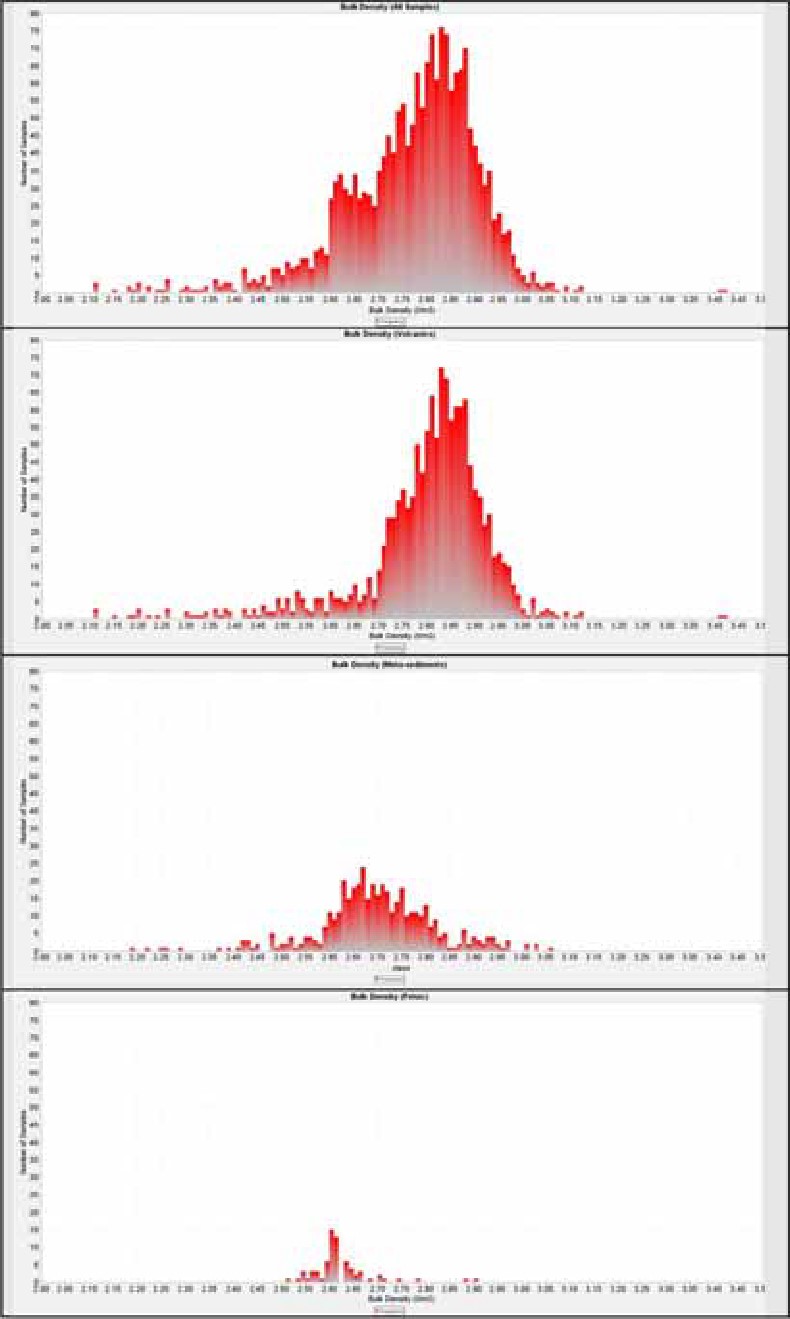

11.5Bulk Density .................................................................................................................................... | |

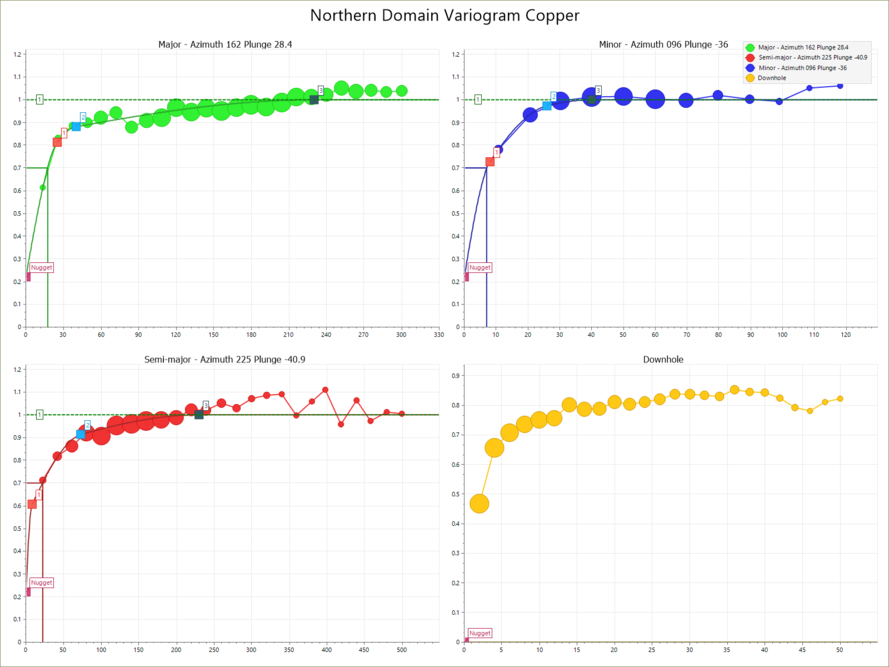

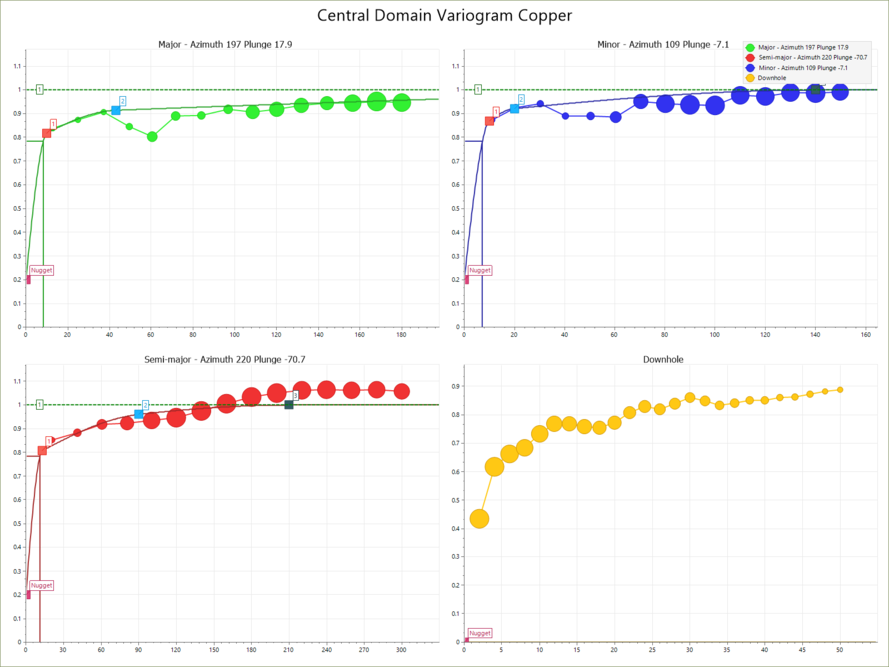

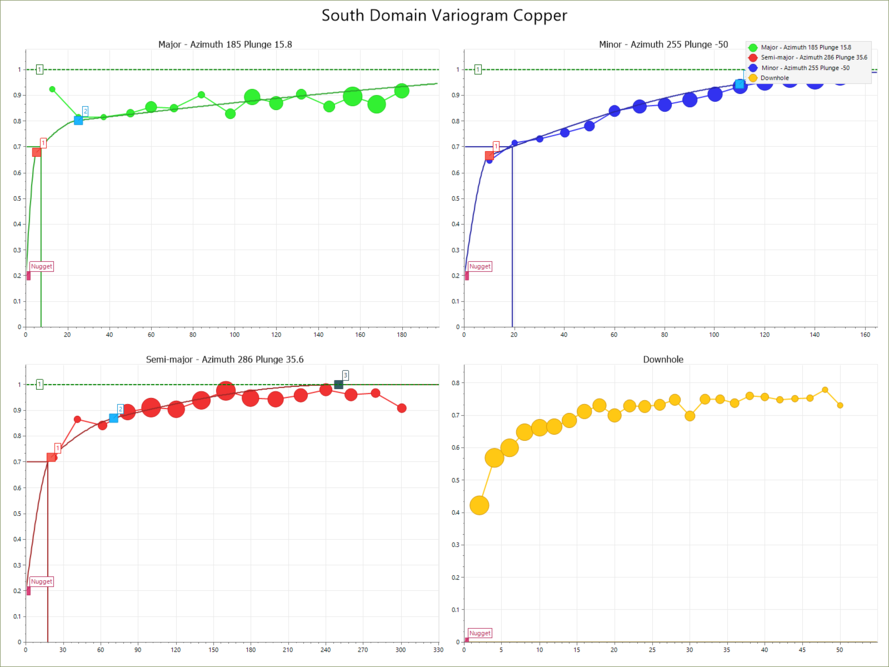

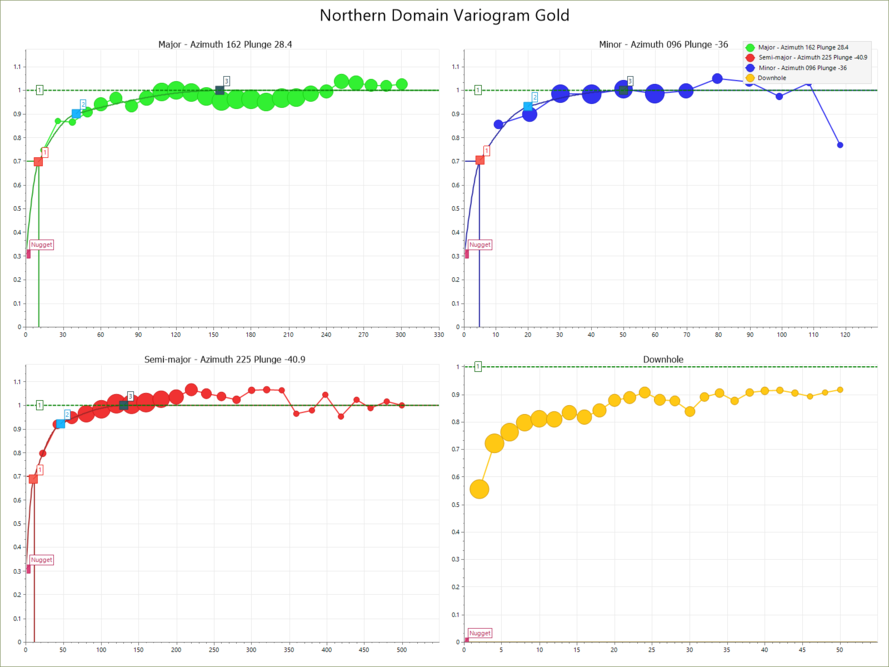

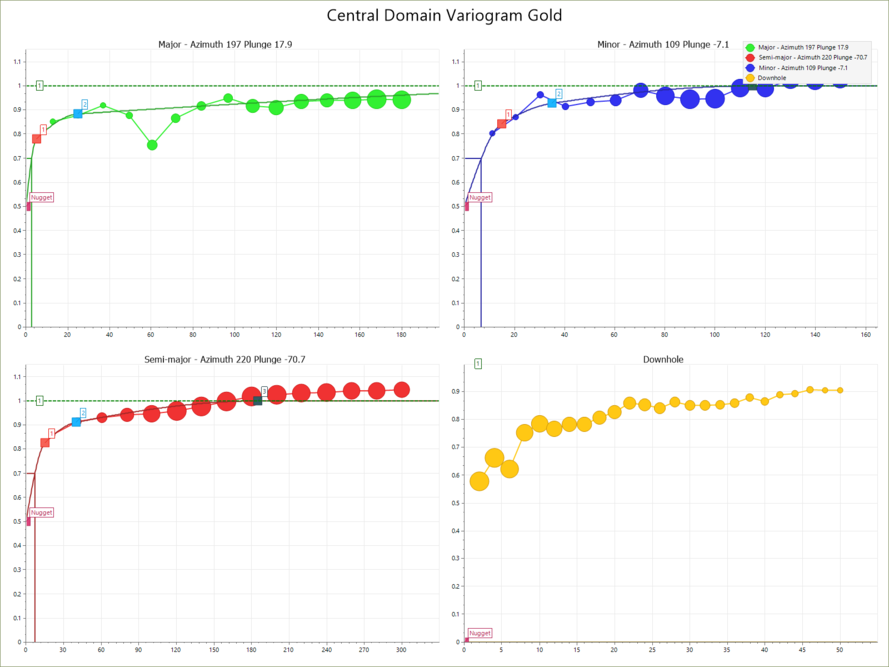

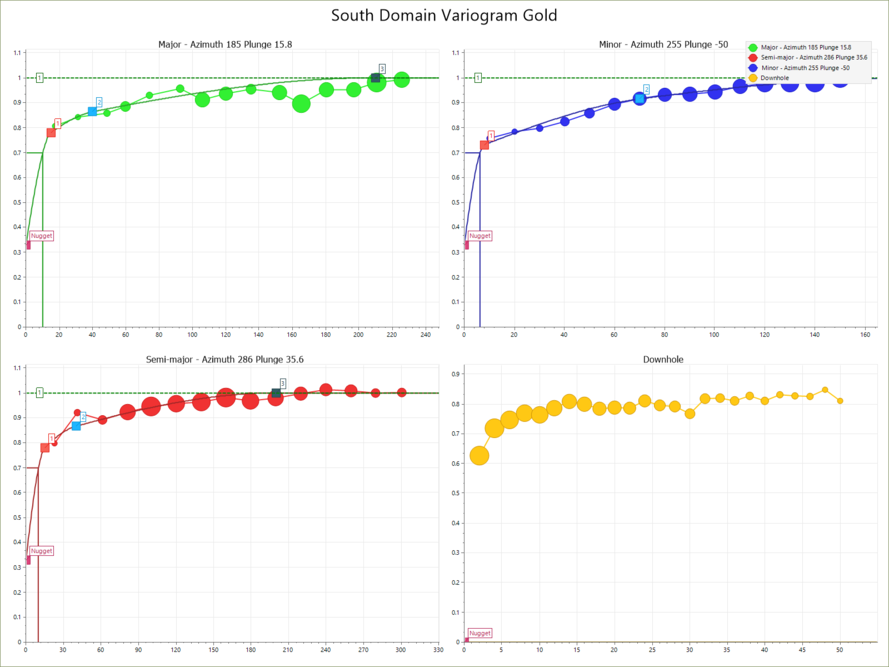

11.6Variography .................................................................................................................................... | |

11.7Grade Interpolation ........................................................................................................................ | |

11.8Classification and Mineral Resource Statement ............................................................................ | |

11.9Resource Verification ..................................................................................................................... | |

12Mineral Reserve Estimates ............................................................................................................................ | |

13Mining Methods ............................................................................................................................................ | |

14Processing and Recovery Methods ............................................................................................................... | |

15Infrastructure ................................................................................................................................................ | |

16Market Studies .............................................................................................................................................. | |

Groups .......................................................................................................................................................... | |

18Capital and Operating Costs .......................................................................................................................... | |

19Economic Analysis ......................................................................................................................................... | |

20Adjacent properties ...................................................................................................................................... | |

20.1Mining Properties (Regional) .......................................................................................................... | |

20.2Mining Properties (Adjacent) ......................................................................................................... | |

20.3Non-Mining Properties ................................................................................................................... | |

21Other Relevant Data and Information .......................................................................................................... | |

22Interpretation and Conclusion ...................................................................................................................... | |

22.1Geology, Mineral Resources ........................................................................................................... | |

22.3Metallurgical Testwork and Mineral Processing ............................................................................ | |

22.4Process Plant .................................................................................................................................. | |

22.5Infrastructure ................................................................................................................................. | |

22.6Environmental, Permitting, and Social Considerations .................................................................. | |

22.7Capital and Operating Costs ........................................................................................................... | |

23Recommendations ........................................................................................................................................ | |

23.1Mineral Resources and Mineral Reserves ...................................................................................... | |

24References ..................................................................................................................................................... | |

24.1References ...................................................................................................................................... | |

25Reliance on information provided by the registrant .................................................................................... |

Effective date: 30 June 2025

vi

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

List of Figures

Effective date: 30 June 2025

vii

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

Effective date: 30 June 2025

viii

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

List of Tables

Effective date: 30 June 2025

ix

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

Effective date: 30 June 2025

x

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

Units of Measure and Abbreviations

Unit / Abbreviation | Description or Definition |

°C | degrees Celsius |

µm | Micrometers |

2D | Two-dimensional |

3D | Three-dimensional |

AE | Abnormal expenditure |

Ag | Silver |

Al | Aluminium |

AMD | Absolute Mine Datum (+1000m) |

AngloGold | AngloGold Limited |

Au | Gold |

Ave. | Average |

BMD | Below mine datum |

Bn | Billion |

c. | Approximately |

CIP | Carbon-In-Pulp |

cm | Centimetre |

cmg/t | Centimetre-grams per tonne |

CODM | Chief Operating Decision-Maker |

Company | Harmony Gold Mining Company Limited |

COP | Code of Practice |

CRG | Central Rand Group |

CRM | Certified Reference Material |

Cu | Copper |

CV | Coefficient of Variation |

DMPR | Department of Mineral and Petroleum Resources |

DWS | Department of Water and Sanitation |

EIA | Environmental Impact Assessment |

EMPR | Environmental Management Program |

EMS | Environmental Management System |

ESG | Environmental Social and Governance |

ETF’s | Exchange Traded Funds |

EW-SX | Electro-wining solvent extraction |

FAIG | Fellow of the Australian Institute of Geoscientists |

FAusIMM | Fellow of the Australasian institute of Mining and Metallurgy |

Fe | Iron |

FS | Feasibility Study |

FX | Foreign Exchange rate |

g | Gram |

g/t | Grams per metric tonne |

GHG | Greenhouse gas |

GIS | Geographic Information System |

GISTM | Global Industry Standard on Tailings Management |

ha | Hectare |

Harmony | Harmony Gold Mining Company Limited |

HPE | Hydro-powered |

kg | Kilogram |

km | Kilometre |

km2 | Square kilometre |

kV | Kilovolt |

Effective date: 30 June 2025

xi

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

Unit / Abbreviation | Description or Definition |

kWh | Kilowatt-hour |

L | Litre |

LDL | Lower detection limit |

LIB | Long Inclined Borehole |

LOM | Life of Mine |

Ltd | Limited |

m | Meter |

M | Million |

m3/hr | Cubic metres per hour |

masl | Metres above sea level |

MCC | Mining Charter Compliance |

MCF | Mine Call Factor |

Mg | Magnesium |

Mintek | South Africa's national mineral research organization |

mm | Millimetre |

Moz | Million troy ounces |

MPRDA | Mineral and Petroleum Resources Development Act, 28 of 2002 |

Mt | Million tonnes |

Mtpa | Million tonnes per annum |

Mtpm | Million tonnes per month |

NEMA | National Environmental Management Act, 107 of 1998 |

No. | Number |

NSR | Net Smelter Return |

NPV | Net present value |

oz | Troy ounce |

Pb | Lead |

PSD | Particle Size Distribution |

Pty | Proprietary |

QA/QC | Quality Assurance/Quality Control |

QP | Qualified Person |

ROM | Run-of-Mine |

SACNASP | South African Council for Natural Scientific Professions |

SAMREC | The South African Code for the Reporting of Exploration Results, Mineral Resources and Mineral Reserves |

