ANNUAL INFORMATION FORM

of

B2GOLD CORP.

March 30, 2022

TABLE OF CONTENTS

- 2 -

B2GOLD CORP.

ANNUAL INFORMATION FORM

INTRODUCTORY NOTES

Date of Information

In this Annual Information Form ("Annual Information Form"), B2Gold Corp., together with its subsidiaries, as the context requires, is referred to as "we", "our", "us", the "Company" or "B2Gold". All information contained in this Annual Information Form is as at December 31, 2021, unless otherwise stated, being the date of our most recently completed financial year, and the use of the present tense and of the words "is", "are", "current", "currently", "presently", "now" and similar expressions in this Annual Information Form is to be construed as referring to information given as of that date. Readers are also encouraged to review our annual financial statements and management's discussion and analysis of the Company for the year ended December 31, 2021.

Cautionary Note Regarding Forward-Looking Information

Capitalized terms used but not defined in this Cautionary Note have the meaning given to them in this Annual Information Form.

This Annual Information Form includes certain "forward-looking information" and "forward-looking statements" (collectively "forward-looking statements") within the meaning of applicable Canadian and United States securities legislation, including, but not limited to: objectives, strategies, intentions and expectations; projections; forecasts; estimates; outlook; guidance; schedules; plans; designs; and other statements regarding future or estimated financial and operational performance, gold production and sales, revenues and cash flows, capital costs (sustaining and non-sustaining) and operating costs; budgets on a consolidated and mine by mine basis; closure and reclamation costs; our planned capital and exploration expenditures; future or estimated mine life, metal price assumptions, ore grades or sources, gold recovery and mining rates, stripping ratios, throughput, ore processing; statements regarding anticipated exploration, drilling, development, construction, permitting and other activities or achievements of B2Gold; and including, but not limited to: the impact of the novel coronavirus COVID-19 that was designated as a pandemic by the World Health Organisation on March 11, 2020 and its related variants ("COVID-19") on our operations, including our ability to manage and respond to the evolving risks associated with COVID-19; the performance and impact of the Fekola Solar Plant; the completion of the Masbate Gold Project HSE audit; our dividend obligations with respect to the Fekola Mine, including dividends payable to the Government of Mali; the further advancement of our pipeline of development and exploration projects; operating and design practices at the Cardinal Zone being similar to the Fekola Mine; the delivery of material from the Cardinal Zone and Anaconda Area to the Fekola mill in 2022, including the nature, amount and timing of any such deliveries; projected gold production, including production being weighted heavily to the second half of 2022, Fekola's annualized throughput rate averaging 9.0 Mtpa over the long-term, gold production at the Fekola Mine of between 570,000 and 600,000 ounces in 2022, gold production at the Masbate Gold Project of between 205,000 and 215,000 ounces in 2022, and gold production at the Otjikoto Mine of between 175,000 and 185,000 ounces in 2022; the development of the Wolfshag underground mine at Otjikoto, including the results of such development and the costs and timing thereof; ore production at the Wolfshag underground mine at Otjikoto commencing in the first half of 2022; the potential to improve the economics of the Gramalote Project, including the timing and completion of a feasibility study and a mineral resource update, and the results therein; the Gramalote Project benefiting from anticipated key operational advantages; the potential payment of future dividends, including the timing and amount of any such dividends, and the expectation that quarterly dividends will be maintained at the same level; the availability of our revolving credit facility for future draw downs; our attributable share of Calibre's production; and the expected impact of any tax or regulatory changes in the countries in which we operate, including Mali, the Philippines and Namibia. Estimates of mineral resources and reserves are also forward-looking statements because they constitute projections regarding the amount of minerals that may be encountered in the future and/or the anticipated economics of production, should a production decision be made. All statements in this Annual Information Form that address events or developments that we expect to occur in the future are forward-looking statements. Forward-looking statements are statements that are not historical facts and are generally, although not always, identified by words such as "expect", "plan", "anticipate", "project", "target", "potential", "schedule", "forecast", "budget", "estimate", "intend" or "believe" and similar expressions or their negative connotations, or that events or conditions "will", "would", "may", "could", "should" or "might" occur. All such forward-looking statements are based on the opinions and estimates of management as of the date such statements are made.

- 3 -

Forward-looking statements are inherently subject to known and unknown risks, uncertainties and other factors, many of which are beyond our ability to control, that may cause our actual results, level of activity, performance or achievements to be materially different from those expressed or implied by such forward-looking information. Such risks include, without limitation, the risks, uncertainties and other factors referred to in this Annual Information Form including under "Risk Factors" and elsewhere herein.

Forward-looking statements are based on the applicable assumptions and factors management considers reasonable as of the date hereof, based on the information available to management at such time. These assumptions and factors include, but are not limited to, assumptions and factors related to our ability to carry on current and future operations, including: the duration and effects of COVID-19 on our operations and workforce; development and exploration activities; the timing, extent, duration and economic viability of such operations, including any mineral resources or reserves identified thereby; the accuracy and reliability of estimates, projections, forecasts, studies and assessments, including geotechnical, mining and metallurgical recovery assumptions and interpretations of mineralization geometry and grade continuity; stockpiling assumptions, including the amount and grade of stockpile material; our ability to meet or achieve estimates, projections and forecasts; the availability and cost of inputs; the price and market for outputs, including gold; foreign exchange rates; taxation levels; the timely receipt of necessary approvals or permits; laws and regulations applicable to our operations, including our continued ability to retain mineral and surface rights titles; the continued health, availability and cost of labour; the continued availability and use of infrastructure; the ability to meet current and future obligations; the ability to obtain timely financing on reasonable terms when required; the current and future social, economic and political conditions; the continued ability to access our sites; the ability to maintain the social license to operate; and other assumptions and factors described herein or that are generally associated with the mining industry.

Forward-looking statements are based on the opinions and estimates of our management and reflect their current expectations regarding future events and operating performance. We do not assume any obligation to update forward-looking statements if circumstances or management's beliefs, expectations or opinions should change other than as required by applicable law. Although we have attempted to identify important factors that could cause actual results to differ materially from those contained in the forward-looking statements, there may be other factors that cause actual results to differ materially from those which are anticipated, estimated, or intended. There can be no assurance that forward-looking statements will prove to be accurate, and actual results, performance or achievements could differ materially from those expressed in, or implied by, these forward-looking statements. Accordingly, no assurance can be given that any events anticipated by the forward-looking statements will transpire or occur, or if any of them do, what benefits or liabilities we will derive therefrom. For the reasons set forth above, undue reliance should not be placed on forward-looking statements. All the forward-looking statements contained in this Annual Information Form are qualified by these cautionary statements.

Currency and Exchange Rate Information

Our financial statements are reported in U.S. dollars. All dollar amounts referenced in this Annual Information Form, unless otherwise indicated, are expressed in U.S. dollars. A reference in this Annual Information Form to:

"C$" or "Canadian dollar" is to the lawful currency of Canada;

"N$" or "Namibian dollar" is to the lawful currency of Namibia;

"Philippine peso" is to the lawful currency of the Philippines;

"West African CFA franc" is to the lawful currency of Mali;

"Colombian peso" is to the lawful currency of Colombia;

"Euro" is to the lawful currency of the European Union; and

- 4 -

The high, low, average and closing exchange rates for Canadian dollars in terms of U.S. dollars, as quoted by the Bank of Canada, for each of the three years in the period ended December 31, 2021, were as follows:

|

|

Fiscal Year Ended December 31, |

||

|

2019 |

2020 |

2021 |

|

|

Highest rate during period |

US$0.7710 |

US$0.7863 |

US$0.8306 |

|

Lowest rate during period |

US$0.7393 |

US$0.6898 |

US$0.7727 |

|

Average rate during period |

US$0.7543 |

US$0.7461 |

US$0.7980 |

|

Rate at the end of period |

US$0.7699 |

US$0.7854 |

US$0.7888 |

On March 29, 2022, the daily average rate of exchange for one Canadian dollar in U.S. dollars, as quoted by the Bank of Canada, was C$1.00 = US$0.7994.

