Please wait

Exhibit 1.01

| | | | | | | | |

| QORVO, INC. |

| CONFLICT MINERALS REPORT |

| FOR THE YEAR ENDED DECEMBER 31, 2024 |

INTRODUCTION

Qorvo, Inc. (herein referred to as the “Company”, “Qorvo”, “we”, “us”, or “our”) presents this Conflict Minerals Report (“CMR”) for the year ended December 31, 2024 (“Reporting Period”), pursuant to Rule 13p-1 under the Securities Exchange Act of 1934, as amended (“Rule 13p-1”). This CMR should be read in conjunction with the definitions contained in the instructions to Form SD and related rules of the Securities and Exchange Commission (“SEC”). The SEC defines “conflict minerals” as columbite-tantalite (coltan), cassiterite, wolframite, gold, and their derivatives, which are limited to tantalum, tin, and tungsten (also referred to as “3TG”).

COMPANY DESCRIPTION

Qorvo (Nasdaq: QRVO) is a global leader in the development and commercialization of technologies and products for wireless, wired and power markets. We are organized into three operating and reportable segments that align our technologies and applications with customers and end markets: High Performance Analog (“HPA”), Connectivity and Sensors Group (“CSG”) and Advanced Cellular Group (“ACG”).

HPA is a leading global supplier of radio frequency (“RF”), analog mixed signal and power management solutions. CSG is a leading global supplier of connectivity and sensor solutions, with broad expertise spanning ultra-wideband (“UWB”), Matter®, Bluetooth® Low Energy, Zigbee®, Thread®, Wi-Fi®, cellular solutions for the Internet of Things (“IoT”) and microelectromechanical system (“MEMS”)-based sensors. ACG is a leading global supplier of advanced cellular solutions for smartphones, wearables, laptops, tablets and other devices.

Visit www.qorvo.com to learn how Qorvo connects the world.

OVERVIEW

Qorvo is committed to the responsible sourcing of minerals and strives to conduct activities that respect and support human rights throughout its global supply chain. We work extensively on issues related to conflict minerals and recognize that collaborative efforts among industry stakeholders are needed to identify and mitigate the potential risks associated with 3TG extraction in the Democratic Republic of the Congo or an adjoining country (collectively referred to as the “Covered Countries”).

As a member of the Responsible Minerals Initiative (“RMI”), we regularly collaborate with industry peers and other stakeholders to address 3TG related issues and promote responsible mineral sourcing.

Although most of our products contain conflict minerals, Qorvo does not directly source 3TG from mines or “mineral processors” (herein referred to as “smelters and refiners” or “SORs”). Instead, we source components and materials from suppliers, who source their components and materials from sub-tier suppliers. Qorvo is far removed from the mine sites and SORs in its global supply chain, and is therefore considered a “downstream” company, as described by the Organisation for Economic Co-operation and Development Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas (“OECD Due Diligence Guidance”). Due to our position in the supply chain, we rely on our suppliers to provide information on the conflict minerals necessary to the functionality and production of Qorvo products, and we collaborate with industry peers and other stakeholders to meet our responsible mineral goals and customer expectations. Suppliers are requested to assist in our annual Reasonable Country of Origin Inquiry (“RCOI”) and due diligence efforts, which include

identifying the smelters and refiners who process the conflict minerals used in components and/or materials supplied to Qorvo.

For the Reporting Period, in accordance with Rule 13p-1, we conducted a good faith RCOI to determine if any of the conflict minerals used in our products originated in the Covered Countries, or from recycled or scrap sources. As a result of this effort, we determined that some of the 3TG used in our products may have originated in the Covered Countries. Therefore, we have exercised due diligence to determine the source of these conflict minerals, as described in this CMR below.

Upon the exercise of our due diligence – which is subject to and limited by our ability to obtain reliable information for the conflict minerals used in our products – we did not identify any occurrence where our 3TG sourcing has directly or indirectly financed or benefited armed groups in the Covered Countries.