SEC | Securities and Exchange Commission |

SGM | Sequential Grid Mining |

SLP | Social Labour Plan |

STD | Standard Deviation |

t | Metric tonne |

t/m3 | Tonne per cubic meter |

TMM | Trackless mobile machinery |

TRS | Technical Report Summary |

TSF | Tailings Storage Facility |

USD | United States Dollars |

USD/oz | United States Dollar per troy ounce |

WRG | West Rand Group |

WUL(s) | Water Use License(s) |

ZAR | South African Rand |

ZAR/kg | South African Rand per kilogram |

Zn | Zinc |

Effective date: 30 June 2025

xii

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

Glossary of Terms

Term | Definition |

Co-kriging | A method that is used to predict the value of the point at unobserved locations by sample points that are known to be spatially interconnected by adding other variables that have a correlation with the main variable or can also be used to predict 2 or more variables simultaneously. |

Cut-off grade | Cut-off grade is the grade (i.e. the concentration of metal or mineral in rock) that determines the destination of the material during mining. For purposes of establishing “prospects of economic extraction,” the cut-off grade is the grade that distinguishes material deemed to have no economic value (it will not be mined in underground mining or if mined in surface mining, its destination will be the waste dump) from material deemed to have economic value (its ultimate destination during mining will be a processing facility). Other terms used in similar fashion as cut-off grade include net smelter return, pay limit, and break-even stripping ratio. |

Dilution | Unmineralized rock that is by necessity, removed along with ore during the mining process that effectively lowers the overall grade of the ore. |

Head grade | The average grade of ore fed into the mill. |

Economically viable | Economically viable, when used in the context of Mineral Reserve determination, means that the qualified person has determined, using a discounted cash flow analysis, or has otherwise analytically determined, that extraction of the Mineral Reserve is economically viable under reasonable investment and market assumptions. |

Indicated Mineral Resource | Indicated Mineral Resource is that part of a Mineral Resource for which quantity and grade or quality are estimated on the basis of adequate geological evidence and sampling. The level of geological certainty associated with an Indicated Mineral Resource is sufficient to allow a qualified person to apply modifying factors in sufficient detail to support mine planning and evaluation of the economic viability of the deposit. Because an Indicated Mineral Resource has a lower level of confidence than the level of confidence of a Measured Mineral Resource, an Indicated Mineral Resource may only be converted to a probable Mineral Reserve. |

Inferred Mineral Resource | Inferred Mineral Resource is that part of a Mineral Resource for which quantity and grade or quality are estimated on the basis of limited geological evidence and sampling. The level of geological uncertainty associated with an Inferred Mineral Resource is too high to apply relevant technical and economic factors likely to influence the prospects of economic extraction in a manner useful for evaluation of economic viability. Because an Inferred Mineral Resource has the lowest level of geological confidence of all Mineral Resources, which prevents the application of the modifying factors in a manner useful for evaluation of economic viability, an Inferred Mineral Resource may not be considered when assessing the economic viability of a mining project, and may not be converted to a Mineral Reserve. |

Kriging | A method of interpolation based on Gaussian process governed by prior covariances. It uses a limited set of sampled data points to estimate the value of a variable over a continuous spatial field |

Mine Call Factor | The ratio, expressed as a percentage, of the total quantity of recovered and unrecovered mineral product after processing with the amount estimated in the ore based on sampling. |

Measured Mineral Resource | Measured Mineral Resource is that part of a Mineral Resource for which quantity and grade or quality are estimated on the basis of conclusive geological evidence and sampling. The level of geological certainty associated with a Measured Mineral Resource is sufficient to allow a qualified person to apply modifying factors, as defined in this section, in sufficient detail to support detailed mine planning and final evaluation of the economic viability of the deposit. Because a Measured Mineral Resource has a higher level of confidence than the level of confidence of either an Indicated Mineral Resource or an Inferred Mineral Resource, a Measured Mineral Resource may be converted to a Proven Mineral Reserve or to a Probable Mineral Reserve. |

Mineral Reserve | Mineral Reserve is an estimate of tonnage and grade or quality of Indicated and Measured Mineral Resources that, in the opinion of the qualified person, can be the basis of an economically viable project. More specifically, it is the economically mineable part of a Measured or Indicated Mineral Resource, which includes diluting materials and allowances for losses that may occur when the material is mined or extracted. |

Mineral Resource | Mineral Resource is a concentration or occurrence of material of economic interest in or on the Earth’s crust in such form, grade or quality, and quantity that there are reasonable prospects for economic extraction. A Mineral Resource is a reasonable estimate of mineralization, taking into account relevant factors such as cut-off grade, likely mining dimensions, location or continuity, that, with the assumed and justifiable technical and economic conditions, is likely to, in whole or in part, become economically extractable. It is not merely an inventory of all mineralization drilled or sampled. |

Effective date: 30 June 2025

xiii

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

Term | Definition |

Modifying Factors | Modifying factors are the factors that a qualified person must apply to Indicated and Measured Mineral Resources and then evaluate in order to establish the economic viability of Mineral Reserves. A qualified person must apply and evaluate modifying factors to convert Measured and Indicated Mineral Resources to Proven and Probable Mineral Reserves. These factors include but are not restricted to; mining; processing; metallurgical; infrastructure; economic; marketing; legal; environmental compliance; plans, negotiations, or agreements with local individuals or groups; and governmental factors. The number, type and specific characteristics of the modifying factors applied will necessarily be a function of and depend upon the mineral, mine, property, or project. |

Pre-Feasibility Study | A pre-feasibility study (or preliminary feasibility study) is a comprehensive study of a range of options for the technical and economic viability of a mineral project that has advanced to a stage where a qualified person has determined (in the case of underground mining) a preferred mining method, or (in the case of surface mining) a pit configuration, and in all cases has determined an effective method of mineral processing and an effective plan to sell the product. (1) A pre-feasibility study includes a financial analysis based on reasonable assumptions, based on appropriate testing, about the modifying factors and the evaluation of any other relevant factors that are sufficient for a qualified person to determine if all or part of the Indicated and Measured Mineral Resources may be converted to Mineral Reserves at the time of reporting. The financial analysis must have the level of detail necessary to demonstrate, at the time of reporting, that extraction is economically viable. (2) A pre-feasibility study is less comprehensive and results in a lower confidence level than a feasibility study. A pre-feasibility study is more comprehensive and results in a higher confidence level than an initial assessment. |

Probable Mineral Reserve | Probable Mineral Reserve is the economically mineable part of an Indicated and, in some cases, a Measured Mineral Resource. |

Proven Mineral Reserve | Proven Mineral Reserve is the economically mineable part of a Measured Mineral Resource and can only result from conversion of a Measured Mineral Resource. |

Qualified Person | A qualified person is: (1) A mineral industry professional with at least five years of relevant experience in the type of mineralization and type of deposit under consideration and in the specific type of activity that person is undertaking on behalf of the registrant; and (2) An eligible member or licensee in good standing of a recognized professional organization at the time the technical report is prepared. For an organization to be a recognized professional organization, it must: (i) Be either: (A) An organization recognized within the mining industry as a reputable professional association; or (B) A board authorized by U.S. federal, state or foreign statute to regulate professionals in the mining, geoscience or related field; (ii) Admit eligible members primarily on the basis of their academic qualifications and experience; (iii) Establish and require compliance with professional standards of competence and ethics; (iv) Require or encourage continuing professional development; (v) Have and apply disciplinary powers, including the power to suspend or expel a member regardless of where the member practices or resides; and (vi) Provide a public list of members in good standing. |

Tailings | Finely ground rock of low residual value from which valuable minerals have been extracted is discarded and stored in a designed dam facility. |

Tailings Freeboard | The vertical height between the beached tailings against the embankment crest and the crest itself. |

Effective date: 30 June 2025

1

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

1Executive Summary

Section 229.601(b)(iii){B}(96)(1)

The Qualified Person (“QP”) of Harmony Gold Mining Company Limited (“Harmony” or the “Company”) has

prepared this TRS to disclose the Mineral Resource estimates for the Company’s Eva Copper Project (the

'Project" or the "Eva Copper Project"). The TRS has been prepared in accordance with the U.S. Securities and

Exchange Commission (“SEC”) Regulation, S-K 1300, with an effective date as at 30 June 2025. This TRS is a

2025 update to the previously filed 2024 TRS. This TRS updates the Technical Report Summary filed by

Harmony on the Eva Copper Project on 31 October 2023, named Exhibit 96.14 Technical Report Summary of

the Mineral Resources and Mineral Reserves for the Eva Copper Project, North West Queensland, Australia,

which was effective on 30 June 2023. This TRS is prepared to satisfy the requirement of Item 1302(e)(6) of

Regulation S-K. No material changes have occurred between the effective date and the date of signature of

this TRS.

The Project is 100% owned by Harmony Eva Copper Limited, a subsidiary of Harmony Gold Mining Company

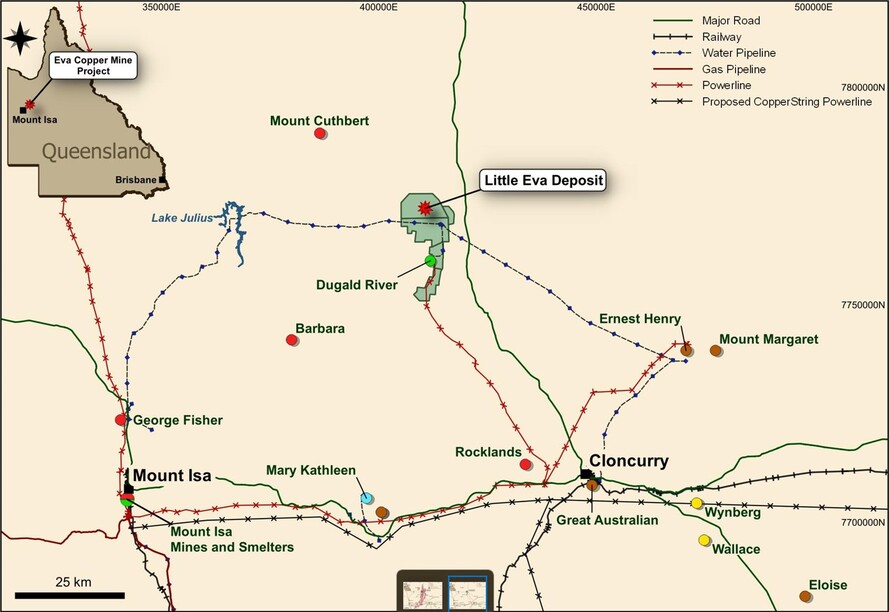

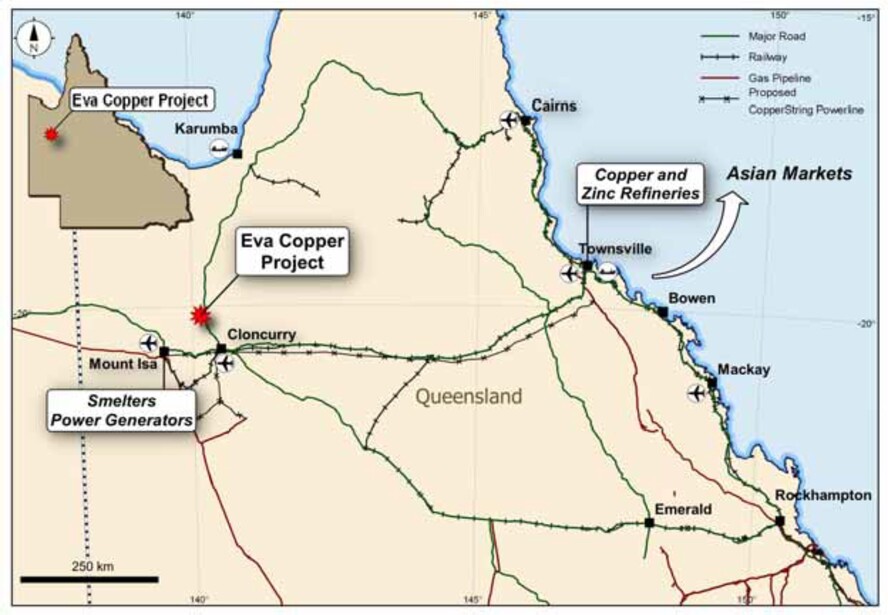

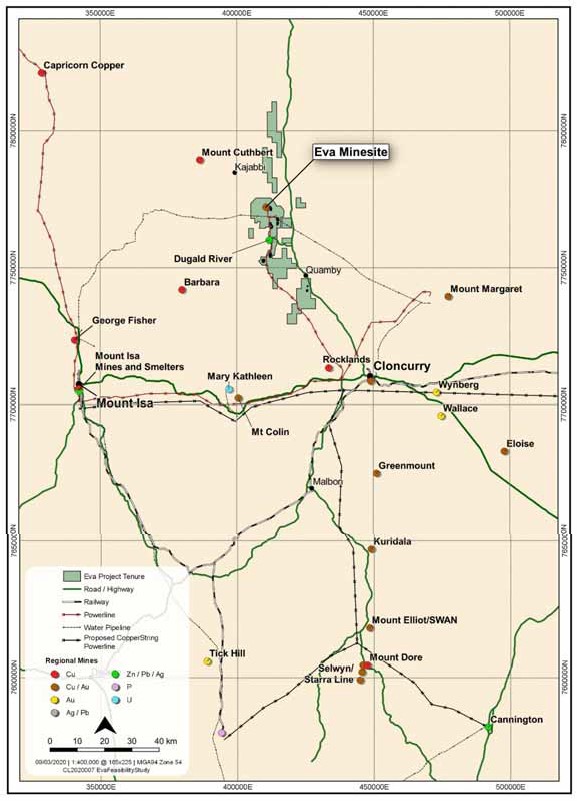

Ltd. The Project is in North West Queensland, approximately 76 kilometres (km) northwest of Cloncurry, and

194 km northeast of Mount Isa.

The Project is in the Feasibility Study stage that is testing a multiple open pit operation feeding a copper

concentrator to produce copper concentrate for sale. There are seven deposits informing the Resource and

in order of size are Little Eva, Blackard, Scanlan, Turkey Creek, Lady Clayre, Bedford, and Ivy Ann.

Existing major infrastructure closely surrounding the Project site includes the Burke Developmental Road,

located 8.5 km to the east of the Project, which connects Cloncurry with Normanton. A power transmission

line installed by MMG Limited for their Dugald River mine, located 11 km south of the Project. A water

pipeline that runs from Lake Julius to the Ernest Henry Mine traverses the southern portion of the Project

site. A residential area, known as the Mount Roseby Homestead, is located approximately 17.5 km to the

south of the Project plant site. Current infrastructure located on the Project site itself is minor, and includes

dirt tracks for exploration, water points, and fences.

Key Facts

Units of measurement used in this TRS conform to the metric system. All currency is United States dollars

(US$) unless otherwise noted.

Table 1-1: Eva Copper Project Summary

Contained Metal | |||||

Mineral Resources | Tonnes (Mt) | Copper Grade (%) | Gold Grade (g/t) | Copper (Mlb) | Gold (Moz) |

Total Mineral Resources – Measured and Indicated | 391.7 | 0.40 | 0.03 | 3,112 | 420 |

– Inferred | 83.2 | 0.39 | 0.03 | 653 | 77 |

Total Mineral Reserves – Proven and Probable | — | — | — | — | — |

Notes

1. Mineral Resources are reported in accordance with the SAMREC Code, 2016 and have an effective date of 30 June 2025. For the

purposes of this TRS, the Mineral Resources have been classified in accordance with § 229.1302(d)(1)(iii)(A) (Item 1302(d)(1)(iii)(A) of

Regulation S-K). The Qualified Person is responsible for the estimate and has relied on data provided by Mr R Reid, Group Resource

Geologist, and employee of Harmony Australasia Services Pty Ltd.

2. Mineral Resources are reported on a 100% basis. Harmony holds a 100% interest.

5. Mineral Resources are reported exclusive of Mineral Reserves. Mineral Resources that are not Mineral Reserves do not have

demonstrated economic viability.

6. Mineral Resources at the Project are reported assuming bulk open pit mining with metallurgical recovery for copper and gold by

sulphide flotation. Mineral Resources are reported above a variable copper grade cut-off based on the results of a profit algorithm NSR

calculation that equates to a marginal ore cut-off grade. The profit algorithm takes account of metal price, grade, ore processing route,

recoveries of 95% (Cu Sulphide), 56% (Cu Native Copper) and 78% (Au) and costs. Metal price assumptions are USD1,941/oz gold,

USD5.10/Lb copper and a 0.68 USD/AusD exchange rate. Adjustments to these figures will potentially impact upon the economic cut-

off grade.

7. Tonnages are metric tonnes. Copper pounds, and Gold and silver ounces are estimates of metal contained in tonnages and do not

include allowances for processing losses.

8. Rounding as required by reporting guidelines may result in apparent differences between tonnes, grade and contained metal content.

Rounding is to three significant figures.

Effective date: 30 June 2025

2

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

Project Overview

Eva Copper Mine Pty Ltd is a wholly owned subsidiary of Harmony Gold Company Mining Limited which owns

100% of the Project. Harmony acquired the Project from Copper Mountain Mining Pty. Ltd. ("CMMC") in

December 2022.