Production Results, Technical Information and Cautionary Note for United States Readers

Actual and projected production results presented in this Annual Information Form reflect total production at the mines we operate on a 100% project basis. As further discussed in this Annual Information Form, a wholly-owned B2Gold subsidiary has a direct ownership interest of 80% in the Fekola Mine, 90% in the Otjikoto Mine and the right to purchase all ore from the Masbate Gold Project (each mine and project are as defined herein). In respect of La Libertad and El Limon, production is presented on an approximately 33% basis for the period up to January 11, 2022 and subsequently on a 25% basis, reflecting our approximate equity interest in Calibre Mining Corp. ("Calibre") (subject to reduction if our interest in Calibre dilutes further).

The disclosure included in this Annual Information Form uses Mineral Reserve and Mineral Resource classification terms that comply with reporting standards in Canada and the Mineral Reserve and Mineral Resource estimates are made in accordance with the Canadian Institute of Mining, Metallurgy and Petroleum ("CIM") Council - Definition Standards for Mineral Resources & Mineral Reserves adopted by CIM Council on May 19, 2014 (the "CIM Standards"), which were adopted by the Canadian Securities Administrators' (the "CSA") National Instrument 43-101 Standards of Disclosure for Mineral Projects ("NI 43-101"). NI 43-101 is a rule developed by the CSA that establishes standards for all public disclosure an issuer makes of scientific and technical information concerning mineral projects. The following definitions are reproduced from the CIM Standards:

A Modifying Factor or Modifying Factors are considerations used to convert Mineral Resources to Mineral Reserves. These include, but are not restricted to, mining, processing, metallurgical, infrastructure, economic, marketing, legal, environmental, social and governmental factors.

A Mineral Resource is a concentration or occurrence of solid material of economic interest in or on the earth's crust in such form, grade or quality and quantity that there are reasonable prospects for eventual economic extraction. The location, quantity, grade or quality, continuity and other geological characteristics of a Mineral Resource are known, estimated or interpreted from specific geological evidence and knowledge, including sampling. Mineral Resources are sub-divided, in order of increasing geological confidence, into Inferred, Indicated and Measured categories.

An Inferred Mineral Resource is that part of a Mineral Resource for which quantity and grade or quality are estimated on the basis of limited geological evidence and sampling. Geological evidence is sufficient to imply but not verify geological and grade or quality continuity. An Inferred Mineral Resource has a lower level of confidence than that applying to an Indicated Mineral Resource and must not be converted to a Mineral Reserve. It is reasonably expected that the majority of Inferred Mineral Resources could be upgraded to Indicated Mineral Resources with continued exploration.

- 5 -

An Indicated Mineral Resource is that part of a Mineral Resource for which quantity, grade or quality, densities, shape and physical characteristics are estimated with sufficient confidence to allow the application of Modifying Factors in sufficient detail to support mine planning and evaluation of the economic viability of the deposit. Geological evidence is derived from adequately detailed and reliable exploration, sampling and testing and is sufficient to assume geological and grade or quality continuity between points of observation. An Indicated Mineral Resource has a lower level of confidence than that applying to a Measured Mineral Resource and may only be converted to a Probable Mineral Reserve.

A Measured Mineral Resource is that part of a Mineral Resource for which quantity, grade or quality, densities, shape, and physical characteristics are estimated with confidence sufficient to allow the application of Modifying Factors to support detailed mine planning and final evaluation of the economic viability of the deposit. Geological evidence is derived from detailed and reliable exploration, sampling and testing and is sufficient to confirm geological and grade or quality continuity between points of observation. A Measured Mineral Resource has a higher level of confidence than that applying to either an Indicated Mineral Resource or an Inferred Mineral Resource. It may be converted to a Proven Mineral Reserve or to a Probable Mineral Reserve.

A Mineral Reserve is the economically mineable part of a Measured and/or Indicated Mineral Resource. It includes diluting materials and allowances for losses, which may occur when the material is mined or extracted and is defined by studies at pre-feasibility or feasibility level as appropriate that include application of Modifying Factors. Such studies demonstrate that, at the time of reporting, extraction could reasonably be justified. The reference point at which Mineral Reserves are defined, usually the point where the ore is delivered to the processing plant, must be stated. It is important that, in all situations where the reference point is different, such as for a saleable product, a clarifying statement is included to ensure that the reader is fully informed as to what is being reported. The public disclosure of a Mineral Reserve must be demonstrated by a pre-feasibility study or feasibility study.

A Probable Mineral Reserve is the economically mineable part of an Indicated, and in some circumstances, a Measured Mineral Resource. The confidence in the Modifying Factors applying to a Probable Mineral Reserve is lower than that applying to a Proven Mineral Reserve.

A Proven Mineral Reserve is the economically mineable part of a Measured Mineral Resource. A Proven Mineral Reserve implies a high degree of confidence in the Modifying Factors.

Unless otherwise indicated, the scientific and technical disclosure in this Annual Information Form was prepared in accordance with NI 43-101, which differs significantly from the requirements of the United States Securities and Exchange Commission (the "SEC"). Accordingly, mineral resource and mineral reserve information and other scientific and technical information contained or referenced in this Annual Information Form may not be comparable to similar information disclosed by public companies subject to the technical disclosure requirements of the SEC.

The term "Qualified Person" as used in this Annual Information Form means a Qualified Person as that term is defined in NI 43-101. Except where otherwise disclosed:

William Lytle, P.E., Senior Vice President and Chief Operating Officer of B2Gold, a Qualified Person, has approved the scientific and technical information related to operations matters contained in this Annual Information Form.

Tom Garagan, P. Geo., Senior Vice President, Exploration of B2Gold, a Qualified Person, has approved the scientific and technical information regarding exploration matters contained in this Annual Information Form.

- 6 -

CORPORATE STRUCTURE

Name, Address and Incorporation

We were incorporated under the Business Corporations Act (British Columbia) (the "BCBCA") on November 30, 2006. Our head office is located at Suite 3400, Park Place, 666 Burrard Street, Vancouver, British Columbia, Canada V6C 2X8 and our registered office is located at 1600-925 West Georgia Street, Vancouver, British Columbia, Canada V6C 3L2.

Intercorporate Relationships

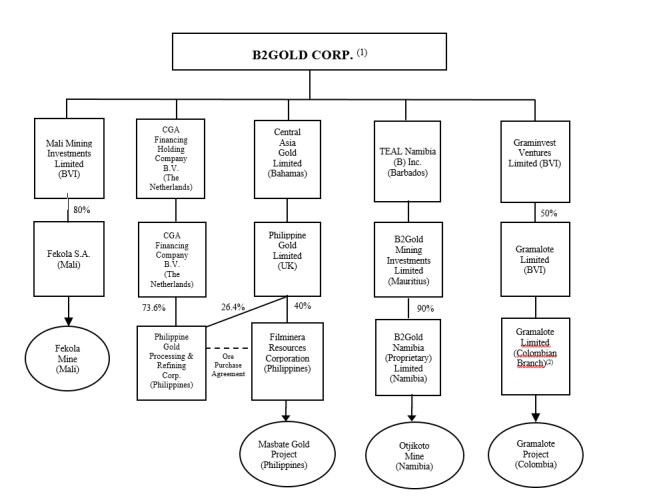

A significant portion of our business is carried on through our subsidiaries. The chart below includes the name and jurisdiction of incorporation of our material subsidiaries and certain subsidiaries holding an interest in mineral projects that we consider significant as described in this Annual Information Form.

Notes:

(1) All ownership of subsidiaries is 100% unless otherwise indicated. Certain subsidiaries are indirectly owned by us through wholly-owned subsidiaries not reflected above.

(2) Colombian branch is not a separate legal entity.

- 7 -

GENERAL DEVELOPMENT OF THE BUSINESS

We are an international, low-cost senior gold producer based in Vancouver, Canada with three operating mines (one mine in each of Mali, Namibia and the Philippines). In addition, we have a portfolio of other development and exploration projects in several countries including Mali, Colombia, Namibia, Finland and Uzbekistan. Our material properties consist of the following three mines:

Fekola mine (80% ownership), an open pit gold mine located approximately 40 kilometres ("km") south of the city of Kéniéba, Mali (the "Fekola Mine");

Otjikoto mine (90% ownership), an open pit gold mine (and underground mine under development) located approximately 300 km north of Windhoek, the capital of Namibia (the "Otjikoto Mine"); and

Masbate gold project (ownership as described under "Material Properties - Masbate Gold Project" below), an open pit gold mine, located near the northern tip of the island of Masbate, 360 km southeast of Manila, the capital of the Philippines (the "Masbate Gold Project").