REASONABLE COUNTRY OF ORIGIN INQUIRY

For the year ended December 31, 2024, Qorvo’s RCOI process began with identifying our “relevant suppliers” – direct suppliers who supply Qorvo with components and/or materials containing 3TG – and surveying those suppliers with the RMI developed Conflict Minerals Reporting Template (“CMRT”). This survey requested relevant suppliers to identify the smelters and refiners used to process the 3TG contained in the components and/or materials supplied to Qorvo. We evaluated supplier responses for completeness, accuracy, and degree of compliance with Qorvo's conflict mineral sourcing requirements and engaged with those suppliers whose CMRTs we identified to contain potential supply chain risks and/or incomplete or inaccurate data. We also reviewed the smelters and refiners identified by our suppliers against the lists of processing facilities that are validated as conformant to a third-party audit program, such as the RMI’s Responsible Minerals Assurance Process (“RMAP”), London Bullion Market Association (“LBMA”) Responsible Gold Program, or the Responsible Jewellery Council (“RJC”) Chain-of-Custody Certification. To the extent reasonably possible, we determined country of origin information for the SORs identified by our suppliers from sources including supplier CMRT responses, third-party audit programs, and publicly available resources such as smelter and refiner company websites, if we determined such publicly available information to be reliable.

Results of RCOI

Qorvo conducted a 3TG survey of 213 suppliers for the Reporting Period.

As of April 29, 2025, the results of our RCOI were as follows:

•99% of relevant suppliers provided a CMRT response to our 3TG survey request.

•Relevant suppliers identified 219 “eligible” SORs which may have processed the conflict minerals contained in the components and/or materials supplied to Qorvo during the Reporting Period.

•We know or have reason to believe that some of the 3TG processed by at least 41 of the 219 SORs may have originated in the Covered Countries and not solely from recycled or scrap sources.

We had two suppliers who did not provide a response to our 3TG survey for the reporting period, and 8 suppliers that were unable to identify all the SORs supplying 3TG to their supply chains. Due to these limitations in our sourcing data, we were unable to determine the origin of all the conflict minerals used in our products for the Reporting Period. Qorvo’s due diligence with these suppliers is ongoing and we continue to work our escalation process to drive improvements in their responses.

DUE DILIGENCE DESIGN

Qorvo’s responsible minerals program includes due diligence measures for the use of 3TG in its global supply chain and is designed to conform with the OECD Due Diligence Guidance as it relates to our position in the supply chain as a “downstream” company.

DUE DILIGENCE MEASURES PERFORMED

In alignment with the OECD’s five-step framework for risk-based due diligence, Qorvo performed the following activities to exercise due diligence on the sources of 3TG used in our products for the Reporting Period.

(1) Establish Strong Company Management Systems

•Maintained a Responsible Minerals Policy, which includes Qorvo’s commitment to use responsibly sourced 3TG originating from the Covered Countries. This Policy is publicly available on our website at https://www.qorvo.com/about-us/sustainability. The content of any website referred to in this report is included for general information only and is not incorporated by reference in this report.

•Operated an internal responsible minerals team, led by Qorvo’s Environmental, Social and Governance organization, to implement our responsible minerals policy and regularly communicate on program activities and due diligence efforts to senior management and other relevant Qorvo employees.

•Managed a process for achieving control and transparency over our supply chain, which utilizes the CMRT and supplier engagement to identify the SORs used to process the 3TG contained in Qorvo’s products, and to obtain the information necessary to meet legal and customer reporting requirements related to conflict minerals.

•Communicated our Responsible Minerals Policy, expectations and requirements to relevant suppliers using multiple channels, including Qorvo’s responsible minerals database, supplier document portal, and external website. Specific requirements related to conflict minerals are also included in Qorvo’s standard Purchase Order Terms and Conditions, which are available on our website at https://www.qorvo.com/support/supplier-resources.

•Maintained a whistleblower policy and our existing grievance mechanism to provide an open and anonymous reporting channel, where internal and external stakeholders can submit ethics and compliance concerns, or any grievance related to Qorvo policies and procedures. Our whistleblower policy and grievance mechanism can be accessed from Qorvo’s Sustainability web page at https://www.qorvo.com/about-us/sustainability.

•Monitored the RMI’s Minerals Grievance Table, and RMI sub-team discussions for 3TG related issues that could be applicable to Qorvo’s supply chain: http://www.responsiblemineralsinitiative.org/rmap/grievance-mechanism.

(2) Identify and Assess Risks in the Supply Chain

•Carried out our process for identifying relevant 3TG suppliers for the Reporting Period.

•Conducted bi-annual surveys or “CMRT campaigns” of our relevant suppliers, designed to identify our 3TG sourcing information for the Reporting Period, including the smelters and refiners that may have processed the conflict minerals used in Qorvo products, and the country-of-origin of those conflict minerals.