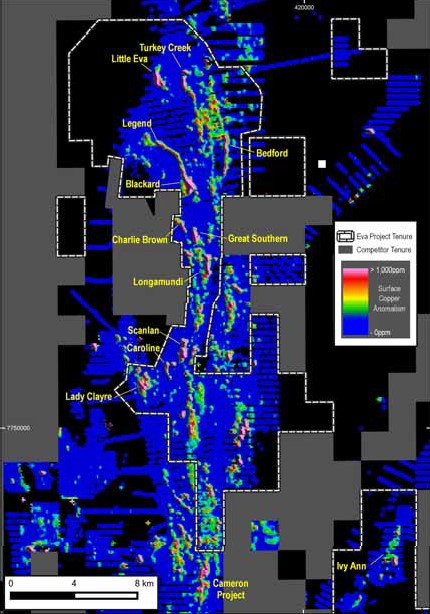

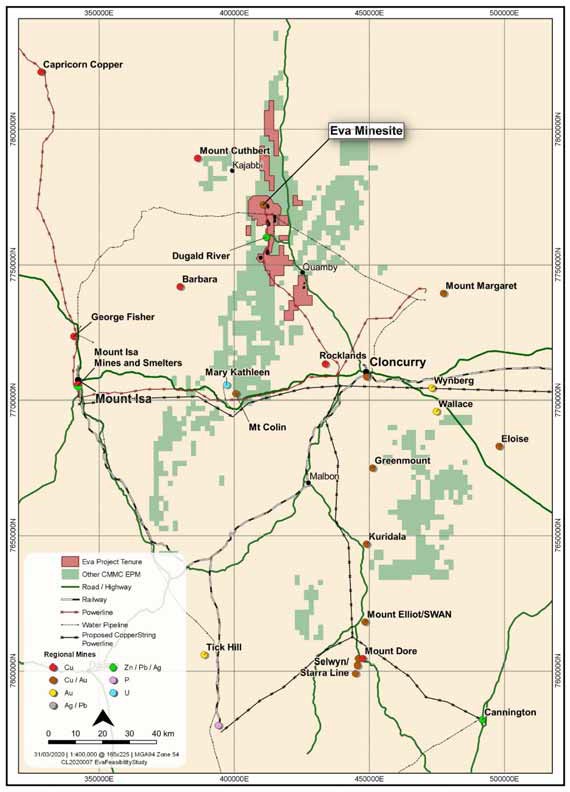

Eva Copper is located approximately 76 km northwest of Cloncurry in North West Queensland, Australia, and

has extensive exploration potential in the approximately 4,000 km2 (379,000 hectare [ha]) mineralised land

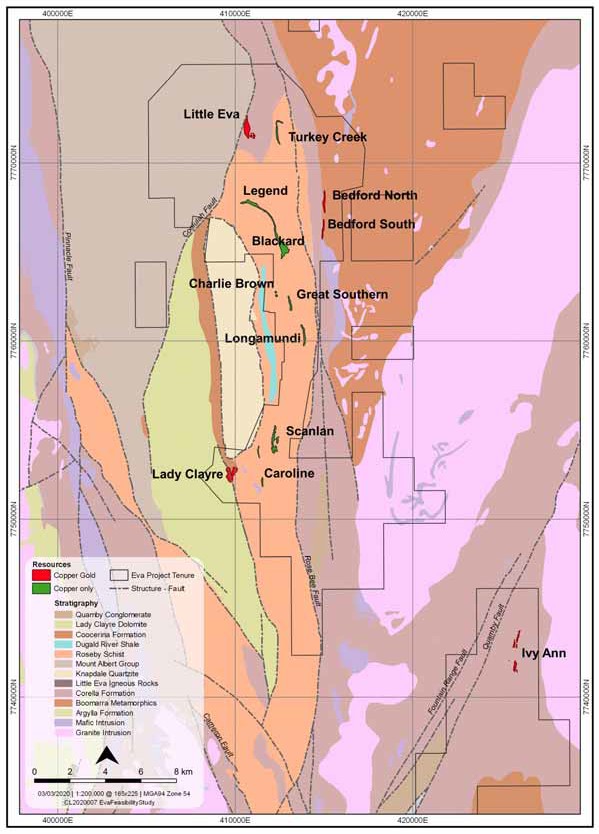

package (Figure 1-1).

CMMC reported a technically and financially viable operation through its 2020 Feasibility Study Update in

which it declared Reserves. This operation consisted of seven (7) deposits with ore processed through a

copper concentrator to produce a copper concentrate for sale. During its due diligence phase, Harmony

identified a number of risks and opportunities it wished to test in an update of the study. These studies are

ongoing and not yet complete. Harmony is not in position to declare Reserves at this point in time.

Figure 1-1: Eva Copper Project Location, Tenure, and Regional Infrastructure

Ownership

The Eva Copper Project is owned by Harmony Eva Services Pty Ltd, a 100% owned subsidiary of Harmony.

Reliance on Other Experts

The QPs’ opinions contained herein are based on public and private information provided by Harmony and

others throughout the course of the study. The authors have carried out due diligence reviews of the

information provided to them by Harmony and others for preparation of this TRS. The authors are satisfied

that the information was accurate at the time of writing, and that the interpretations and opinions expressed

are reasonable and are based on a current understanding of the mining and processing techniques and costs,

economics, mineralisation processes, and the host geological setting. The authors have made reasonable

efforts to verify the accuracy of the data relied on for this TRS.

Effective date: 30 June 2025

3

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

Property Description and Location

The Eva Copper Project is located 76 km northwest by road from Cloncurry, and 194 km northeast by road

from Mount Isa, a regional mining centre (Figure 1-1). Access to the Project is via the sealed Burke

Developmental Road from Cloncurry. This road passes 8.5 km to the east of the proposed processing plant

site and the Little Eva and Turkey Creek pits. The site is also 11 km north of the major operating Dugald River

zinc mine.

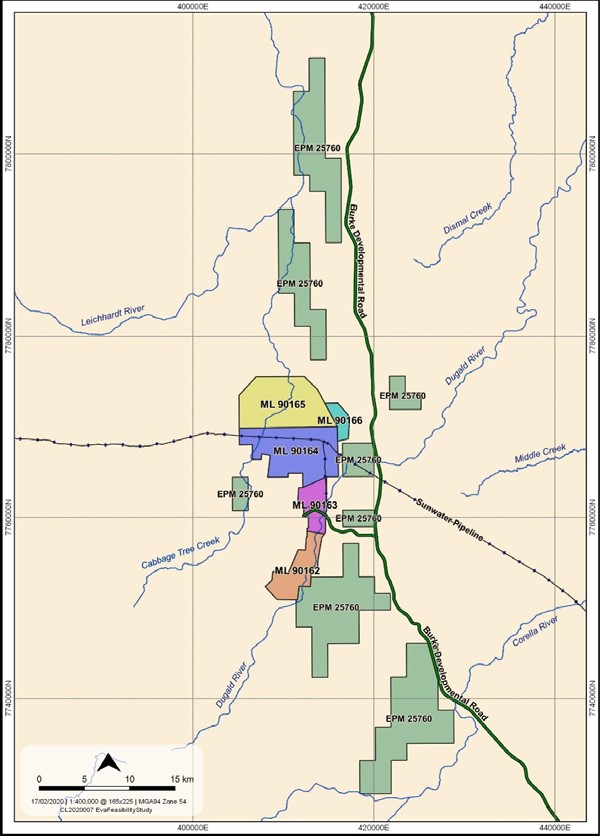

The Mineral Resources are within five granted Mining Leases ("ML"), except for the Ivy Ann pit, which is

within the Exploration Permit for Minerals ("EPM") 25760 (King). The MLs total an area of 143 km2 and are

situated across from two pastoral lease holdings and within one Native Title grant. There are two freehold

lots granted in the late 1800s, and 100% owned by the Company, that lie within the MLs; the first sits over

part of the Little Eva deposit, the second over part of the Longamundi deposit.

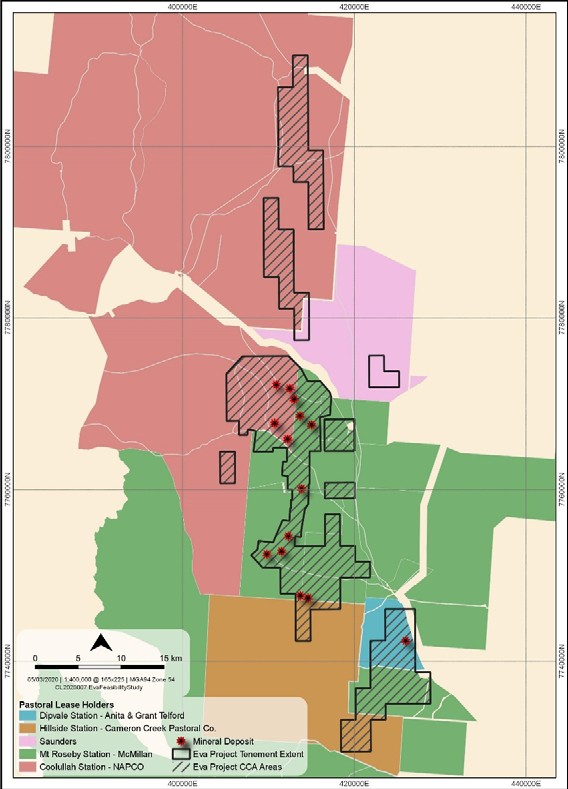

Necessary agreements are secured with the pastoral leaseholders and Native Title party (Kalkadoon People)

that set out conduct and compensation terms for the future mining activities to proceed.

Numerous royalties apply to the Project. Royalties on minerals are payable annually to the Queensland State

Government on an ad valorem basis, with various costs being permitted as a deduction from sales revenue.

Copper and gold royalty rates vary between 2.5% and 5.0% of value, depending on average metal prices, as

per Schedule 3 of the Mineral Resources Regulation of 2003. No state royalty on copper is applicable to the

two freehold lots owned by the Company. Several royalties also apply to the Project from purchase

agreements and are payable to several parties variably across portions of the Project area. These apply to all

of the deposits in the Project mine plan: a total 1.5% net smelter return ("NSR") royalty is applicable to the

Little Eva, Blackard, Scanlan, Turkey Creek, Bedford, and Lady Clayre deposits, and a 2% NSR royalty is

applicable to the Ivy Ann deposit. Compensation for the effects of mining activities on the Native Title of the

Kalkadoon People has been agreed upon.

Accessibility, Climate, Local Resources, Infrastructure, and Physiography

Current site access is by way of a new access road from a sealed road that passes 8.5 km to the east of the

proposed plant site. The site is also 11 km north of the major operating Dugald River zinc mine, owned by

MMG.

The town of Cloncurry is located on the railway line from Townsville to Mount Isa, and has container handling

facilities, an airport that hosts both commercial and fly-in/fly-out ("FIFO") jet aircraft services, and a regional

fuel depot. It also has schools, hospitals, and other services. The Project lies within the Shire of Cloncurry,

which is the local government administrative area. The Shire offices are also based in Cloncurry.

Grid power is generated in Mount Isa at two gas-fired power stations and is transmitted from Mount Isa to

Cloncurry. A 220 kV power line has been constructed from the Chumvale substation near Cloncurry to the

Dugald River mine.

The Cloncurry region is semi-arid, with a distinct hot, wet season from November to March, which is typical

of inland northern Australia. Average monthly temperatures range from 10.6°C to 38.5°C, with extremes

recorded from 1.8°C to 46.9°C. Rainfall in the wet season largely occurs as storms. Rainfall is highly variable

from year to year, with the region often experiencing both multi-year droughts and large-scale flooding from

major rainfall events.

The Project site is serviced by a complex system of surface drainages that flow generally northward. On the

western side of the processing plant and Little Eva pit is Cabbage Tree Creek, which is joined by other creeks

flowing northward to become a tributary of the Leichhardt River. Creeks and rivers flow only during, and for a

brief period following, the wet season.

The Project has groundwater sources from both hard rock fracture zone systems and from a graben-like

structure infilled with Phanerozoic sediments and alluvial deposits within a paleodrainage adjacent to the

current course of Cabbage Tree Creek.

Effective date: 30 June 2025

4

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

The mine site and broader operation area is gently undulating flat topography, with the predominant land

use being low-intensity cattle grazing, although exploration and mining activities have been conducted over

the area since the late 1800s. The site is currently crossed by several gravel roads from pastoral and

exploration activities. Additionally, SunWater Limited’s water pipeline from Lake Julius to the Ernest Henry

mine crosses the lease area from west to east.

History

The Project has a long history, and has been held under various tenures by a variety of exploration and

mining companies. Small-scale mining dating back to the early 1900s has occurred at deposits such as Little

Eva, Bedford, and Lady Clayre. Early explorers that contributed significantly to the Project with the discovery

of the copper-only or native copper deposits are Ausminda Pty. Ltd., and then CRA Exploration ("CRAE"), who

completed the first substantive work between 1990 and 1996, also defining a small resource at Little Eva.

CRAE sold its interest in the Project to Pasminco Limited ("Pasminco") in 1998. Universal Resources Limited

("URL") acquired the Project in 2001. URL also purchased the tenement hosting the Ivy Ann deposit from

Dominion Metals Pty. Ltd. ("Dominion") and Pan Australian Resources NL ("PanAust").

The remaining property was acquired by purchasing tenure from both Pasminco and Lake Gold Pty. Ltd. in a

50:50 ownership split between URL and Roseby Copper Pty. Ltd. ("RCPL"). In 2004, URL purchased RCPL, and

thus URL held 100% of the Eva Copper Project resources. Until 2009, work focused extensively on the copper-

only resources, with completion of two feasibility studies based on blends of sulphide ore and copper-only

ore. In 2010 URL merged with Vulcan Resources to become Altona Mining Limited ("Altona"), Altona took

over ownership of the Eva Copper Project. From 2010 to 2012, Altona carried out additional drilling, resulting

in Mineral Resource upgrades at the Little Eva, Bedford, Lady Clayre, Ivy Ann, Blackard, Legend, and Scanlan

deposits. Little Eva’s resource estimate was doubled based on the additional drilling.

In 2012, Altona completed a Feasibility Study based on the increased resources at the copper-gold sulphide

deposits, and excluding the Blackard and Scanlan deposits. Altona published Mineral Reserves for the Little

Eva, Bedford, Lady Clayre, and Ivy Ann deposits as part of the 2012 Feasibility Study. Altona published

updates to the Feasibility Study in 2014 and 2017. The 2017 update incorporated the subsequently

delineated significant Mineral Resource at Turkey Creek.

MLs and an EA were granted in 2012 based on the 2009 Feasibility Study mine plan. Following EA

amendments, the Project is currently authorised by EA EMPL00899613, granted 23 October 2024.

Altona completed a DFS update in 2017, incorporating the Turkey Creek deposit in the mine plan and

significant layout changes that included changes to the size and location of the TSF and a Cabbage Tree Creek

diversion channel at Little Eva pit. To support the previous studies, the Little Eva, Bedford, Lady Clayre, and

Ivy Ann deposits have had a number of formal Mineral Resource estimates that reflect stages of resource

definition dating from 2006 to 2017. The Mineral Resource estimate for Turkey Creek was completed in 2015.

Estimates were largely undertaken by external independent experts, initially by McDonald Speijers, and most

recently Optiro, based on data and geological models provided by the CMMC.

In December 2022 Harmony purchased the project from CMMC. In February 2023 Harmony commenced a

confirmatory and expansion drilling programme and other studies designed to progress the project to a

decision to mine.

Geological Setting and Mineralisation

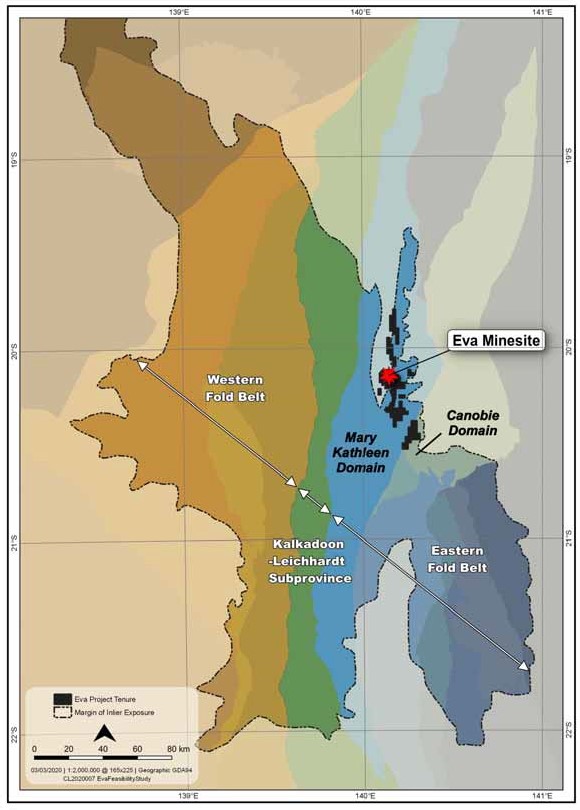

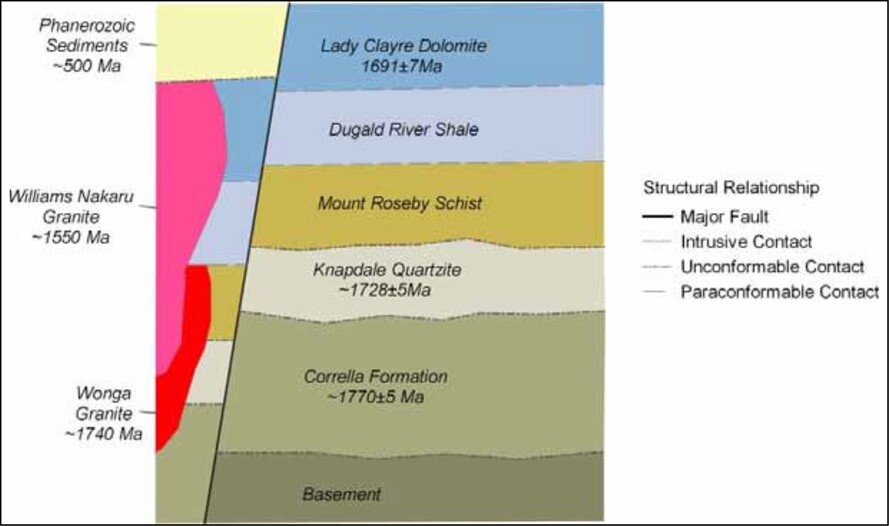

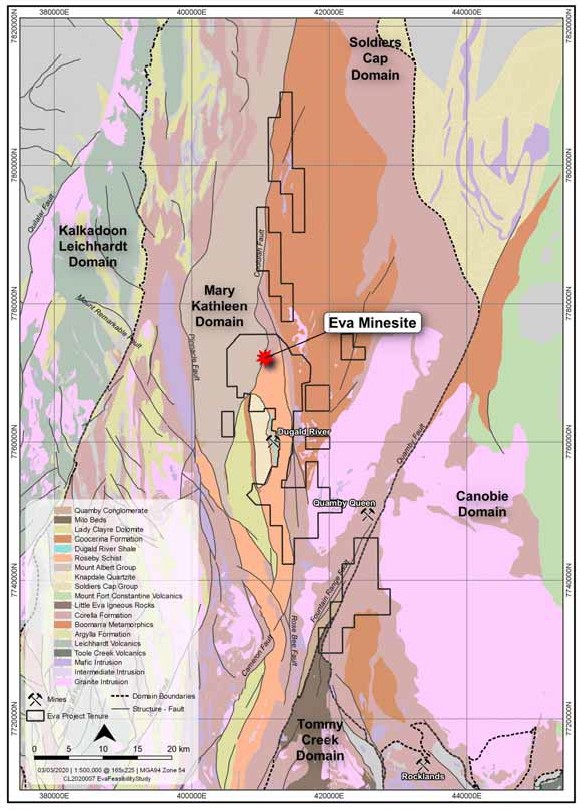

The Project area is situated within the Mount Isa and North West Region of Queensland, Australia, an area

that is one of the premier base metal-bearing areas of Australia, with mining activities having taken place

since the discovery of copper and gold near Cloncurry in the 1860s. The Mount Isa area hosts numerous base

metal copper, zinc, and lead deposits of global significance, including the Mount Isa, Ernest Henry, Century,

Dugald River, Cannington, and Selwyn deposits. The Eva Copper Project is hosted by Proterozoic-aged,

metamorphosed and poly-deformed marine sedimentary and volcanic rocks of the Mary Kathleen domain of

the Eastern Fold Belt Inlier. Deformation, metamorphism, and plutonic activity took place during the Isan

Orogeny, approximately 1,600 to 1,500 million years (Ma) ago.