Our other significant asset is the Gramalote project (50% ownership), a gold development project located 230 km northwest of Bogota, the capital of Colombia (the "Gramalote Project").

Three Year History

Over the three most recently completed financial years, the significant events described below contributed to the development of our business.

2019 Developments

On March 26, 2019, we announced positive results from the Expansion Study Preliminary Economic Assessment for the Fekola Mine (the "Fekola PEA"). Based on the Fekola PEA results, we proceeded with an expansion project to increase processing throughput by 1.5 million tonnes per annum ("Mtpa") to 7.5 Mtpa, from an assumed base rate of 6 Mtpa.

- 8 -

On May 10, 2019, we amended and restated our revolving credit facility (the "Credit Facility") with our existing syndicate of banks plus one new lender to upsize the Credit Facility from $500 million to an aggregate amount of $600 million, and to increase the accordion feature from $100 million to $200 million.

In June 2019, the Fadougou village relocation was completed. The village of Fadougou was originally located adjacent to the main Fekola Mine open pit. Construction of the new planned urban town commenced in late 2017 and was completed in February 2019. This involved building over 700 new structures, including solar panel lighting and latrines for all homes.

On October 15, 2019, we completed the sale of the El Limon and La Libertad gold mines, the Pavon gold project and additional mineral concessions in Nicaragua to Calibre (the "Calibre Transaction"). Pursuant to the terms of the share purchase agreement, we received on closing (i) an aggregate of 87,986,666 common shares of Calibre ("Calibre Shares"), representing approximately 28.35% of the then issued and outstanding Calibre Shares on closing, (ii) $40 million in cash (plus a working capital adjustment), and (iii) a $10 million convertible debenture (the "Debenture"). On November 5, 2019, we received an additional $12,833,047, representing a portion of the working capital adjustment. On November 18, 2019, Calibre exercised its right to redeem the outstanding principal amount owing under the Debenture, increasing our equity interest in Calibre to approximately 34% of the then issued and outstanding Calibre Shares (as at the date of this Annual Information Form we hold approximately 25% of the issued and outstanding Calibre Shares, following the completion of Calibre's acquisition of Fiore Gold Ltd. ("Fiore Gold")). In October 2020, Calibre paid to us the balance of the consideration in connection with the Calibre Transaction (a total of $15,525,099, representing $10 million in deferred consideration and the balance of the working capital adjustment).

On November 5, 2019, the Board declared our inaugural quarterly dividend of $0.01 per Common Share, which was paid on December 13, 2019 to shareholders of record as at the close of business on November 27, 2019.

On December 23, 2019, we entered into an amended and restated shareholders agreement (the "Shareholders' Agreement") with AngloGold Ashanti Limited ("AngloGold") relating to the ownership and management of the Gramalote Project. On January 1, 2020, we assumed the role of operator of the Gramalote Project. Pursuant to the Shareholders' Agreement, we sole-funded the first $13.9 million of expenditures in 2020 on the Gramalote Project, and as a result now hold a 50% ownership interest in the Gramalote Project.

2020 Developments

Effective January 1, 2020, Ms. Liane Kelly was appointed to our Board.

On January 16, 2020, we announced an updated Fekola Mineral Resource estimate, including a substantial increase in Indicated Mineral Resources at the Fekola Mine following a successful infill drill program in 2019. The updated Fekola Indicated Mineral Resource estimate as at December 31, 2019 provided the basis for an updated design pit and new Fekola Probable Mineral Reserve estimate.

On January 21, 2020, we announced positive results from the updated Preliminary Economic Assessment for the Gramalote Ridge deposit at the Gramalote Project (the "Gramalote PEA"). See "Other Properties - Gramalote Project" below for additional details on the Gramalote Project.

For the second quarter of 2020 dividend, we increased our dividend rate by 100%, and we again raised our dividend rate by another 100% in the third quarter of 2020.

On September 10, 2020, we announced the successful commissioning of the Fekola mill expansion to 7.5 Mtpa (an increase of 1.5 Mtpa from an assumed base rate of 6 Mtpa). Commissioning included completion of all major construction activities associated with the expansion, as well as the successful execution of a five-day mill performance test. In addition, all of the Fekola Mine fleet expansion equipment has arrived on site and is operational, with the overall mine expansion now complete.

- 9 -

On September 29, 2020, we entered into a new term equipment facility (the "New Equipment Facility") with Caterpillar Financial Services Corporation for an aggregate principal amount of up to $40 million. The New Equipment Facility is available to our majority-owned subsidiary, Fekola S.A., to finance or refinance up to 75% of the cost of mining fleet and other mining equipment at the Fekola Mine. On October 26, 2020, Fekola S.A. drew down the entire amount under the New Equipment Facility. Each equipment loan is repayable in 20 equal quarterly installments. The final repayment date is five years from the first disbursement under each equipment loan. The interest rate on each loan is a rate per annum equal to EURIBOR plus a margin of 4.25%. A commitment fee of 0.85% per annum on the undrawn balance on the New Equipment Facility for the term of the facility is also due, payable quarterly commencing 12 months from the date of the agreement. We and our wholly-owned subsidiary, Mali Mining Investments Limited, have guaranteed the New Equipment Facility and security is given over the equipment of Fekola S.A.

2021 Developments

The COVID-19 pandemic continued to have a wide ranging and global impact during 2021. Despite some of the challenges that the current COVID-19 pandemic has created worldwide and in each of the locations where we operate or are head-quartered, we continued to operate virtually unimpeded. Our executive team is very proud of our employees' dedication and resilience in these challenging times. We continue to address the COVID-19 pandemic and minimize its potential impact at our operations. We place the safety and well-being of our workforce and all stakeholders as our highest priority and continue to encourage input from all our stakeholders as the COVID-19 situation evolves. We continue to implement measures and precautionary steps to manage and respond to the evolving risks associated with COVID-19 to ensure the safety of our employees, contractors, suppliers and surrounding communities where we work while continuing to operate. We are continually updating these plans and response measures based on the safety and well-being of our workforce, the severity of the pandemic in areas where we operate, global response measures, government restrictions and extensive community consultation. We are working closely with national and local authorities and continue to closely monitor each site's situation, including public and employee sentiment to ensure that stakeholders are in alignment with continued safe operation of our mines.

In 2021, we commenced the Gramalote feasibility study (the "Gramalote Feasibility Study") to evaluate recovery of gold from an open pit mining operation with an 11.0 Mtpa processing plant that includes crushing, grinding, flotation and a carbon-in-pulp recovery process to produce doré bullion. The Gramalote Feasibility Study approach focused solely on a production scenario based on the Indicated Mineral Resource estimate from the Gramalote Ridge deposit of 173,400,000 tonnes grading 0.73 grams per tonne ("g/t") gold for a total of 4,060,000 ounces of gold, and did not include any potential production from the nearby Trinidad deposit, which has a current Inferred Mineral Resource estimate, or the Monjas West zone. We expect that the results of the Gramalote Feasibility Study will be available by the end of the second quarter of 2022 with the final Gramalote Feasibility Study delivered in the third quarter of 2022.

In July 2021, the heavy fuel oil ("HFO") hybrid-solar plant at the Fekola Mine (the "Fekola Solar Plant") reached full production capacity. The Fekola Solar Plant is expected to reduce the Fekola Mine's HFO consumption by over 13 million litres per year and lower carbon dioxide emissions by an estimated 39,000 tonnes per year. During 2021, 14.6% of total electricity on site at the Fekola Mine was produced by the Fekola Solar Plant, reducing fuel consumption by over 10 million litres and reducing carbon dioxide emissions by 31,500 tonnes.