•Maintained a database and process for tracking communications with relevant suppliers, analyzing the CMRTs provided by relevant suppliers, aggregating supplier CMRT data for Qorvo reporting, and following up with suppliers whose CMRTs we identified to contain potential supply chain risks and/or incomplete or inaccurate data.

•Reviewed the SOR data provided by our suppliers against the list of processing facilities that have received a “conformant” designation from an independent third-party audit program (herein referred to as “conformant” SORs).

•Compared the conformant SORs reported by our suppliers to the RMI’s sourcing data, which is provided as a benefit of our RMI membership, to conduct our RCOI.

(3) Design and Implement a Strategy to Respond to Identified Risks

•Maintained a supplier monitoring procedure, which is designed to identify and mitigate potential risks presented by relevant suppliers not meeting Qorvo's expectations for the responsible sourcing of conflict minerals.

•Contacted suppliers whose CMRT responses contained incomplete or potentially inaccurate information to request additional clarification to ensure accuracy of the 3TG data reported.

•Provided resources to relevant suppliers to increase awareness of Qorvo’s expectations and requirements for responsible mineral sourcing and to reduce the risk of inaccurate information received from our suppliers.

•Monitored potential supply chain risks related to relevant suppliers and their 3TG sourcing data in our responsible minerals database.

•Performed mitigation efforts with relevant suppliers identified as not meeting Qorvo’s responsible minerals sourcing requirements to help bring them into compliance.

•Contacted a portion of SORs identified in our supply chain to encourage their participation in the RMAP.

•Provided progress updates to senior management summarizing the 3TG data received from our suppliers during Qorvo’s bi-annual CMRT campaigns, and if necessary, the status of any ongoing mitigation efforts.

(4) Support Independent Third-Party Audits of SOR Due Diligence

•Utilized the due diligence conducted by programs such as the RMI, LBMA and RJC to coordinate third-party audits of global 3TG processors and validate their responsible sourcing practices.

•Maintained our membership and participation in the RMI, where we were able to contribute to the organization’s ongoing work in identifying and assessing the sourcing practices of mineral processing facilities. Qorvo is a co-chair of the RMI’s Smelter Engagement Team, a work group focused on communication with SORs to encourage and support their participation in the RMAP. In addition, the Company is the member lead of the RMI’s Supply Chain Data Management team, which maintains the research data gathered and reported on 3TG processing facilities. We also participate on teams that determine if facilities meet the RMI’s definition of a smelter or refiner, manage the development of the CMRT form, and develop guidance and best practices for supply chain due diligence. The data on which we relied for certain statements in this CMR was obtained through our membership in the RMI, using the RCOI report for Qorvo (Member Code: QRVO).

(5) Report on Supply Chain Due Diligence

•Communicated the results of Qorvo's RCOI and due diligence for the Reporting Period through Qorvo’s Form SD and CMR, which are filed annually with the SEC and available on our website at: https://ir.qorvo.com/node/5876.

•Communicated on our responsible minerals program in our annual Sustainability Report, made available on Qorvo’s website at https://www.qorvo.com/about-us/Sustainability.

DUE DILIGENCE RESULTS

Inherent Limitation on Due Diligence Measures Taken

The due diligence measures listed above can only provide reasonable, not absolute, assurance regarding the origin of the conflict minerals used in our products. Our due diligence process is based on obtaining accurate 3TG information from our relevant suppliers and those suppliers obtaining similar information from their supply chains to identify the original sources of the 3TG used in our products. As we do not directly purchase from any SORs – nor do the majority of our suppliers – we have very little influence over SOR sourcing. We rely, to a large extent, on the information provided by independent third-party audit programs. Such sources of information may contain incomplete or inaccurate data and may be subject to fraud.

Smelter and Refiner Due Diligence Results

We rely on the good faith efforts of our relevant suppliers to provide us with reasonable representations of the smelters and refiners used to process the 3TG contained in our products for the Reporting Period. However, many of our suppliers provided survey responses representing their supply chains at the company level or included 3TG data for components and/or materials beyond those that were supplied to Qorvo. As a result, the processing facilities our suppliers identified for the Reporting Period likely include more facilities than those that were actually involved in the processing of conflict minerals contained in our products.

For the Reporting Period, our suppliers identified 244 facilities as potential SORs used to process the 3TG believed to be in Qorvo’s supply chain. We conducted due diligence on these reported facilities, including whether they are actual smelters or refiners (according to the definitions used by the RMI); whether they are currently operational; and whether they are conformant to a third-party audit program such as the RMAP, LBMA or RJC.