There are twelve known mineral deposits in the Project area, of which six have been included in the current

mine plan. Mineral deposits are grouped into two types: copper-gold, and copper only. There are five of the

copper-gold deposits, four of which are in the mine plan. These deposits are classified as iron oxide copper-

gold ("IOCG") deposits, where mineralisation is associated with regional-scale hematite and albite alteration

Effective date: 30 June 2025

5

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

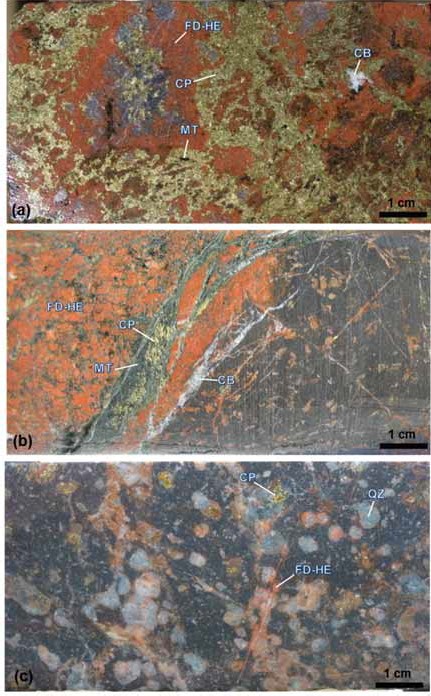

(red-rock alteration), and localised magnetite alteration. Copper sulphide mineralisation, primarily

chalcopyrite with lesser bornite, occurs as veins, breccias, fracture fill, and disseminations in mafic to

intermediate volcanic or intrusive rocks. Gold is generally correlated with copper and is recovered in the

copper concentrate. Mineralisation appears to be localised and/or bounded by faults and other deformation-

related structures. The copper-only deposits are stratabound, locally stratiform, and most occur within

metamorphosed calcareous metasedimentary rocks, forming an approximately linear trend stretching over 7

km. The origin of these deposits is uncertain; they may be deformed and metamorphosed versions of

sedimentary or red-bed type copper deposits, or they could be more closely related to the IOCG deposits, but

with enhanced stratigraphic controls related to the calcareous beds being particularly reactive with

hydrothermal fluids.

All of the deposits have a 10 m to 25 m thick overlying zone of oxidation, where the rock is extensively

weathered, and copper sulphide minerals have been leached or converted to various oxide minerals that

cannot be recovered by flotation. The oxide zones are treated as waste, but tonnages and copper grades

have been estimated and the oxide mineralisation will be stockpiled separately. With the exception of the

Turkey Creek deposit, the copper-only deposits commonly have a significant thickness of supergene material,

where carbonate has been leached from the rock, reducing hardness and density, and the copper occurs as

native-copper, chalcocite, and other low-sulphur copper species. The carbonate-leached zone is separated

from the underlying sulphide zone by a thin transition zone. Each of these mineralogical zones has been

modelled so that resources can be estimated for each and the appropriate metallurgical recoveries can be

applied for reserve estimation.