On November 30, 2021, we completed the sale of our 81% interest in the Kiaka gold project located in Burkina Faso (the "Kiaka Project") to West African Resources Limited ("WAF") (the "Kiaka Transaction"). Pursuant to the terms of the Kiaka Transaction, on closing we received a cash payment of US$22.5 million (in addition to the US$450,000 already received), 22,190,508 ordinary shares of WAF ("WAF Shares"), and a 2.7% net smelter return ("NSR") royalty interest on the first 2,500,000 ounces of gold produced at the Kiaka Project and thereafter a 0.45% NSR royalty interest on the next 1,500,000 ounces of gold produced. We will also receive an additional payment of US$45 million (the "Additional Payment") payable on the earlier of (i) commencement of construction at the Kiaka Project (provided such date will be no earlier than April 25, 2022), (ii) completion of a positive feasibility study at the Kiaka Project, and (iii) October 25, 2022. The Additional Payment will be paid in cash or WAF Shares, at our option but subject to any required WAF shareholder approval to issue the WAF Shares.

- 10 -

Concurrently with the closing of the Kiaka Project, we also completed the sale of our 90% interest in the Toega gold project located in Burkina Faso (the "Toega Project") to WAF (the "Toega Transaction"). Pursuant to the terms of the Toega Transaction, on closing we received a cash payment of US$9 million (in addition to the US$9 million already received), and a 2.7% NSR royalty interest on the first 1,500,000 ounces of gold produced at the Toega Project until such time as the royalty payments total US$22.5 million and thereafter a 0.45% NSR royalty interest.

On December 16, 2021, we amended and restated our Credit Facility with our existing syndicate of banks to extend the maturity date to December 16, 2025. The maximum available for drawdown under the Credit Facility remains $600 million with an accordion feature, available on the receipt of additional binding commitments, for a further $200 million. The interest rates and commitment fees have been reduced. The Credit Facility now bears interest on a sliding scale of between LIBOR plus 2.0 % to 2.50% based on our consolidated net leverage ratio. Commitment fees for the undrawn portion of the facility are also on a similar sliding scale basis of between 0.45% and 0.563%. The Credit Facility continues to be secured by a general security interest over our assets and pledges creating a charge over the shares of certain of our direct and indirect subsidiaries. In connection with the Credit Facility, we must also maintain certain ratios for leverage and interest coverage. As at the date of this Annual Information Form, the full amount of the Credit Facility was undrawn and available.

In December 2021, we reached an agreement in principle with the Government of Mali, pursuant to which the Government agreed that it would grant a new exploration permit covering the same perimeter as the Menankoto exploration permit (the "Menankoto Permit") to a new Malian subsidiary of B2Gold, and we would withdraw the international arbitration proceedings that our Malian subsidiary Menankoto SARL ("Menankoto") had previously commenced. On February 2, 2022, we announced that a Malian subsidiary of B2Gold had received the new Menankoto Permit, issued by the Government in compliance with the procedures and requirements set out under the 2019 Mining Code (Mali) (the "2019 Mining Code") (the previous permit had been issued under the 2012 Mining Code (Mali) (the "2012 Mining Code")), which provides for an initial term of three years and is renewable for two additional three year periods. Menankoto has now withdrawn the related international arbitration proceedings against the Republic of Mali.

DESCRIPTION OF THE BUSINESS

General

We are an international, low-cost senior gold producer based in Vancouver, British Columbia, with a strategic focus on acquiring and developing interests in mineral properties with demonstrated potential for hosting economic mineral deposits, with gold deposits as the primary focus. We conduct gold mining operations and exploration and drilling campaigns to define and develop Mineral Resources and Mineral Reserves on our properties with an intention of developing, constructing and operating mines on such properties.

Our corporate objective is to continue to maximize profitable production from our mines, grow as a profitable and responsible gold producer through further advancement of our pipeline of development and exploration projects, evaluate new exploration, development and production opportunities, make accretive acquisitions, irrespective of the gold price, and continue to pay an industry leading dividend yield.

Principal Product

Our principal product is gold, with gold production forming all our revenues. There is a global market into which we sell our gold and, as a result, we are not dependent on a particular purchaser with respect to the sale of the gold that we produce.

Special Skills and Knowledge

Various aspects of our business require specialized skills and knowledge, certain of which are in high demand and in limited supply. Such skills and knowledge include the areas of permitting, engineering, geology, metallurgy, logistical planning, implementation of exploration programs, mine construction and development, mine operation, as well as legal compliance, finance, accounting, risk management, safety and security, community relations and human resources. We have highly qualified management personnel and staff, an active recruitment program, and believe that persons having the necessary skills are generally available. We have found that we can locate and retain competent employees and consultants in such fields and have maintained a high retention rate of highly skilled employees. We do not anticipate having significant difficulty in recruiting other personnel as needed. Training programs are in place for workers that are recruited locally.

- 11 -

Competitive Conditions

The gold exploration and mining business is a competitive business. We compete with numerous other companies (including, as a senior gold producer, some of the largest mining companies in the world) and individuals in the search for and the acquisition of quality gold properties, mineral claims, permits, concessions and other mineral interests, as well as recruiting and retaining qualified employees. Our ability to acquire and develop gold properties in the future will depend not only on our ability to develop and operate our present properties, but also on our ability to select and acquire suitable producing properties or prospects for development or mineral exploration.

Cycles

The mineral exploration, development and production business is subject to mineral and commodity price cycles. The marketability of minerals is also affected by worldwide economic cycles.

Employees

Our business is administered principally from our head office in Vancouver, British Columbia, Canada. We also have offices in Bamako, Mali; Manila, Philippines; Windhoek, Namibia; and Medellin, Colombia. As at December 31, 2021, we, including our subsidiaries, employ a total of 3,263 permanent employees and 1,426 fixed-term (temporary) employees for a total of 4,689 employees.

Production at our mining operations is dependent upon the efforts of our employees and our relations with our unionized and non-unionized employees. Some of our employees are represented by labour unions under various collective labour agreements. The collective bargaining agreement covering the workers at the Otjikoto Mine has historically been negotiated annually, however, the current collective bargaining agreement was valid for a two-year term, which expired on February 28, 2022. The collective bargaining agreement remains in place until the negotiations relating to the next subsequent agreement are complete. In addition, our employees at the Fekola Mine are part of a union that governs the entire mining industry in Mali and the Fekola delegates have created an executive office, affiliated with the Section of Trade, Mines and Industry in Mali and the National Workers Union in Mali. Currently, all labour discussions are managed through union delegates that are elected during site-wide elections. Labour relations are currently positive at the Otjikoto Mine and the Fekola Mine.

International Operations

Our principal operations and assets are located in Mali, Namibia, the Philippines and Colombia. In addition, we have an approximate 25% indirect ownership interest in Calibre's assets in Nicaragua and the United States through our equity interest in Calibre. Our operations are exposed to various levels of political, economic and other risks and uncertainties. These risks and uncertainties vary from country to country and include, but are not limited to, government regulations (or changes to such regulations) with respect to restrictions on production, export controls, income taxes, royalties, excise and other taxes, expropriation of property, repatriation of profits, environmental legislation, land use, water use, local ownership requirements and land claims of local people, regional and national instability and security, mine safety, corruption and sanctions. The effect of these factors cannot be accurately predicted. See "Risk Factors" below.

- 12 -

Environmental Protection

Our activities are subject to extensive laws and regulations governing the protection of the environment, natural resources and human health. These laws address, among other things: emissions into the air; discharges into water; management of waste and hazardous substances; protection of natural resources, cultural heritage and endangered species; and reclamation of lands disturbed by mining operations. We are required to obtain governmental permits and, in some instances, provide bonding requirements under federal, state, or provincial air, water quality, and mine reclamation rules and permits. Violations of environmental and health and safety laws are subject to civil sanctions and, in some cases, criminal sanctions, including the suspension or revocation of permits. The failure to comply with environmental laws and regulations or liabilities related to hazardous substance contamination could result in project development delays, material financial impacts or other material impacts to our projects and activities, fines, penalties, lawsuits by the government or private parties, or material capital expenditures.

