economic factors, such as global supply chain flows, supply and demand and raw material price developments, affect the cost of our materials.

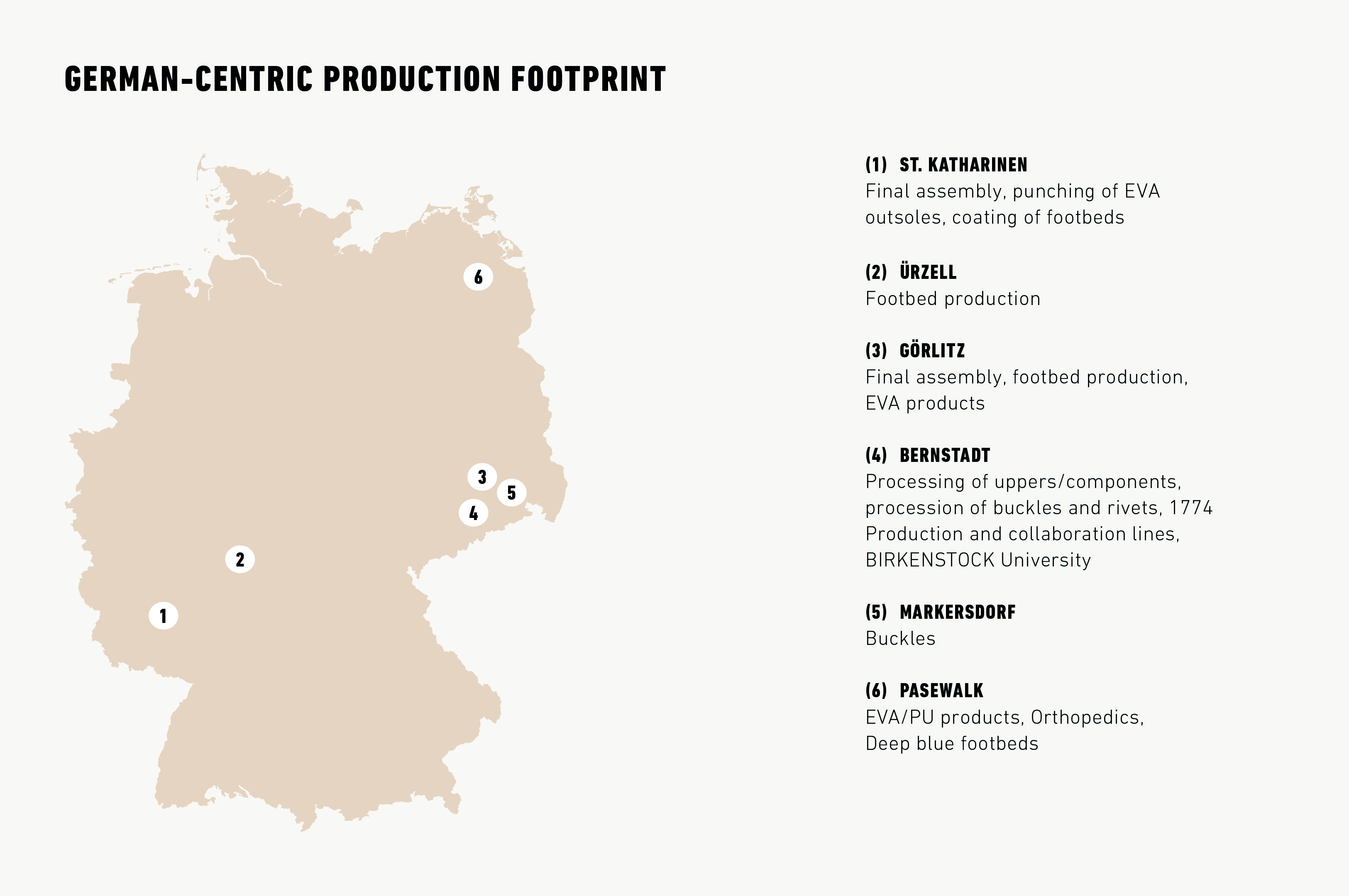

We source components and other raw materials (including leather, EVA, cork, adhesives, natural latex, jute, copper, wool felt and brass buckles) from suppliers located mainly in Europe, but also in Turkey, the Americas and Asia. For certain materials, we may rely on specific suppliers that are able to meet the level of quality and supply we require. For example, although our leathers are sourced from different tanneries, our requirement for materials of high quality may result in reducing the pool of available tanneries that can meet such requirements. In addition, some of our products use materials of high technical complexity and high-quality standards, such as EVA, or that require specific IP rights, such as the EVA buckles. We also have some regional dependencies. For example, while we do have multiple cork suppliers, they are predominantly based in Portugal, thus creating a specific geographical dependency, and we have similar regional dependencies for other raw materials. Such geographic dependencies expose us to risks in the case of, for example, extreme weather events affecting such areas.

Our relationships with suppliers are either based on individual purchase orders, on purchase orders governed by a framework agreement or on separate agreements governing the conditions for the supply of specific materials. Although our contracts with these suppliers contain provisions that ensure the suppliers are not able to terminate the contract on short notice, if one or more of these suppliers is unable to supply or decides to cease supplying us with raw materials and components, or decides to increase prices significantly due to indirect price increases, shortages or for other reasons that may be beyond our control, we may be unable to identify alternative suppliers of such materials at a reasonable cost or at all and, in any event, it may take a significant period of time to receive any materials from alternative suppliers. Moreover, if we expand beyond the production capacity of our current suppliers as we continue to grow, we may not be able to find new suppliers with an appropriate level of expertise and capacity in a timely manner.

In addition, with some exceptions, our arrangements with our suppliers generally are not exclusive. As a result, our suppliers could provide similar products for our competitors, some of which could potentially purchase products in significantly greater volume. Further, while certain of our long-term contracts stipulate contractual exclusivity, those suppliers could choose to breach our agreements and work with our competitors. Our competitors could enter into restrictive or exclusive arrangements with our suppliers that could impair or eliminate our access to supplies. Our suppliers could also be acquired by our competitors, and may become our direct competitors, thus limiting or eliminating our access to supplies.

Our supply chain could also be materially adversely affected by a number of other factors, including, among other things, increasing costs of labor, scarcity of labor at our production sites or at our office locations, potential economic and political instability in countries where our suppliers are located, increases in shipping or other transportation costs, manufacturing and transportation delays and interruptions, whether as a result of natural disasters or force majeure events (including, without limitation, unrest, civil disorder, war, terrorist attacks, subversive activities or sabotage, fires, floods, explosions, epidemics, pandemics or other catastrophes), industrial action in the supply chain or other factors, supplier compliance with applicable laws and regulations, adverse fluctuations in currency exchange rates and changes in laws affecting the importation and taxation of goods, including duties, tariffs and quotas, or changes in the enforcement of those laws. We may also be subject to potential reputational damage if one or more of our suppliers violates or is alleged to have violated applicable laws or regulations including improper labor conditions or human rights abuses, fails to meet our requirements or does not meet industry standards and safety specifications.

Any of these risks, in isolation or in combination, could restrict the availability of merchandise or significantly increase the cost of such merchandise, require us to divert financial and management resources and subject us to reputational damage, any of which could have a material adverse effect on our business, financial condition and results of operations.