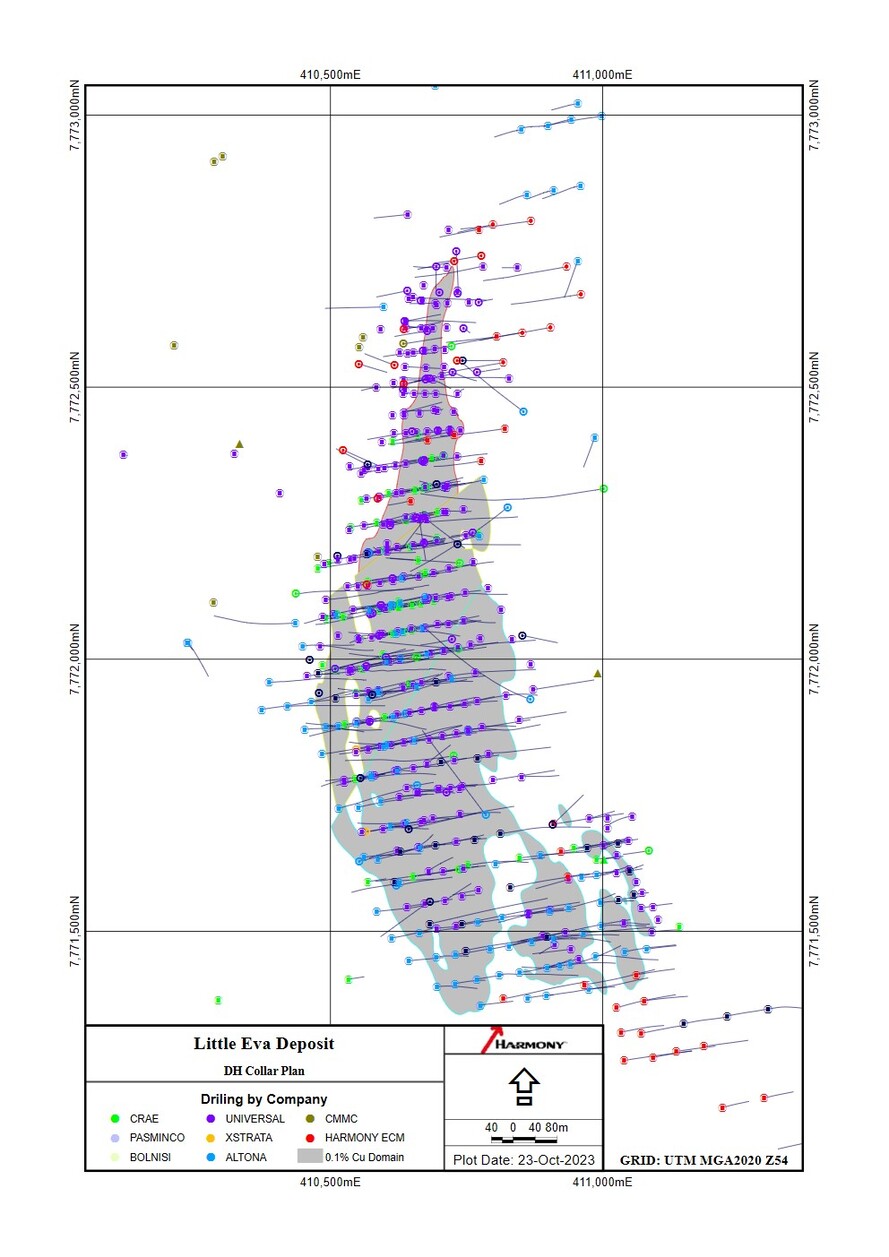

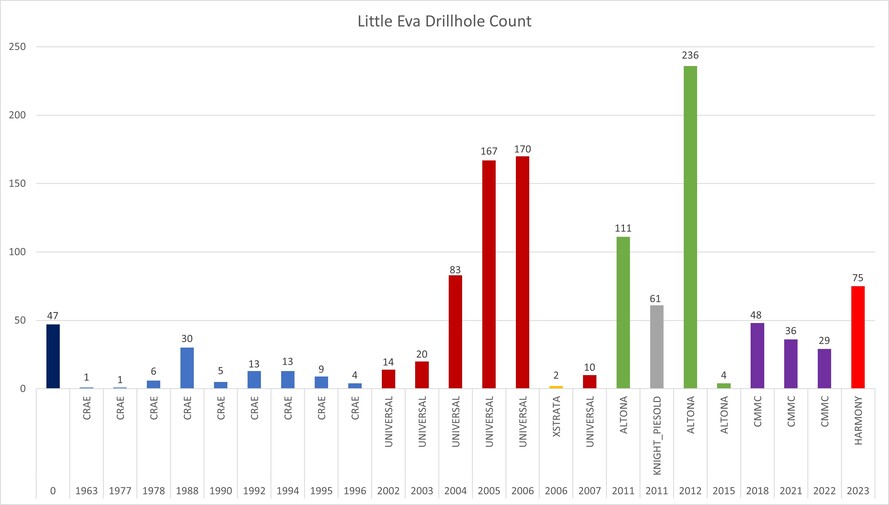

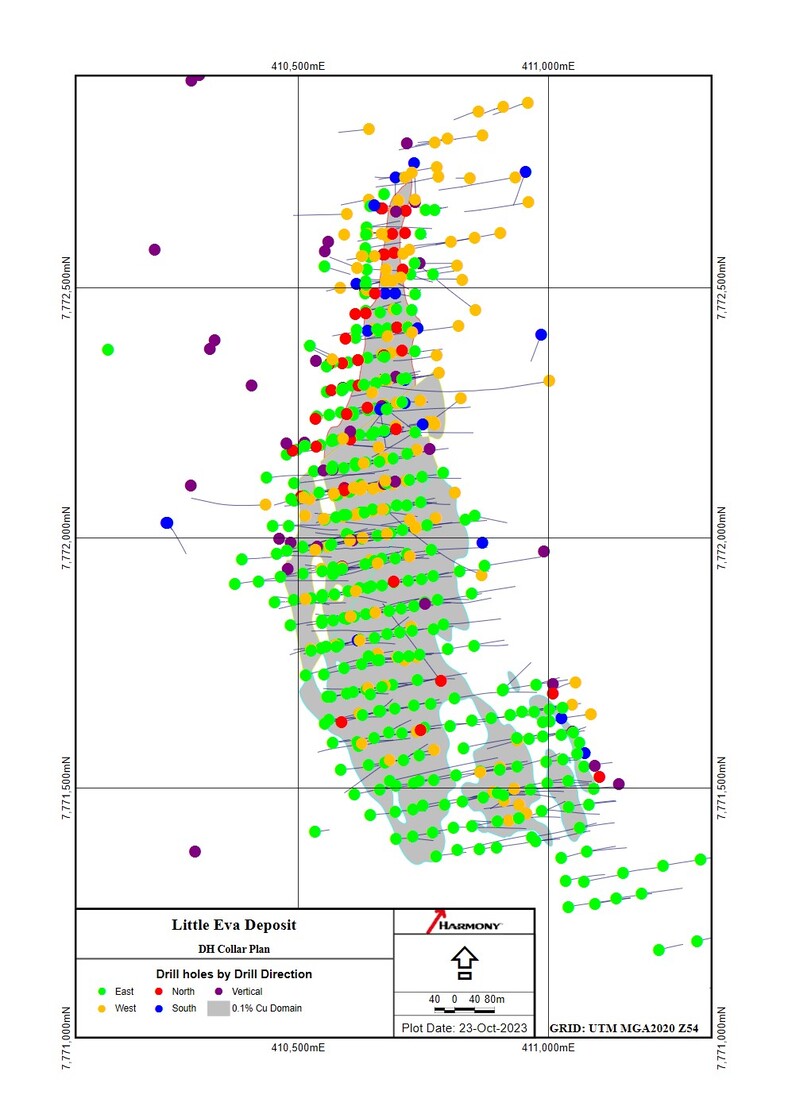

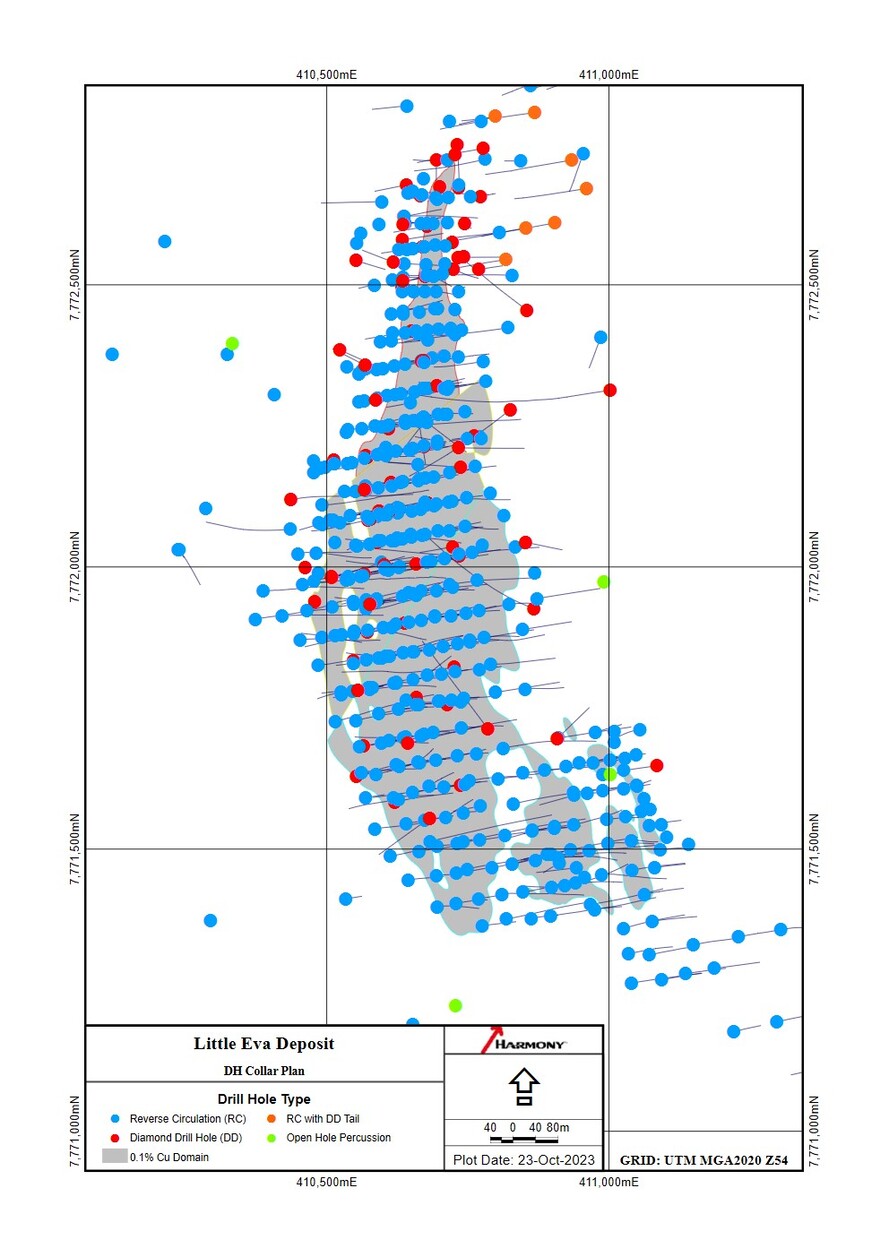

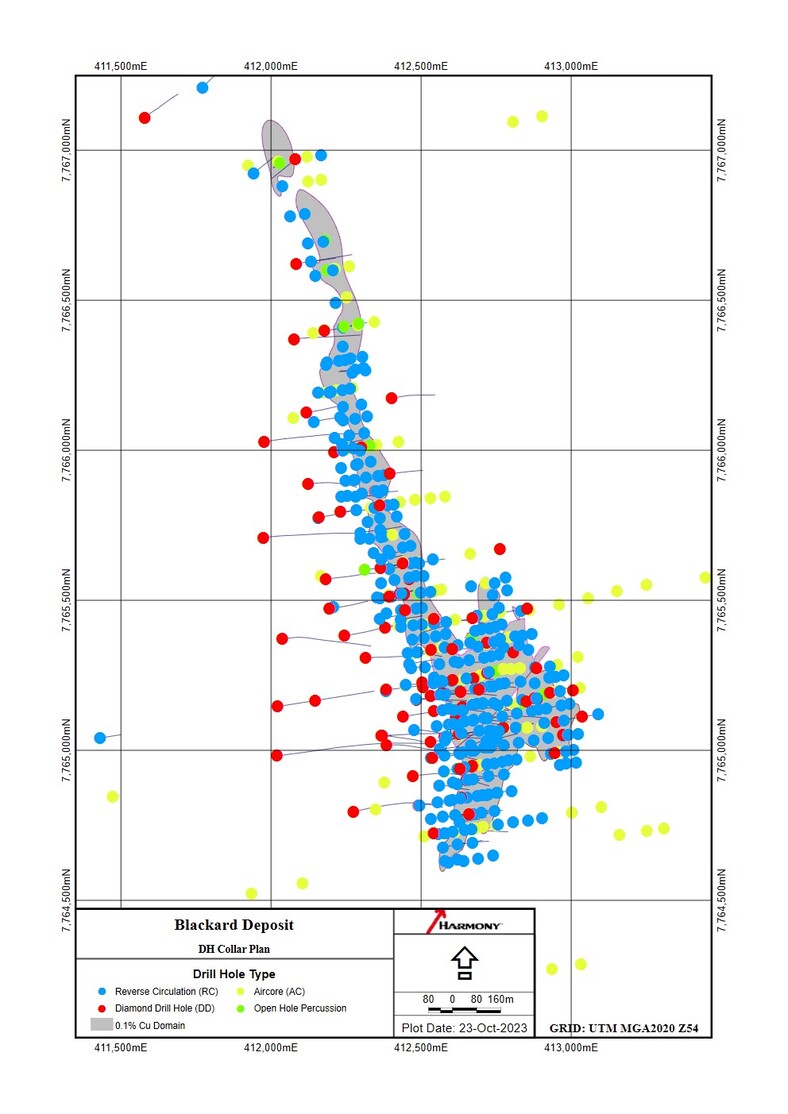

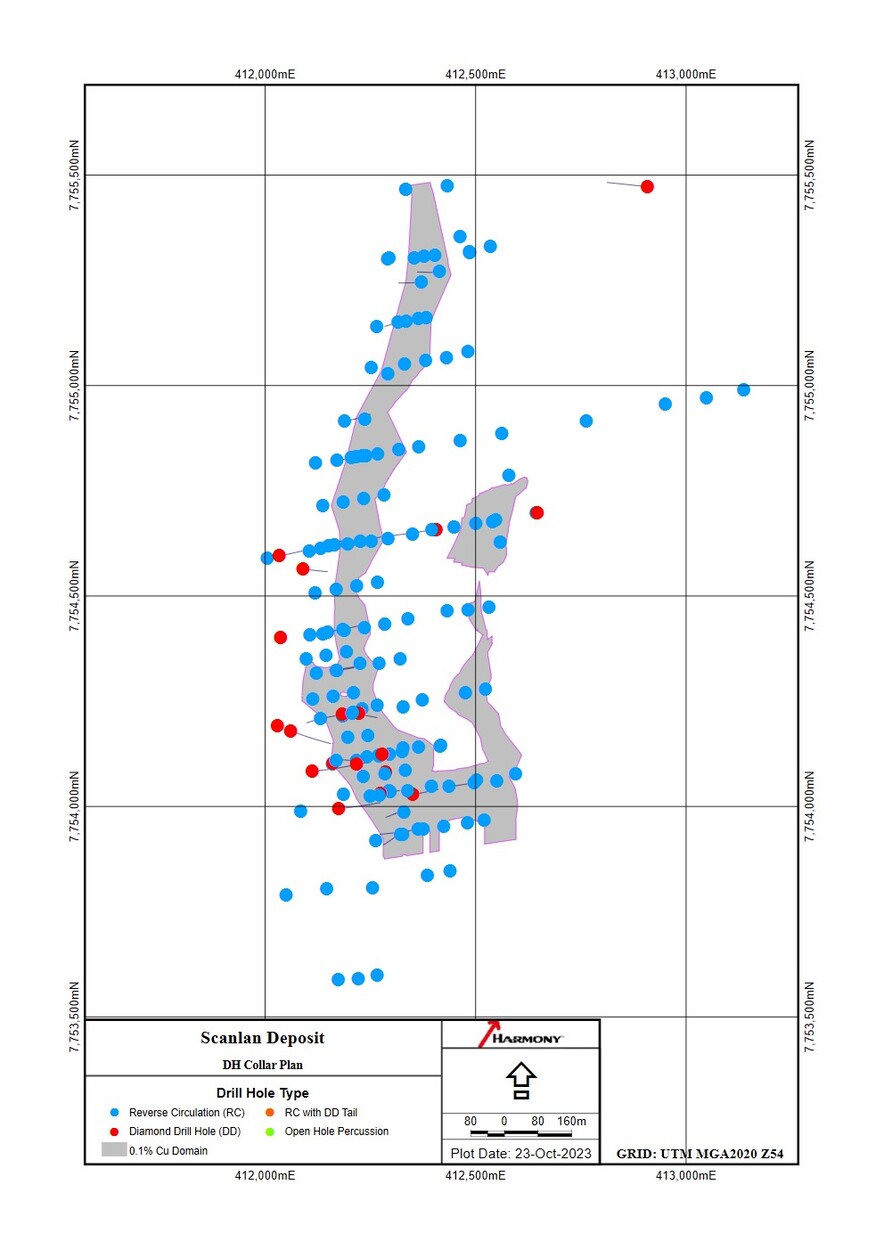

Drilling

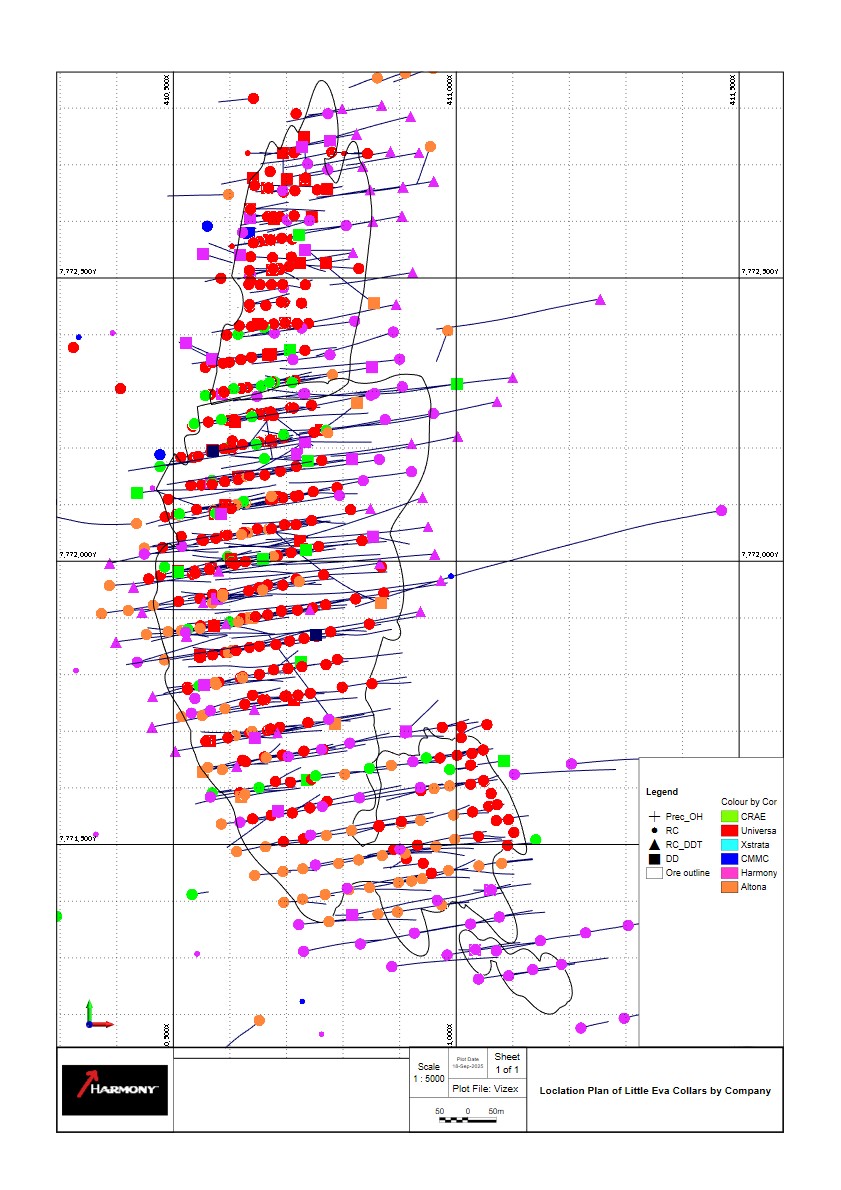

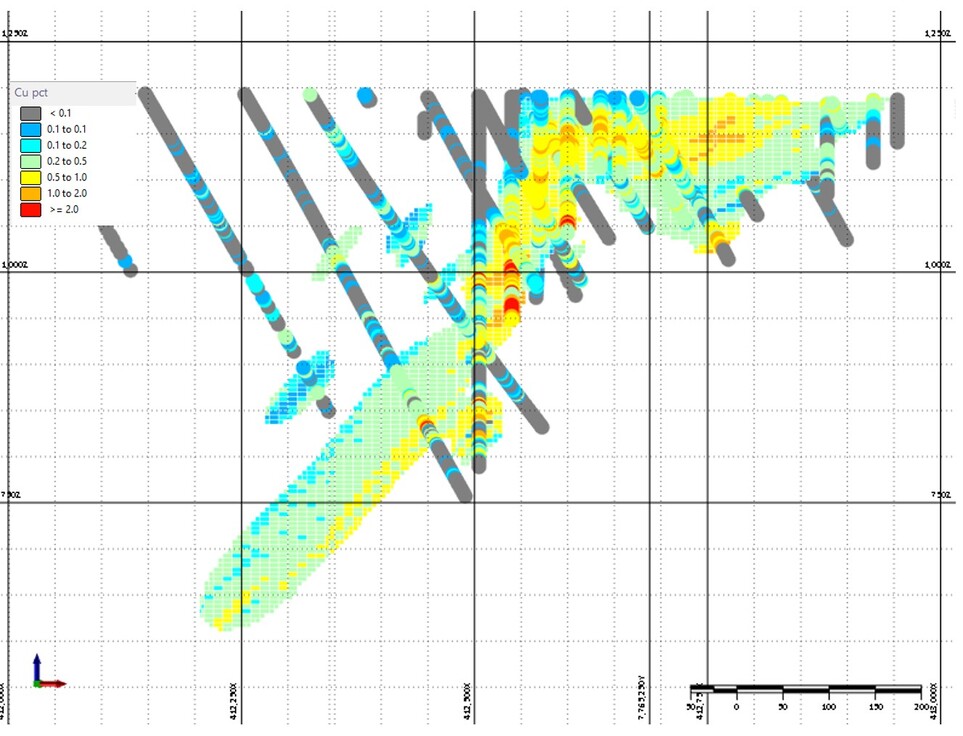

Although exploration work has been recorded within the Eva Copper Project area since 1963, usable drill

data dates back to 1988. Total drilling in the seven deposits with planned production includes 1,470 drill

holes for 208,637 m. All the drill holes used for Mineral Resource estimation have accurate collar and

downhole surveys, including the older holes, which were subsequently resurveyed by later exploration

companies (URL, or more recently, Altona). Most of the drilling was done by reverse circulation ("RC")

methods, with a small percentage being diamond drill holes ("DD").

Statistical analysis of the type of drilling, age, and operating company does not indicate any bias to the drill

hole assay data. Assay data from two DDs completed by Sichuan Railway Investment Group (SRIG) in 2017,

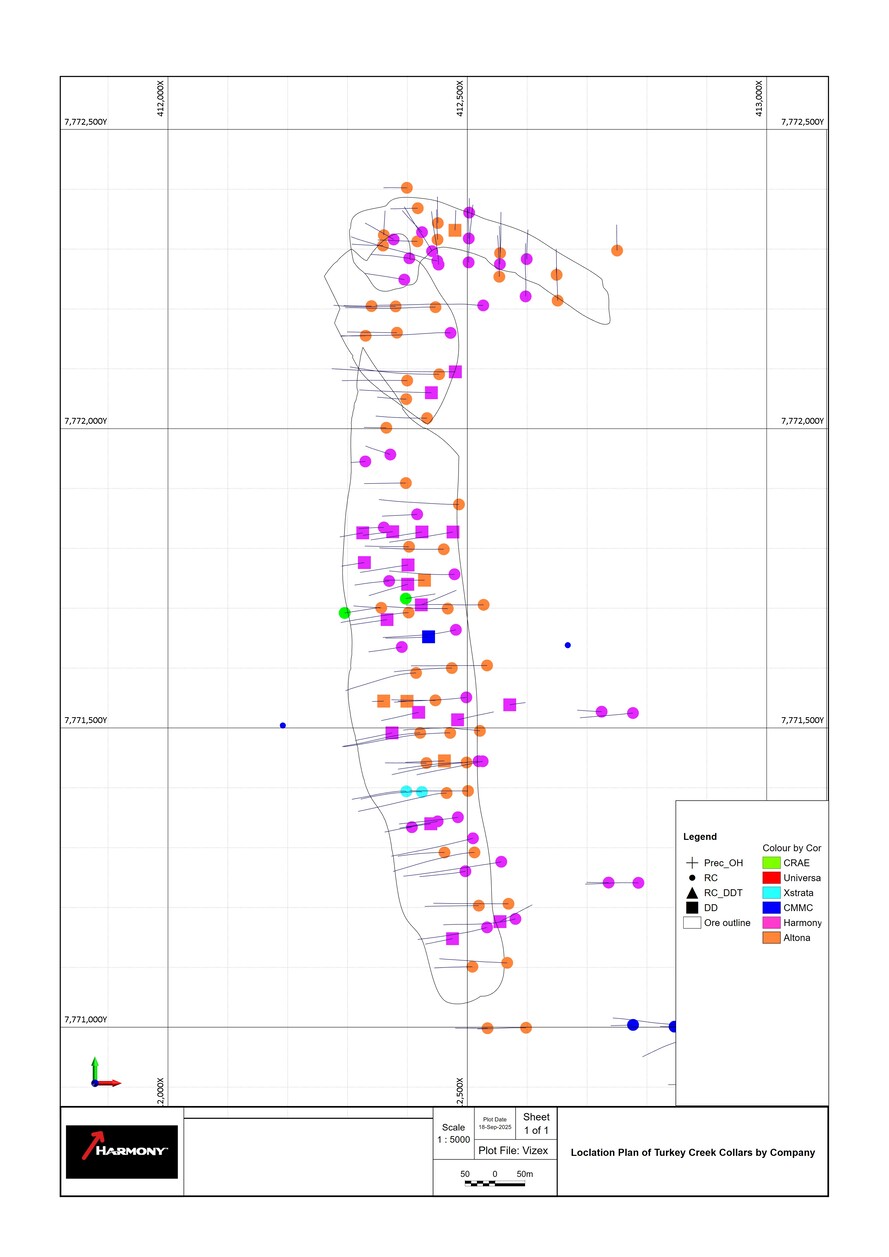

and two DD completed in 2018 by CMMC within the Little Eva deposit, provided material for metallurgical

testing and were used to verify the resource block model. Two holes were drilled in the Turkey Creek deposit

in 2018 and 2019 for grade verification and metallurgical material. Eighteen RC holes were drilled in the

Blackard deposit in 2019 by CMMC to upgrade resource classification. Assay data from the 2019 RC drilling

within the Blackard deposit is statistically indistinguishable from historical drilling. Since obtaining the

Project, Harmony has commenced an extensive infill drilling campaign designed to confirm, and extend

confidence in, the Resource and geological models. To date Harmony has drilled 724 drill holes across the

project for a total of 155,914m. These holes have informed the ongoing feasibility study (metallurgical and

geotechnical holes) and recent Resource model updates to grade estimates and classification.

Exploration

Mineral exploration on lands of the Eva Copper Project dates back more than 40 years. The exploration

database for the area contains information from numerous geological, geophysical, and geochemical surveys

carried out by the current and previous operators, in addition to regional government data on geology and

geophysics. Almost all data from historical geophysical and geochemical work is compiled in the Company

database and has been used in the design and guidance of current exploration work.

The most useful historical geophysical work includes ground and airborne magnetics and gravity surveys

which, when combined with soil geochemistry, provide good drill targeting tools. Induced polarization ("IP")

and electromagnetic ("EM") geophysical surveys have also proven to be useful or have some benefit in the

right circumstances. Continuous improvements in electronic instrumentation, computer data processing,

inversion technology for geophysics, and multi-element analysis (particularly in handheld, portable X-ray

fluorescence (XRF) units), provide significant rationale to continue geophysical and geochemical surveying on

the property.

Effective date: 30 June 2025

6

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

Deposit Types

Copper deposits of the Eva Copper Project are of two types. The most significant are those of the IOCG type,

which are hydrothermal copper-gold deposits associated with relatively high contents of iron oxide minerals

(magnetite or hematite), a general lack of quartz, and extensive sodic alteration. The hydrothermal fluids are

believed to be sourced from, and/or driven by, magmatic systems with possible addition of basin brines;

however, mineralisation is commonly distal (or spatially distinct) from the causative plutonic rocks.

Mineralisation can take many forms, but the dominant ones are vein networks, breccias, dissemination, and

replacement. Both structure (fault or fracture systems) and lithology (chemistry and rheology) are key

features in localization of mineralisation. The second type of copper deposit is termed copper-only; these

deposits do not contain significant gold and are typically hosted within deformed and metamorphosed

calcareous sedimentary rocks as stratabound mineralisation. One deposit, Turkey Creek, is a strataform

copper-only deposit within calc-silicate and schistose rocks but has processing characteristics similar to those

for the copper-gold deposits.

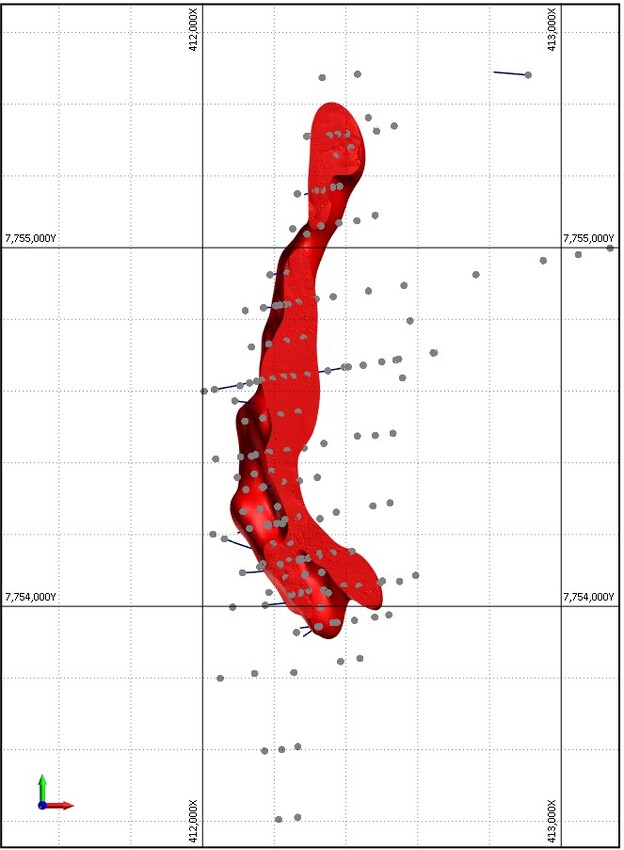

There are 12 defined deposits within the Eva Copper Project, ranging in size from 0.7 Mt to over 100 Mt, six

of which are included within the current mine plan. Three are copper-gold deposits, and three are copper-

only deposits. Metallurgical recoveries for the copper-gold deposits are favourable, due to relatively coarse-

grained chalcopyrite and lesser bornite. All of the deposits have a thin, 10 m to 40 m weathered or oxide

zone at surface, for which tonnage and grades have been estimated, but which have been treated as waste

within the mine plan. The copper-only deposits hosted within calcareous metasedimentary rocks have

additional zones of weathering and/or acid leaching, which has removed carbonate, reducing rock strength

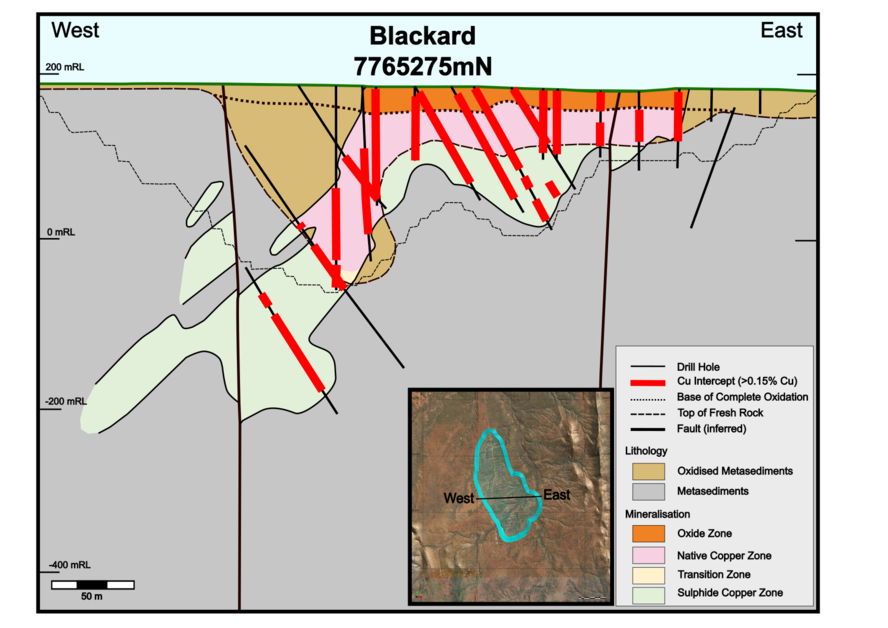

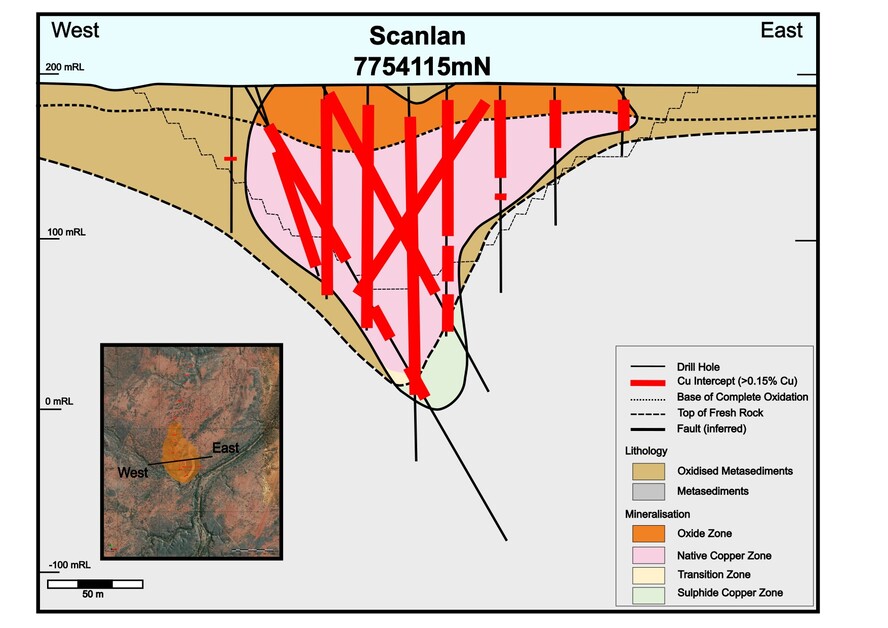

and density in addition to changing sulphide mineralogy. In the two such deposits, Blackard and Scanlan, a

supergene zone termed native copper occurs below the oxide zone, and contains abundant native copper in

addition to chalcocite, cuprite, and other low-sulphur copper species and some copper locked in

hydrobiotite. Extensive metallurgical testing has been carried out on these deposits, with appropriate

processing design and estimation of recoveries. Within these deposits a narrow transition zone occurs

between the copper zone and underlying sulphide zone.