Additionally, environmental laws in some of the countries in which we operate, as well as certain organizations that we are members of, require that we periodically perform audits and environmental impact studies at our mines. These studies could reveal presently unknown environmental impacts that would require us to make significant capital outlays or cause material changes or delays in our intended activities.

Our current estimated aggregate closure and reclamation cost at the Fekola Mine, the Masbate Gold Project and the Otjikoto Mine is approximately $103 million on an undiscounted basis. These estimates are generally based on conceptual level engineering and will be updated periodically to reflect changes in site conditions and the life of mine ("LoM") plans. See "Environmental, Occupational Health and Safety, Social and Regulatory" below and the disclosure regarding environmental matters under the respective descriptions of our material properties for further details regarding environmental matters.

Environmental, Occupational Health and Safety, Social and Regulatory

Our Board has a Health, Safety, Environment, Social and Security Committee (the "HSESS Committee") that assists the Board in overseeing our health, safety, environmental, corporate social responsibility and security policies and programs, and our health, safety, environmental, corporate social responsibility and security risk management and performance, including cybersecurity. The HSESS Committee, comprised of five directors, four of which are independent directors, meets quarterly with management to review current and emerging issues, evaluate performance and risk management, and to evaluate and update policies and procedures.

HSE Management Systems

We have implemented Health, Safety and Environmental ("HSE") Management System and Performance Standards and Occupational Health and Safety Standards at the corporate level that define the requirements for the development and implementation of both corporate and site HSE management systems. Our HSE Management System and Performance Standards are based on international standards including compliance with in-country regulations, relevant International Organization for Standardization ("ISO") and occupational health and safety standards, and reliance on the International Finance Corporation (the "IFC") Performance Standards and international best practices in cases where national regulatory systems are not sufficiently stringent. These management systems enable us to mitigate and manage the potential risks and impacts of our operations.

We implement the HSE management systems and manage HSE and social performance with dedicated HSE and social personnel at both the corporate and site levels. The following is a brief summary of HSE management systems in place across our different projects:

- 13 -

Masbate Gold Project: The Masbate Gold Project maintains an HSE management system based on our HSE Management System and Performance Standards, which is audited biannually by independent experts. The Masbate Gold Project recently completed the recertification audit by SGS Philippines, Inc. and was able to maintain its ISO 14001:2015 certification. The external audit program has been temporarily suspended since 2020 due to COVID-19 travel restrictions, which continued into 2021. As a result, we have conducted internal reviews at the Masbate Gold Project to ensure their management system processes remain robust. We expect the external audit will be conducted shortly after the Philippine Government reinstates foreign travel into the country.

Otjikoto Mine: The Otjikoto Mine maintains an HSE management system based on our HSE Management System and Performance Standards, which is audited annually by independent experts. Following a suspension in 2021 due to COVID-19 travel restrictions, the external audit program of the HSE management system at the Otjikoto Mine was completed in the fourth quarter of 2021. The results of the external audit confirm that the Otjikoto Mine has improved its HSE management system and performance standard processes and now maintains safety systems and processes in alignment with our standards. Improvement plans based on auditor recommendations for standards needing further improvement and/or refinement are being developed for implementation in 2022.

Gramalote Project: The Gramalote Project remains in the development stage of the mine lifecycle, but also maintains a comprehensive HSE and social management system. The Gramalote Project continues the process of adapting its systems to our HSE Management System and Performance Standards (following our transition to operational manager in 2020). The Gramalote Project maintains ISO 45001 certification for its occupational health and safety management system. The Gramalote Project will implement an external audit program of its HSE and social management systems and performance as it progresses into construction and operations.

Regional Exploration Projects: Regional exploration projects adhere to the same HSE Management System and Performance Standards as the rest of our projects, and apply specific standards, procedures, and processes as are relevant and applicable to each site.

Reclamation and Care and Maintenance Sites: Reclamation and care and maintenance sites adhere to the same HSE Management System and Performance Standards as the rest of our projects, and apply specific standards, procedures, and processes as are relevant and applicable to each site.

In addition, we work with occupational health, safety, and environmental regulatory agencies to ensure that the performance of our operations is at a level that is acceptable to regulatory authorities. We have adopted occupational health and safety policies designed to ensure the protection and promotion of the safety, human health and welfare of our employees. We encourage open dialogue and have prepared procedures for responding to concerns of all entities with respect to HSE issues.

We have implemented measures and introduced best practice steps in accordance with the Centers for Disease Control and Prevention ("CDC"), the World Health Organization ("WHO") and national health agencies to manage and respond to the risks associated with COVID-19 to ensure the safety of our employees, contractors, suppliers and surrounding communities. For the last two years, corporate travel to our operations has been restricted to absolute minimum requirements and employees have been encouraged to work remotely. At each of our three mining operations in Mali, the Philippines and Namibia, and at the Gramalote Project in Colombia, we have implemented many control measures for dealing with the outbreak of COVID-19 in line with CDC and WHO guidelines. These include: pre-screening for symptoms and travel history with possible COVID-19 exposure of any employees, visitors and contractors (site personnel) prior to any travel to or from a site and isolation, where necessary, from the general site population; pretests (PCR and Rapid Antigen); operational protocols; aggressive contact tracing; and close work with local health authorities. Each site has implemented restrictions and isolation procedures that are particular to each region's situation and response capabilities. We also introduced a mandatory vaccination policy at the corporate level and have supported each of our operations and national governments with vaccinations of employees and the communities in which we operate. In 2022, we will continue to monitor COVID-19 with medical experts and support and encourage workers and their families to be vaccinated.

- 14 -

Environmental

We comprehensively updated our Environmental and Biodiversity Standards in 2018 and our Environmental and Biodiversity Policies in 2021 to incorporate recent developments and improvements in industry standards, as well as our growth. In 2019, we developed a comprehensive Environmental Strategic Plan for 2020 to 2023. This Strategic Plan identifies key environmental aspects and defines specific objectives and targets for our operations, providing a road map for improved environmental risk management and performance in line with our overall company strategy. The Strategic Plan is currently defined through 2023 but will be extended and updated at regular intervals. Two critical areas that have come to the forefront in recent years are tailings stewardship and climate change risk, and both of these aspects are integral to our environmental management strategies.

Community

Our Social Responsibility and Human Rights Policy, updated in 2020, defines our commitment to facilitate a positive and sustainable legacy by understanding and managing the social and economic impacts and opportunities resulting from our presence. We are committed to open and respectful engagement with our stakeholders. We respect community rights, interests and culture, and where Indigenous Peoples are identified we work to obtain their free, prior and informed consent. We recognize human rights, as defined in the International Bill of Human Rights, and align our approach to human rights risk management with the United Nations Guiding Principles on Business and Human Rights (the "UNGPs") and the Voluntary Principles on Security and Human Rights (the "VPSHR").

We have also adopted a set of Social Performance Standards at the corporate level to provide minimum requirements for the social practices and performance of our operations. Our Social Performance Standards align with international best practices, including those of the IFC, the International Council on Mining and Metals (the "ICMM") and the UNGPs. Our Social Performance Standards manage key issues including stakeholder engagement, grievance management, community investment, land acquisition and resettlement, local content, human rights, artisanal and small-scale mining ("ASM"), social closure, security and human rights, and social baseline and impact assessment and management.

We conducted internal audits of these Social Performance Standards at all our operations by the end of 2019, with results reported to the Senior Vice President, Operations and site general managers. In 2021, we conducted third-party audits of these Social Performance Standards at our Fekola and Otjikoto mines. Due to restrictions associated with entering the Philippines in 2021 as a result of the COVID-19 pandemic, our third-party audits at the Masbate Gold Project were postponed to 2022. With the support of external experts, we also conduct human rights assessments and security risk assessments in accordance with the VPSHR. These assessments, including recommendations to address salient risks and impacts, are discussed and confirmed with our executives and reported to the HSESS Committee. In 2021, we carried out a VPSHR risk assessment at the Fekola Mine and Masbate Gold Project and conducted a VPSHR risk assessment and a human rights impact assessment at our Gramalote Project.

We have also implemented a Supplier Code of Conduct as part of our commitment to human rights and ongoing efforts to improve supplier management. It outlines our expectations that suppliers act in accordance with our corporate commitments in their management of health and safety, labour and human rights, the environment, business conduct and ethics, and socio-economic development.