Of the 244 potential SORs identified by our suppliers, 25 were subsequently found to be ineligible for the RMAP as they were either inoperative or did not meet the RMI’s definition of a 3TG smelter or refiner. These facilities are not included in this report as “processing facilities” and are not included in the sections below.

Processing Facilities (“SORS”) Identified for the Reporting Period

The use of the terms “smelters and refiners” and “processing facilities” throughout this CMR refers to 3TG entities that 1) were reported in a supplier’s CMRT for the Reporting Period; 2) determined to meet the RMI’s definition of a smelter or refiner; and 3) determined to be operational in 2024. In some cases, our suppliers reported facilities that Qorvo believes are not currently eligible to participate in a third-party audit program. These facilities are not included in the data below. However, we continue to conduct due diligence on such entities and work with our relevant suppliers to improve the quality of the 3TG data reported to Qorvo.

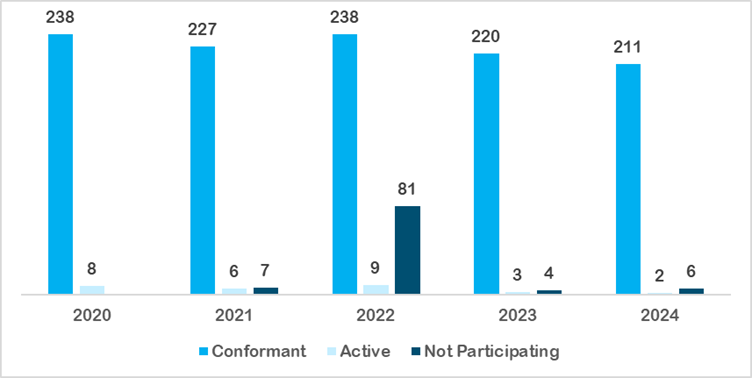

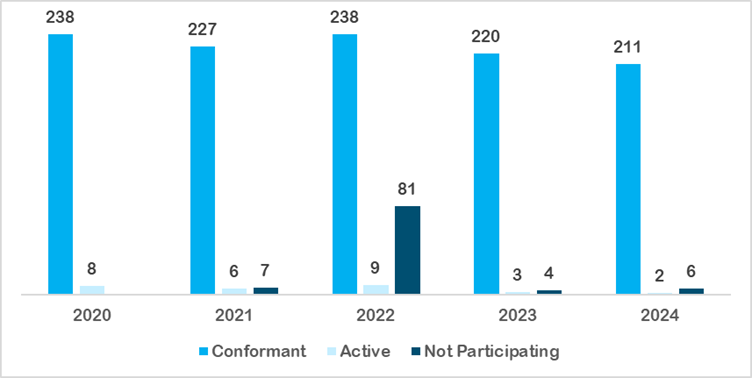

Figure 1: Participation Status of Identified SORs by Reporting Year

For the purposes of this CMR, participation status is defined in the following manner:

•Conformant – SOR has been validated by a third-party audit and found to be conformant to relevant audit protocols including the RMAP, LBMA or RJC.

•Active – SOR is engaged and participating in a third-party audit program but has not yet completed the audit.

•Not Participating – SOR has not yet committed to, or has not successfully completed, third-party verification of their responsible mineral sourcing processes.

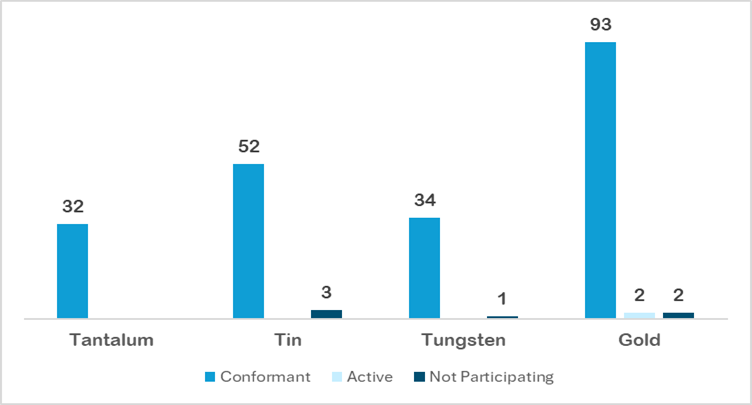

Figure 2: SOR Participation Status* by Metal for the Reporting Period

*Data is based on smelter participation status as of April 29, 2025.