Sample Preparation, Analyses, and Security

There is very little documentation about sample collection, preparation, and security for the pre-1997 drilling

campaigns, although the nature of the exploration programmes, preservation of data, and logging records all

indicate that the drilling programmes were carried out in a professional and competent manner. Later

exploration programmes by URL (beginning in 2002) and Altona (in 2011), which provided the vast majority

of the drill data, were carried out with above industry-standard sample collection methods, and appropriate

quality assurance and quality control (QA/QC) protocols. RC drilling accounts for more than 90% of the

Project samples, and these samples were collected using standard cyclones and splitters at the drill site.

Samples lengths were initially 2 m for URL; however, they were changed to 1 m in 2003. Almost all of Altona’s

samples were 1 m in length.

Samples were bagged and sealed in the field, and shipped to commercial laboratories in either Townsville or

Brisbane. Regular duplicate samples of RC chips were inserted into the sample stream at a rate of 1 in every

20, and triplicate samples collected at the time of drilling were inserted into the sample stream at the rate of

1 in every 40. Appropriate reference standards and blank samples were inserted at rates of 1 in every 20 and

1 in every 45, respectively. Much of the sample material has been retained, mostly as pulp samples; however,

there is some coarse reject material, and it is stored in carefully organised warehouses, which also contain

split diamond drill core. All analytical information has been carefully archived in an electronic database,

which has been reviewed for accuracy by independent consultants and Harmony.

Data Verification

Historical drill locations were checked and resurveyed by subsequent operators, and assay data has been

examined and checked by third-party consultants involved in previous Feasibility Studies. There is no

apparent bias in the assay data from drill campaigns involving four different companies. The resource QP

examined drill core on site and found adequate agreement between geology and historical logs, and visual

estimates of copper grade were in agreement with assays. Assay results from drill holes completed to obtain

metallurgical samples in the Little Eva and Turkey Creek deposits in 2018, and in the Blackard deposit in 2019

and additional drilling completed by Harmony during 2023-2025, compare favourably to adjacent block

grades within the block models, supporting both the database and Mineral Resource estimation.

Effective date: 30 June 2025

7

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

Metallurgical Testwork and Process Design

This section summarises both historical and recent test work associated with the various mineralisation types

on the Project property. This report generalises the various ore sources into one of two classes for design

purposes: sulphides, and native copper. The various ore sources were studied from the perspective of newer

technologies including direct flotation reactors for flotation.

The Little Eva deposit is the largest deposit in the Project. This deposit has been well studied, with 145

flotation tests from multiple sources that ranged in scope from benchtop to pilot plant. This mineralisation

consistently demonstrates high recovery performance with a high degree of liberation at relatively coarse

grinds. The average feed competency lies near the 50th percentile of the JK database, with medium to hard

Bond work indices. Copper is present as chalcopyrite with trace amounts of pyrite. Strong flotation kinetics

result in high recoveries, concentrating to a good final concentrate grade following a nominal regrind with no

pH modification. Overall, this material type presents low technical risk.

The sulphide satellite deposits, comprising Turkey Creek, Bedford, Lady Clayre, and Ivy Ann, are smaller

sources. These mineralisation types are generally similar to Little Eva from both a comminution and flotation

perspective. Some differences include a stronger deportment of copper to bornite, and varying grade

distribution. Overall, these deposits show average copper recoveries of 88% to 95%, and represent sources of

high recovery material. The specific recoveries for each pit are used as inputs into the mine schedule and

financial model.

The copper-only deposits, Blackard and Scanlan, are distinctly different from other deposits in the area,

containing oxide cap, native copper, sulphide transition, and sulphide zones. The native copper zones are the

largest copper-bearing zones within these deposits, containing a relatively fine distribution of native copper

with varying quantities of sulphides. These deposits were studied by previous owners; however, several

recent updates have been completed. In total, 410 flotation tests (including blended ore feed) have been

completed, ranging from benchtop to pilot scale work. On a flotation basis, the native copper zones typically

achieve 60% recovery, with an additional 2% to 3% achievable by gravity methods. Recovery is highly variable

as deportment shifts from native copper to sulphides, requiring flexibility within any processing flowsheet

between gravity and flotation operations to achieve an average of 56% overall recovery. This ore is typically

very soft, resulting in low comminution costs and high mill throughputs. Below the native copper- bearing

zones of both Blackard and Scanlan are sulphide zones containing bornite and chalcopyrite, behaving

similarly to Turkey Creek ore. The flotation response of the ore from the native copper to the sulphide

transition zone increases with sulphide content, as expected.

In total, the abovementioned work has been sourced from 25 metallurgical testing campaigns completed at

established metallurgical labs throughout Australia and British Columbia, Canada, from 1996 to 2019.

Concentrate Characterization

Detailed chemical analyses were performed on the concentrates produced from the testwork programmes,

and the results indicate that there appear to be no impurity elements present in the concentrate at a level

that will incur smelter penalties. Provision for separate dewatering and containment of gravity concentrates

is included in the plant design for future sampling or marketing opportunities.

Tailings Handling

Tailings generated from the bulk samples processed during the DFR testwork were sent to Paterson & Cooke

in Denver, Colorado, for tailings characterisation. The samples were examined both separately and as a

blend. In both cases no concerns were highlighted with tailings settling performance. A reasonable target of

63% solids was selected for tailings thickener underflow design.

Mineral Resources Estimate

Eva Copper Project Resources

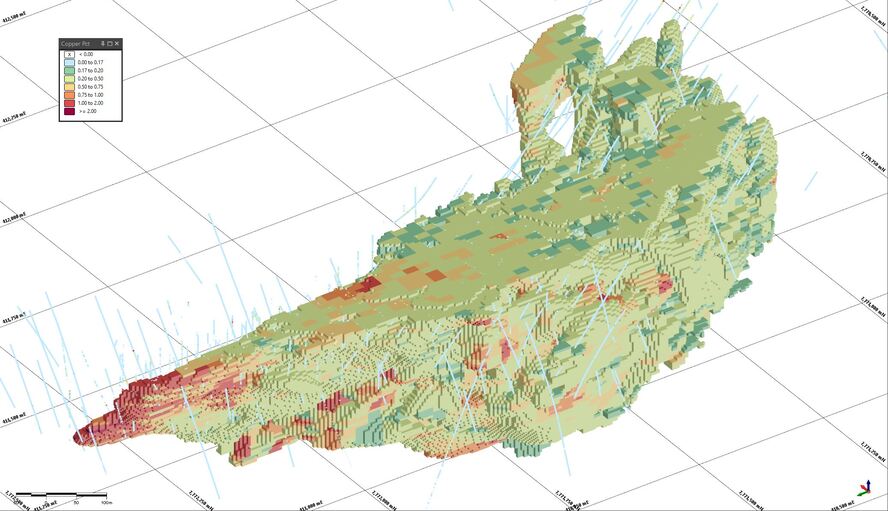

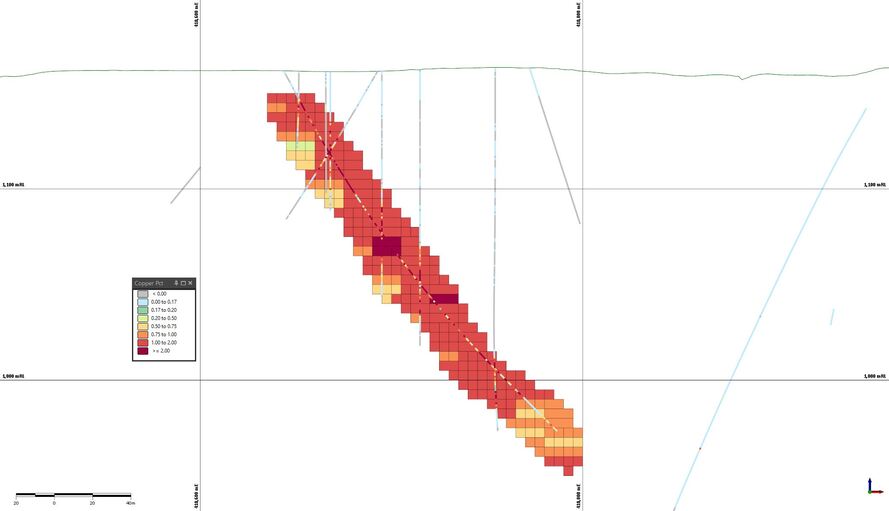

Mineral Resource estimates for the three largest deposits (being Little Eva, Blackard and Turkey Creek) were

prepared by SRK and Harmony personnel, based on all drilling conducted up to January 2024. The Resource

models from CMMC have been audited and retained for the other deposits.The effective date of the resource

estimates is 30 June 2025.

Effective date: 30 June 2025

8

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

The Mineral Resource for mineralisation, assumed to be amenable to open pit and underground mining

methods, is reported in situ.

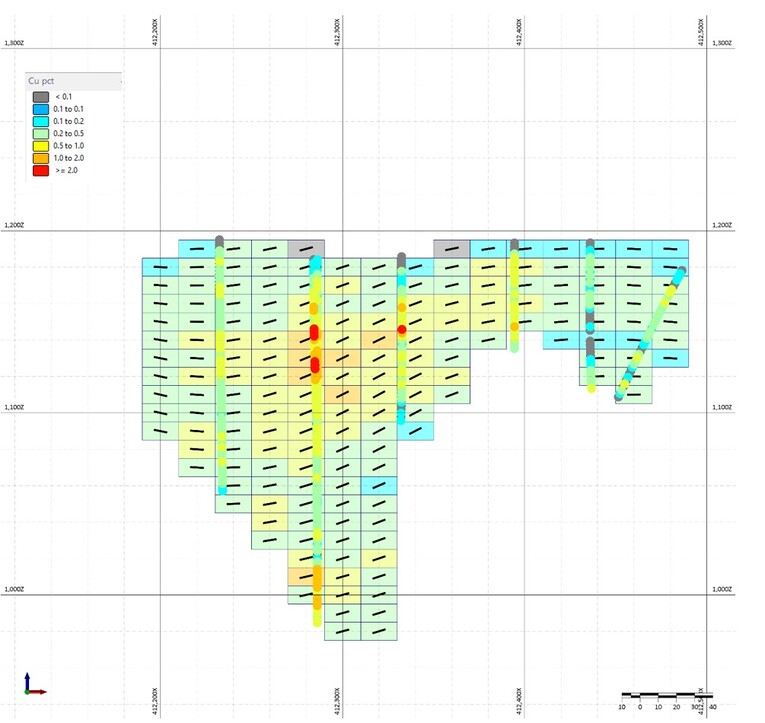

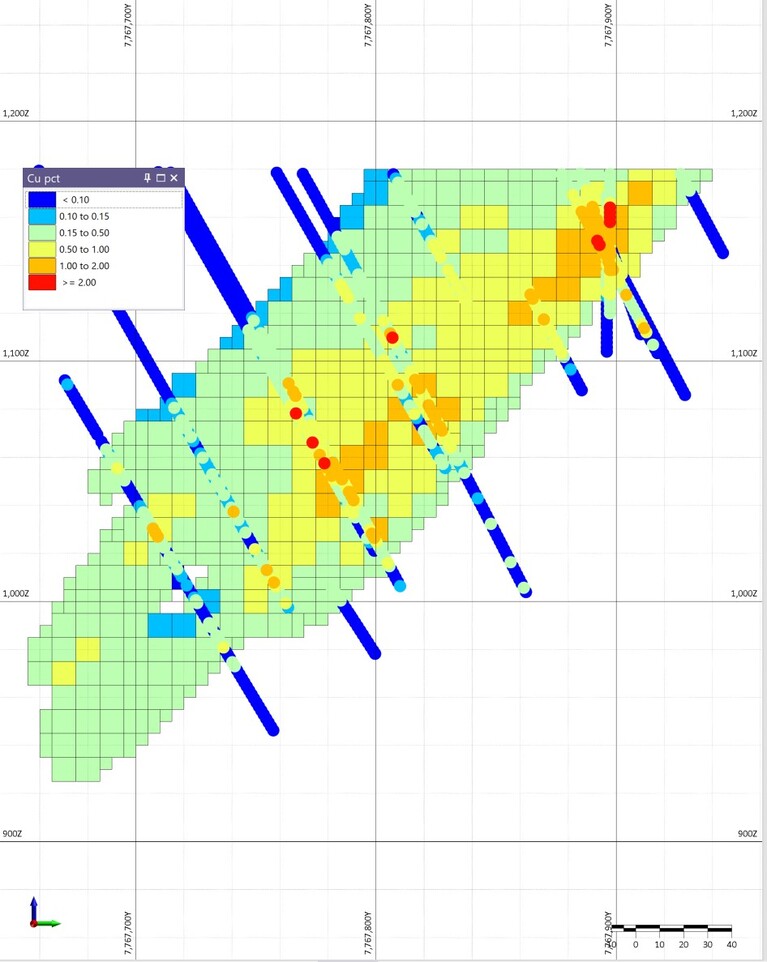

The resource estimates were built using Ordinary Kriging for Little Eva, Blackard and Turkey Creek, all other

deposits utilised Inverse distance weighting. Block sizes were selected based on the drillhole spacing to

ensure the estimate is fully informed, Block sizes were matched to the anticipated mining methods and

mining equipment sizes.

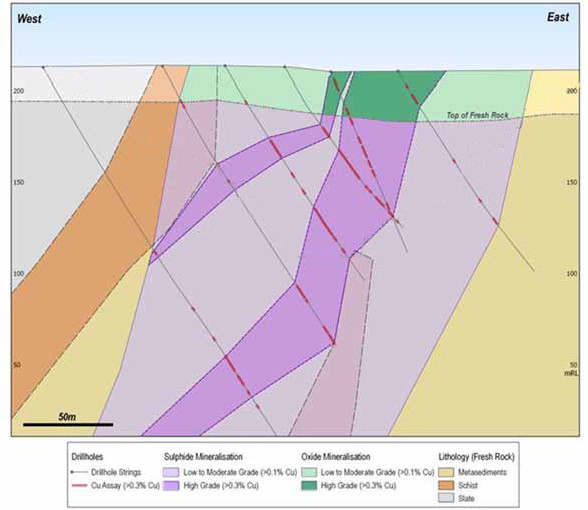

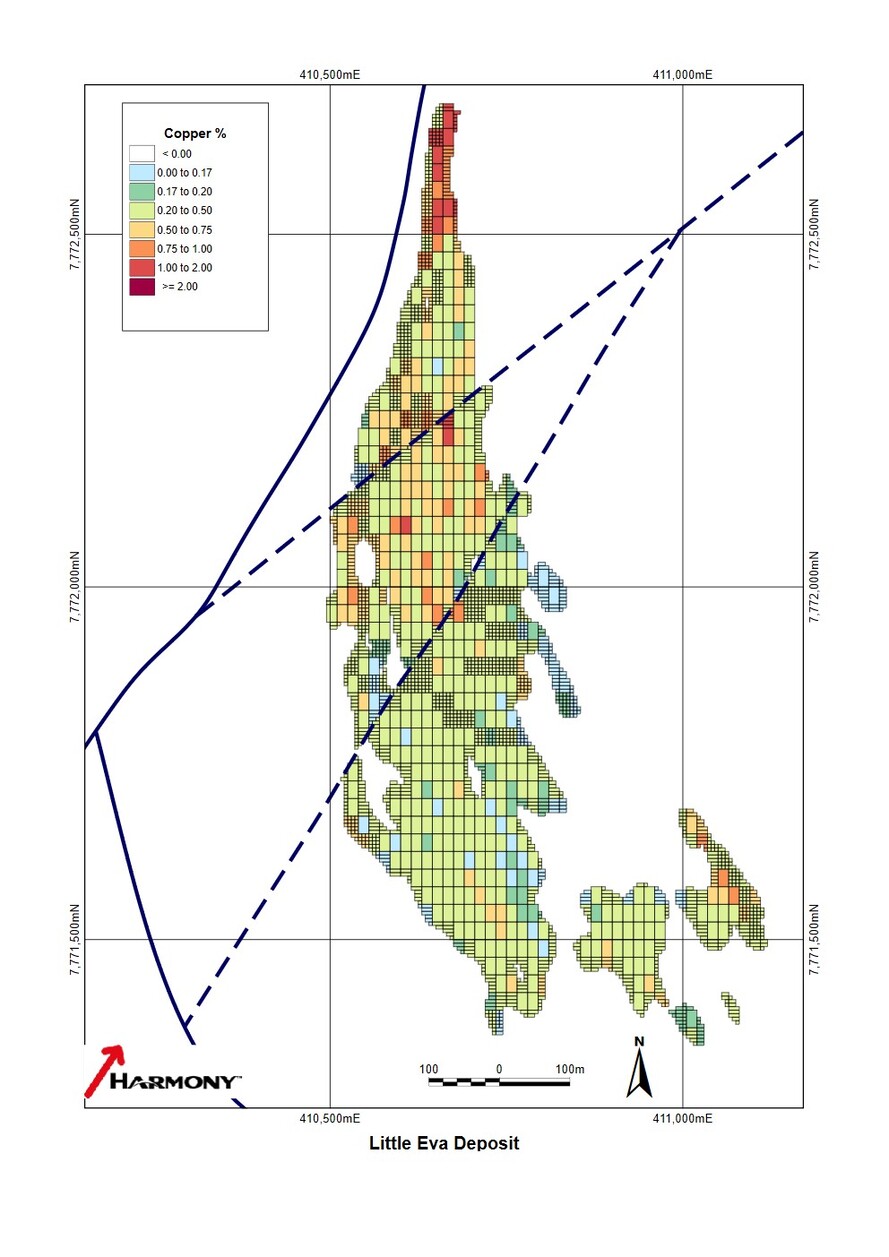

Resource domains were based on an assessment of the lithology, alteration, grade distribution and structure.

The grade-based domains resulted from an analysis of the grade distribution from the assay table. For the

IOCG deposits the domains were based on the 0.1% copper grade shell which equates to the first visual

occurrence of chalcopyrite in logging. Turkey Creek and Blackard were constrained by a 0.1% copper shell,

defined by statistical analysis of the drill hole data, the earlier CMMC resource models were defined by a

0.1% copper shell.