Our Community Investment Standard, which aligns with the IFC Performance Standards and ICMM guidance on community development, defines how we focus on sustainable contributions to the communities where we operate. The following is a brief summary of our community development efforts in 2021:

- 15 -

Fekola Mine: We continued the implementation of planned community investment programs in the areas of education, health, water and sanitation, child protection and alternative livelihoods. Community investment programs are implemented pursuant to a multi-year Community Development Plan developed in consultation with local stakeholders (the "CDP"), which provides for decision-making driven by local stakeholders. Under the CDP, 10 projects were presented by communities in 2021 and approved by the CDP steering committee for implementation. Six projects were completed in 2021 and four were still in progress as of December 31, 2021, including the construction of a school fence and teachers' accommodation, construction of a water supply project and construction of a community market.

Masbate Gold Project: Philippine regulations mandate that a social development expenditure equal to 1.5% of the annual operational costs is invested in support of socio-economic development in the areas impacted by a mining operation, resulting in a significant community investment budget managed separately by Filminera Resources Corporation ("Filminera") and Philippine Gold Processing & Refining Corp. ("PGPRC") in consultation with local stakeholders through an annual Social Development and Management Program (the "SDMP"). Over 300 SDMP projects, programs and activities were identified for implementation in 2021, including procurement of equipment and farm machinery to support agricultural livelihoods, provision of scholarships for 2,198 students, provision of medical services and supplies for local residents, and various infrastructure improvements to support connectivity, electrification, and water supply. The 2021 expenditure for community development utilizing the SDMP fund amounted to US$2.58 million.

Otjikoto Mine: Our community investment in Namibia is focused on education, health, environment, small business development and arts and culture. In 2021, we supported programs in early childhood development, primary and secondary schools, vocational education, and teacher skills development. Healthcare programs provided mobile services to reach remote communities and informal settlements in Windhoek.

Gramalote Project: The Gramalote Project continued the implementation of four projects for the formalization of informal ASM in line with applicable national policies and regulations. We supported ASM miners in preparing and obtaining environmental permits and complementary work plans, along with technical training and analysis for best gold processing alternatives. Other social investment activities supported in 2021 included educational support programs to rural schools, small-scale agricultural programs and training initiatives to improve local capacity in technical skills.

Vancouver, Canada: As a Canadian company, we are also committed to supporting community initiatives at home through our Canadian Corporate Social Responsibility Fund. In 2021, we provided C$1 million in financial support to community organizations in Metro Vancouver, Canada, including C$100,000 to the Red Cross to support those affected by the British Columbia floods.

Diversity and Inclusion

In 2020, we implemented a three-year Equitable, Diversity and Inclusivity ("EDI") Strategy. As part of this work, in late 2021, the EDI Workplace Policy was implemented, as well as a new Diversity Policy for Board and Management-level positions.

In our EDI Workplace Policy, we recognize the value of diversity and strive to eliminate employment barriers that interfere with the establishment of equal opportunities. We are dedicated to equitable treatment of all persons, irrespective of gender, race, ethnicity, nationality, religion and sexual orientation, as well as reasonable and safe accommodation of people with disabilities. We promote diversity through: global and regional leadership that is active, committed and accountable; strategies and plans to identify and remove barriers; policies that are fair, call for equal access and treatment, and inform principled decision-making and behaviour, including with respect to pay equity; training and development that support growth in the Company, providing career advancement opportunities and building talent pipelines; engagement that stimulates dialogue, awareness, education and collaboration; change by way of actionable measures that is informed by and assessed through metrics; and grievance mechanisms with remedial action in cases of proven discrimination and harassment.

- 16 -

Our Diversity Policy defines our approach to diversity with respect to Board and Management positions, including the identification, nomination and appointment of Board members, as well as our succession plan. "Management" is defined as appointed directors, officers, heads of department and other managers who support the Executive in carrying out our strategy and plans, assist in managing governance and risk, oversee people and/or resources and ensure our standards are implemented, maintained and reported on. This includes engineering and mining departments, but also legal, governance, sustainability, external relations, human resources, health and safety, environment, finance and accounting, information technology ("IT") and other essential business functions. The Diversity Policy sets targets of 30% for female representation on our Board and in Management-level positions.

Our annual Responsible Mining Report, a copy of which is available on our website at www.b2gold.com, provides an expanded discussion of our environmental, social and governance risk management and performance.

SUMMARY OF MINERAL RESERVE AND MINERAL RESOURCE ESTIMATES

Mineral Reserves are reported from pit designs and underground stope designs based on Indicated Mineral Resources. Mineral Resources are reported inclusive of those Mineral Resources that have been converted to Mineral Reserves.

Economic parameters such as mining costs, processing costs, metallurgical recoveries and geotechnical considerations have been applied to determine economic viability of the Mineral Reserves based on a gold price of US$1,500 per ounce ("/oz") (unless otherwise stated). Mineral Reserves contained in stockpiles that meet the project-specific Mineral Reserve cut-off grades are also included for the Fekola Mine, the Masbate Gold Project and the Otjikoto Mine.

Mineral Resources amenable to open pit mining are constrained with conceptual pit shells defined by economic parameters and using a gold price of US$1,800/oz. Mineral Resources amenable to underground mining methods are reported above cut-off grades defined by site operating costs and using a gold price of US$1,800/oz. Mineral Resources contained in stockpiles that meet the project-specific cut-off grades are also included for the Fekola Mine, the Masbate Gold Project and the Otjikoto Mine. Gold grades are expressed in grams per tonne of gold ("g/t Au").

Mineral Reserve and Mineral Resource estimates for our operating mines have been updated to account for mining depletion, using topographic surfaces as of December 31, 2021. These Mineral Reserve and Mineral Resource estimates are reported by project/mine on both a 100% project basis reflecting the total Mineral Resources and Mineral Reserves and the applicable project/mine specific attributable basis reflecting our ownership interest (details in table footnotes below).

- 17 -

Probable Mineral Reserves Statement

|

Country |

Mine or Project |

100% Project Basis |

Attributable Ownership Basis |

|||||

|

Tonnes (x 1,000) |

Gold Grade (g/t Au) |

Contained Gold Ounces |

Attributable Percentage |

Tonnes (x 1,000) |

Gold Grade (g/t Au) |

Contained Gold Ounces |

||

|

Mali |

Fekola Mine and Cardinal Zone |

62,000 |

1.86 |

3,710 |

80 |

49,600 |

1.86 |

2,960 |

|

Philippines |

Masbate Gold Project |

73,500 |

0.80 |

1,890 |

1003 |

73,500 |

0.80 |

1,890 |

|

Namibia |

Otjikoto Mine and Wolfshag Deposit |

11,600 |

1.66 |

620 |

90 |

10,400 |

1.66 |

560 |

|

Total Probable Mineral Reserves (includes stockpiles) |

6,210 |

|

5,410 |

|||||

Notes:

1. Mineral Reserves have been classified using the CIM Standards. All tonnage, grade and contained metal content estimates have been rounded; rounding may result in apparent summation differences between tonnes, grade, and contained metal content.

2. Fekola Mine: Mineral Reserves are reported on a 100% project and an 80% attributable basis, the remaining 20% interest is held by the State of Mali. The Mineral Reserves have an effective date of December 31, 2021 and have been prepared by Peter Montano, P.E., our Vice President, Projects, and a Qualified Person under NI 43-101. Mineral Reserves of the Fekola Mine are based on a conventional open pit mining method, gold price of US$1,500/oz, metallurgical recovery of 94%, selling costs of US$126.38/oz including royalties, average mining cost of US$2.42/t mined, average processing cost of US$15.24/t processed, and site general costs of US$6.93/t processed. Reserve model dilution and ore loss for Fekola was applied through whole block averaging such that at a 0.65 g/t cut-off grade there is a 0.3% increase in tonnes, a 1.3% reduction in grade, and 1.0% reduction in ounces when compared to the Mineral Resource model. Mineral Reserves are reported above a cut-off grade of 0.65 g/t Au. Mineral Reserves of the Cardinal Zone (defined below) are based on a conventional open pit mining method, gold price of US$1,500/oz, metallurgical recovery of 94%, selling costs of US$126.38/oz including royalties, mining costs ranging from US$1.90/t mined for saprolite to US$2.40 for fresh rock, processing costs ranging from US$8.87/t processed for saprolite to US$13.61/t processed for fresh rock, and site general costs of US$0.44/t processed. Reserve model dilution and ore loss for the Cardinal Zone was applied through whole block averaging such that at a 0.40g/t cut-off grade there is a 26% increase in tonnes, a -24% reduction in grade, and 5.0% reduction in ounces when compared to the subcell model. Mineral Reserves are reported above a cut-off grade of 0.65 g/t Au.