Table 1: Identified SORs with Covered Country Sourcing*

All smelters and refiners that we know or have reason to believe may source from the Covered Countries are conformant to a third-party audit program as of April 29, 2025.

| | | | | | | | | | | |

| Mineral | Total SORs Identified | Believed to Source from the Covered Countries | Percentage |

| Tantalum | 32 | 19 | 59% |

| Tin | 55 | 10 | 18% |

| Tungsten | 35 | 9 | 26% |

| Gold | 97 | 3 | 3% |

| Total | 219 | 41 | 19% |

*Data is based on the RMI’s RCOI report dated March 28, 2025.

Table 2: Potential Countries of Origin for SORs Identified for the Reporting Period

Below is a list of the countries from which the 3TG used in Qorvo’s products may have originated, based on the RMI’s RCOI report dated March 28, 2025*.

| | | | | | | | |

| ARGENTINA | GERMANY | PANAMA |

| AUSTRALIA | GHANA | PAPUA NEW GUINEA |

| AUSTRIA | GREECE | PERU |

| AZERBAIJAN | GUINEA | PHILIPPINES |

| BELGIUM | GUYANA | PORTUGAL |

| BENIN | HONDURAS | RUSSIA |

| BOLIVIA | HONG KONG | RWANDA** |

| BOSNIA AND HERZEGOVINA | INDONESIA | SAUDI ARABIA |

| BOTSWANA | ITALY | SENEGAL |

| BRAZIL | JAPAN | SIERRA LEONE |

| BULGARIA | KAZAKHSTAN | SLOMON ISLANDS |

| BURKINA FASO | KENYA | SLOVAKIA |

| BURUNDI** | KOREA, REPUBLIC OF | SOUTH AFRICA |

| CAMBODIA | KYRGYZSTAN | SPAIN |

| CANADA | LAO PEOPLE’S DEMOCRATIC REPUBLIC | SUDAN** |

| CHILE | LIBERIA | SURINAME |

| CHINA | MADAGASCAR | SWEDEN |

| COLOMBIA | MALAYSIA | TAJIKISTAN |

| CONGO, DEMOCRATIC REPUBLIC OF THE** | MALI | TANZANIA** |

| CÔTE D’IVORIE | MAURITANIA | THAILAND |

| DOMINICAN REPUBLIC | MEXICO | TURKEY |

| ECUADOR | MONGOLIA | UGANDA** |

| EGYPT | MOROCCO | UNITED KINGDOM |

| ESWATINI | MOZAMBIQUE | UNITED STATES OF AMERICA |

| ETHIOPIA | MYANMAR | UZBEKISTAN |

| FIJI | NAMIBIA | VIETNAM |

| FINLAND | NEW ZEALAND | ZAMBIA** |

| FRANCE | NICARAGUA | ZIMBABWE |

| FRENCH GUIANA | NIGER | |

| GEORGIA | NIGERIA | |

*RMI provides member companies with an aggregated list of potential countries of origin for all conformant SORs. This list may include countries that are not actual sources of the 3TG used in Qorvo’s products for the Reporting Period.

**Covered Countries

2025 PLANNED IMPROVEMENTS

Qorvo is committed to the responsible sourcing of 3TG and will continue to advance the implementation of its responsible mineral program with relevant suppliers.

For the 2025 reporting period, we plan to:

•Continue working with suppliers who may provide incomplete or inaccurate sourcing information and drive them towards 100% identification of the SORs that may process the conflict minerals contained in the components and/or materials supplied to Qorvo.

•Continue encouraging 3TG smelters and refiners to participate in a third-party responsible sourcing audit, such as the RMAP.

Forward Looking Statements

This Conflict Minerals Report contains forward-looking statements, including statements regarding our due diligence planned improvements, and other statements preceded by terminology such as “believes,” “continue,” “could,” “estimates,” “expects,” “goal,” “hope,” “intends,” “may,” “plans,” “potential,” “predicts,” “projects,” “reasonably,” “should,” “thinks,” “will” or the negative of these terms or other comparable terminology, and include, among others, our planned improvements. These statements are only predictions or our current intentions. We do not guarantee future activities, performance or achievements, which could be affected by, among other things, changes in Rule 13p-1, interpretations of Rule 13p-1, international due diligence frameworks, law, our internal allocation of resources or emphasis, customer demands or expectations, and the cooperation of suppliers. We do not intend to update any of the forward-looking statements after the date of this Conflict Minerals Report. These forward-looking statements are made in reliance upon the safe harbor provision of The Private Securities Litigation Reform Act of 1995.