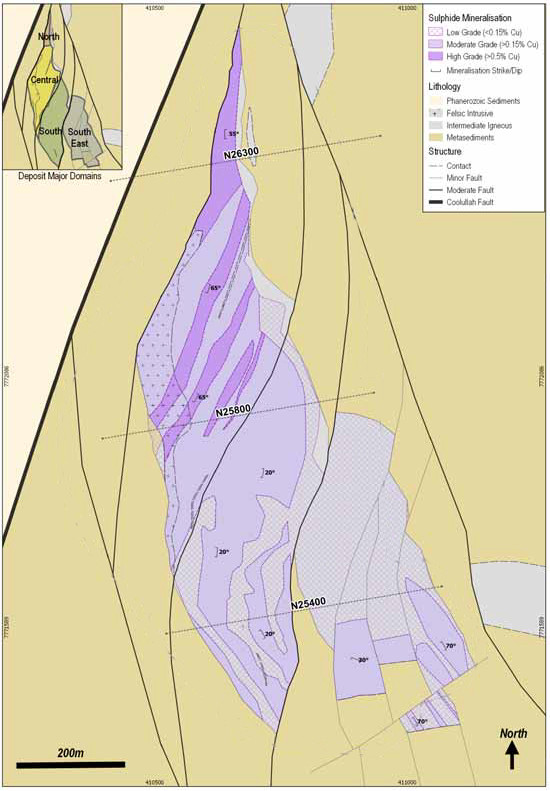

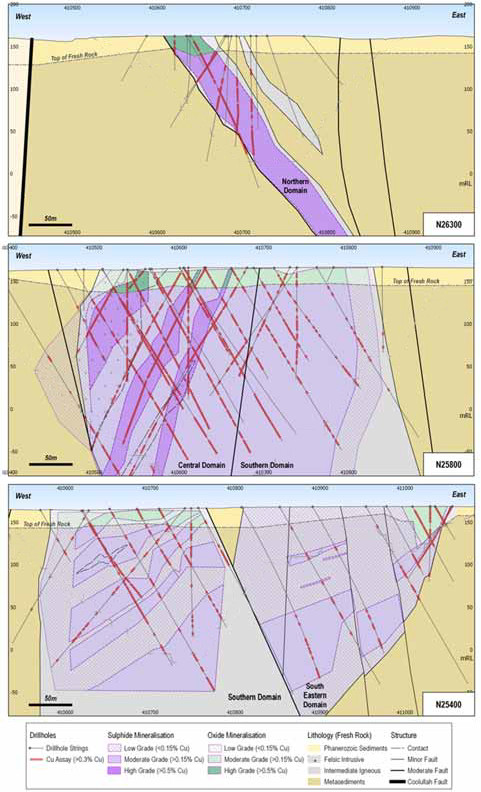

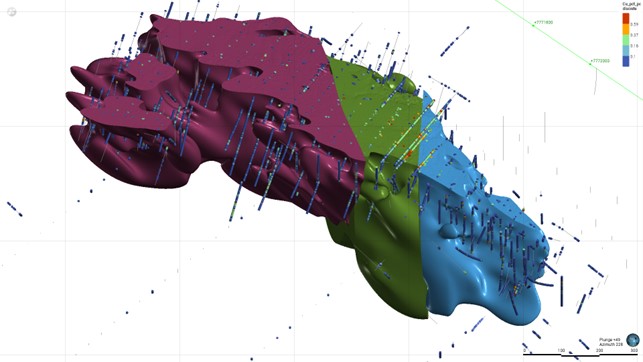

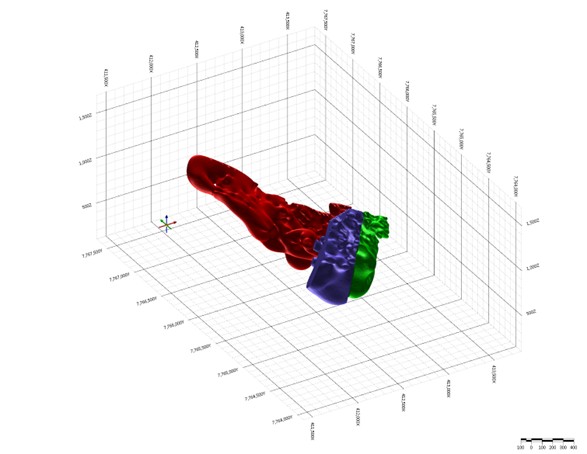

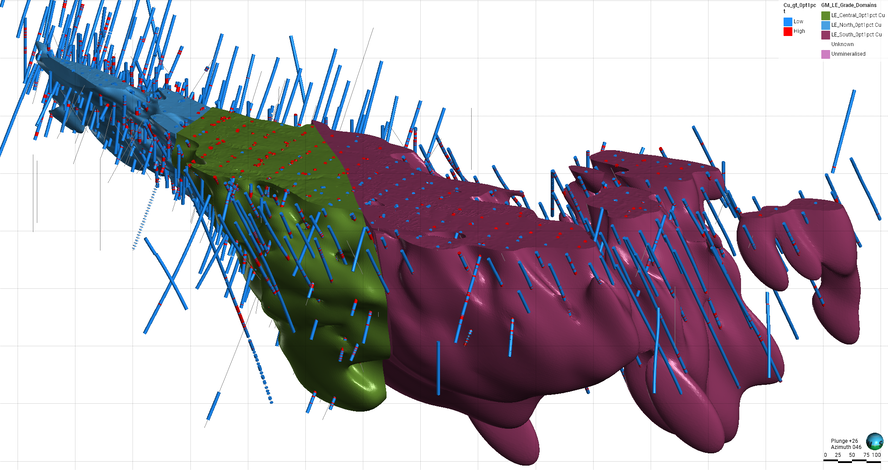

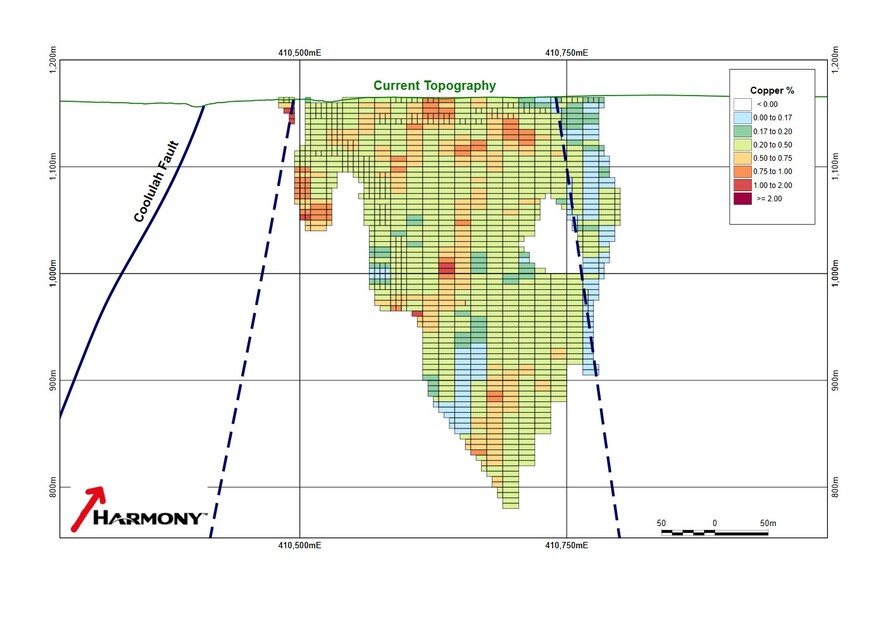

Analysis at the Little Eva deposit of the underlying lithology indicates it does not have a significant impact on

grade distribution and so lithology was not included in the domain construction, likewise for the oxidation

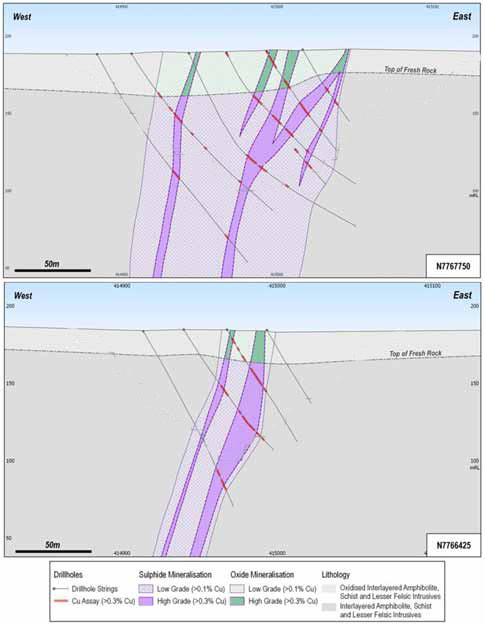

profile. There are, however, several significant faults that have an impact on the deposit and these were

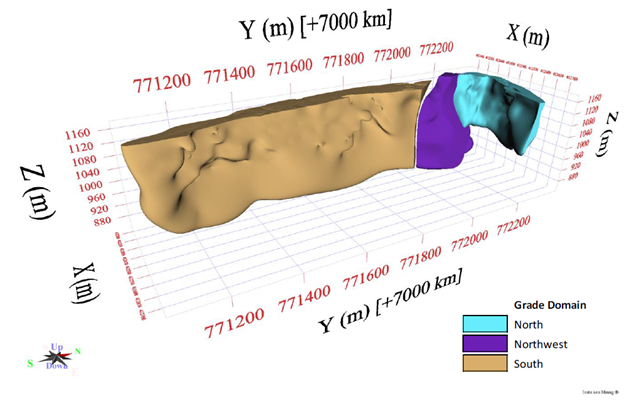

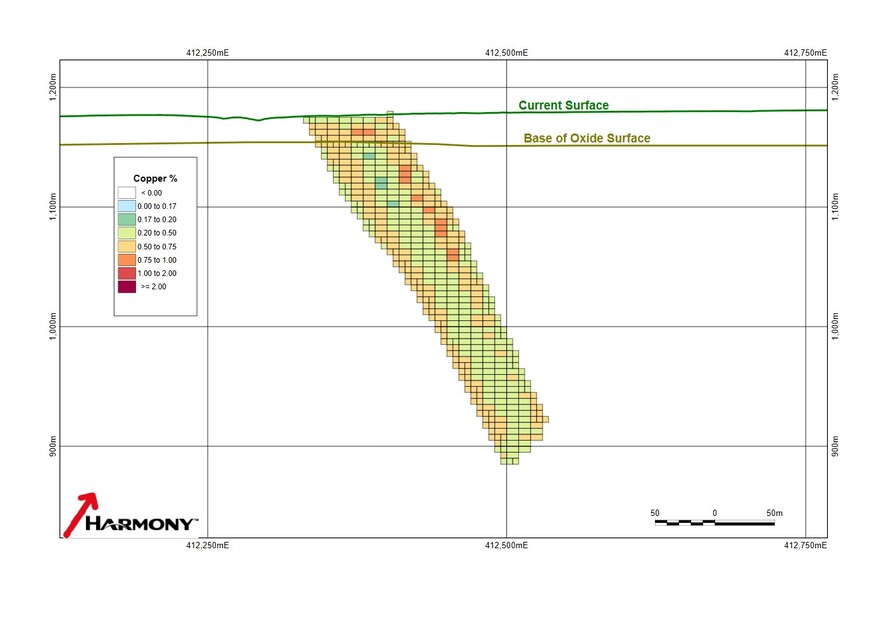

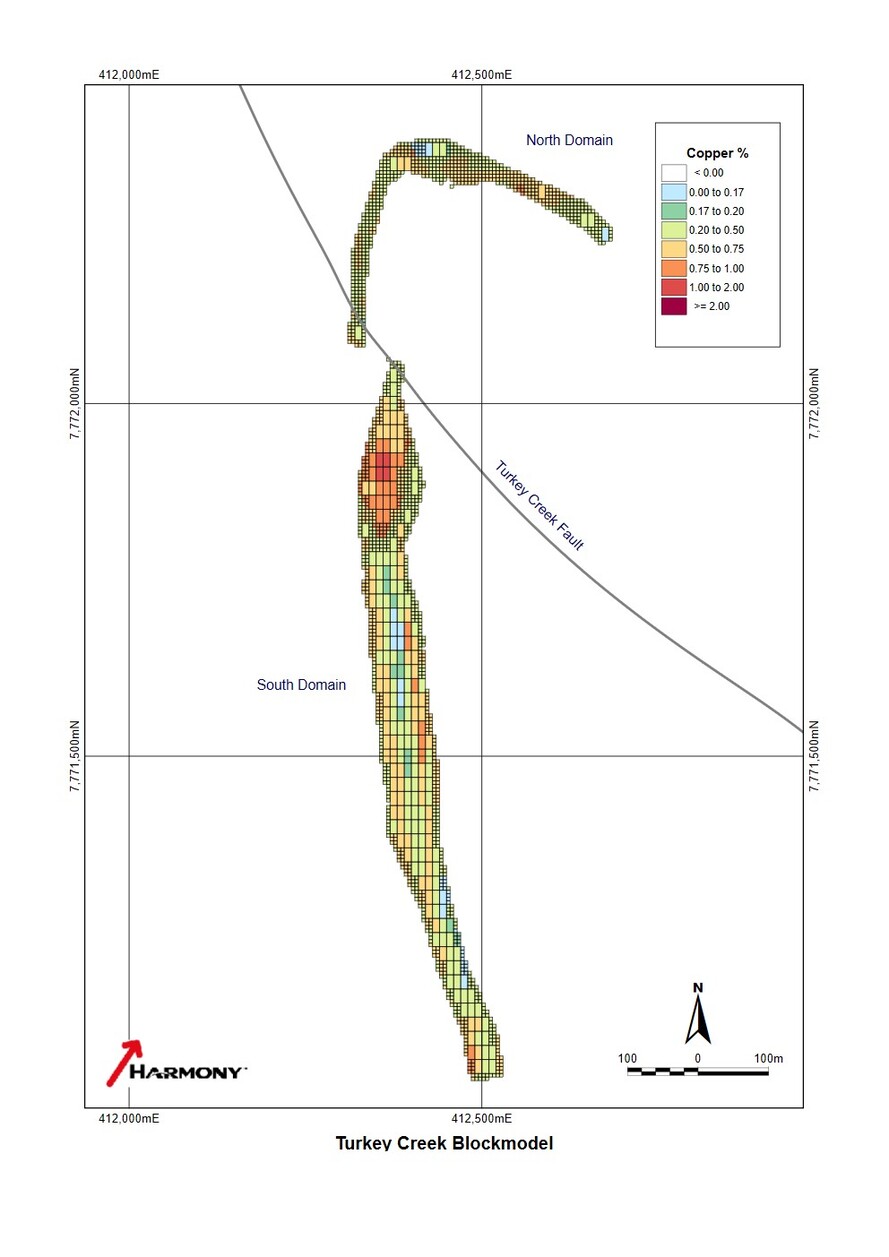

incorporated into the estimate, dividing the Little Eva estimation domain into 3 parts. While Turkey Creek

comprises of two sub-parallel high grade domains with a central low grade core, these domains were not

used in the estimate. Lithology and oxidation profiles, while assessed for impact were found to not be

significant contributors to grade distribution and did not inform the grade domains. A significant fault with

splays, the Turkey Creek Fault, cut across the northern end of the deposit and splits the domain into two

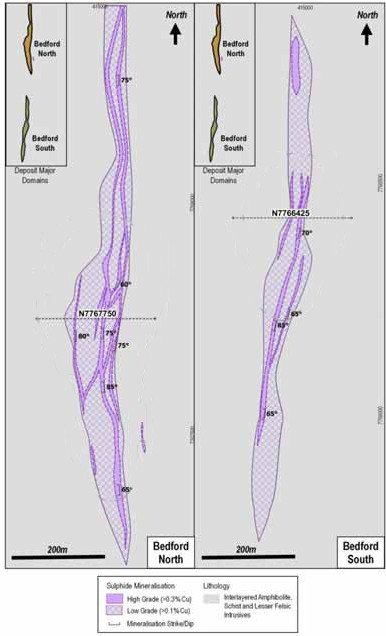

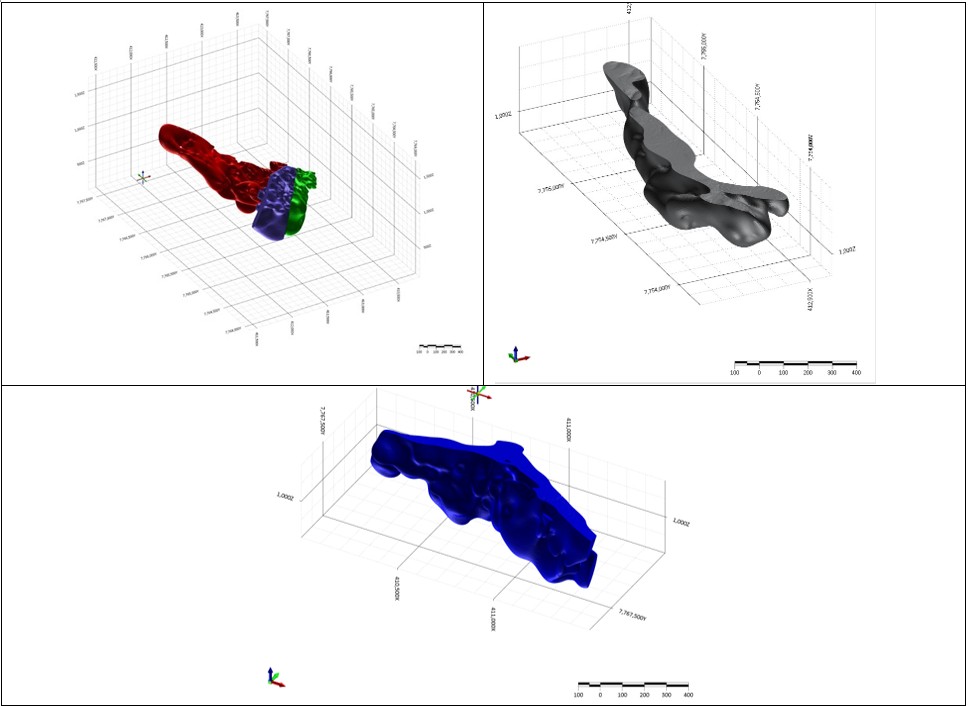

components. Blackard and Scanlan are both native copper deposits and analysis of these deposits indicate a

0.1% copper shell was appropriate. Both these deposits are folded and comprise antiform/synform pairs that

were used to inform the estimate, Blackard utilised dynamic anisotropy, guided by the fold surface, Scanlan

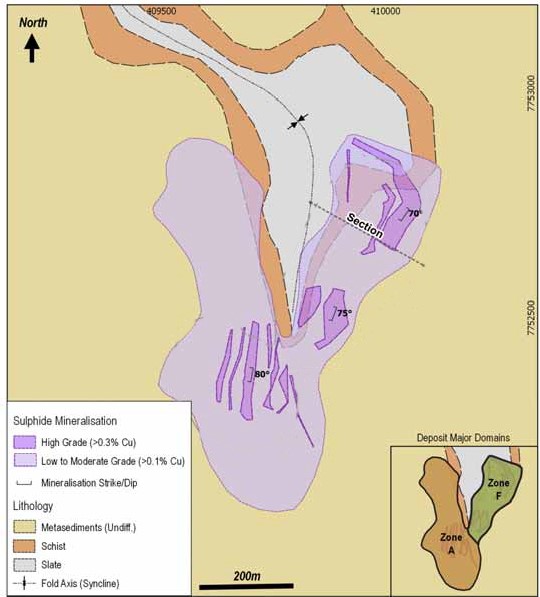

was divided into several separate domains in order to handle the changing anisotropy. Lady Clayre comprises

five separate mineralised zones, defined by copper shells at 0.1% based on analysis of the grade distribution.