3. Masbate Gold Project: Mineral Reserves are reported on a 100% project and attributable basis. Pursuant to the ore sales and purchase agreement between Filminera and PGPRC, our wholly-owned subsidiary, PGPRC has the right to purchase all ore from the Masbate Gold Project. We have a 40% interest in Filminera, which owns the majority of the Masbate Gold Project tenements, and the remaining 60% is owned by Zoom Mineral Holdings Inc. ("Zoom"), a Philippine shareholder company. Please see "Material Properties - Masbate Gold Project" below for a further discussion of the foregoing. The Mineral Reserves have an effective date of December 31, 2021. The Qualified Person for the estimate is Peter Montano, P.E., our Vice President, Projects, and a Qualified Person under NI 43-101. Mineral Reserves are based on a conventional open pit mining method, gold price of US$1,500/oz, modeled metallurgical recovery (resulting in average LOM metallurgical recoveries by pit that range from 64% to 89%), and average base operating cost estimates of US$1.60-$1.90/t mined (mining), US$12.95/t processed (processing) and US$4.22/t processed (general and administrative). Dilution and ore loss were applied through whole block averaging such that at a cut-off grade of 0.45 g/t Au, there is a 5.8% increase in tonnes, a 5.5% reduction in grade and 0.1% increase in ounces when compared to the Mineral Resource model. Mineral Reserves are reported at cut-off grades that range from 0.36-0.38 g/t Au.

4. Otjikoto Mine: Otjikoto Mineral Reserves are reported on a 100% project and a 90% attributable basis, the remaining 10% interest is held by EVI Mining (Proprietary) Ltd. ("EVI"), a Namibian empowerment company. The Otjikoto Mine Mineral Reserves within the open pits and stockpiles have an effective date of December 31, 2021 and have been prepared by Peter Montano, P.E., our Vice President, Projects, and a Qualified Person under NI 43-101. Mineral Reserves to be mined using open pit methods or in stockpiles are based on a conventional open pit mining method, gold price of US$1,500/oz, metallurgical recovery of 98%, selling costs of US$63.61/oz Au including royalties and levies, average mining cost of US$2.55/t mined, average processing cost of US$12.60/t processed, and site general costs of US$3.36/t processed. Reserve model dilution and ore loss was applied through whole block averaging such that at a 0.45 g/t Au cut-off grade there is a 2.3% decrease in tonnes, a 2.2% reduction in grade, and a 4.4% reduction in ounces when compared to the Mineral Resource model. Mineral Reserves to be mined using open pit methods or in stockpiles are reported above a cut-off grade of 0.45 g/t Au. Mineral Reserves to be mined using underground methods at Wolfshag have an effective date of December 31, 2021, and have been prepared Randy Reichert, P. Eng, our Vice President, Operations, and a Qualified Person under NI 43-101. Mineral Reserves to be mined using underground methods are based on a modified transverse longhole stoping mining method, gold price of US$1,350/oz, metallurgical recovery of 98%, selling costs of US$63.49/oz including royalties and levies, average mining cost of US$84.83/t mined, average processing cost of US$12.06/t processed, general costs of US$3.07/t processed, 10% dilution, and 90% mining recovery. Mineral Reserves to be mined using underground methods are reported above a cut-off grade of 2.68 g/t Au.

- 18 -

5. Stockpiles: Mineral Reserves in stockpiled material are reported in the totals for the Fekola Mine, the Masbate Gold Project and the Otjikoto Mine, and were prepared by mine site personnel at each operation. Ore stockpile balances are derived from mining truck movements to individual stockpiles or detailed surveys, with grade estimated from routine grade control ("GC") methods. Stockpile cut-off grades vary by deposit, from 0.40 - 0.65 g/t Au.

Indicated Mineral Resource Statement

|

Country |

Mine or Project |

100% Project Basis |

Attributable Ownership Basis |

|||||

|

Tonnes (x 1,000) |

Gold Grade (g/t Au) |

Contained Gold Ounces |

Attributable Percentage |

Tonnes (x 1,000) |

Gold Grade (g/t Au) |

Contained Gold Ounces |

||

|

Mali |

Fekola Mine |

102,800 |

1.51 |

4,980 |

80 |

82,200 |

1.51 |

3,980 |

|

Anaconda Area |

32,400 |

1.08 |

1,130 |

80 and 85 |

27,100 |

1.08 |

940 |

|

|

Cardinal Zone |

8,000 |

1.67 |

430 |

80 |

6,400 |

1.67 |

340 |

|

|

Philippines |

Masbate Gold Project |

126,500 |

0.78 |

3,180 |

1005 |

126,500 |

0.78 |

3,180 |

|

Namibia |

Otjikoto Mine and Wolfshag Deposit |

48,200 |

0.88 |

1,370 |

90 |

43,400 |

0.88 |

1,230 |

|

Colombia |

Gramalote Project |

173,400 |

0.73 |

4,060 |

50 |

86,700 |

0.73 |

2,030 |

|

Total Indicated Mineral Resources (includes Stockpiles) |

15,140 |

|

11,700 |

|||||

Inferred Mineral Resource Statement

| Country | Mine or Project | 100% Project Basis | Attributable Ownership Basis | |||||

| Tonnes (x 1,000) |

Gold Grade (g/t Au) |

Contained Gold Ounces (x 1,000) |

Attributable Percentage (%) |

Tonnes (x 1,000) |

Gold Grade (g/t Au) |

Contained Gold Ounces (x 1,000) |

||

| Mali | Fekola Mine | 10,100 | 1.23 | 400 | 80 | 8,100 | 1.23 | 320 |

| Anaconda Area | 63,700 | 1.12 | 2,280 | 80 and 85 | 53,100 | 1.12 | 1,890 | |

| Cardinal Zone | 19,000 | 1.21 | 740 | 80 | 15,200 | 1.21 | 590 | |

| Philippines | Masbate Gold Project | 27,800 | 0.77 | 690 | 1005 | 27,800 | 0.77 | 690 |

| Namibia | Otjikoto Mine and Wolfshag Deposit | 6,600 | 1.80 | 380 | 90 | 6,000 | 1.80 | 340 |

| Colombia | Gramalote Project | 58,200 | 0.59 | 1,100 | 50 | 29,100 | 0.59 | 550 |

| Total Inferred Mineral Resources | 5,590 | 4,390 | ||||||

- 19 -

Notes:

1. Mineral Resources have been classified using the CIM Standards. Mineral Resources are reported inclusive of those Mineral Resources that have been modified to Mineral Reserves. Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. All tonnage, grade and contained metal content estimates have been rounded; rounding may result in apparent summation differences between tonnes, grade, and contained metal content.

2. Fekola Mine: Mineral Resources are reported on a 100% project and an 80% attributable basis, the remaining 20% interest is held by the State of Mali. Mineral Resources have an effective date of December 31, 2021. The Qualified Person for the resource estimate is Tom Garagan, P.Geo., our Senior Vice President, Exploration. The Qualified Person for the stockpile estimate is Peter Montano, P.E., Vice President, Projects. Mineral Resource estimates are reported within a conceptual open pit based on a gold price of US$1,800/oz, metallurgical recovery of 94%, selling costs of US$151.13/oz including royalties, average mining cost of US$2.42/t mined, average processing cost of US$15.24/t processed, and site general costs of US$6.93/t processed. Mineral Resources are reported at a cut-off grade of 0.40 g/t Au.