The geology is strongly deformed and the various domains define the different components of this folded

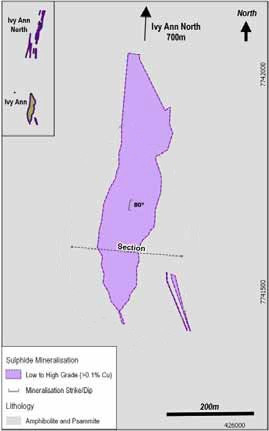

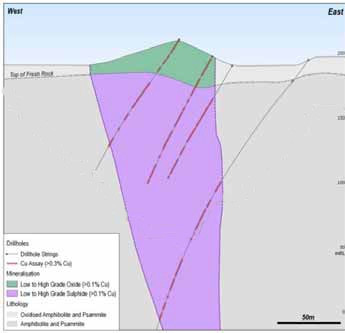

stratigraphy. The Bedford deposit is a narrow mineralised shear zone, and the estimation domain is

controlled by the 0.1% copper shell which defines the boundaries of the shear, the estimation domain is

entirely geologically based. The Ivy Ann deposit estimation domain is based on the 0.1% Cu shell equating to

the first occurrence of chalcopyrite and comprises several independent structural domains.

The constraining pit shells for defining the limits of Inferred resources and to define reasonable prospects for

economic extraction are based on copper prices, costs and metallurgical recoveries determined from work

carried out, and described, in this TRS. Resources were constrained by Whittle pit shells generated using

metal prices of US$5.10/lb Cu, US$1,941/oz Au and an exchange rate of 0.68 AU$:US$. The Whittle shell was

based on the following parameters:

•Plant throughput of 18 Mtpa, with a mining rate of 60 Mtpa

•A mining reference cost of AU$3.93/tonne

•Approximately AU$11.00/t Ore processing cost.

•Ore Haulage cost of AU$0.35/t/km

•Slope angles informed by historic studies with an average of 45 degrees.

•Copper Recovery is dependant on copper mineralogy, 95% Sulphide and 56% native copper.

•A 10mx10mx10m diluted block model.

A zone of oxidation overlies all of the seven deposits in the Eva Copper Project. The base of the oxidised zone

is generally sharp (±2 m), and was modelled during resource estimation. In the current mine plan, the

oxidised material is treated as waste, as currently there does not appear to be any form of economic

extraction; however, grades have been modelled and tonnages tabulated for general interest and in the

event of a possible processing path being identified in the future. The tonnage and grade of oxidised material

were determined in the same manner and at the same time as the other resource estimations.

Effective date: 30 June 2025

9

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

Table 1-2: Eva Copper Project Mineral Resources, 30 June 2025

Copper | Tons (Mt) | Cu Grade (% Cu) | Cu Pounds (Mlb) |

Measured | |||

Little Eva | — | — | — |

Bedford | — | — | — |

Lady Clayre | — | — | — |

Ivy Ann | — | — | — |

Turkey Creek | — | — | — |

Blackard | — | — | — |

Scanlan | — | — | — |

Legend | — | — | — |

Great Southern | — | — | — |

Total Measured | — | — | — |

Indicated | |||

Little Eva | 202.000 | 0.32 | 1,310.000 |

Bedford | 4.000 | 0.55 | 40.000 |

Lady Clayre | 5.000 | 0.43 | 42.000 |

Ivy Ann | 6.000 | 0.34 | 39.000 |

Turkey Creek | 31.000 | 0.42 | 263.000 |

Blackard | 128.000 | 0.48 | 1,223.000 |

Scanlan | 16.000 | 0.59 | 195.000 |

Legend | 34.000 | 0.47 | 324.000 |

Great Southern | 14.000 | 0.42 | 118.000 |

Total / Ave. Indicated | 440.000 | 0.40 | 3,554.000 |

Measured + Indicated | |||

Little Eva | 202.000 | 0.32 | 1,310.000 |

Bedford | 4.000 | 0.55 | 40.000 |

Lady Clayre | 5.000 | 0.43 | 42.000 |

Ivy Ann | 6.000 | 0.34 | 39.000 |

Turkey Creek | 31.000 | 0.42 | 263.000 |

Blackard | 128.000 | 0.48 | 1,223.000 |

Scanlan | 16.000 | 0.59 | 195.000 |

Legend | 34.000 | 0.47 | 324.000 |

Great Southern | 14.000 | 0.42 | 118.000 |

Total / Ave. Measured + Indicated | 440.000 | 0.40 | 3,554.000 |

Inferred | |||

Little Eva | 26.000 | 0.33 | 175.000 |

Bedford | 1.000 | 0.38 | 8.000 |

Lady Clayre | 1.000 | 0.43 | 7.000 |

Ivy Ann | 1.000 | 0.33 | 9.000 |

Turkey Creek | 6.000 | 0.44 | 52.000 |

Blackard | 37.000 | 0.40 | 300.000 |

Scanlan | 11.000 | 0.48 | 102.000 |

Legend | 6.000 | 0.33 | 36.000 |

Great Southern | 2.000 | 0.39 | 17.000 |

Total Inferred | 91.000 | 0.39 | 706.000 |

Effective date: 30 June 2025

10

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

Gold | Tons (Mt) | Au Grade (oz/t Au) | Au Ounces (Moz) |

Measured | |||

Little Eva | — | — | — |

Bedford | — | — | — |

Lady Clayre | — | — | — |

Ivy Ann | — | — | — |

Total / Ave. Measured | — | — | — |

Indicated | |||

Little Eva | 202.000 | 0.002 | 367.000 |

Bedford | 4.000 | 0.004 | 16.000 |

Lady Clayre | 5.000 | 0.005 | 25.000 |

Ivy Ann | 6.000 | 0.002 | 12.000 |

Total / Ave. Indicated | 217.000 | 0.002 | 420.000 |

Measured + Indicated | |||

Little Eva | 202.000 | 0.002 | 367.000 |

Bedford | 4.000 | 0.004 | 16.000 |

Lady Clayre | 5.000 | 0.005 | 25.000 |

Ivy Ann | 6.000 | 0.002 | 12.000 |

Total / Ave. Measured + Indicated | 217.000 | 0.002 | 420.000 |

Inferred | |||

Little Eva | 26.000 | 0.003 | 66.000 |

Bedford | 1.000 | 0.004 | 4.000 |

Lady Clayre | 1.000 | 0.004 | 3.000 |

Ivy Ann | 1.000 | 0.003 | 4.000 |

Total / Ave. Inferred | 29.000 | 0.003 | 77.000 |

Notes:

Resources are reported at a cut-off grade are based on approximate NSR values which equate to a copper grade of 0.16% Cu for sulphide

material and 0.25% for native copper .

Mineral Resources:

1.SAMREC and CIM definitions were followed for Mineral Resources.

2.Mineral Resources are exclusive of Mineral Reserves (however no Mineral Reserve are declared)

3.Mineral Resources are constrained within a Whittle pit shell generated with a copper price of $5.10/lb, a gold price of $1,941/oz and

an exchange rate of AU$1.00 = US$0.68

4.Density measurements were applied (ranges from 2.4 t/m3 to 3.0 t/m3).

5.Significant figures have been reduced to reflect uncertainty of estimations and therefore numbers may not add due to rounding.

6. Tonnes are Metric Units (1t = 1000Kg)

7. Mineral Resource tonnages and grades are reported in situ.

Mineral Reserve Estimate

Not applicable to this TRS

Mineral Reserves were declared by CMMC as reported in their 43-101 2020 Feasibility Update.

During Harmony due diligence prior to acquiring the Project, a number of risks and opportunities were

identified. Accordingly, upon purchase, Harmony planned and commenced a drilling programme to expand

and refine the resource and commenced studies to test processing, infrastructure, water and power

assumptions. Due to the significant potential change these studies may imply, it is deemed premature to

release the Reserves. It is anticipated that these studies will be completed in late 2025, upon which a Reserve

may be declared.

Effective date: 30 June 2025

11

Technical Report Summary of the

Eva Copper Project, North West Queensland, Australia

Royalties

State of Queensland royalties apply to all lands except freehold claims prior to 1904. State royalties range

between 2.5% and 5.0% of metal value, less certain allowable expenses. If the concentrate is processed in

Queensland (Mount Isa) there is a 20% reduction in the copper royalty. 100% of the royalty savings from the

Queensland Government is for the account of CMMC. Royalties are discussed in detail in Section 3.6.

Environment, Permitting, Social, or Community Impact

To support environmental assessments and project studies, flora and fauna surveys, groundwater

programmes and waste and tailings rock characterisation, amongst others, have been undertaken to support

an appreciation of the environment and its sensitivities, to predict impacts and inform mitigation and control

measures. This dataset continues to be supplemented by contemporary studies and monitoring data.

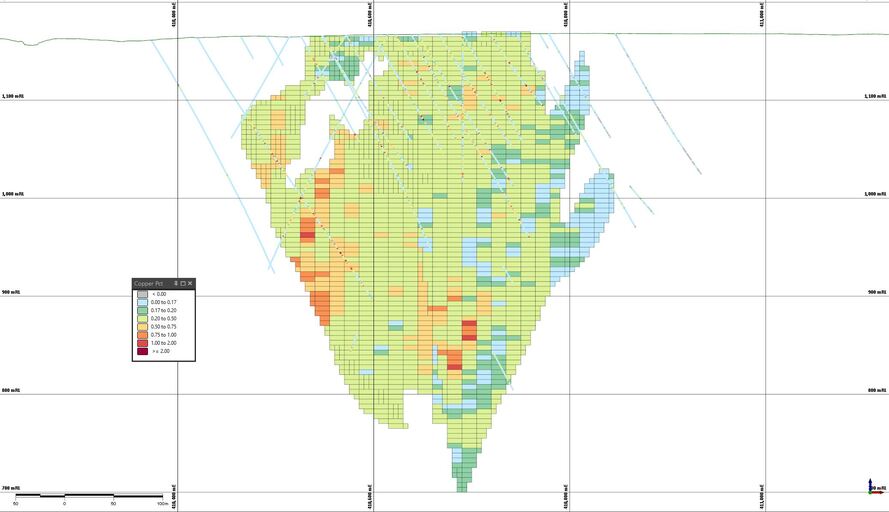

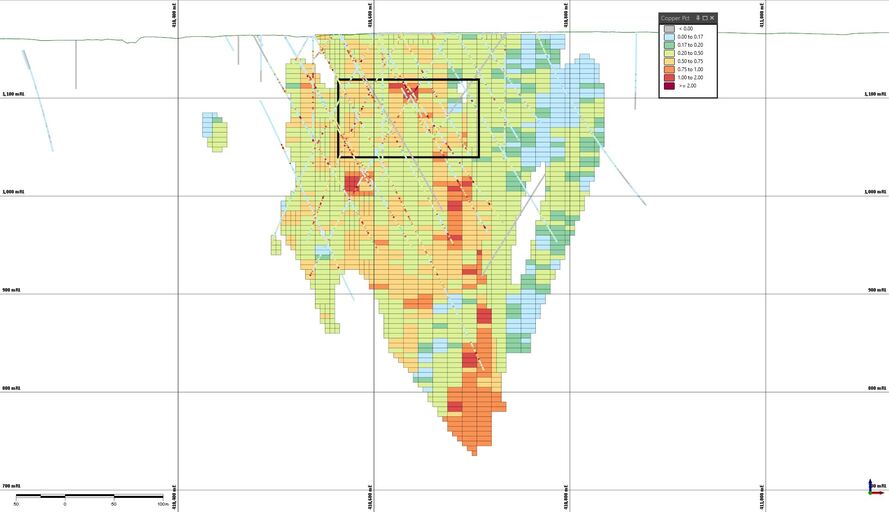

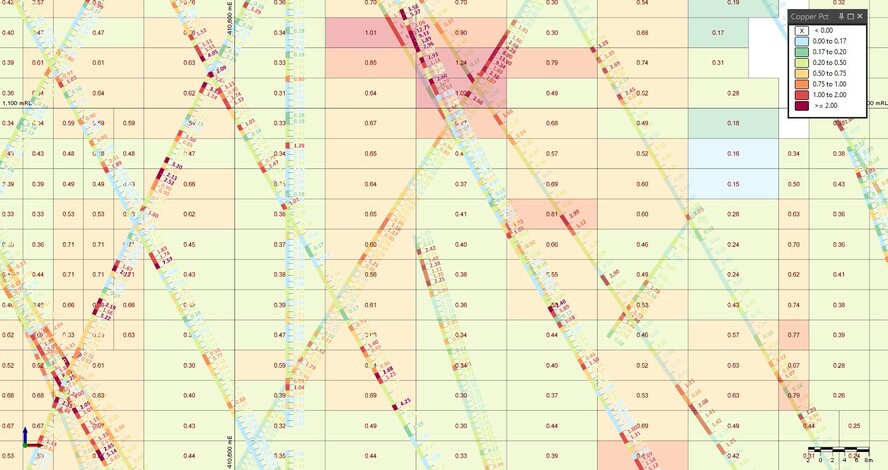

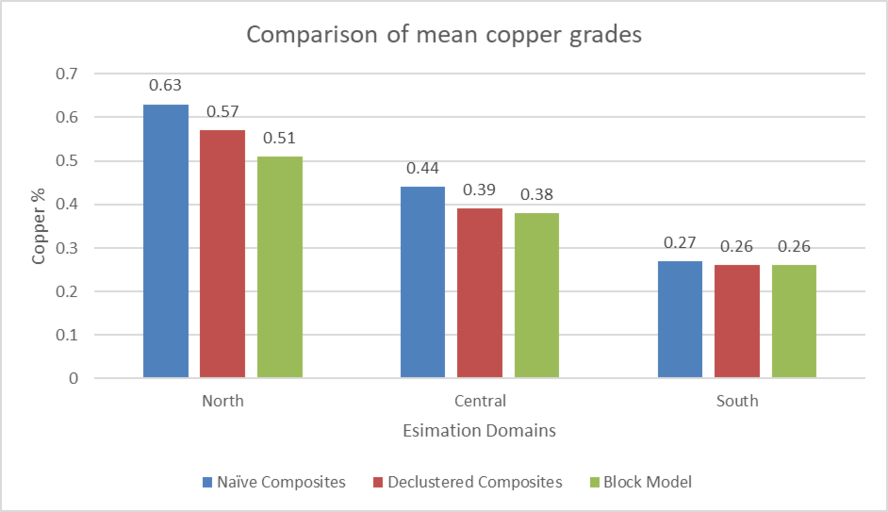

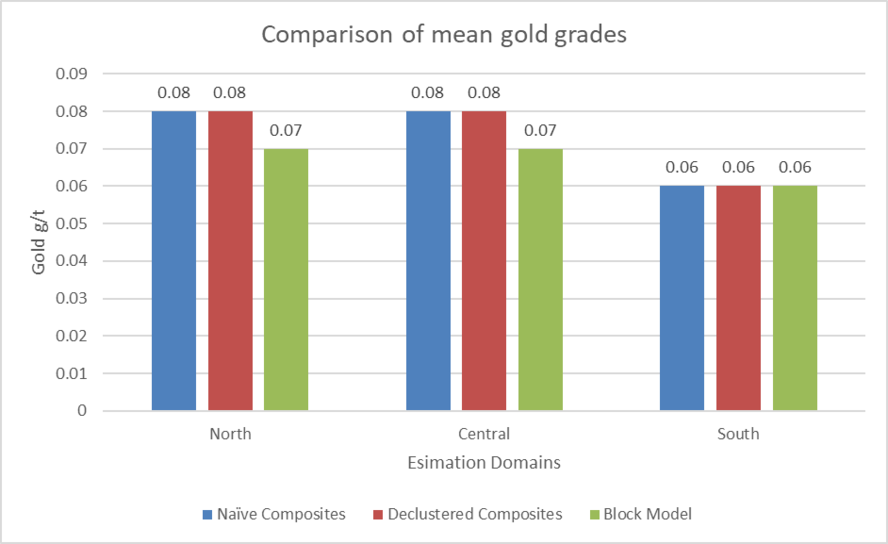

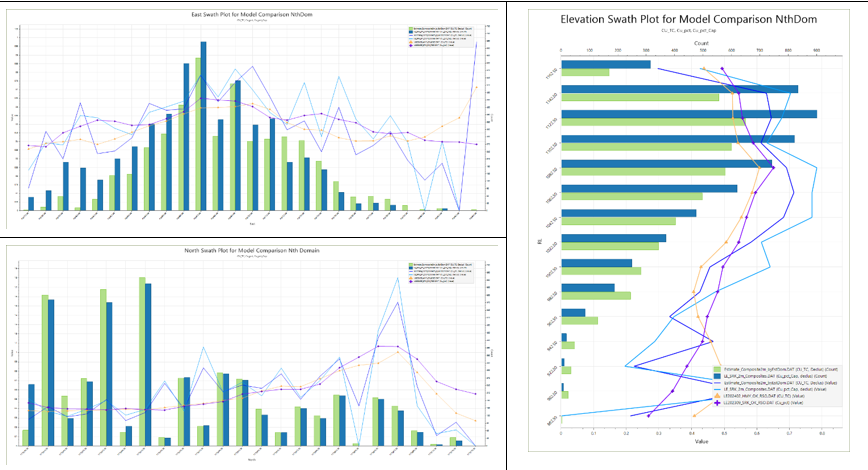

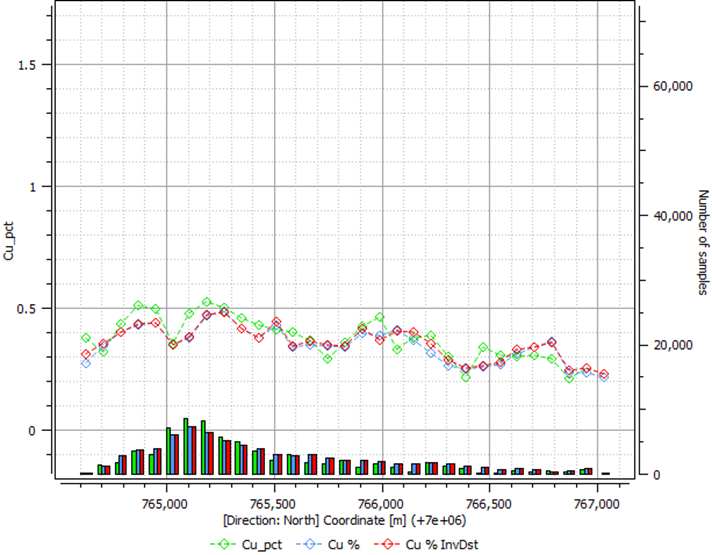

All regional ecosystems mapped within the Project area are classed as Least Concern under the Vegetation