3. Cardinal Zone: Mineral Resources are reported on a 100% project and an 80% attributable basis, the remaining 20% interest is held by the State of Mali (as part of the Médinandi Exploitation Licence). Mineral Resources have an effective date of December 31, 2021. The Qualified Person for the resource estimate is Tom Garagan, P.Geo., our Senior Vice President, Exploration. Mineral Resource estimates are reported within a conceptual open pit based on a gold price of US$1,800/oz, metallurgical recovery of 94%, selling costs of US$151.00/oz including royalties, and operating cost estimates of US$1.90-US$2.40/t mined (mining), US$8.37-US$13.11/t processed (processing), US$0.50/t processed (haulage), and US$0.44/t processed (general and administrative). Mineral Resources are reported at a cut-off grade of 0.25 g/t Au for oxide and 0.40 g/t Au for sulphide.

4. Anaconda Area (as defined below): Mineral Resources are reported on a 100% project and an 85% attributable basis for the Menankoto Permit. Under the applicable Malian mining legislation, the State of Mali has a 10% free-carried interest with an option to acquire an additional 10% participating interest (which option has not been exercised to date), and 5% is held by a Malian third party. Mineral Resources are reported on an 80% attributable basis for the Bantako Nord Permit (as defined below)]. Under the applicable Malian mining legislation, the State of Mali has a 10% free-carried interest with an option to acquire an additional 10% participating interest (which option has not been exercised to date), and 10% is held by a Malian third party. Mineral Resources have an effective date of January 11, 2022. The Qualified Person for the resource estimate is Tom Garagan, P.Geo., our Senior Vice President, Exploration. Mineral Resource estimates are reported within a conceptual open pit based on a gold price of US$1,800/oz, metallurgical recovery of 94%, selling costs of US$151.00/oz including royalties, and operating costs of US$0.97-US$2.00/t mined (mining at surface) plus a sinking rate of US$0.035 per 10 metres ("m") depth, US$8.37-US$13.11/t processed (processing), US$3.50/t processed (haulage), and US$2.33/t processed (general and administrative). Mineral Resources are reported at a cut-off grade of 0.30 g/t Au for oxide and a cut-off grade of 0.40 g/t Au for sulphide.

5. Masbate Gold Project: Mineral Resources are reported on a 100% project and attributable basis. Pursuant to the ore sales and purchase agreement between Filminera and PGPRC, our wholly-owned subsidiary, PGPRC has the right to purchase all ore from the Masbate Gold Project. We have a 40% interest in Filminera, which owns the majority of the Masbate Gold Project tenements, and the remaining 60% is owned by Zoom, a Philippine shareholder company. Please see "Material Properties - Masbate Gold Project" below for a further discussion of the foregoing. Mineral Resources have an effective date of December 31, 2021. The Qualified Person for the resource estimate is Tom Garagan, P.Geo., our Senior Vice President, Exploration. The Qualified Person for the stockpile estimate is Peter Montano, P.E., our Vice President, Projects. Mineral Resource estimates are reported within a conceptual open pit based on a gold price of US$1,800/oz, modeled metallurgical recovery (resulting in average metallurgical recoveries by resource area that range from 59% to 89%), and operating cost estimates of US$1.60-US$1.92/t mined (mining), US$11.87/t processed (processing) and US$2.53-US$4.22/t processed (general and administrative). Mineral Resources are reported at an average cut-off grade of 0.34 g/t Au.

6. Otjikoto Mine: Mineral Resources are reported on a 100% project and a 90% attributable basis, the remaining 10% interest is held by EVI, a Namibian empowerment company. Mineral Resources have an effective date of December 31, 2021. The Qualified Person for the resource estimate is Tom Garagan, P.Geo., our Senior Vice President, Exploration. The Qualified Person for the stockpile estimate is Peter Montano, P.E., our Vice President, Projects. Mineral Resource estimates that are amenable to open pit mining methods are reported within a conceptual open pit based on a gold price of US$1,800/oz, metallurgical recovery of 98%, selling costs of US$75.49/oz including royalties and levies, and operating cost estimates of US$2.55/t mined (mining), US$12.60/t processed (processing) and US$3.36/t processed (general and administrative). Mineral Resources that are amenable to open pit mining are reported at a cut-off grade of 0.27 g/t Au. Mineral Resources that are amenable to underground mining are reported at cut-off grades of 1.5, 2.25 or 3.25 g/t Au and a minimum thickness of 1.5 m.

7. Gramalote Project: Mineral Resources are reported on a 100% project and a 50% attributable basis, the remaining 50% interest is held by a subsidiary of AngloGold. The Mineral Resource estimate has an effective date of December 31, 2020. The Qualified Person for the estimate is Tom Garagan, P.Geo., our Senior Vice President, Exploration. Mineral Resources assume an open pit mining method and are reported within a conceptual pit based on a gold price of US$1,800/oz., metallurgical recovery of 81.7% to 84% for oxide and 90.9% to 97.6% for sulphide, and operating cost estimates of US$1.99-US$2.36/t mined (average mining cost), US$4.79-US$4.89 for oxide, US$7.45-US$7.55/t for sulphide processed (processing) and US$2.10/t processed (general and administrative). Mineral Resources are reported at cut-off grades of 0.15 g/t Au for oxide and 0.18 g/t Au for sulphide.

8. Stockpiles: Mineral Resources in stockpiled material are reported in the totals for the Fekola Mine, the Masbate Gold Project and the Otjikoto Mine and were prepared by mine site personnel at each operation. Ore stockpile balances are derived from mining truck movements to individual stockpiles or detailed surveys, with grade estimated from routine GC methods.

- 20 -

MATERIAL PROPERTIES

Fekola Mine

Certain portions of the following information are derived from and based on the technical report entitled "Fekola Gold Mine, Mali, NI 43-101 Technical Report" that has an effective date of December 31, 2019, and was prepared by Tom Garagan, P.Geo., Peter Montano, P.E., John Rajala, P.E., our Vice President, Metallurgy, and Ken Jones, P.E., our Director, Sustainability (the "Fekola Report"), and is based on the assumptions, qualifications and procedures set out therein. For a more detailed overview of the Fekola Mine, please refer to the Fekola Report, which is available on SEDAR at www.sedar.com. Information that post-dates the Fekola Report is provided by B2Gold.

Property Description, Location, and Access

The Fekola Mine is located in southwestern Mali on the border between Mali and Senegal, about 210 km south of Kayes and approximately 40 km south of the city of Kéniéba. The Fekola Mine is accessible by road from Dakar or by road or air from Bamako. From Bamako to Kéniéba, it is approximately 480 km along the Millennium Highway, then 40 km on unsealed roads to the mine site. The main access to the mine is by air. We constructed a gravel airstrip adjacent to the mine and operate regularly scheduled flights from Bamako to the mine site.

Permit number 2014/0070 PM-RM (the "Médinandi Exploitation Licence"), which has an area of 75 square kilometers ("km2") was granted on February 13, 2014, and is valid to February 13, 2044, a 30-year term, which is renewable by successive periods of 10 years until the exhaustion of the Mineral Reserves. The Médinandi Exploitation Licence hosts the Fekola Mine and Cardinal zone, which is a conventional open pit owner-operated mine located within 500 m of the Fekola Mine open pit, and includes the Cardinal and FMZ deposits (the "Cardinal Zone").

The Médinandi Exploitation Licence was initially held in the name of Songhoi Resources SARL ("Songhoi"). In October 2014, we acquired a 90% interest in Songhoi through the acquisition of Papillon Resources Pty. Ltd. ("Papillon"), and in January 2015 we purchased the remaining 10% non-controlling interest in Songhoi held by Mani SARL.

Fekola S.A., our Malian exploitation company, was incorporated on March 17, 2016 and merged with Songhoi in December 2016 to become the holder of the Médinandi Exploitation Licence. As required under the 2012 Mining Code, we were required to contribute a 10% free carried non-dilutable interest in Fekola S.A. to the State of Mali, and the State of Mali also had the option to purchase an additional 10% participating interest in Fekola S.A., which it exercised as described below. As a result, the State of Mali holds a 20% interest in Fekola S.A., and we hold the remaining 80% interest.